How to purchase spare parts for a Grundfos pump

When purchasing pumping equipment for home water supply, sewerage, heating or drainage systems, each buyer first of all tries to find out how long the manufacturer’s warranty is given and how its maintenance is generally carried out. This also applies to the products of such well-known world brands as Grundfos - after all, as we know, there are no mechanisms that never break.

In this article we will tell you what accessories and spare parts can be purchased from dealers and what warranty services offer Grundfos pumps today.

Designation of circulation pumps

In the marking of circulation pumps, two numbers are usually indicated after the brand.

The first of them indicates the nominal diameter of the supply pipes in millimeters . By this figure you can judge the connecting thread of the pump. For example, if the pump pipes have a nominal diameter of 25, then their connecting thread is 1 inch. The correspondence between nominal diameters (DN) and thread sizes is indicated below:

- DN 15 – 1/2 thread

- DN 20 – 3/4 thread

- DN 25 – thread 1

- DN 32 – thread 1 1/4

What do the numbers 25-40, 25-60 32-80 mean in the pump brand?

The designation of the pump Grundfos UPS 25-40 or Compass 25-40 means that the nominal diameter of its nozzles is 25 mm, which means the connecting thread is 1 inch, this pump is capable of developing a pressure of up to 4 meters (40 decimeters).

Considering that there are 10 decimeters in 1 meter, we can draw conclusions about other designations:

- 25-60 – connecting thread 1 inch, head 6 meters

- 32-80 – connecting thread 1 1/4 inches, head 8 meters

Model range SP

The SP series product range features more powerful technical characteristics. The model range is represented by different pumps, from SP 1A-14A to SP215, the capacity of which varies from 1 to 280 m³. The most popular among the population for domestic use are automatic installations 8A and 14A with modifications that differ in the number of steps that affect productivity.

So, in the SP 14A-10 unit the number of stages is 10, the flow is 14 m³/h, in the SP 1A-57 pump the parameters are as follows:

- head - 200 m;

- nominal flow rate - 1 m³/h;

- number of steps - 57.

In addition to standard models, the manufacturer has developed pumping units of the SP series with some features indicated in the marking, for example, the letter “N” indicates the manufacture of the housing from stainless steel type DIN 1.4401, “E” - the ability to operate the pump in an aggressive environment.

General characteristics of automatic pumps of the SP group for individual use:

- maximum height of the water column - 36/52/78/95/108/137/168/195/210/280/330/380/480/540/560 m;

- power - 0.37/0.55/0.75/1.1/1.5/2.2/5/7.5/9.2/11/13/15 kW;

- flow - 1/2/3/4.4/5/7/14 m³/h.

The following electric motors are installed in pumping equipment of various modifications:

- MS type:

- 1-phase 4-inch power up to 2.2 kW;

- 4-inch 3-phase - up to 7.5 kW;

- 3-phase T60 - up to 5.5 kW;

- 6-inch 3-phase - 5.5-30 kW;

- Submersible 2-pole with rewindable MMS winding:

- 6-inch 3-phase - 3.7-37 kW;

- 8-inch 3-phase - 22-110 kW;

- 10-inch 3-phase - 75-190 kW;

- 12-inch 3-phase - 147-250 kW.

Borehole pumps can be installed vertically, horizontally (when using a protective casing) and inclined, but not below the location of the electric motor. They are installed in shafts starting from 101 mm in size without additional equipment.

Designation of centrifugal pumps

The designation of centrifugal pumps often indicates information about the characteristics - flow and pressure of the pump.

What do the numbers 60/35, 70/50 mean in the pump brand?

The designation of the Jumbo pump 60/35 indicates that the nominal flow is 60 l/min and the maximum head is 35 meters.

The Jumbo 70/50 brand indicates that the nominal pump flow is 70 l/min, and the maximum pressure reaches 50 meters.

When choosing a circulation pump, sometimes unnecessary questions arise. Owners of heating systems do not suspect that making the right choice is very simple. Next, we will consider which pump to choose for heating in most cases that are found in private homes.

How important is it to choose the right pump?

For heating to work, a certain volume of liquid must move through the pipes. It transfers thermal energy from the boiler to the radiators. If the pumping volume is small (weak pump), the boiler will overheat and the radiators will remain cold.

But the reverse situation is no better. If the pump is too powerful, it will consume excess electricity, which will add up to a fair amount over the years, while the speed of water movement will be excessively high and there will be noise in the radiators, disturbing residents.

Therefore, when choosing a circulation pump for heating, it is important to get into some middle ground - all the energy should be taken from the boiler and spent on the radiators, but the water speed should not be too high, since this is not very profitable.

