Design and principle of operation

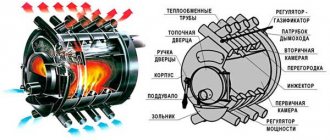

The design of a gasketed plate heat exchanger includes:

- a stationary front plate on which the inlet and outlet pipes are mounted;

- fixed pressure plate;

- movable pressure plate;

- package of heat exchange plates;

- seals made of material that is heat-resistant and resistant to aggressive environments;

- upper supporting base;

- lower guide base;

- bed;

- set of coupling bolts;

- Set of support feet.

This arrangement of the unit ensures maximum intensity of heat exchange between working media and compact dimensions of the device.

Design of a gasketed plate heat exchanger

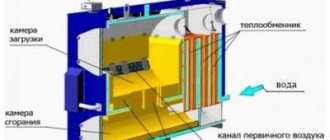

Most often, heat exchange plates are made by cold stamping from stainless steel with a thickness of 0.5 to 1 mm, however, when using chemically active compounds as a working medium, titanium or nickel plates can be used.

All plates included in the working kit have the same shape and are installed sequentially, in a mirror image. This method of installing heat exchange plates ensures not only the formation of slot channels, but also the alternation of primary and secondary circuits.

Each plate has 4 holes, two of which provide circulation of the primary working fluid, and the other two are isolated by additional contour gaskets, eliminating the possibility of mixing working fluids. The tightness of the connection between the plates is ensured by special contour sealing gaskets made from a material that is heat-resistant and resistant to active chemical compounds. The gaskets are installed in the profile grooves and secured using a clip lock.

Operating principle of plate heat exchanger

The effectiveness of any plate maintenance is assessed according to the following criteria:

- power;

- maximum temperature of the working environment;

- bandwidth;

- hydraulic resistance.

Based on these parameters, the required heat exchanger model is selected. In collapsible plate heat exchangers, the throughput and hydraulic resistance can be adjusted by changing the number and type of plate elements.

The intensity of heat transfer is determined by the flow regime of the working medium:

- with laminar flow of the coolant, the intensity of heat transfer is minimal;

- the transition regime is characterized by an increase in the intensity of heat transfer due to the appearance of turbulence in the working environment;

- The maximum intensity of heat exchange is achieved with turbulent movement of the coolant.

The performance characteristics of the plate heat exchanger are calculated for a turbulent flow of the working medium.

Depending on the location of the grooves, there are three types of heat exchange plates:

- with “soft”

channels (grooves are located at an angle of 600). Such plates are characterized by slight turbulence and low heat transfer intensity, however, “soft” plates have minimal hydraulic resistance; - with “medium”

channels (corrugation angle from 60 to 300). The plates are a transitional option and are distinguished by average turbulence and heat transfer rates; - with “hard”

channels (corrugation angle 300). Such plates are characterized by maximum turbulence, intense heat transfer and a significant increase in hydraulic resistance.

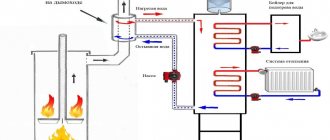

To increase the efficiency of heat exchange, the movement of the primary and secondary working fluid is carried out in the opposite direction. The heat exchange process between the primary and secondary working fluids occurs as follows:

- The coolant is supplied to the inlet pipes of the heat exchanger;

- When moving the working media along the corresponding circuits formed from heat-exchange plate elements, intense heat transfer occurs from the heated medium to the heated one;

- Through the outlet pipes of the heat exchanger, the heated coolant is directed to its destination (heating, ventilation, water supply systems), and the cooled coolant again enters the working area of the heat generator.

Operating principle of a plate heat exchanger

To ensure efficient operation of the system, complete tightness of the heat exchange channels is required, which is ensured by sealing gaskets.

Materials and operating temperatures

A variety of gasket elastomers are available that offer chemical and temperature resistance combined with good sealing properties.

Most often this is:

- Butyl rubber (IIR)

- Silicone rubber (VMQ, MQ, PVMQ)

- Rubber (VIR)

- Teflon (stretchable) (PTFE)

Operating temperatures:

Collapsible devices

can operate at a pressure of 0.002-1.0 MPa and a temperature of working media from -20 to +200°C. Efficiency - 95%

Semi-collapsible

— at a pressure of 0.002-2.5 MPa and a temperature of working media from -20 to +350°C. Efficiency - 85%

Non-separable

— at a pressure of 0.002-4 MPa and a temperature of working media from -100 to +900°C. Efficiency - 85%

Requirements for gaskets

To ensure complete tightness of the profile channels and prevent leakage of working media, sealing gaskets must have the necessary heat resistance and sufficient resistance to the effects of an aggressive working environment.

