From the author: Hello, dear readers! Air locks are the real bane of any heating system. When formed in pipes or radiators, they block the coolant flow partially or completely, so the equipment heats up unevenly. But, in fact, this is the least of the problems. The presence of air in the heating system can lead to quite detrimental consequences.

This is especially true for autonomous systems. That is why it is useful for any owner of a private home to know how to bleed air from the heating pump and other elements. The problem is not limited to cold radiators. There are several other negative factors that are a consequence of the presence of air locks:

- loud noise. The plug prevents the coolant from flowing in the required volume, so when it is “squeezed”, a hum and even vibration occurs. All this is very unpleasant, especially at night,

- failure of system elements. For example, the bearings of a circulation pump, as a rule, must be surrounded by coolant. If an air lock forms in the area where they are located, they will begin to run dry. The consequence will be their rapid abrasion, overheating of the pump and, accordingly, its breakdown. Air pockets threaten other elements of the system due to the effects of various negative chemical processes. For example, they can cause corrosion or scale formation. Pipes are especially affected. Rust eats away at their walls, and scale clogs the gap, greatly reducing the throughput of the elements. As a result, sooner or later, the pipe will simply begin to leak under the pressure of circumstances.

As you can see, the presence of air in the heating system can cause quite serious damage. Therefore, it is important to release it in a timely manner. This is much easier to do than replacing eventually broken heating system elements with new ones. So let's figure out how to get rid of air locks and what to do to prevent their occurrence.

Washing methods

Today, it is customary to distinguish between four technological methods for cleaning a heating system.

Chemical washing. This cleaning method allows you to remove 100% of system contaminants, with a minimum of effort required. However, this cleaning method is only suitable for metal heating pipelines.

To perform chemical cleaning yourself, you need to have the following tools and materials on hand:

- washing solution, which may contain mineral or organic acids, as well as all kinds of solvents and alkalis;

- container for draining liquid;

- pump;

- hoses.

The procedure is as follows:

- water is drained from the heating system;

- acid solution is poured;

- a special pump is connected to the system, which pumps cleaning liquid throughout the entire heating circuit for several hours;

- the waste liquid is drained and clean water is pumped in.

An important point: it is strictly forbidden to pour the used acid solution into the sewer. If it is not possible to dispose of it yourself, then you can purchase special neutralization products.

Hydrodynamic flushing. This method of cleaning the heating system is carried out using special equipment, which includes thin hoses and special nozzles.

The principle of cleaning with this method is that water is supplied under pressure to a nozzle, which generates thin jets of water. With the help of these jets, all grease, rust and scale are removed from the working area.

It is worth noting that although this method of flushing pipes is quite effective, due to its high cost it is used too little.

Pneumohydropulse flushing of the heating system. In order to perform this type of cleaning yourself, you will need:

- compressor;

- outlet pipe;

- hose;

- clamp;

- ball valve;

- drain container.

The order of work consists of the following steps:

- water is drained from the system;

- the outlet pipe is connected to the “return”;

- the compressor is connected to the outlet, and we pump up a pressure of approximately 5 atmospheres. Strong pressure in the pipes causes all kinds of contaminants to break off from the walls.

- close the outlet pipe and disconnect the compressor and connect the hose;

- We open the valve, and as a result, all contaminants come out under pressure.

It is worth noting that for better cleaning, the pneumohydropulse procedure can be repeated several times.

And in conclusion, I would like to note that after studying our recommendations, you will be able to flush the heating system yourself with greater confidence.

Watch the video, which popularly explains the need to flush the heating system and the specifics of carrying out the relevant work:

Other problems

In addition to the above reasons, there are other moments when the pressure in the heat generator rises above normal:

- Closed or insufficiently open shut-off valves. The pressure on the supply flow increases, the unit is blocked. In order to reduce the pressure, open the valves all the way, check if the shut-off valves are leaking.

- The dirt filter is dirty. Washing the filter will help reduce the pressure; if it is in very poor condition, replace it with a new one.

- Malfunction of the make-up tap when water drips from it. Liquid from the water main, where the pressure is about 2.5-3.5 Bar, flows into the heating circuit, where the pressure is less.

Make-up valve in the heating system

As a result, the pressure in the heating circuit increases. In order to reduce it, replace the tap, but most often the gasket needs to be replaced; it wears out quickly, especially if the water is very hard.

