When installing individual heating systems, users have to ensure their optimal functioning using various types of built-in equipment and plumbing fixtures. One of the main problems when operating a heating main is airing; in this case, homeowners need to independently solve the problem of how to bleed air from the heating system.

To simplify the de-airing procedure, at the installation stage of the system, technical devices for air release are built into the circuit and heat exchange devices. Also, proper maintenance and operation of the heating main plays a significant role in ensuring uninterrupted operation.

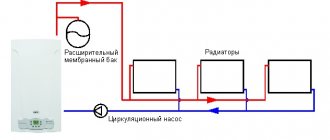

Rice. 1 Examples of individual heating boiler piping

Risks of airing the system

The formation of an air lock is considered a serious malfunction because:

- the room is not heated properly;

- heating costs increase;

- noise increases during system operation;

- due to the formation of compounds, calcium, magnesium and bicarbonate, metal corrosion increases, which leads to premature failure of pipes.

Therefore, timely removal of air from the heating serves as a guarantee of long service life of the heater and other elements of the system.

Top supply in an apartment building - how to release air

Buildings with a top spill have the following characteristics:

- The supply bottling is located on the technical floor, and the return bottling is in the basement;

- each riser is a jumper between them, disconnection is possible both from below and from above;

- the feeding bottling is done with a slight slope;

- at the very top there is an expansion device with a discharge outlet, while the discharge is often discharged through all floors to the elevator unit in the basement or at most close to it.

The function of the air vents is assigned to the vent on the expansion device. Thanks to the discharge to the basement, the start of heat supply in the fall is simplified.

Option No. 4 to solve the problem - sump on the expansion tank

To fix the problem, before pushing through the air lock in the heating system, the top filling must be put into working condition.

To do this you should:

- Slowly fill the system to prevent water hammer. It is necessary to slightly open the house valve on the supply or return, located between the elevator unit and the heating circuit.

- After filling the system, open the second valve completely.

- After 5 - 10 minutes, open the vent on the expansion device and wait until the air is replaced by water.

Reasons for the formation of an air lock in heating

Such a malfunction results from:

- Incorrect installation. If the pipes are not laid out with a constant slope, then the curved sections of the system will become places where air pockets will form regularly.

- Violations of tightness. In this case, air will enter through various connections or cracks in the pipes.

- Violations in the installation of air vents. Or clogging of device elements with solid particles.

- Ignoring the rules for preparing the system for the heating season.

- Repair work or prevention.

- Replenishment of volume, since the liquid contains a certain percentage of gas bubbles.

Consequently, the formation of a plug may be a consequence of natural causes or installation errors. Knowing the cause will allow you to choose the optimal method for troubleshooting.

Reasons for stopping fluid circulation

Air trapped in the heating system interferes with the circulation of the coolant.

Ultimately, the home will not heat up as it should, fuel will be consumed in large quantities, and the worst thing that will happen in this case is the system will defrost.

Air in the heating main of a private house can accumulate in various places, this contributes to the cooling of both individual sections of the batteries and the riser as a whole.

Of course, air should not be in the heating system, it has no place there, you need to remove it from there in any way known and available to you.

Below we will try to understand this issue and consider the main reasons for this phenomenon.

- During the design process or at the installation stage, serious mistakes may have been made, which consisted of an incorrectly executed slope or the absence of Mayevsky cranes on all batteries and other imperfections.

- During repair work, air entered the disconnected system.

- There is insufficient pressure in the pipes , and this contributes to a decrease in the coolant level as a whole.

- The emergence of the “emulsion effect” .

This is when a liquid substance is saturated with air bubbles in the first stages of its journey to the radiator, and then, once inside the pipeline, it is released there. - Rapid filling of the system with water .

The coolant should fill the line slowly. At the same time, it is necessary to release the air that has accumulated in the pipes during the summer downtime. - Depressurization may have occurred pipeline at the welding points or in the area where the fitting is installed.

In this case, the leak itself may not be noticeable, since the liquid from hot batteries quickly evaporates.And for air to get inside the pipe, all it takes is a miniature crack, which is sometimes not possible to notice visually.

- The devices through which air is taken in or removed may be faulty.

- Radiators of poor quality.

- A floor heating system is connected to the general heating main of the house; the pipes are mounted at the wrong level.

Do you know which is the best titanium to buy for heating water using wood? This useful article describes various models and popular brands from global manufacturers.

About the certificate of conformity of steel, water and gas pipes, galvanized pipes is written on this page.

How can you tell if there is excess air in the system??

The following factors may indicate this:

- extraneous noise in heating radiators,

- low heat transfer,

- Radiators heat up unevenly

- in areas where there is air, the battery will be cold.

Such situations, unfortunately, occur quite often.

Signs of system airiness

The air in the heating system manifests itself:

- Through cold pipes, if the boiler is on and operating at full power. This happens if the coolant circulation is disrupted.

