Every spring, the garden plot becomes a source of large amounts of household waste. The container sites of gardening associations are overcrowded, and are often so far away that it is not possible to move the waste. Smokeless waste incinerators come to the rescue.

Construction of a furnace for smokeless waste incineration Source pvsservice.ru

Smokeless burning of garden waste

By burning garbage on a property, the owner runs the risk of facing dissatisfaction with neighbors due to smoke, unpleasant odors and the danger of open fire. The board of a gardening association may decide to ban the burning of waste on the surface of the earth. But even a special barrel will not save you from conflict with your neighbors.

Burning trash in a stove is not only safe, but also completely legal. The special design allows you to burn any waste efficiently and, most importantly, without smoke. Industrial samples of smokeless stoves are surprising in their price - even economy-segment stoves cost no less than 200 thousand rubles.

External view of a homemade stove for smokeless waste incineration Source Cleanbin.ru

Alternative disposal options

Garbage removal by special services is the most reasonable method.

Other disposal methods can also be used.

- The most reasonable method is waste removal by special services, but this is only available in populated areas with developed infrastructure.

- Compost is made from some of the waste, such as dry leaves, branches, and food waste. To do this, dig a hole and put garbage in it for the winter. By spring, the summer resident receives excellent fertilizer.

Construction waste can be reused to build fences, vegetable beds, gazebos in the garden, carousels for children, benches in the recreation area.

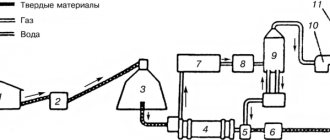

Industrial technology

Commercial versions of residential furnaces are called waste boilers. In accordance with current legislation, the amount of harmful substances emitted when burning waste in such a furnace should not exceed the standards established for full-fledged waste processing plants. This imposes some restrictions on manufacturers, so these furnaces operate on a rather complex principle, far from burning waste in an ordinary barrel.

Industrial enterprises use large waste incinerators Source 1-teplodom.ru

In its original form, garbage should never be completely burned, as this leads to the release of harmful substances, including carcinogenic ones. Therefore, from the receiving hopper the garbage enters the pyrolysis chamber, where there is no open source of fire. The temperature in the chamber does not exceed 300 degrees. At this stage, light volatile gases that are involved in the afterburning process are removed from the garbage. Due to the fact that the process of their formation is extremely unstable, natural gas is supplied to the afterburning chamber (from a stationary system or cylinder). The temperature in the afterburning chamber reaches 1000 degrees or more. At this temperature, all flue gases burn, so only a mixture of carbon dioxide and water vapor remains at the outlet of the furnace. At the end of the combustion process, dry ash remains in the furnace, suitable for further industrial processing in order to extract rare earth metals and even gold.

Ease of transportation and ease of installation

Penoplex or extruded polystyrene foam

Lightweight polystyrene foam sheets can be transported by car. They will not damage or stain the upholstery. Loading and unloading work can be done with your own hands without the help of assistants.

Construction work using polystyrene foam can be carried out alone. Easy to cut and attach - adhesives, dowel fastening (fungi).

Attention! Do not use hot mastics (bitumen) or adhesives containing organic solvents!

Manufacturers offer EPS with geotextile fabric and milled grooves. In this case, the insulation system performs several functions:

- insulation;

- protection of the waterproofing layer from mechanical damage;

- drainage of water into the drainage system.

Garden technology

Unfortunately, none of the household garden “trash stoves” on the market today meets the requirements for smokeless combustion. Moreover, most of them smoke even more than the simplest “leaky barrel”, insofar as the access of air to the combustion chambers of such furnaces is strictly limited by their design. The most popular models are:

- “Dacha according to the mind”;

- "Barrel";

- "MD-25";

- "MSW"

- "Terminator";

- "Incinerator";

- "Recycler";

- "Darkie";

- "Nada."

Each of them is functionally no different from a regular barrel, with the exception of the presence of a chimney and door, as well as a presentable appearance.

