ISOVOL insulation is one of the recent discoveries in the market for modern generation building materials. ISOVOL insulation, the technical characteristics of which indicate high thermal insulation performance, is intended for work on insulating walls, roofs, floors, various ceilings, etc.

This material is a good soundproofing barrier, which plays a special role in modern apartment buildings. It is an obstacle to the penetration of a variety of noises into the room. The material is also noted for its high fire resistance, which facilitates its use in cottage construction of wooden houses.

Based on this, we can say that ISOVOL insulation, reviews of which are also mostly positive from buyers, is a modern mineral wool insulating material that is widely used in building structures.

Types of thermal insulation material ISOVOL

ISOVOL products have the following classification:

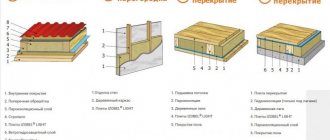

IZOVOL ST insulation is characterized by a material density of 50, 75 or 90 kg/cm3. It is used as a thermal insulator in ventilated facades with an air gap, as well as in various wall structures.

IZOVOL K insulation is characterized by a material density of 100 or 120 kg/cm3. It is used as a bottom layer in two-layer systems of thermal insulation materials (usually such insulation systems are used for roofing).

IZOVOL L insulation – characterized by a material density of 35 kg/cm3. This material is intended for lightly loaded structures that have a vertical or horizontal direction. It is also used for insulation of main types of structures, pitched roofs, partitions, frame walls, etc.

IZOVOL KV insulation is characterized by a material density of 150, 175 or 200 kg/cm3. This density is selected depending on the task facing the repairman. Such boards are used as the top layer in two-layer thermal insulation systems.

IZOVOL V insulation is characterized by a material density of 50, 75 or 90 kg/cm3. These boards are used in ventilated facade systems that have an air gap. ISOVOL insulation, the technical characteristics of which fit category B, has additional laminated slabs using fiberglass.

IZOVOL P insulation is characterized by a material density of 100 or 175 kg/cm3. This type of material is extremely rigid, so it is used for thermal insulation of floors that have an electric heating system built into them.

IZOVOL F100 and F150 insulation materials are characterized by a material density of 100 and 150 kg/cm3, respectively. Both types of heat insulators are intended for external walls (after insulating the wall, in the first case, plastering is done over a reinforcing metal mesh, and in the second case, over a fiberglass mesh).

An interesting fact is that a 100 mm thermal insulation layer of ISOVOL insulation (density 100 kg/cm3) can be compared in characteristics to:

- masonry made of ordinary bricks 160 cm thick;

- silicate brick masonry 20 cm thick;

- wood 22.5 cm thick.

The only drawback that was identified with ISOVOL insulation (reviews talked about this) is its high cost.

Nevertheless, buyers actively use ISOVOL products, since this disadvantage is very well compensated by the positive qualities of the product.

Group No. 1. General building thermal insulation

It includes many types of insulation; for the convenience of users, all technical characteristics are presented in table form.

| Name | Dimensions, LxWxT | Packaging volume, m3 | Vapor permeability, mg/M*h*Pa | Thermal conductivity, measured in W/(m*k) |

| Light | 100x60x4-25 centimeters | 0,24 | 0,3 | 0,035 |

| "Protection from noise" | 100x60x4-25 centimeters | 0,24 | 0,3 | 0,035 |

| Isobel | 100x60x5-10 centimeters | — | 0,3 | 0,036 |

| Isobel Light | 100x60x7.5-10 centimeters | 0,24-0,27 | 0,3 | 0,036 |

| L-35 | 100x60x4-25 centimeters | 0,24 | 0,3 | — |

| ST-50 | 100x60x4-25 centimeters | 0,24 | 0,3 | — |

| ST-60 | 100x60x4-25 centimeters | 0,24 | 0.3 | — |

| ST-75 | 100x60x4-25 centimeters | — | — | — |

| ST-90 | 100x60x4-25 centimeters | — | — | — |

| B-50 | 100x60x4-25 centimeters | — | 0,3 | 0,035 |

| B-75 | 100x60x4-25 centimeters | — | — | — |

| B-90 | 100x60x4-25 centimeters | — | — | — |

| F-100 | 100x60x4-25 centimeters | — | — | — |

| F-120 | 100x60x4-25 centimeters | — | — | — |

| F-150 | 100x60x3-10 centimeters | — | — | — |

| K-100 | 120x100x4-25 centimeters | — | 0,3 | — |

| K-120 | 120x100x4-20 centimeters | — | 0,3 | — |

| KV-150 | 120x100x3-18 centimeters | — | 0,3 | — |

| KV-175 | 120x100x3-12 centimeters | — | 0,3 | — |

| KV-200 | 120x100x3-10 centimeters | — | 0,3 | — |

| P-100 | 100x60x4-25 centimeters | — | 0,3 | — |

| P-175 | 100x60x3-12 centimeters | — | 0,3 | — |

Note! The above-mentioned “Noise Protection” is an insulation material that also has excellent noise insulation characteristics. Izovol insulation comes in other types, let’s get acquainted with them.