How to bleed air from a heating system

Surely many people have encountered such a problem when, touching the heating radiator, they realized that the upper part of it was hot and the lower part was absolutely cold. This is the first sign that there is air in the heating radiators, which prevents the coolant from entering the lower part of the radiator, thereby heating it.

Therefore, answering the question of what is affected by airing the heating system, we can safely say that airing affects, first of all, the efficiency of the entire heating system. With one half heated, the heating radiator will not be able to give off as much heat to the rooms as during normal operation.

Airing the heating system also affects the performance of the heating boiler. It is much easier for a heating boiler pump to pump coolant without air in it. Often the reasons for stopping the circulation pump in a heating boiler is also an excess of air in the heating system.

These are not all the problems associated with airing the heating system, since there are many more of them. Therefore, it is obvious that as soon as you hear that something is gurgling in the heating radiators, and this is nothing more than air, you should immediately begin to de-air the heating system.

In fact, venting the heating system is not particularly difficult. Depending on what kind of heating radiators are in the house, there are several ways to ventilate the heating system.

How to remove air from old cast iron batteries

If the house has old cast iron heating radiators, then in order to bleed air from the heating system, there should be a small ball valve on the top of the radiator. Having opened the tap, you need to wait until all the air leaves the heating device and only water comes out. If there is no tap, then you can use plumbing “crabs” to unscrew the nut or air vent, thereby bleeding the air from the cast iron battery.

How to remove air from aluminum radiators

The situation is much simpler if you need to bleed air from the heating system if new aluminum or steel panel radiators are installed in your house or apartment. In such heating devices, on top of one of the sides there must be a Mayevsky tap.

In order to ventilate the radiator using a Mayevsky valve, a special Mayevsky key is used, which is inserted into the valve and then turned counterclockwise several turns. After the air has completely left the heating radiator, you can screw the Mayevsky valve back clockwise.

It happens that it is not possible to find the May key, then you can use it to bleed the air from the radiator with a regular flat-head screwdriver. But the only obligatory condition for this is that the screwdriver must have a thin and durable tip.

Otherwise, the screwdriver can simply be broken. The fact is that in the process of heating the radiator, the Mayevsky tap can simply “boil” and stick. Therefore, unscrewing it with a screwdriver is often problematic.

As you can see, airing the heating system is not as big a problem as it seems at first glance. Well, in order to bleed air from the heating system it will take no more than half an hour, or an hour maximum.

What can lead to traffic jams in the circuit?

The importance of air vents cannot be overstated. Traffic jams in the circuit can lead to different processes:

- circulation disturbance;

- pressure surges;

- reduction in the efficiency of heating equipment;

- corrosion of metal.

Autonomous air vent

Installing an air vent in the heating system prevents the formation of plugs and pockets. When bumping into them, the coolant stops. Sometimes plugs cut off entire sections with radiators from the circuit. At the same time, the pressure in the system increases. When it reaches a critical level, an emergency release of coolant occurs. This, in turn, leads to a drop in pressure. At the same time, there are many cases when air collected in the batteries, the circuit continued to work, only half of the radiator became cold. This significantly reduces the heating efficiency and slightly increases the cost of its operation.

For open systems, one of the most serious threats is rust. At the same time, the question of how to remove air from the heating system arises only at the design stage. Such circuits are assembled at an angle from pipes with a large diameter, so there is a lot of water in the system. Considering the fact that the coolant is in contact with air and draws it into circulation, the oxygen level in the pipes is more than sufficient. Since it takes a long time to remove air from the heating system, oxygen reacts intensively with the metal. The result of the interaction is the formation of corrosion on the inner walls of the pipes. Rust sometimes eats up the tank so much that you have to replace it.

The direct consequences of traffic jams in the circuit entail indirect ones, which are no less dangerous:

Occurs if the valve for bleeding air from the heating system and all sensors are in good working order and working correctly. Due to the increase in pressure, an emergency release of the coolant occurs, which leads to a decrease in its quantity in the circuit. After cooling, there will not be enough fluid in the system, and the pressure will drop sharply. If it does not correspond to the minimum required to turn on the boiler, the heater will not turn on. And from this moment in winter, the countdown begins when the pipes defrost. Depends on how insulated the house is. Sometimes this happens in just three hours. In this case, unpleasant news awaits you at home from work;

This occurs if there is a malfunction of the valve for bleeding air from the heating system, or the temperature-controlling equipment. An unlikely situation, although possible. The results of this are very disastrous. At best, repair or replacement of the boiler; at worst, injury;

- rupture of the circuit and release of the hot water fountain.

