A heating system with natural circulation of coolant is a classic, which has several disadvantages. Firstly, the low speed of coolant movement, which reduces its temperature in the return circuit. Secondly, uneven distribution of hot water across the radiators. All this reduces the overall heating efficiency.

There is one solution to this problem - install a circulation pump. But which one? Almost all experts agree on one opinion: today you cannot find a better pump than the Grundfos UPS pump.

Grundfos circulation pump design

Circulation pump with a wet rotor for a home heating system

According to their design, Grundfos heating circulation pumps are divided into two types: with a “wet” and with a “dry” rotor. The first of the designs historically appeared earlier than the second version. Its basis is a body made of cast iron, steel, bronze or aluminum, inside of which a movable rotor is located in an aquatic environment. An impeller is installed on the shaft, causing the working fluid to move.

Pumps with a “dry” rotor began to be produced a little later; the engine and the liquid in them are separated from each other. Due to liquid lubrication, first class pumps are highly reliable. But at the same time, the efficiency of such devices is very small (does not exceed 50 percent).

Units with a “dry” rotor have a slightly higher efficiency indicator (it reaches 70%). These models are most often used for industrial purposes, where operating conditions require pumping large volumes of water. For domestic needs, circulation pumps operating on a “wet” circuit are usually used.

A little about the brand

If you translate the word Grundfos from Danish into Russian, it will sound like “Spring”. The concern was founded in 1945. Now the brand is represented in 45 countries, the company occupies a leading position as a manufacturer of pumps for heating, hot water supply and sewerage.

The main function of the manufactured equipment is the efficient delivery of water, both drinking and domestic, for various needs. The brand is constantly researching new materials and technologies, which allows it to produce innovative equipment that meets all modern quality standards. As a result, the user receives efficient, reliable, energy-saving devices.

Specifications

The main technical indicators that attention is paid to when choosing a suitable equipment model are:

- graph of the dependence of liquid pressure on the amount of liquid supplied to the system;

- power consumed by the unit’s engine from the network;

- coolant performance;

- permissible temperature of the pumped medium;

- dimensions and weight of the device.

Devices are selected by power depending on the volume of water pumped.

The first of the characteristics allows you to understand what volumes of water are pumped by the pump depending on the pressure developed in the system. The higher this indicator, the less water resource must be passed through the unit to obtain the required pressure. To correctly select a sample of equipment, the operating point must be located under the graph curve. When choosing this indicator, it is advisable to ensure a supply margin of at least 20%. Another parameter is directly related to it - pump performance.

The power taken from the network is determined by the amount of current in the load and the supply voltage (220 or 380 Volts). This parameter is taken into account when selecting current protection devices for power supply circuits and when calculating the cross-section of wires included in the power supply lines. The performance of pumping equipment depends on this value, increasing with its increase.

The dimensions of the purchased sample and its weight are also taken into account when choosing a suitable model. This also applies to the operating conditions of the pump – the minimum and maximum permissible temperature of the pumped medium. The reliability and durability of the purchased sample depends on the correct selection of this indicator.

Blitz tips

- If the sewage submersible pump suddenly begins to consume less current, and its supply has also decreased, then, most likely, the liquid suction area is clogged

When choosing a circuit breaker for the input of power supply lines, it is better to take one that has a Latin D in the marking. This designation shows that this circuit breaker is designed for high starting overloads. For pumps, for example, they can be 3-5 times greater than at steady state.

- When ordering equipment, you should pay attention to the length of the cable that comes with the kit. If possible, it is better to indicate exactly the value that you need. If the cable is short, it can be extended with another one with the same properties. Splicing is done using couplings, or, in extreme cases, PVC tape. It is necessary to carry out this work very carefully, since a short circuit may occur if the twisting is of poor quality.

- High power units - from 4 kW and above, must be switched on through soft starters or through frequency converters (FCs). This equipment prevents hydraulic shocks in the system and also protects the unit from wear. If, in addition to smooth starting, it is also necessary to control the engine frequency, then it is better to choose a frequency converter.

- During maintenance, it is necessary to tighten the screws on the pump power switches every month. Self-unscrewing of screws occurs due to vibration. When contacts rattle, heat is generated in the clamping area, which ultimately leads to burning of the cable ends and possible failure.

- You also need to monitor the flow and passage readings, as well as the current and voltage, every day. Based on these readings, it is sometimes possible to draw conclusions about the correct operation of the unit. For example, if a sewage submersible pump suddenly begins to consume less current, and its supply has also decreased, then, most likely, the liquid suction area is clogged. With a sharp increase in current consumption, we can conclude that the rotation of the impeller is jammed.

- If it is necessary to build wells or sewer pumping stations at a large distance from each other, a telemetry system must be created to control them. It collects data on the operation of these structures in real time and signals accidents.