The following types of gaskets are used in modern plate heat exchangers:

- ethylene propylene (EPDM). Used when working with hot water and steam in the temperature range from -35 to +1600C, unsuitable for fatty and oily environments;

- NITRIL gaskets (NBR) are used for working with oily working media, the temperature of which does not exceed 1350C;

- VITOR gaskets are designed to work with aggressive working environments at temperatures not exceeding 1800C.

The graphs show the dependence of the service life of seals on operating conditions:

We recommend: Why do you need a bypass in a heating system, installing a bypass line

As for attaching the sealing gaskets, there are two ways:

- on glue;

- using a clip.

The first method is rarely used due to the complexity and duration of installation; in addition, when using glue, maintenance of the unit and replacement of seals is significantly more complicated.

The clip lock ensures quick installation of plates and ease of replacement of failed seals.

Where are they used?

Plate heat exchangers are used in various fields, including: food and chemical industries, heating systems for technical and food liquids, cooling of industrial equipment, for connecting buildings to centralized heating and cooling networks.

They are especially widely used in the food industry because they are compact, can be manufactured in different types and are easy to clean. The deposition of materials on hot surfaces (fouling) reduces thermal and hydrodynamic performance and requires periodic cleaning (often after just a few hours of operation).

Many industrial plants use plate heat exchangers for purposes such as pasteurization and waste heat recovery. For example, a manufacturing facility may use water to cool a hot, recently produced beverage. The hot finished liquid product must be cooled before bottling so that it passes through a plate heat exchanger connected to the chiller's refrigeration circuit (water chiller). This removes unwanted heat without mixing the two liquids.

Design of heat exchange equipment

Corrugated plates are made of stainless steel (most often acid-resistant) and are connected to each other using sealing gaskets. This structure is then attached to the frame (size depends on the equipment model). In this case, the plates can be removed or added at any time (both before installation and during operation), which allows you to achieve the most effective heat transfer coefficient.

Advantages of plate heat exchangers

The main purpose of such devices is the transfer of heat between coolants that are separated from each other (mixing of working media is excluded).

Due to their design features, plate heat exchangers have a number of significantly different technical parameters:

- compactness (the heat exchanger is selected according to the required heat transfer rates; the smaller the differences, the fewer plates are used);

- versatility (can be used in heating points at various facilities and used depending on the required power);

- cost-effectiveness (the cost depends on the number of plates, there is a choice, repairs cost by replacing a worn (damaged) package of plates, and not the entire system);

- temperature range is from -50 to +200 ˚С;

- ease of maintenance (cleaning is carried out by unscrewing the bolts of the pressure plate, then the plates with sealing gaskets are removed and washed).

Heat exchanger and its types

A heat exchanger is a special device for heat exchange between two media that differ in temperature. Depending on the principle of operation, they are divided into devices of regenerative and recuperative type .

- The recuperator has in its design a wall made of material with high thermal conductivity, separating and isolating the moving coolant flows from each other.

- In regenerative heat exchangers, the exchange of thermal energy occurs on one surface, with which the working liquid media come into alternate contact.

The following designs of recuperative heat exchangers are popular in industry:

- shell-and-tube - made of pipes forming a lattice structure in the manufacture of which soldering or welding is used

- plate - a prefabricated structure of modular plates interconnected with heat-resistant gaskets

- twisted - these are structures with concentric coils, where coolants move along a spiral pipe and annular volume

- spiral - made of thin metal sheets rolled into a kind of spiral

- water, air and others

The most in demand are plate heat exchangers - recuperative equipment.

Characteristics and calculation

Plates and seals as the main parts of heat exchange devices are made from materials that differ in their performance and characteristics. When choosing a particular product, the main role is played by its purpose and scope of application.

If we consider heating systems and hot water supply, then in this area, plates that are made of stainless steel and plastic seals made of special rubber NBR or EPDM are most often used. The presence of stainless steel plates makes it possible to work with a coolant heated to 120 degrees; in another case, the heat exchanger can heat the liquid up to 180°C.

Gaskets are located between the plates for sealing

When using heat exchangers in the industrial sector and connecting them to technological processes exposed to oils, acids, fats, alkalis and other aggressive media, plates made of titanium, bronze and other metals are used. In these cases, the installation of asbestos or fluorine rubber gaskets is required.