A very likely situation is that the joints may not be tightened enough. As the pressure increases, they cannot withstand and crack. At the same time, hot coolant flows from the pipe like a fountain. Not only does the circuit need to be repaired, but the neighbors also need to repair the ceiling, since you flooded it thoroughly. This is the kind of chain that can be caused by simply airing the system.

A plug in the circuit can lead to serious consequences, such as system defrosting or an accident.

Mayevsky crane how to bleed air

The Mayevsky crane should be given special attention. This is a needle radiator unit that includes an air valve, screw and cone-shaped body design.

All these parts are tightly adjacent to each other, which completely eliminates the leakage of water. As for the air that may be in the radiator, it exits through a small hole located on the side of the tap. Such an installation can be opened using a special key, which is always included in the kit; if one is missing, then you can use a regular screwdriver, and some models provide the ability to open manually.

If we take into account a modern bimetallic installation, then they already have holes for installing taps. The Mayevsky tap itself must be installed in such a way that the air vent tube is located on the opposite side and is parallel to the floor

If your batteries are made of cast iron, then automatic air vents are best suited here. They correspond to the design features and composition of the material.

In order to remove air using a Mayevsky tap, you need to follow a sequence of certain actions.

In order to bleed air in the Mayevsky tap, you should first prepare a screwdriver and a container

- Prepare keys or a screwdriver, a container for liquid and a rag;

- If your system includes a pump, then it must be temporarily turned off;

- Place the container under the tap and carefully turn it counterclockwise;

- Air will begin to drain from the faucet and may include dirt or rust;

- You need to wait until water flows from the tap and turn it off.

If the water quality is not the best, then you need to install a few additional shut-off valves. They should be located up to the Mayevsky tap and protect it from possible blockages.

Why does pollution occur?

The problem with clogging of metal pipelines is rust.

Accumulating inside the system, it prevents the free circulation of the coolant, and as a result, malfunctions occur in the heating operation. As for plastic pipes, they are naturally not susceptible to rust, but, nevertheless, scale appears on their walls, which also contributes to malfunctions of the heating system.

One of the causes of pollution is also the quality of water, which may contain various impurities that cause pipes to clog.

Thus, there are the following types of blockages:

- scale;

- rust;

- silty sand;

- garbage.

Where does the air in the system come from?

Practice shows that it is impossible to ideally isolate a water heating network from the external environment. Air penetrates the coolant in various ways and gradually accumulates in certain places - the upper corners of the batteries, turns of highways and highest points. By the way, the latter should be equipped with automatic bleed valves shown in the photo (air vents).

Types of automatic air vents

Air enters the heating system in the following ways:

- Along with water. It's no secret that most homeowners replenish the lack of coolant directly from the water supply. And from there comes water saturated with dissolved oxygen.

- As a result of chemical reactions. Again, water that is not properly demineralized reacts with the metal and aluminum alloy of the radiators, releasing oxygen.

- The pipeline network of a private house was initially designed or installed with errors - there are no slopes and loops are made that face upward and are not equipped with automatic valves. It is difficult to remove air accumulations from such places even at the stage of filling with coolant.

- A small amount of oxygen penetrates the walls of plastic pipes, despite the special layer (oxygen barrier).

- As a result of repairs with dismantling of pipeline fittings and partial or complete drainage of water.

- When microcracks appear in the rubber membrane of the expansion tank.

When cracks occur in the membrane, gas mixes with water

Note. Water taken from wells and shallow wells is prone to chemical reactions, since it is saturated with active salts of magnesium and calcium.

Also, a situation often arises when, after a long period of inactivity during the off-season, the pressure in a closed heating system decreases due to air ingress. Draining it is quite simple: you just need to add a couple of liters of water. A similar effect occurs in open-type systems if you stop the boiler and circulation pump, wait a couple of days and start the heating again. As the liquid cools, it contracts, allowing air to enter the lines.

As for the centralized heat supply systems of apartment buildings, air penetrates into them exclusively along with the coolant or when the network is filled at the beginning of the season. How to deal with this - read below.