Main technical characteristics of ISOVOL products

Since ISOVOL insulation illustrates the technical characteristics on each package of the material, the buyer can independently, without the help of a consultant, select the most suitable type of heat insulator.

All ISOVOL materials are characterized by the following properties:

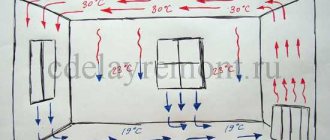

- stone wool (as IZOVOL products are sometimes called) absorbs noise and blocks the transmission of vertical sound waves;

- The environmental friendliness of the product allows it to be used in almost any work;

- ease of installation ensures a quick process of insulating residential buildings;

- a high level of fire resistance is very important when using materials in facilities with chemical compounds or explosive substances;

- the thermal technical efficiency of materials is formed due to low thermal conductivity (thermal resistance is achieved by creating a wall made of wood (0.25 m thick) or sand-lime brick (2 m thick));

- the service life of ISOVOL products reaches 50 years;

- resistance to acids, alkalis and solvents increases service life (this property also helps to avoid corrosion);

- The property of double action vapor permeability contributes to the rapid removal of all moisture from the room and evaporation from the surface of the material itself.

See more on this topic on our website:

- Insulation Rockwool technical characteristics Thermal insulation materials produced by Rockwool have long been noticed by professional construction companies. ROKVUL insulation has outstanding technical characteristics, which explains its widespread use: in civil,…

- Extruded polystyrene foam - reviews and technical characteristics of PENOPLEX Extruded polystyrene foam is a very popular product in the building materials market. The qualities and properties of this material are recognized as truly unique, as they make it possible to lighten the building structure...

- PAROC insulation - technical characteristics and reviews about insulation. Production facilities of the PAROC brand are available in Sweden, Finland, Lithuania and Poland. Official representative offices from which you can purchase PAROC insulation (technical characteristics and properties are…

- Isorok insulation - reviews and technical characteristics of insulation The ISOROK company produces a large list of thermal insulation materials intended for use in a wide variety of places in buildings and structures (in walls, ventilation shafts, various floors, roofing, pipelines...

- ISOBEL insulation technical characteristics and reviews from home owners ISOBEL insulation is a new productive material that is produced using innovative technologies using the latest foreign-made equipment. It is created on the basis of mountain basalt rocks. ISOBEL insulation,…

Technical thermal insulation

This group is not as numerous as the one described above - it includes only five different versions of mineral wool. Product parameters can be found in the table below. By the way, they are all produced in the form of cylinders.

| Name | Operating temperature, degrees | Thermal conductivity, measured in W/(m*k) | Acidity | Density, kilograms per cubic meter |

| 50 | -180 to +650 | 0,034-0,078 | 2,0 | 50 |

| 80 | -180 to +650 | 0,034-0,078 | 2,0 | 80 |

| 100 | -180 to +650 | 0,034-0,078 | 2,0 | 100 |

| 120 | -180 to +650 | 0,034-0,078 | 2,0 | 120 |

There is also technical insulation made in the form of mats. The dimensions of such mats (WxD) are 100x4-10 centimeters, density varies between 40 and 80 kilograms, thermal conductivity - from 0.034 to 0.093, operating temperature range - from -180 to +570 degrees.

Fire retardant materials

This group is even less numerous than the previous one. To be more precise, this includes only one type of insulated material being described - this is F-150.

Here are the main characteristics of the insulation:

- dimensions (LxWxT) – 100x60x3-18 centimeters;

- tensile strength – 20 kPa;

- compressive strength (if the material is deformed by ten percent) – 6 kPa;

- humidity – no more than 0.5 percent.

Well, it remains to deal with the last group.

Scope of application of ISOBEL insulation

Insulation materials produced by ISOBEL are divided into two main categories - soft and hard materials. The category of soft materials contains most of the existing varieties and in most cases belongs to economy class insulation.

Thermal insulating basalt slabs are intended for use in the construction of industrial and civil structures as fire-resistant non-load-bearing structures. They are generally invisible, since they are located under the facing materials, but it is very difficult to underestimate their role in creating a comfortable environment indoors.

In hot weather, materials keep the room cool, and in winter, on the contrary, they do not release heat.

Due to the fact that ISOBEL insulation, reviews of which are exclusively positive, is not able to absorb moisture, it is used:

- when insulating the attic (when insulating the inside of the heat-insulating material, it is necessary to lay a layer of vapor barrier; you also need to ensure that no cracks or gaps form between the slabs);

- when insulating the floor (thermal insulation material is usually laid between the joists, but when load-bearing wooden beams rest directly on the basement of the building, ISOBEL slabs can be laid directly on top of the boards);

- when insulating interior partitions (during the construction of special interior partitions, the insulation is placed inside a metal or wooden frame, after which the partition is sheathed on both sides with facing material - boards, siding, plasterboard, clapboard).