The choice of heat exchanger is carried out taking into account calculations that are made using special software.

During calculations it is necessary to take into account:

- consumption of heated liquid;

- initial temperature of the coolant;

- heating fluid costs;

- required heating temperature.

The heating medium that flows through the heat exchanger can be heated water to a temperature of 90-120°C or steam with a temperature of up to 170°C. The type of coolant is selected taking into account the type of boiler equipment used. The dimensions and number of plates are selected so as to produce a coolant with a temperature that complies with current standards - no higher than 65°C.

The heat exchanger can be made of different types of metal

It must be said that the main technical characteristics, which are also considered the main advantages, are the compact dimensions of the equipment and the ability to provide a fairly significant flow rate.

The range of exchange areas and probable costs for the devices is quite high. The smallest of them, for example, from Alfa Laval, have a surface size of up to 1 m² and at the same time provide the passage of a coolant amount of up to 0.3 m³/hour. The largest devices have a size of about 2500 m² and a flow rate that exceeds 4000 m³/hour.

Advantages and Limitations

If we compare plate structures with shell-and-tube structures, the former have a higher heat transfer coefficient with an identical area. Capable of transmitting more power while maintaining original size and weight.

Other advantages of the device:

- extensive modernization opportunities to increase heat transfer rates;

- accessibility and easy maintenance - cleaning by disassembly.

Restrictions apply to:

- temperature used - maximum 180 degrees;

- operating pressure – maximum 2.5 MPa (25 bar).

The efficiency of plate heat exchangers is considered the highest among similar designs.

Types of plate heat exchangers

Plate heat exchangers are divided according to the degree of accessibility of the heat exchange surface for mechanical cleaning and inspection:

- collapsible

- semi-collapsible (semi-welded)

- non-separable (soldered and welded)

The most widely used are plate heat exchangers , in which the plates are separated from one another by rubber seals. Installation and dismantling of these devices is carried out quite quickly, cleaning the heat exchange surfaces requires little labor.

Connecting plate heat exchangers

The classic connection diagram for plate heat exchangers has coolant inlet and outlet pipes on the front plate. In most cases, the inlets and outlets are located in such a way as to ensure a counterflow of heat exchange media. The operation of a plate heat exchanger with a counterflow of working media is shown in the video:

There are designs of plate heat exchangers in which the coolant inlet and outlet pipes are located both on the front and rear plates:

Connection to the inputs and outputs of working media is carried out using flanged connections, welded connections (steel pipe) or threaded connections. It is also possible that there is no pipe at the inlet or outlet of the coolant. In this case, holes with internal threads for studs are made around the hole on the plate, with the help of which you can connect a pipeline with coolant using a heat-resistant rubber or rubber seal.

Story

Plate heat exchangers were first introduced in 1923 for the pasteurization of milk, but are now used in many applications in the chemical, petroleum, climate control, refrigeration, dairy, pharmaceutical, food and medical industries. This is due to their unique advantages such as flexible thermal design (plates can simply be added or removed to meet different thermal or processing requirements), ease of cleaning to maintain strict hygienic conditions, good temperature control (necessary in cryogenic processes) and better heat transfer characteristics.

Plates for plate heat exchangers

Serially produced plate heat exchangers are equipped with plates stamped from sheet metal up to 1 mm thick. The materials used are corrosion-resistant steel, titanium, and special alloys. The plates of a plate heat exchanger have a corrugated surface to turbulize flows in the channels, which increases heat transfer efficiency and prevents the deposition of contaminants. The corrugations of the plates usually have the cross-section of an equilateral triangle. The steeper the angle at which the plate corrugations are located, the greater the resistance created in the channels; the sharper the angle, the lower the resistance and the higher the flow speed.

Plates for gasketed plate heat exchangers

On a note!

Let us note this subtlety: The surface of the plates is corrugated to increase the turbulence of the liquid as it flows into the channels.

The figure shows the main parameters of the corrugation:

- Corrugation pitch p;

- chevron angle β compared to the main flow direction.

The angle of the corrugated pattern affects heat transfer and performance:

- Plate angle β > 45° gives higher heat transfer with high pressure.

- Plate angle β < 45° gives lower heat transfer rates but also lower pressure drops.

Therefore, it is very important to find a compromise angle β between high exchange rates and acceptable load losses.