External view of the industrially manufactured Nada oven Source Sdelai-lestnicu.ru

What waste can be processed using pyrolysis

Note! MSW - municipal solid waste - different substances that cannot be reused in human household activities without treatment.

Solid waste is a mixture of substances of organic and inorganic origin that have different properties. In Russia, waste is not sorted. However, abroad, and in our country too, there is a tendency to reduce the share of food waste in garbage and increase the share of packaging materials: plastic, cardboard, paper. Studies have shown that approximately 30 percent by weight and 50 percent by volume of solid waste comes from packaging material. And 13 percent by weight and 30 percent by volume of packaging material falls on the share of plastic products, the vast majority of which are plastic tableware. The organic component of garbage is divided into:

- compostable (kitchen waste, sawdust, tree bark and branches, wood chips, old newspapers, cardboard);

- non-compostable (plastics, rubber, leather, discarded old tires, cables, viscous pasty waste such as motor oil, oil sludge, soil contaminated with fuels and lubricants).

Compostable and non-compostable components of waste are subjected to pyrolysis.

Smart home technology

The simplest option for smokeless waste disposal is burning it at temperatures close to 1000 degrees Celsius. At these temperatures, the most hazardous wastes burn without residue:

- plastic;

- poisons;

- household chemicals;

- medicines;

- pesticides, fertilizers.

The easiest way to make such a stove is from a “potbelly stove”.

Drawing of a universal furnace for incinerating waste based on a stove of the “potbelly stove” type Source Homecoll.ru

The main technical solutions are:

- Sprinkling the stove jacket with heat-intensive material - sand. During the combustion process, it will work as a heat accumulator, helping to instantly heat the supply air, bringing the temperature in the firebox to the highest values.

- The absence of a blower also helps maintain the temperature in the firebox, reducing heat losses.

- Wide window for air intake located under the grate. This creates rapid draft, supplying a large amount of air into the firebox. Firewood in such a stove will burn very quickly, but this will allow you to achieve a temperature of 1000 or more degrees Celsius under the roof of the stove.

- The screen inside the firebox heats up to critical temperatures, and also lengthens the path of flue gases, due to which they are burned in the firebox with high efficiency. Instead of the standard one, a hole with a diameter of 8-10 mm is made in the burner, through which additional air penetrates above the screen, thanks to powerful draft. An additional portion of air guarantees effective afterburning of the remaining gases.

Method one. Upgraded barrel

Agree, the options described above using a metal barrel are hardly able to decorate your site. Therefore, you can do it differently.

First, you will need a diagram of the future structure, so we’ll draw it up. It will look something like this.

Preparatory activities

As for the materials, more of them will be required than in any of the methods already known to us. So, in addition to the barrel, you need to prepare:

- 5-meter metal profile (we will cut it into five equal sections);

- 5-meter steel rod;

- a pair of loops;

- 1 m2 of welded mesh;

- spark arrester (the diameter of its fasteners should be 11.5 centimeters);

- 200 grams of wire;

- 1.5-meter tin pipe with a diameter of 11.5 centimeters;

- degreaser;

- a handle with a wooden attachment attached to it;

- bolts - 6 pieces, the same number of nuts;

- electric jigsaw, metal files for it;

- 20 self-tapping screws with wide caps;

- metal drill with a diameter of 1.2 centimeters;

- grinder, circles for it - emery and for metal;

- Bulgarian herself;

- fireproof paint;

- brushes (as an option, we can use a sprayer);

- electric drill;

- jigsaw

Having prepared everything you need, we begin to build a garbage stove for our dacha with our own hands.

The working process

- Cut out the door. To do this, draw a straight line on the bottom to which this door will be attached. We cut along the line with a grinder, while making every effort not to touch the side walls.

- We make a hole in one of the corners of the formed cut. It is important that it is close to the side wall of the structure and directly on the cut line. From this point we will move forward with a jigsaw.