- Through uneven heating in radiators. The difference is easily determined by touching different sections with your hands.

- Through increased noise during system operation due to the movement of microbubbles.

- Through periodic vibration caused by chemical reactions in the pipes due to the presence of air.

If these alarm bells are detected, you need to take care of venting the air from the heating system.

Advice from experts

- At the beginning of the heating season, pour water into the heating system slowly, without causing traffic jams. It is advisable to fill only from below.

- When starting up for the first time, do not heat it too much. Let the pipes and radiators first warm up to 60 degrees. Then drain some water and turn up the heat.

- When draining water through the Mayevsky tap, do not unscrew it completely or remove it. Due to the high pressure, screwing the device back in will be very difficult. There is no need to open the taps suddenly, so as not to rip them off and flood the apartment with boiling water.

- If removing air does not produce results, you need to check the entire heating system. Perhaps the reason lies in clogged pipes or risers that need to be blown out and cleaned.

In general, you can get rid of air in your heating system in simple situations yourself, but care and caution are required. If you have any doubts, it is better to entrust the matter to specialists who are confident in the thermal wiring of a house or apartment and have the necessary tools and skills.

Troubleshooting Methods

Methods for expelling air from a heating system are divided into 2 types: gravity or forced. In the first case, the physical properties of air are used. The second option is necessary in complex sealed systems where it is difficult to remove the plug naturally.

The procedure is most simply performed in open-type systems that are equipped with expansion tanks. Here it is enough to take care of the correct angle of inclination of the pipes so that accidentally trapped air can easily escape without creating traffic jams. If a problem occurs in such a system, it is necessary to check the correct installation and eliminate any identified deficiencies.

In addition, complex structures must be equipped with air vents. The device includes a barrel-shaped chamber. If the volume of gases in it begins to exceed the norm, a valve is automatically activated to bleed air from the system. The following systems are required for installation:

- at the highest nodes of the system;

- next to heat exchangers;

- in the upper parts of complex heated towel rails;

- in the area of the collector comb and hydraulic needle;

- next to safety devices.

Heating system air vents are divided into mechanical and automatic. In the first case, the valve must be activated manually. The second type of device works independently.

A forced method of eliminating air locks includes heating. Since the working medium expands as the temperature rises, it squeezes out air. In this case, heating is carried out within 70-100 degrees.

It is also considered effective to install separators that represent a barrel with a mechanism that extracts microbubbles. The most common option is to install a fine mesh, although analogues can be used. The air separated from the liquid is directed to the drain valve and then discharged outside.

Some are supplemented with a sludge modeler to the heating system. This device allows you to retain solid particles and then remove them from the system by opening the bottom tap. This device reduces the need for flushing pipes.

How to bleed air in autonomous systems

For autonomous heat supply systems with forced circulation of the working environment, everything is different. Typically, the pressure created by pumping equipment exceeds the height of the heating circuit and it can function even if the pipes are airy.

But as air bubbles move in pipes and batteries, extraneous sounds arise - hydraulic noise. If they are distributed continuously, this will cause a lot of unpleasant moments for residents.

In addition, air contributes to the formation of corrosion processes in steel parts of the heating circuit, such as panel radiators, pipes made of black steel, and cores of bimetallic devices.

When there is no oxygen, it does not come into contact with the coolant and rust does not appear. Now it’s clear why an air lock in the heating system of a private home is such a nuisance.

Recommendations for bleeding air

If the heating system includes automatic devices, excess air in it is eliminated without human intervention, subject to proper installation. However, in order to save money, some equip their heating with mechanical devices.

In this case, containers for the coolant are pre-prepared. After this, the heads on the exhaust valves are unscrewed. Then it is necessary to observe how the liquid leaves the system.

Hissing will indicate the presence of air bubbles. When the noise stops and the stream becomes smooth, the valves can be closed. Then all that remains is to return the coolant to the circuit.

How to bleed air from radiators

See if the Mayevsky valve - an air vent - is installed on the battery. The tap is installed on one of the connecting threaded flanges. This makes it easier to release accumulated air. In other cases, more effort will be required.

How to remove air through a faucet

Mayevsky taps, or air valves, are installed in apartment buildings instead of shut-off and control valves. This design allows air to bleed and water to drain. The faucet is a plug with a head on which there is a hole or groove. In the middle there is a tap for a slotted screwdriver. The most convenient designs are equipped with a rotary key.

The procedure is as follows:

- Turn the faucet. After several revolutions, the air will begin to bleed out with a hiss, and later a mixture of gas and coolant will flow. The liquid needs to be drained. Do not twist too much, otherwise the media, which emerges under high pressure, will splash the walls, floor and furniture.

- A fair amount of water will have to be released. In a high-rise building you will need to release 20–30 liters, that is, two or three buckets. In a private house you don’t need to drain so much - just wait until the liquid flows in an even, non-bubbling stream. After this, you can screw the tap back on.