Example from practice. It was necessary to remove air pockets from the open heating system every day due to a completely clogged mud trap. A working pump created a vacuum in front of itself and thus drew oxygen into the pipelines through the slightest leaks.

The thermal image shows the area of the heating device where an air bubble usually lingers.

What should be the pressure in the expansion tank of a BAXI double-circuit boiler?

If you open the instructions, it indicates the pressure in the expansion tank is 0.5 bar, but this is the minimum value, correctly - the pressure should be about 20% less than the pressure in the heating circuit at room coolant temperature.

Based on the fact that for most systems the recommended filling pressure is in the range of 1.2 to 1.5 bar, we obtain the required pressure in the air cavity of the expansion tank equal to 0.8-1 bar. Experts usually recommend setting the pressure in the BAXI expansion tank to 1 bar.

Heating system without air locks

To ensure that air in an individual heating system does not accumulate in problem areas, but goes outside, it is necessary:

- correctly design and install the pipeline, correctly install radiators;

- use automatic and manual air vents.

Let's look at how to expel air from a heating system with natural circulation and top wiring

When arranging a pipeline, it is important to maintain an inclination angle at which air bubbles move freely upward, to the highest point of the circuit, without accumulating at turns and flat areas. At the highest point of such a system, an open-type expansion tank must be installed, through which air bubbles enter the atmosphere

Bleeding air from the heating system using an automatic air vent

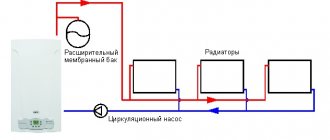

To bleed air from a system with forced movement of coolant or a gravity system with bottom wiring, a different principle is used

. Return pipelines are installed at a slope (this simplifies draining liquid from the system), and at the top point of all individual circuits, automatic valves are installed through which air is discharged as it accumulates.

In addition to automatic air vents, the system also uses manual Mayevsky valves. Such air vents are mounted on heating radiators - on the upper pipe on the opposite side of the pipe supplying the heated coolant. To ensure that air enters the valve and does not accumulate in the upper radiator manifold, it is recommended to install the heating device at a slight angle. Air release is performed manually as needed.

How to find an air lock?

Ideally, the system independently copes with airing thanks to automatic valves through which air is released. If you discover that a particular heating device or part of the circuit is not working properly, you need to find the place where the air has accumulated.

Touch the radiator - if its upper part is colder than the lower part, it means that coolant is not flowing there

. To release air, open the Mayevsky valve installed on a steel, aluminum or bimetallic radiator, or the valve valve mounted on cast iron batteries.

How to determine an air lock in a battery

You can also determine the place of airing by sound - under normal conditions, the coolant moves almost silently, extraneous gurgling and sounds of overflow occur due to an obstacle in the flow

.

Metal pipes and heating appliances are tapped with light blows - in places where air accumulates, the sound is noticeably louder.

Getting rid of the airlock

If there are manual air vents on radiators, there are no problems with how to remove air from the batteries. Using a screwdriver or a standard wrench, the stem of the Mayevsky tap is slightly unscrewed, and a suitable container is placed under the drain hole (a half-liter glass jar is enough). Bleeding air from the heating system using a manual air vent is accompanied by hissing and whistling, then splashes appear, after which the coolant begins to flow in a thin stream. At this stage, the Mayevsky tap should be closed.

Note! If the battery continues to heat poorly after de-airing, the problem may lie in a blockage. In this case, the heating device is dismantled and washed

After reinstalling the radiator, check the system for air pockets.

To remove an air lock from the heating system if it has accumulated away from the air vent (manual or automatic), proceed as follows

:

- Open the air tap or valve closest to the air bubble.

- They begin to gradually replenish the system with coolant so that the liquid, due to an increase in volume, displaces the air bubble towards the open air vent.

Automatic air vent valve with corner connection

What to do in difficult cases when adding more coolant volume does not remove the plug? In such a situation, in addition to increasing the amount of coolant, it is necessary to add pressure, heating the liquid to critical temperatures. You should act extremely carefully so as not to be scalded by the splashes that accompany the release of air through the automatic valve.

Important! If a plug is systematically formed in the same section of the pipeline, cut a tee in this place and install an automatic valve

Types of equipment and principle of its operation

- open type expansion tank.