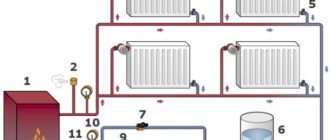

What happens in the heating system

The circulation pump pumps coolant through the pipes, most often ordinary water. With its impeller it creates a small pressure H (pressure measured in meters of water column) and sets a certain speed of fluid movement. The result is the fluid flow through the pump Q (m cubic hour) - the volume that is pumped per unit time.

Each pipe system has its own hydraulic resistance, which prevents the movement of fluid. If there were no such resistance, then any unit would pump unlimited volumes over an endless distance... But in order to push water through the pipes, the pump creates pressure and consumes electricity. The pipes resist the movement of water, resulting in a certain number of liters per minute (cubic meters per hour).

What is most important when choosing a pump?

The trick to choosing a pump for your home is that if the user doesn't want to understand performance graphs, they don't have to. Just read how to choose a circulation system for your home below...

For those who want to understand the problem, you can report the following. The main characteristics of this unit are the pressure it creates N, m, at a certain flow rate Q, m cubic/hour.

Each circulator has a performance curve. Moreover, they are different for each speed of its operation.

The heating network of a house also has a dependence of flow on pressure. If this graph is superimposed on the characteristics, then they will intersect somewhere, and the operating point of the pump will be obtained. This is exactly how much coolant it will drive, creating such and such a pressure.

Calculation of pump performance

To select a productive pump for a well, you need to know its main parameters. To determine the pressure, the distance from the bottom of the water source to the farthest point of water intake is calculated. Measurements are taken not in a straight line, but along a pipeline with all bends.

Calculations are carried out as follows:

Calculation of pump pressure.

- in a vertical position, the distance is considered 1 to 1;

- in horizontal - 1 to 10;

- the resulting segments are added;

- add 10% for bends, deviations and errors.

When determining productivity, it is necessary to know the number of persons permanently residing in the house, the number of operating points inside and outside the house.

The maximum liquid consumption is obtained by summing the water supply to each consumer during simultaneous operation; to be sure, another 20% is added to the result.

Advantages of devices

Thanks to the special properties of the Wilo pump, the efficiency of the heating system increases significantly. In this case, thin pipes can be used, which, in turn, helps reduce material and fuel costs. Also, when using a pump, the volume of carbon dioxide that is released into the atmosphere is reduced, and the daily consumption of electrical energy is no more than 250 W.

Of course, such a device is not cheap. You will have to pay a large amount for its purchase, but the cost will certainly pay off later when used due to energy savings and durability. The device will not require repair for a long time.

Vilo pumps have many positive properties.

The most important of them are the following:

- After water evaporates, there is no heat loss.

- The operation of the system can be controlled automatically. The device has a liquid crystal screen, a built-in thermostat and other elements that allow control. You can also manually switch the speed of rotation of the working shaft.

- Compared to many circulation pumps from other brands, Wilo devices are quite compact and therefore do not take up much space.

- The motor and rotor have a multi-stage protection system that helps prevent failure due to sudden surges in voltage in the electrical network.

- The motor operates silently, making it possible to install the device in residential buildings.

Wilo pumps are used in small rooms of several hundred square meters. The selection is carried out according to such parameters as power, volume of circulated water, room area and pressure height. The last parameter is the most important.

You can see how to distinguish an original pump from a fake in the following video:

Areas of application

The Wilo brand produces pumps designed for different purposes and therefore having different characteristics.

With the help of such a pump, you can water the beds directly from a well, borehole or the nearest body of water.

The scope of their application is wide and varied:

- Wilo devices are used in heating systems in closed circuits.

- They are used in the water supply of private houses and in wells for water extraction.

- Such pumps are also suitable for pumping out groundwater when creating basements and cellars.

- They are also used on construction sites when working with contaminated water.

- Owners of private suburban areas have found good use for them, in particular those who grow plants on their plots.

The Vilo pump can operate in the most difficult conditions, and it does not matter what the temperature of the water circulated through the pipes will be or what the pressure will be.

You can connect the device yourself without any problems. For this purpose, it is equipped with special spring terminals. It does not have a fan, so there is virtually no noise during operation.

Types of circulation pumps

Circulation devices manufactured under the Wilo brand are divided into two categories. Some of them may have a wet rotor, while others may have a dry rotor. Those devices equipped with a wet rotor can be used in a heating system for a room with an area of 100 to 750 m², while the liquid circulating in the pipes can be heated to 120°C.