Production of izobel insulation

The basis for the production of fibers is basalt. Izobel insulation is produced in this way:

- The stone is crushed and melted at a temperature of 1200°C to form lava.

- Special machines blow threads out of it using directed air flows, which are collected into bundles.

- The fibers are impregnated with oil, which guarantees water resistance.

- Press to the desired thickness and cut.

- Quality checked and packaged.

The fibers have a diameter of 2 to 7 microns, they are intertwined and bonded with formaldehyde resins.

How to make Isobel insulation

In green packaging, the mineral wool density is 25 kg/m. cube

Isobel is a basalt fiber insulation material. To obtain such fiber, rock (frozen magma) mined from dormant volcanoes is delivered to a processing plant where it is crushed into small pieces. Then the resulting placer is melted at a temperature of over 1 thousand degrees, resulting in a liquid mass.

To obtain fibers from molten magma, a strong air flow is directed at it. The material seems to be sprayed, and when the fibers land in a special container, they no longer stick together. To make Isobel slabs, basalt fibers are treated with an adhesive composition and sent to a molding machine, where the material is given the required dimensions. Also, the molding machine compresses the mineral wool to a set level, in our case it is 25 or 35 kg/m. cube

The last stage is checking the insulation by a technical control body for compliance with the established characteristics and packaging the thermal insulation in polyethylene. Unlike glass wool, basalt fiber is packaged in its original form, that is, not compressed. Advantages of Isobel insulation:

- produced in the Russian Federation;

- is cheap;

- does not contain blast furnace slag and coke.

It should be noted that phenol-formaldehyde is added to the adhesive composition for basalt fiber.

In its pure form it is a toxic substance, but as part of insulation it does not pose any danger. In addition, phenol-formaldehyde is contained in all plastic products, cabinet furniture and other materials that surround us in everyday life. Claims that mineral wool is dangerous to health are too exaggerated. If you want absolutely ecological thermal insulation without any impurities, then use expanded clay to insulate the floor, walls and ceiling.

To reduce heat loss, thermal insulation of pipelines with mineral wool in rolls or cylinders is necessary.

Read about which mineral wool is best for the attic in this article.

Reviews about Isobel insulation

Isobel is an economical insulation material.

If the insulation is used for its intended purpose, then there are no complaints from users. So, Isobel is perfect for insulating horizontal floors. In this case, the density of the material is not of key importance, since the thermal insulation is not affected by high mechanical loads. The only thing that can be a problem is the accumulation of moisture in the thermal insulation, but this is not caused by the quality of the insulation, but by improper installation of the vapor barrier. The same problem is encountered when insulating a roof with mineral wool. If you position the vapor barrier and waterproofing incorrectly or forget to leave a ventilation gap, the insulation will be wet.

Negative reviews about Izobel thermal insulation can be found from those who have used the material to insulate walls. The complaints are caused by shrinkage, which is inevitable when soft fiber insulation is installed incorrectly. What to do to prevent Isobel from shrinking:

- install horizontal support bars every 2-3 meters;

- glue each slab to the wall;

- fasten the slabs with mushroom dowels.

And remember the requirements for insulation density for different types of work. For example, only material with a density of 55 kg/m is suitable for walls. cube or more. When using lighter materials, you need to resort to one of the above methods to prevent shrinkage during operation.

Insulation for sandwich panels

The group includes five types of materials, let’s get acquainted with them.

| Name | Dimensions, LxWxT | Thermal conductivity, measured in W/(m*k) | Vapor permeability |

| SS-105 | 120x60-62.7-100-101x10.2-12.2-15.1 centimeters | 0,037 | 0,3 |

| SS-110 | 120x60-62.7-100-101x10.2-12.2-15.1 centimeters | 0,037 | 0,3 |

| SK-120 | 120x60-62.7-100-101x10.2-12.2-15.1 centimeters | 0,036 | 0,3 |

| SK-130 | 120x60-62.7-100-101x10.2-12.2-15.1 centimeters | 0,036 | 0,3 |

| SK-140 | 120x60-62.7-100-101x10.2-12.2-15.1 centimeters | 0,037 | 0,3 |

So we looked at what Izovol insulation is. The range is simply huge, all products are of high quality and have excellent characteristics, and they are relatively inexpensive. In other words, an excellent combination of price + quality. That's all, good luck with your work and have a warm winter!

We also advise you to thoroughly familiarize yourself with the thematic video material below.

Video - How to insulate a balcony with Izovol thermal insulation

Insulation Tehnoruf

Previously, we talked about the main advantages of the Tekhnoruf material, its areas of application and prices, in addition to this article we advise you to read this information, see details here