Advantages and disadvantages

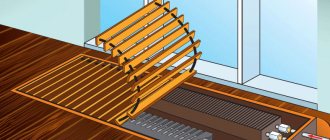

The pump in the floor heating circuit system operates silently - it can be located in the house next to the living rooms.

The advantages of pumps from the Danish manufacturer include:

- high work efficiency;

- reliability of all components and parts;

- low level of own noise;

- versatility of application.

Grundfos pumps are used as part of heating systems and are in demand for organizing hot water supply (DHW) circuits. In addition, they can be installed in “warm floor” systems or in climate control equipment.

The versatility of Grundfos units is also evident in the fact that after purchasing them, the user will be able to work with the following types of coolants:

- water heated to a certain temperature;

- antifreeze that does not contain solid components;

- coolant with the addition of ethylene glycol in a volume of no more than 40 percent.

The advantages of equipment of this class include the operation of the rotor in direct contact with the coolant; it is separated from the other components by a metal cup made of stainless steel. In addition, in these models the inlet and outlet pipes are located at the same level, which ensures quiet operation of the entire unit. The significant advantages of products from the Danish manufacturer include:

- optimal ratio of declared price and quality;

- high energy efficiency indicators;

- a large selection of models capable of satisfying the most demanding customer;

- long service life and developed technical support system.

Characteristic disadvantages of Grundfos pumps are the relatively high price per unit of goods (from 6,500 rubles) and the absence of a cable for connecting to the electrical network.

history of the company

The history of Grundfos dates back to 1945. Danish engineer Paul Du Jensen set up a small production facility called "Bjerringbro Pressestoberi og Maskinfabrik", which translated means: press casting and machining factory in Bjerringbro.

Initially, the engineer was engaged in the development and production of pumping equipment only. Quality and a non-standard approach to solving many problems related to the design and size of devices have made the company's products very popular. Production grew, there were more and more consumers.

Until 1967, the Dane renamed his company several times. And only this year the name Grundfos appeared, which still exists.

According to world statistics, pumps from this company account for 50% of global consumption. Why? Quality has already been mentioned. But there is another reason - the company has turned into an international concern. Factories, factories, and small assembly shops are scattered all over the world. Russia was no exception. A representative office was established in Moscow in 1992, which grew into a subsidiary with the opening of a plant near the city of Istra.

Features of choice

The size of the union nut depends on the diameter of the connected pipes.

When choosing the right sample of pumping equipment from Grundfos, much attention is paid to the diameter of the union nuts. It is selected depending on the size of the pipe prepared for installation in the heating system:

- if a polypropylene pipe with standard sizes of 20, 25 mm is used, nuts with a diameter of 25 mm are suitable for installation;

- when using pipes of larger diameter (or steel blanks from 25 mm and above), it makes sense to purchase equipment designed for the use of union nuts with an internal diameter of 32 mm.

If the listed requirements are met, no serious problems will arise when installing the equipment if you follow the instructions.

Pump energy efficiency

Well-known European manufacturers of pumping equipment have made great strides in optimizing energy consumption, introducing several wet rotor models to the market. This was achieved through the use of modern DC electric motors controlled by a controller. Such models belong to class “A” equipment, which is considered the most effective in terms of minimizing energy losses - their consumption does not exceed 0.09-1.3 kW).

Grundfos specialists have developed a whole series of energy-saving pumps under the names ALPHA2 and MAGNA3. The former are distinguished by simple functionality and are intended for use in heating and hot water systems of private houses. Models of the second type have the AUTOAdapt function, which allows you to automatically set the optimal power consumption mode. Their capabilities meet modern requirements for the efficiency and performance of equipment in this class. They are designed for use in heating systems of private homes and industrial enterprises.

Review of popular models

The devices produced by this company have gained popularity all over the world. They are used in heating systems of country houses, cottages and industrial premises. At the moment, Grundfos produces several lines of equipment with different parameters and features.

UPS 25–60 180

Grundfos UPS 25 60 180 is a circulation pump whose body can be made of two materials. The cast iron version is used for heating, and the stainless steel device is used for the hot water system. The design includes an induction motor, a 3-speed shifter and a sleeve that separates the rotor from the starter.

Mounted in both vertical and horizontal planes. Using this model, you can pump coolant of various temperatures: from +2 to +110 °C.

Advantages:

- Suitable for closed and open loop;

- made from high-quality materials that are resistant to wear and corrosion;

- economical - consumes 60 W;

- low noise - no more than 43 dB;

- compact - 18 × 13 × 13 cm;

- has a light weight - 2.6 kg;

- protected from overheating thanks to a “wet” rotor cooled by a coolant;

- easy to install and maintain;

- has a long service life - up to 10 years.