- We insert the jigsaw into the hole and carefully cut out the bottom of the barrel. We do not touch its upper part. We move extremely close to the edges of the barrel. A grinder, of course, is not suitable for this - only a jigsaw.

- We make several holes in the door through which air will flow. We do them at the bottom, you can do them in any order.

- If necessary, clean the barrel from paint or rust using a grinder with an emery disc.

- We build trestles. For this we use five pieces of metal profile. The goats will consist of a pair of crosses connected by a rod. We connect the profile strictly at an angle of 90 degrees, for which we make a pair of holes in each of them and tighten them with bolts.

- We degrease and paint the barrel, and do not forget about the elements of the goats. It is advisable to carry out these procedures in a disassembled state. We paint all the elements in several layers, after each layer we wait for the paint to dry completely.

- We collect goats. We start this a day after painting. Be sure to place washers under the nuts and securely tighten all structural elements. The resulting strength is quite enough for the barrel and the additional weight of the garbage.

- We install hinges and handles. To do this, we use a screwdriver and screws with wide caps.

- We form a hole for the chimney. At the top of the barrel we draw a circle with a diameter of 11.5 centimeters.

- We equip our dacha garbage stove with a chimney with our own hands. We install it on the “petals” so that they are inside. After this, we screw the pipe to the “petals” in several places with self-tapping screws so that it does not come off.

- We install the grate. We do everything as shown in the image below.

- Install the cover. We secure it with clamps, although we can resort to a homemade design made from bolts.

Note! It is advisable to install the hinges with an assistant, as the door will constantly fall through.

Next, we cut this circle into a kind of “petals” with a grinder. We should have about ten segments. We bend the “petals” up so that they are positioned vertically.

As a result, we got this design. That's it, the garbage stove is ready, you can start using it!

How to make a Russian stove with your own hands

Previously, we talked about how to make a real Russian stove yourself, in addition to this article, we advise you to read this information, see all the details here

Primitive home technology

As you know, laziness is the engine of progress. Gardener-inventors have long found a way to effectively burn waste in ordinary barrels.

Floating barrel

The simplest option. A large number of holes are made in the bottom of the barrel. The barrel is raised above the ground to a height of at least 30 cm. Dry firewood is placed at the bottom of the barrel, followed by a layer of burnt garbage, which is covered with branches or leaves on top. A fire is built under the barrel. At first the barrel will smoke a little, but after a few minutes it will dissipate. If you try to load more garbage, the barrel will begin to smoke heavily. You should wait until it burns completely and repeat the procedure.

Schematic drawing of a floating barrel for burning waste Source Stroi-mario.ru

Some gardeners raise the barrel to the height of 1 brick, light a fire at the bottom and, after waiting for coals, fill the barrel with garbage. In this case, the barrel will smoke heavily, spreading a pungent odor and a cloud of harmful substances throughout the area. Visually it will seem that there is less smoke, but this is just a misconception.

Fuel

A pyrolysis furnace can use two types of solid fuel: wood or pellets. Its humidity can reach 50%. The fuel must be wet and dry - it must be dried in the open air, under a canopy. It must be taken into account that pellets in original packaging can increase their humidity by up to 30% if stored in an unheated room.

Fuel for pyrolysis furnaces

Note: For use in pyrolysis furnaces, it is recommended to increase the fuel moisture level to 12%. To achieve this figure, you can use a homemade dryer.

It is impossible not to mention pyrolysis oil. It is a product of a heating process of up to 800 degrees for a short period - up to 30 s. Essentially, pyrolysis oil is liquefied wood tar. It is characterized by a high calorific value, but contains a lot of sulfur, like household fuel, and corrodes metals. It is used on an industrial scale.

Disadvantages of Smokeless Stoves

All the advantages of smokeless stoves were described above, but industrial installations also have a number of disadvantages:

- The price of the simplest models starts from 200 thousand rubles. The main reason is a complex heat-resistant electromechanical system that moves garbage from one chamber to another, and ash to the ash pan. In addition, the unit requires installation on a foundation, as well as commissioning. For each procedure, the manufacturer will charge the new stove owner a certain amount.