If you don’t want to constantly bleed, buy and install an automated valve. Its price is low. But remember that automation sometimes malfunctions, so heating requires control. The automatic valve allows, if necessary, to manually release the air plug.

How to remove air without a tap

If there is no tap or valve on the radiator, you will have to bleed off the gas-air mixture through a plug. This is a flat element mounted on tow, which is located on the opposite side of the input. In old houses it is often painted over with several layers of paint and is difficult to see.

If it is not possible to isolate the room from the general house heating system, close the common riser before starting work. Otherwise there will be a flood.

You will need:

- Adjustable wrench.

- Paint thinner.

- Bucket or basin for draining water.

- Tow

First of all, soften the paint on the plug with a solvent so that you can unscrew it. Remove the element with an adjustable wrench. But even after the paint softens, the plug is unscrewed with great difficulty. Therefore, you will have to make an effort. Turn the key slowly and carefully until you hear the sound of air escaping. Bleed it and drain about three buckets of coolant. There is tow wound under the plug - replace it with a new one. Then screw everything into place.

Ventilating the heating system in this way is quite troublesome. Therefore, old radiators are now being replaced en masse with new models that are more convenient to use.

Features of filling the heating system

The problems of combating air locks can be partially solved by correctly filling the circuit with coolant. To do this you need:

- start the process from the lower sections, first equipping the pipeline with a ball valve;

- supply water at a moderate speed;

- maintain a pressure reading of 1.5 bar, monitoring it with a pressure gauge;

- between filling the system and starting the air bleeding procedure, warm the liquid to a temperature of 60 degrees;

- after bleeding the air, complete filling the system by returning the drained coolant;

- If uneven heating is detected, the procedure for removing air pockets is repeated.

Therefore, the procedure for removing air from the heating system does not require professional skills or special equipment. At the same time, proper installation of the system and the use of air bleed devices will greatly facilitate the task.

How to bleed air from old batteries

Such models - accordions - are found in houses built a long time ago. They have one drain point for the entire riser, and it is sometimes difficult to find. Find it and start the process:

If the drain is provided on the top floor, there should be a tap on the radiator in one of the apartments. In such heating systems it is simple, with a “lamb” or “butterfly” on the rod. You just need to open it and drain the coolant. Use a heat-resistant container, since in old single-pipe systems and their later analogue, Leningradkas, the liquid temperature is very high.

If there is no thumb on the rod, use an adjustable wrench or a clamshell grip. Typically, after a few turns, bubbling water will begin to come out.

Many older batteries do not have drain devices. You will have to unscrew the plug located on the side of the case with a key. Before doing this, you need to soak the layers of paint that have dried on it with a solvent. After deflating and draining the water, change the tow under the plug and screw everything back.

You can remove the air lock from the basement, but you will have to spend a long time understanding the intricacies of the pipes, looking for your riser and unscrewing the valves on it. It is better to contact specialists so as not to leave the entire house without heat. In old houses with a direct-flow system, the air must be vented from the expansion tank located in the attic or top floor. It is also better to entrust this to the housing office employees.

Photo of the heating system of a private house

How is it formed?

An air lock is a serious problem because it causes overheating of the power unit. Typically, the malfunction appears due to partial “adding” of coolant or after its complete renewal. For example, the occurrence of a plug cannot be avoided if special equipment was not used when replacing the refrigerant. It should drive the coolant under pressure along the circuit. Thanks to the “installation”, the formation of congestion is eliminated.

If plugs appear in the system, this indicates that the rubber “parts” of the system are already fairly worn out. The fact is that microcracks appear on rubber elements over time. Air penetrates and accumulates in the form of bubbles on bends and narrow areas of the contour.

Thus, the plug negatively affects engine performance. This leads to serious problems such as improper circulation of refrigerant and overheating of the engine. Accordingly, the driver will face an expensive overhaul. In winter, airing will further worsen the operation of the stove.

There are different reasons for airing. This is why it is so important to recognize the signs of this process. In addition, you can remove the plug yourself without resorting to the services of specialists.

Purpose of the cooling system

An internal combustion engine operates on the principle that a series of small explosions of fuel occur in the cylinders. As a result of operation, the motor temperature rises to high values. In the absence of a cooling system (CO), this would lead to failure of all mechanisms. Thus, the role of the cooling system is reduced to removing heat from engine parts in order to maintain its normal t mode.

In addition, the CO performs the following functions:

Speeds up engine warm-up.

Heats the air for heating inside the cabin.

Cools the lubrication of the engine and automatic transmission.

When used, recirculation cools the exhaust gases.

Most cars are equipped with a liquid cooling system. The work uses forced circulation. On the one hand, it creates cooling, and on the other hand, it helps to comfortably remove excess heat from the motor.

Not only antifreeze is used as a refrigerant, but also antifreeze or water. The best in terms of price and performance ratio is antifreeze.