How to remove air from a closed heating system with a simple tank? It can perform the function of an air vent only in open circuits. Since it is not possible to ventilate a closed circuit heating system using a tank. Only sealed tanks are installed in them. The open tank is at the peak of the circuit, where oxygen bubbles tend to flow. The problem is that the water is enriched with it in the same tank, so there is a high level of air in the coolant, which is there until the liquid is heated;

Installed at the highest point or in a place where oxygen accumulates. The threaded part of the heating system air bleeder comes in two diameters: ½ or ¾ inch. In shape they can be flat or bent at a right angle, like the letter “g”. The air outlet hole is located either at the end or on the side of the housing. Works offline. Air is released from the heating system when the pressure in the system rises to a critical level. Consists of a valve and a float. The working principle is that when oxygen rises, the float moves down and opens the valve. As soon as a release occurs, the float rises, returning to its original position, and closes the valve;

- air separator for heating.

Placed on the feed. Unlike an automatic air vent, it does not remove the oxygen that itself separated from the coolant and rose up. The air separator in heating independently separates oxygen particles and gets rid of them. It is designed in such a way that the flow mixes when encountering obstacles. Barriers may include:

Air separator for heating

How often should the heating system be flushed?

Many people who carefully care for their heating system are wondering how often to clean the pipes.

There are two types of cleaning work:

- The first flushing is carried out immediately after installation of the heating system. This is due to the fact that when heating equipment was installed, various types of debris or oily contaminants could get inside the pipes. Therefore, the flushing procedure must be carried out until the water in the drain becomes absolutely clean.

- Regular flushing in systems equipped with metal pipes is recommended to occur twice a year - before the start of the heating season and after it ends. For plastic pipelines, it is recommended to clean them once a year - before the start of the heating season.

Knowing now the reasons for contamination of heating systems, as well as the regularity of cleaning, the question involuntarily arises: is it possible to carry out the flushing yourself?

And we will give an affirmative answer to this: cleaning the heating system can be done with your own hands. To do this, you just need to choose the optimal washing option, which will be discussed further.

Do I need an expansion tank for a baxi wall-mounted gas boiler?

The volume of the built-in expansion tank of the baxi boiler is indicated in the characteristics and for the ECOFOUR series it is 6 liters. To answer the question of its necessity in a separate heating system, you need to know the total volume of this system.

Calculating it is not so difficult: the filling volume of the boiler and radiators is in their characteristics, and the filling volume of pipelines can be calculated by knowing their diameter and total length. Water, after heating by 80 degrees Celsius, will increase in volume by approximately 4-5%, therefore, the recommended volume of the expansion tank is 8% of the total volume of the heating system if filled with water and 12% if antifreeze is used as a coolant (thermal coefficient antifreeze expansion is greater). Thus, a standard expansion tank will be sufficient for a heating system with a volume of up to approximately 75 liters when using water and a volume of up to 50 liters when using antifreeze liquid.

These figures are conditional (with a margin) and when selecting the capacity of the expansion tank, you must be guided by the design calculations of a specific heating system, or the manufacturer’s recommendations.

In most cases, the built-in boiler tank is quite sufficient and the decision to use a separate additional tank is made by specialists at the design stage.

Causes and consequences

The reasons for the occurrence of air jams are the following factors:

- Errors were made during installation, including incorrectly placed bends or incorrectly calculated slope and direction of pipes.

- Filling the system with coolant too quickly.

- Incorrect installation of air vent valves or their absence.

- Insufficient amount of coolant in the network.

- Loose connections between pipes and radiators and other parts, which allows air from outside to enter the system.

- The first start-up and excessive heating of the coolant, from which oxygen is more actively removed under the influence of high temperature.

Air can cause the greatest harm to systems with forced circulation. During normal operation, the bearings of the circulation pump are constantly in water. When air passes through them, they are deprived of lubrication, which leads to damage to the sliding rings due to friction and heat or completely damages the shaft.

Water contains oxygen, carbon dioxide, magnesium and calcium in a dissolved state, which, when the temperature rises, begin to disintegrate and settle on the walls of the pipes in the form of limescale. Places of pipes and radiators filled with air are more susceptible to corrosion than others.

Signs by which you can determine whether there are air pockets in pipes and radiators

Due to air in the heating system, the radiators heat up unevenly. When checked by touch, their upper part, compared to the lower part, has a noticeably lower temperature. The voids do not allow them to warm up properly, so the room is less heated. Due to the presence of air in the heating system, when the water is very heated, a noise appears in the pipes and radiators, similar to clicks and water flowing.