In cold climates, having a heating system is simply necessary for a person to feel comfortable

Main technical characteristics of Wilo pumps:

- The minimum temperature that the coolant liquid can have is minus 10°C.

- The pressure height of such devices can be from 2 m to 12 m.

- The rotation speed varies from 950 rpm to 4800 rpm. The pumps have three different operating speeds.

- The weight of the equipment also varies. The lightest devices weigh just over 2 kg, while the heaviest ones can weigh up to 8 kg.

- The working parts of the motor are placed in the coolant, due to which it is lubricated and its operation becomes silent.

In rooms with an area exceeding 750 m², as well as in heating systems that serve not one, but several buildings at once, another type is used - equipped with a dry rotor. Their rotation speed does not exceed 3 thousand rpm.

Grundfos brand pumps

Before we talk about where to buy spare parts for Grundfos pumps and how their maintenance is carried out, let's say a few words about the manufacturer. This brand belongs to a Danish company of the same name, which was founded in the middle of the last century.

So:

- They were the first in many ways. These include fundamentally new design solutions, standardization of certain components in pumps, the use of titanium for the manufacture of quickly wearing parts, as well as automatic regulation of network operation. It was Grundfos that created the DDD system, which makes it possible to avoid regulating pressure in pipelines using valves.

- Thanks to the use of permanent magnets, the products of this manufacturer break all records in both energy efficiency and efficiency indicators. So the higher price of Grundfos pumps is compensated for quite quickly due to economical energy consumption.

- If you want to learn more about the innovations of this company, just type “grundfos pump official website” in the search bar. Of course, not all of their products present on the Russian pumping equipment market are manufactured in Denmark. Grundfos factories are located in most European countries, as well as in all major countries, including China.

Grundfos industrial pumps

- We have such an enterprise in the Moscow region, but not the entire range of products is produced there. These are mainly drainage and sewerage units, booster pumping stations, fire extinguishing installations, as well as control systems. As for household pumps for wells and wells, domestic stores most often sell products originating from Germany or China.

Their sales and service in Russia are carried out by dealer enterprises. There are dealers of Grundfos pumps in all major cities and regional centers of the country.

In order not to run into a fake, you should purchase equipment and spare parts for pumping stations from them. Moreover, you can order absolutely any part: from the oil seal to the engine.

Brief overview of our products

Among the types of equipment produced by Grundfos, there are at least fifteen categories. These are household and industrial pumps for pumping various types of liquids; circulation equipment for heating systems; sewerage installations; dosing and booster pumps; drainage and mud aggregates; automatic membrane tanks, and various components. As you can see: there is something to discuss.

To make it easier to perceive the information, we will offer you an overview in the form of a table:

| Equipment category | Pump series and their features |

| For installation in wells, two series of pumps are offered: SPO and SB. Their main difference is the design of the case. The SPO has a stainless steel body, while the SB has a plastic body. Each series has several options with different performance characteristics.

The Grundfos pump passport provides complete information about the capabilities of the mechanism, the rules of its operation and maintenance. In addition, the manufacturer’s recommendations and a visual connection diagram make it possible to install the pump in the well yourself. |

| The Grundfos line of downhole equipment includes series such as three-inch SQ pumps; SQE; SQ-N and four-inch SP. Basically, they are distinguished by different types of engines. All over the world, these pumps are appreciated for their optimal diameter and light weight ratio. They are used not only for supplying water from wells, but also for irrigation systems and pumping into reservoirs.

For example, pumps of the SQE series have additional equipment in the form of automation with remote control and a frequency converter. Some models are even equipped with a one-piece power cable with a length of 40 to 80 m, installed without a coupling.

|

| This category includes domestic water supply stations of the MQ, JP Basic, Hydrojet JP series, ejector pumps, and self-priming pumps for swimming pools. Pumping stations are compact, fully equipped with connecting fittings and instrumentation.

Depending on the modification, the pressure developed by the pump is 40-48 m, the flow rate is 3 and 4.5 m3/hour. Considering that MQ stations can only obtain water from a depth of 9 m, then for pumps equipped with an ejector from the JP series, 20 m is not the limit. In addition, they are able to work with heated water.

|

| Among the range of fecal equipment are pumping units of the Sololift and Multilift series, designed for collecting and discharging wastewater of varying degrees of contamination. The permissible size of solid particles for these pumps does not exceed 7 cm. They are used not only in everyday life, but also in office buildings, baths and saunas, beauty salons, various medical institutions, etc.