- The service life of the installation rarely exceeds 3-5 years. After this, the installation requires major repairs, the cost of which can be up to 50% of the price of a new furnace.

- The furnace requires a source of natural gas to operate. One standard gas cylinder can be enough for 2-3 furnace operating cycles. Some installation models require connection to a stationary gas distribution network at home.

View inside a horizontal waste incinerator Source Otzyvprofi.ru

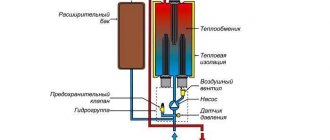

Stove modernization

A blower fan will ensure temperature stability in all heated rooms.

Almost any pyrolysis furnace can be converted into a boiler for water heating. To do this, ready-made or homemade (from metal pipes) heat exchangers are built inside. Radiators are installed in the rooms, water is poured into the system - full heating is ready.

For these purposes, it is best to adapt a pyrolysis furnace with a blower fan - equip it with an external control unit that monitors the temperature and controls the operation of the fan.

Hobs and built-in ovens are what else you can equip any oven with. The energy of pyrolysis combustion is enough not only for heating, but also for cooking. Cooking surfaces and oven boxes are purchased in specialized stores. You can make your own oven from sheet iron. As for the hobs, they are made of cast iron - you can’t do this yourself.

Pyrolysis of solid waste should help earthlings cleanse the environment of debris and reduce the burden on the oil refining industry. This is a production that can provide significant income to the businessman who has established it, since the raw material is cheap garbage, of which 3.5 billion tons are generated in Russia alone per year.

Video description

A very efficient waste incinerator.

Household smokeless incinerators are also not without their disadvantages:

- Low efficiency. Any furnace design implies a one-time addition of garbage for each cycle of its operation. When you try to reload the stove, it will turn into an ordinary smoking barrel, and the garbage may simply not burn out, clogging the holes at the bottom of the barrel.

- Low environmental friendliness. The combustion temperature of garbage in homemade stoves is unstable. And the absence of an additional heat source in the form of natural gas leads to the fact that such stoves smoke a little. At the same time, the remaining smoke is the most toxic, therefore, for your own safety, such a stove should be operated no closer than 15 meters from residential buildings.

- Ash from smokeless stoves is unsuitable for fertilizer, as it contains a huge amount of harmful compounds.

External view of a furnace suitable for modification for smokeless waste incineration Source Ekdel.ru

Pyrolysis boiler - manufacturing scheme, main stages

To assemble a gas generator heating unit yourself, you must adhere to the following requirements:

The necessary elements should be cut using a grinder. The fuel loading hole is located slightly higher than that of solid fuel devices. To control the amount of air entering the combustion chamber, it is necessary to install a limiter. It can be made using a pipe with a diameter of 70 mm, and the length should be slightly longer than the boiler body. Using a welding machine, a steel disk is welded, which, together with the walls of the pipe, should form a gap of approximately 40 mm. To install a limiter in the boiler lid, you need to make a corresponding hole. It should have a rectangular shape. The hole is closed by a door equipped with a steel plate. This will ensure a secure fit. Below is a hole designed to remove water. Using a pipe bender, it is necessary to bend the pipe intended to move the coolant inside the boiler. This ensures maximum heat transfer. The amount of coolant sent to the device can be regulated by means of a valve mounted externally. As soon as the equipment is started for the first time, there should be no carbon monoxide in the combustion products. If this condition is met, the piping of the pyrolysis boiler (the diagram is indicated) is done correctly

It is important to regularly monitor the condition of the device’s welds and promptly remove any soot and ash that has formed from it.

An excellent option would be to combine a pyrolysis boiler not with classic water heating, but with air heating systems. As a result, air will be transferred through pipelines, and its return to the system will be through the floor. Such a system has numerous advantages: it does not freeze in severe frosts, and there is no need to drain the coolant when the owner leaves.