The relationship between plate width W and plate length L also affects performance, but to a lesser extent than the angle of the corrugation pattern.

Plate heat exchanger piping diagrams

There are several ways to connect a PHE to a heating system. The simplest is considered to be parallel connection with a control valve, the circuit diagram of which is shown below:

PHE parallel connection diagram

The disadvantages of such a connection include increased load on the heating circuit and low efficiency of water heating at a significant temperature difference.

Parallel connection of two heat exchangers in a two-stage scheme will ensure more productive and reliable operation of the system:

Two-stage parallel connection diagram

1 – plate heat exchanger; 2 – temperature regulator; 2.1 – valve; 2.2 – thermostat; 3 – circulation pump; 4 – hot water flow meter; 5 – pressure gauge.

The heating medium for the first stage is the return circuit of the heating system, and the heated medium is cold water. In the second circuit, the heating medium is the coolant from the direct line of the heating system, and the heated medium is the preheated coolant from the first stage.

We recommend: Gas boiler room: design standards, diagram

How to choose a heat exchanger

To correctly select a plate heat exchanger, it is necessary to determine and calculate its technical characteristics based on the following data:

1 - DHW connection diagram;

2 — heat load, in Gcal/hour;

3 - information about the heating medium:

- inlet temperature (for winter/summer), in °C;

- outlet temperature (for winter/summer), in °C;

- medium consumption (in the absence of load data), in m3/hour;

- pressure loss, in atm (permissible);

4 - information about the heated medium:

- inlet temperature (for winter/summer, in °C);

- outlet temperature (for winter/summer, in °C);

- medium consumption (in the absence of load data), in m3/hour;

- pressure loss, in atm (permissible);

- power reserve (surface), in %;

Calculation example

Flushing the plate heat exchanger

The functionality and performance of the unit largely depends on high-quality and timely washing. The frequency of washing is determined by the intensity of work and the characteristics of technological processes.

Methodology for cleaning work

Scale formation in heat exchange channels is the most common type of PHE contamination, leading to a decrease in heat exchange intensity and a decrease in the overall efficiency of the installation. Descaling is carried out using chemical washing. If, in addition to scale, other types of contamination are present, it is necessary to mechanically clean the heat exchanger plates.

Chemical washing

The method is used for cleaning all types of PHE, and is effective with minor contamination of the working area of the heat exchanger. To carry out chemical cleaning, disassembling the unit is not required, which can significantly reduce the work time. In addition, no other methods are used for cleaning brazed and welded heat exchangers.

Chemical washing of heat exchange equipment is carried out in the following sequence:

- a special cleaning solution is introduced into the working area of the heat exchanger, where scale and other deposits are intensively destroyed under the influence of chemically active reagents;

- ensuring circulation of detergent through the primary and secondary maintenance circuits;

- flushing heat exchange channels with water;

- draining cleaning agents from the heat exchanger.

During the chemical cleaning process, special attention should be paid to the final rinsing of the unit, since chemically active components of detergents can destroy seals.

The most common types of contamination and cleaning methods

Depending on the working media used, temperature conditions and pressure in the system, the nature of the contaminants can be different, so for effective cleaning it is necessary to choose the right detergent:

- cleaning from scale and metal deposits uses solutions of phosphoric, nitric or citric acid;

- inhibited mineral acid is suitable for removing iron oxide;

- organic deposits are intensively destroyed by sodium hydroxide, and mineral deposits by nitric acid;

- fatty stains are removed using special organic solvents.

Since the thickness of the heat exchange plates is only 0.4 - 1 mm, special attention should be paid to the concentration of active elements in the detergent composition. Exceeding the permissible concentration of aggressive components can lead to destruction of plates and sealing gaskets.

The widespread use of plate heat exchangers in various sectors of modern industry and public utilities is due to their high performance, compact overall dimensions, ease of installation and maintenance. Another advantage of VET is the optimal price/quality ratio.

Our partners

One of our key partners is located in the glorious city of Chelyabinsk. Their main advantage is their own production of plate heat exchangers since 2008. These guys know everything about them.

They are a certified assembly plant and official dealers of German Funke heat exchangers. They also represent other brands from Turkey and Sweden.

One of the main advantages of the manufacturer we represent is an individual approach to each client and this is not just a hackneyed advertising phrase, it is so! And that's why:

- There are strict regulations for tracking each unit of produced heat exchangers; they are all numbered and the entire journey is tracked by number.