The performance parameter of this unit is 4.3 m3 per hour. The maximum pressure is 5.6 m. The device consumes 0.06 kW of electricity.

This range of pumps, like the UPS 25 80 180, is used in heating and air conditioning systems. Units with bronze and stainless steel bodies are also suitable for domestic hot water supply.

Circulation pumps Grundfos UPS 25 40 180 mm and 25 60 180 are sold at prices starting from 9020 rubles.

UPS 32–40 180

This equipment is suitable for heating and hot water systems. It should be noted that the design does not provide a prefilter, so the coolant must be of high quality: without foreign particles, not viscous and not aggressive.

The UPS 32-40 180 is a single-stage, three-speed model. The user can, if necessary, change the shaft rotation speed, thereby adjusting the performance of the device. For the pump to work properly, it needs to constantly pump liquid - it is the coolant that washes and lubricates its ceramic-graphite bearings.

The model is equipped with a wet rotor. Installation is very simple and does not require additional protective elements - the unit is resistant to current blocking. The almost silent operation of the pump will not distract the user from his work.

Key benefits:

- easy installation;

- easy adjustment of shaft rotation speed;

- built-in protective module;

- no maintenance required;

- The design includes a thermal relay;

- high quality and durable parts;

- efficiency.

This is a compact device that can operate for 10 years without causing problems during operation.

Specifications:

- throughput – 2.72 m3 per hour;

- power – 25 W;

- head – 3.9 m;

- dimensions – 12.6 × 14.1 × 18 cm;

- weight – 2.6 kg.

The circulation pump for heating Grundfos UPS 32–40 180 has a price of 7,200 rubles.

UPS 32–60 180

Thanks to its innovative design, the model is considered universal for all systems: heating, hot water supply, air conditioning. The equipment casing is made from various materials and is selected depending on the operating conditions. In addition, the device is suitable for working in conjunction with a “warm floor” system.

All structural parts are made of high-quality, corrosion-resistant materials. Even if the pump runs around the clock, it can last at least 10 years. Users note that the device is silent - this is an important advantage for domestic use.

Characteristics:

- power – 50 W;

- throughput – 3.35 m3 per hour;

- head – 5.75 m;

- maximum coolant temperature - up to +95 °C;

- weight – 2.6 kg;

- installation - vertical or horizontal.

UPS 32–60 180 has proven itself excellent for domestic purposes. Its power is sufficient for efficient operation of the heating circuit.

Advantages:

- easy connection to the network;

- Thanks to ceramic bearings, silent operation is ensured;

- long service life, for which high-quality design elements and materials are responsible

- there is a motor winding that protects it from current blocking;

- the ability to set the desired rotation speed;

- When starting, unnecessary air is removed from the pump.

You can buy this model at a price of 7,740 rubles.

UPS 40 120 F

This is a small-sized flanged model, characterized by quiet operation and economical energy consumption. The device's motor has a wet rotor and a protected stator. Instead of seals, 2 O-rings are used.

The pumped liquid serves as a lubricant for the bearings. To make the design more reliable, the manufacturer minimized the number of parts. UPS 40 120 F is suitable for heating and air conditioning.

Peculiarities:

- It’s easy to choose the right model based on various parameters;

- 3-speed electric motor;

- ceramic bearings (radial);

- the thrust bearing is made of carbon;

- cast iron body;

- built-in thermal relay on the stator.

Like other products, this line, despite its high power, operates almost silently.

Characteristics:

- power – 470 W;

- throughput – 19 m3 per hour;

- head – 12 m;

- coolant temperature - up to +120 °C;

- weight – 19.1 kg.

This model is suitable for connecting to the heating circuit of a large country house or cottage. Price - from 33,060 rubles.

UP 15–14 BUT

This compact unit circulates liquid for the hot water system. The UP 15 14 BUT pump has a built-in timer and thermostat. Using a timer, the user can program the operation of the device. The task of the thermostat is to automatically maintain the set temperature.

A distinctive design feature is a spherical electric motor, which does not use bearings.

Advantages:

- If service is required, the electric motor can be easily removed;

- Corrosion-resistant material is used to manufacture the impeller;

- body made of bronze;

- heat-insulating casing included.

The single-phase electric motor of this unit does not require additional protection; it is already provided by the manufacturer.

Characteristics:

- power - 25 W;

- maximum pressure - 10 bar;

- protection class - IP42;

- weight - 1 kg;

- head - 1.2 m;

- liquid temperature - up to +95 °C;

- throughput - 0.5 m3 per hour.

The cost of this model for domestic hot water starts at 7,080 rubles.