You can determine the place where the air is located by ordinary tapping. Where there is no coolant, the sound will be louder.

Check the network especially carefully for leaks. When the heating is running, it is extremely difficult to identify leaky connections, since water quickly evaporates on a hot surface.

Causes of traffic jams

Everyone knows that it is better to avoid problems in the first place than to correct them later. Therefore, we will consider some rules for arranging a heating system that will help either completely avoid the formation of air jams, or get rid of them very quickly.

The reasons for the accumulation of air masses in the elements of the heating system can be several factors:

- incorrect installation of the system. For example, the required slope of the highways is not observed, or their arrangement forms loops and the like. It is important to take this point into account at the system design stage,

- Incorrect filling of the circuit with coolant during startup. If you do this too quickly, the liquid may unwittingly create a water lock. The principle of its operation will be the same as that of conventional siphons: do not let anyone in, do not let anyone out, including air,

- violation of the tightness of junctions of various elements - for example, pipes. A leak does not always manifest itself as a fountain. Sometimes it is so small that it appears in the form of a couple of drops that evaporate very quickly. Naturally, the location of such a leak is difficult to detect, so it remains for a long time without repair. And all this time, air penetrates into the system through it, accumulating there and forming a plug,

- absence or incorrect operation of devices responsible for the timely removal of air from the system. When installing heating in a private house, it is necessary to install special devices to perform the air removal function. For example, these could be automatic air vents or Mayevsky taps. If they were not initially installed, or their performance is impaired for some reason, corresponding consequences arise,

- recently completed renovations. For example, when replacing any element of the heating system, a certain amount of air gets into it one way or another. If you don’t release it right away, it will find a cozy corner and sit securely there, interfering with the circulation of the coolant,

- replenishing the coolant volume by adding cold water (for example, this happens after a leak). In any case, fresh liquid contains air. When it heats up, it begins to release in the form of bubbles, which then merge into one large one. This is how a traffic jam is formed. Therefore, after replenishing the volume of liquid, you always need to wait a while and then carry out the air release procedure.

Filling the system with coolant

It’s worth talking separately about filling the circuit with coolant. It is this procedure that, as a rule, most often entails the formation of air jams. Moreover, most often this happens due to incorrectly performed actions. Therefore, it is necessary to know the basic rules for filling the contour and strictly follow them.

Water heating with natural circulation

Open heating system

Heating water systems without a pump are usually classified according to certain characteristic criteria that reflect their functionality.

Depending on the type of expansion tank, heating with natural circulation is usually divided into the following types:

- Open heating system. With this design, the expansion tank is located as high as possible in order to create excess pressure and also to remove air. In this case, the tank also serves to add fluid to the system.

- A closed heating system with natural circulation is distinguished by the fact that instead of an expansion tank, a membrane hydraulic storage cylinder is installed, with the help of which an additional pressure of no more than 1.5 atm is created. To ensure safety, a block with a pressure gauge is built into the design of the system, which regulates the internal pressure.

You can read about the features of the Wilo circulation pump here.

Also, heating structures with natural circulation are divided depending on the method of connecting the heating elements. According to this classification, there are the following types of heating:

- Single pipe heating system. The operating principle of this type of heating is that all heating devices are connected to the system in series, in other words, the coolant circulates from one element to another. The undoubted advantage of this type of heating is that installation is quite simple and requires a minimum of materials.

- Two-pipe heating system with natural circulation. In this heating design, the heating elements are connected to the main pipe in parallel. In other words, the coolant enters each device at the same temperature, and the cooled liquid returns to the boiler through a pipe, which is commonly called “return”.

This heating scheme is the most optimal for heating a living space. The only drawback is that the installation of such heating requires a large number of pipes and other plumbing fittings.

Builder's advice: when choosing a heating system for your home, be sure to consider your options when purchasing all the consumables for heating installation.

Malfunctions of expansion tanks

Checking the pressure of the expansion tank is included in the list of annual maintenance procedures and if it is followed there will be no problems, but if neglected it can give the owner unpleasant surprises:

the pressure in the air chamber gradually decreases and with each refill of the boiler the tank fills more and more with water and gradually ceases to perform its function. In this case, the membrane is so pressed against the wall of the air part of the tank that it can be damaged by the valve spool and the tank will have to be replaced.