- Each client negotiates their own price based on size and technical requirements

- As for the dimensions, the heat exchanger is manufactured according to the customer’s overall dimensions (not all manufacturers take this step)

- Each device has a passport, numbered heat exchangers and a warranty on parts.

- Before handing over the equipment to the client, heat exchangers undergo hydraulic tests in cold water.

Thanks to their large assortment of different plates, the KViP company can repair heat exchangers from other manufacturers on its own! In order to understand the problem, you need the specification of your heat exchanger.

It is also possible to select replacement plates and seals that the customer has.

Personal advice from us: if the cost of a heat exchanger is cheaper than the market price, then pay attention to why! Always look at the thickness of the plate, the standard thickness is 0.4 - 0.5 mm, for “savings” you may be told 0.35 or less, this is usually cheap China! Don't agree! The thickness of the plates affects the weight of the entire device; with thinner plates, the weight of the heat exchanger can be 30% less.

If the problem is more serious, then the heat exchanger will need to be dismantled and sent to Chelyabinsk for diagnostics and repair. But in any case, this is much cheaper than sending it abroad or buying a new one, and this is undoubtedly another plus.

Write to us by email and we will help. [email protected]

Collapsible plate types

Advantages

- minimum production costs

- minimum installation cost

- performance is adjustable

- ease of operation and repair

- low operating costs

- downtime is minimal

- low energy consumption

Application

- heating systems

- residential buildings and premises

- swimming pools

- refrigeration and climate control units

- hot water supply systems

- heating points

Comparison of plate heat exchangers with shell-and-tube analogues

| Characteristic | Shell and tube heat exchangers | Gasketed plate heat exchangers |

| Heat transfer coefficient (conditionally) | 1 | 3 — 5 |

| The difference (possible) between the temperatures of the coolant and the heated medium at the outlet | Not less than 5-10 °C | 1 - 2 °C |

| Change in heat exchange surface area | Impossible | Acceptable within a wide range, a multiple of the number of plates |

| Internal volume (conditionally) | 100 | 1 |

| Assembly connection | Welding, rolling | Detachable |

| Accessibility for internal inspection and cleaning | Non-separable, difficult to access, simple replacement of parts is impossible; only flushing possible | Collapsible. Easily accessible inspection, maintenance and replacement of any part, as well as mechanical washing of the plates. |

| Disassembly time | 90 - 120 min. | 15 minutes. |

| Tube (plate) material | Brass or copper | Stainless steel |

| Seals | Non-separable. Simple replacement is not possible | Glueless seals are easily replaced with new ones. The plates are rigidly fixed in the channels. No leaks after mechanical cleaning and assembly |

| Leak detection | Cannot be detected without disassembly | Immediately after occurrence, without disassembly |

| Susceptibility to corrosion at temperatures above 60 °C | Yes | No |

| Sensitivity to vibration | Sensitive | Insensitive |

| Assembled weight (conditionally) | 10 — 15 | 1 |

| Thermal insulation | Required | Not required |

| Operating life up to cap. repairs | 5 – 10 years | 15 – 20 years |

| Dimensions (conditionally) | 5-6 | 1 |

| Special foundation | Required | Not required |

| Cost (conditionally) | depending on the purpose and connection diagram 0.75 – 1.0 | 1,0 |

Sources

- https://masterok-remonta.ru/otoplenie-i-ventilyatsiya/plastinchatyy-teploobmennik.html

- https://www.teploprofi.com/teploobmennik-razborniy/

- https://sn22.ru/catalog/plastinchatie-teploobmenniki/

- https://sn22.ru/articles/printsip-raboty-teploobmennikov/

- https://kaminguru.com/sistema-otoplenija/shema-plastinchatogo-teploobmennika.html

- https://www.teploobmenka.ru/oborud/art-phe/

- https://teploobmennic.ru/blog/sovety-pokupatelyam/plastinchatyy-teploobmennik/

- https://www.teploprofi.com/plastinchatiy-teploobmennik/

How do you like the article?

Sergey Vladimirovich

Ask a Question

Heat exchanger specifications

- material for making plates: thin steel sheets of grades AISI304 and AISI316, alloy 254SMO, Hastelloy, pure titanium and others

- operating temperature of the coolant in the plates is no more than 180°C

- maximum medium pressure in the heat exchanger is not higher than 25 kgf/cm²

- The heat transfer surface area for one device can range from 0.1 sq. m up to 2100 sq. m

- the number of plates in one ranges from 7-10 pieces and much more, depending on the application