UPA 15–90 N

The scope of application of this unit is heating, heating, air conditioning and hot water supply. The design is such that the impeller of the device comes into contact with the coolant, allowing it to respond more quickly to changes in the system.

Peculiarities:

- 3 stages of speed adjustment;

- presence of built-in thermal protection;

- compact dimensions;

- resistance to corrosion.

The functional task of this model is to increase the pressure in the system. The device turns on and off automatically, you just need to open or close the tap. Thanks to its quiet operation, it can be installed even in an apartment.

Characteristics:

- power – 0.118 kW;

- head – 8 m;

- productivity – 1.8 m3 per hour;

- pressure – 6 bar;

- protection - IP 42.

Price UPA 15 90 N - from 7500 rubles.

ALPHA2 L 25–40 180

This is not only a convenient, but also a high-performance model on the market today. In addition to its compact size, the device is characterized by excellent performance. Thanks to its innovative design, the unit is suitable for heating and domestic hot water, as well as air conditioning and refrigeration.

Advantages:

- easy installation;

- consumes minimal electricity;

- high efficiency, which is achieved thanks to the frequency converter, the most compact stator and permanent magnets;

- the technical parameters of the device are automatically adapted to the features of the system;

- easy control - just one key;

- the presence of a display on the case, which is necessary to monitor the work.

Any user can install this pump, as it is equipped with a proprietary plug designed specifically for this line. Automation of equipment involves operation in “night mode”, which significantly saves energy consumption.

Characteristics:

- power - from 5 to 22 W;

- head – 4 m;

- productivity – 2.4 m3 per hour;

- pressure – 10 bar;

- weight – 2.3 kg;

- protection - IP42.

Price ALPHA2 L 24-40 180 - from 7600 rubles.

ALPHA3 25-40 130

This is an updated version of the previous model, which has become even more functional and technologically advanced. The pump supports two-way data transmission and 2 mobile applications. That is, through a smartphone, the user has the opportunity to set the operating parameters of the device, which greatly facilitates its use.

There are 3 control modes for different circuits: with radiators, “warm floors” and with a combined circuit. ALPHA3 automatically adapts to the heating circuit, optimizing energy consumption. Thanks to the mobile application, you can set the operating schedule of the device.

Advantages:

- simple remote control;

- night and summer operating modes for various systems;

- dry running protection;

- energy efficient and reliable permanent magnet electric motor;

- presence of built-in thermal protection;

- connection via a special plug;

- The equipment is equipped with threaded connections.

Thanks to innovative hydraulic balancing, this model allows you to save up to 20% of fuel, which significantly reduces operating costs.

Characteristics:

- power – 18 W;

- head – 4 m;

- productivity – 2.6 m3 per hour;

- pressure – 10 bar;

- weight – 2 kg.

The price starts from 19,580 rubles.

Magna

This range includes small, medium and large pumps for commercial installations. Each model is equipped with communications and variable speed motors.

Setting up the equipment is very simple - just connect it and leave the factory settings, additionally activating the AUTOADAPT mode. As a result, the pump itself will adjust its own settings taking into account the characteristics of the system. This will allow you to achieve an optimal level of comfort and minimal energy consumption.

Magna is flexible and reliable, has a long service life and requires no maintenance. Thanks to the built-in IR communication system, expansion modules can be connected to the device, thereby simplifying its operation.

Peculiarities:

- pressure and temperature regulation;

- various operating modes;

- the electric motor does not require external protection;

- complete with thermal insulation casing;

- efficiency;

- TFT display;

- convenient control panel;

- possibility of connecting several pumps.

At the moment, the Magna line includes several models with different characteristics. In one hour, the equipment is capable of supplying up to 70 m3 of water with a maximum pressure of up to 18 meters. The operating pressure indicator is no more than 16 bar.

Price Grundfos Magna3 25–40 - from 39,700 rubles.

Operating modes

A modern recirculation pump for heating is a multifunctional device. Various samples of this equipment are capable of operating in the modes indicated in the passport, including “fixed speed”. All of them are equipped with a synchronous motor, the operation of which is controlled by a built-in processor. During operation of the unit, the control unit records the following main parameters:

- current strength;

- rotor speed;

- temperature in the working area and others.

Its presence allows you to adapt to a specific heating network with optimal energy consumption.

Do-it-yourself pump disassembly

If repairs are necessary, the equipment must be taken to a service center if the device is under warranty.

Any user who has thoroughly studied the design can disassemble a purchased sample of pumping equipment if desired. The need for this often arises when it is necessary to repair or overhaul it with the replacement of worn parts. After complete disassembly, the main working components of the mechanism are inspected and then checked for wear.

The main attention is paid to examining the condition of the “wet” rotor. It should be removed and replaced with a new part in the presence of a repair specialist who can supervise this difficult operation.