In addition, the manufacturer offers grinder pumps SEG and APG, as well as single-channel pumps SE and vortex pumps SEV. They are designed not only for pumping liquid waste, but also for processing masses with fibrous and solid inclusions up to 10 cm in size. Such pumps have a cast iron body and are very durable - they can easily start and stop up to 20 times within an hour. |

| This category of pumping equipment is perhaps the most extensive in terms of assortment - it includes 9 series. Grundfos UPS and UPSD (twin) pumps have gained the greatest popularity among domestic consumers.

Some models are equipped with threaded connections, others - with an air separator. There are also pumps that can work not only with hot water, but also with liquids that have a negative temperature. What is very convenient, UPS pumps are equipped with three-speed switches.

|

| The list of drainage pumps also includes several series, with different designs of motors and impellers, power characteristics and housing options. Unilift KP pumps are models for domestic use that can be used to pump water from a flooded basement, pump it from a natural reservoir, or lower the water level.

While Unilift KP are semi-submersible, the DP series pumps operate while completely submerged in water. They are used for draining pits and flooded mines. The operating instructions for each model provide the consumer with comprehensive information about the capabilities of the pump and its application. |

| The Grundfos brand also offers automatic fire extinguishing systems of the Hydro MX1 and MX2 series, as well as Solo FS jockey pumps. The units are very effective in fighting fire and can function for a long time, until the fire source is completely eliminated. There are models designed for deluge systems, and there are pumps for sprinkler systems that are triggered by a signal from a pressure sensor.

|

| A fairly large group of single-stage pumps belongs to the TP and TPD series with in-line pipes. They are used in domestic and industrial water supply, air conditioning, ventilation and heating systems. They are unpretentious, economical and very diverse in parameters.

The multi-stage Grundfos CR series pumps, which you see in the photo on the left, have gained particular popularity. This is a huge range of pumps, with power from 0.37 to 75 kW. They are used everywhere, from irrigation systems to fire-fighting and industrial water supply systems. |

Manufacturer's warranty

The passport for the Grundfos pump is the main document, which clearly states all the characteristics of the pump, diagrams of its installation and safe connection, and warranty periods. And by the way, they are not the same for different types of equipment.

- For example, well, sewer or drainage models (see Drainage pump: use and application) are guaranteed for two years. The operation of the circulation pumps of the MAGNA and UPS series, which you see in the title photo, is guaranteed for three years. And the longest warranty period for pumps under the ALPHA brand is five years. The total service life of pumping equipment, determined by a given manufacturer, is ten years.

Grundfos pumps instructions

- The warranty period for the pump, as is practiced everywhere, is counted from the moment of its sale. But, if it was installed by service center specialists, which is confirmed by the relevant act, then the warranty begins from the day the equipment is put into operation.

- If the pump has undergone warranty repair, then its period: from the date of delivery to the service center until the date of delivery to the client is added to the total warranty period. What are the service center representatives required to do if the repairs were carried out after the warranty period for the unit itself had expired?

Note! You are required to provide at least 12 months of warranty for spare parts for Grundfos pumps replaced during out-of-warranty service.

- Therefore, upon completion of the repair, the consumer must be provided with documentation: a Grundfos pump, with a detailed description of the actions performed and confirmation of the fact that a particular part has been replaced. With a valid warranty, repairs are made free of charge, and replacement components are not issued to the client. Costs associated with dismantling and reinstalling the pump are not reimbursed to the consumer.

- It must be borne in mind that if the equipment malfunction occurs as a result of gross violations committed during installation and connection to the electrical network, mechanical impact, or after opening the pump housing with your own hands, you cannot count on warranty repairs.

To avoid misunderstandings, when purchasing equipment and issuing it after repair, make sure that the warranty card, as well as the service protocol, are filled out properly: user data, signatures and seals, date. The video in this article will help you understand the documentation for Grundfos pumps.

Common labeling

When choosing a Wilo brand pump, you should pay attention to the letter and number designations that come after the main part of the name. Each of the letter designations indicates the type of product, and the numbers in the product labeling indicate its most important characteristics.

Drain TMW 32/11

This Wilo pump model is a vortex drainer made from various materials. The device is capable of pumping slightly polluted water (meaning those in which the diameter of the pollution particles does not exceed 1 cm).

Brief technical characteristics of the circulation pump Vilo Drain TMW 32/11:

- The maximum depth at which it can be used is 3 m.

- This device has overheat protection. In 60 minutes of operation it will be able to pump 15 cubic meters. meters of water.

- As the name implies, the head height of this device is 11 m, cross-section is 165 mm.

Its average cost is 10,500 rubles.