The heating circuit pressure is at the permissible limit, the expansion tank has not been serviced - there is no pressure in it. When the heating system cools down, the volume of liquid decreases, the pressure drop is not compensated for by anything - the boiler stops due to an emergency. This situation can arise, for example, when the boiler operates for a long time in DHW mode or when there is a power outage.

the owner of the boiler often has to top up the boiler for no apparent reason, for example, while hot water is being used - the pressure on the pressure gauge drops and the boiler stops by mistake - the owner tops up. Since thermal expansion is not compensated by anything, with further heating of the coolant, excess pressure is released through the safety valve. Some users set the reset and simply do not notice this situation. Frequently refilling the boiler with untreated water is detrimental to the heat exchanger!

Reasons for air getting into the heating system

The formation of traffic jams can be caused by various reasons; let’s consider them in more detail.

- Lack of tightness of joints of installation connections. This reason is especially often the initial one when operating systems without pressure. A small water leak is not visible and borders on possible evaporation. At the point of a loose connection, air is sucked in and accumulates in the free cavity of the line, forming a plug.

- Inaccuracy in the design or installation of pipelines, which entails the creation of unwanted “loops” that inhibit the movement of the coolant, entails the accumulation of air in such circuits.

- The low-tech method of filling the system with coolant also causes plugs. Very fast or top-down directed filling of lines contributes to the formation of air gaps that interfere with normal operation.

- Faulty operation of automatic air ventilators located on the upper pipelines provokes the creation of traffic jams.

- Poor installation of pipes with the formation of wavy lines (relative to the horizon) is a common and difficult to determine cause of the appearance of air. Elimination of such a cause requires periodic removal of plugs, and complete elimination requires repair of a separate section, with the possible installation of additional devices for air removal.

- Overheating - this reason is typical for solid fuel units. When water boils, air bubbles form in the internal cavity and accumulate in the boiler heat exchanger.

Prevention

To avoid problems with air locks, it is necessary to install air vents at each group of heating elements. So, for example, to remove air from the boiler, an automatic valve for removing gases is mounted directly on it. All collectors are also equipped with it. Mayevsky taps are installed on the radiators at the end.

If, after bleeding the air, the radiators still do not heat up well, the coolant should be completely drained. Since it is possible that there is too much dirt in the network, and it significantly reduces the circulation of fluid in the batteries.

https://youtube.com/watch?v=xUO58oC8yX8%3F

The forum was created for beginners and experienced plumbers, welders, mechanics, electricians and construction workers. Share your experience and receive competent answers from specialists.

- Unanswered topics

- Active topics

- Search

- Users

- our team

Signs of air accumulation: how to bleed the battery

Determining whether your batteries are airy is not difficult.

The following signs indicate this:

- Heat transfer has noticeably decreased (radiators that were previously hot stopped heating);

- You began to notice the presence of noise, crackling, gurgling and a decrease in pressure in the pipes;

- If you have autonomous heating, then an increase in fuel consumption will become obvious;

- Liquid has stopped moving through the system and circulation is disrupted.

The presence of air in radiators threatens not only a decrease in temperature, but also more global problems. For example, batteries made of steel begin to oxidize, rust and fail. Bottlenecks become silted and need to be flushed out or completely replaced. If your heating is individual, then the accumulated gas in the system can lead to failure of the circulation pump, because in normal condition the bearings are constantly in water. In case of airing, the installation is subjected to dry friction, which causes excessive heating and shaft failure.

Other problems

In addition to the above reasons, there are other moments when the pressure in the heat generator rises above normal:

- Closed or insufficiently open shut-off valves. The pressure on the supply flow increases, the unit is blocked. In order to reduce the pressure, open the valves all the way, check if the shut-off valves are leaking.

- The dirt filter is dirty. Washing the filter will help reduce the pressure; if it is in very poor condition, replace it with a new one.

- Malfunction of the make-up tap when water drips from it. Liquid from the water main, where the pressure is about 2.5-3.5 Bar, flows into the heating circuit, where the pressure is less. Make-up valve in the heating system

As a result, the pressure in the heating circuit increases. In order to reduce it, replace the tap, but most often the gasket needs to be replaced; it wears out quickly, especially if the water is very hard.