The characteristics of aluminum batteries can be quantitative and qualitative. The first involves comparing heating elements in terms of weight and size and the power of the emitted heat flow. The latter provide for the specific design and technological features of production.

Household aluminum heating radiator Source mtdata.ru

Advantages and disadvantages

Aluminum heating radiators are one of the most popular options for most heating systems in country houses and apartments. Along with a wide list of product advantages, they are characterized by a voluminous list of disadvantages. Some of them, when analyzed in detail, can play a key role in choosing the appropriate option for a given situation.

Positive factors

One of the fundamental factors is low cost and good heat transfer performance. However, the advantage lies not only in this, but also in a number of other reasons:

- Light weight. The weight of one section is no more than 1.5 kg. Thus, even a long ten-section battery will weigh only 15 kg. This criterion greatly simplifies the task of transportation and installation.

- Maximum coolant temperature. The maximum heating value of the working fluid can reach 130°C, which is significantly higher than the boiling point of water, which is mainly used in domestic heating systems.

- Price. The above-mentioned point, which makes aluminum radiators more acceptable in comparison with their closest competitor - bimetal. The latter is not as malleable in processing as pure metal, which affects the final cost of the product.

- High efficiency. Aluminum has excellent thermal conductivity. One section is capable of converting about 150-200 W of thermal energy. By comparing such a radiator with a bimetallic one, an aluminum one (with the same dimensions) will heat better. It follows from this that to obtain the same efficiency of bimetal sections, more will be required. This results in a corresponding increase in price.

- Selection of standard sizes. If necessary, it is easy to select a radiator of appropriate depth, width, and with different center distances.

- Aesthetic appearance and high-quality powder coating. The neutral appearance of aluminum radiators makes them “not noticeable” on the walls of the room. It should be emphasized that this factor applies to most modern heating convectors. The only exception may be bulky cast iron accordion batteries.

They look good even without decorative screens Source at-54.ru

Flaws

Despite the impressive number of advantages, aluminum radiators also have several disadvantages. Some of them, for one reason or another, may turn out to be key and become the reason for purchasing products from other materials. The most significant disadvantages are:

- Susceptibility to corrosion. The likelihood of affected areas most often occurs at the junction of the radiator with the heating system pipeline. You can avoid the onset of destructive processes by installing more expensive batteries, the inside of which is coated with a special anti-corrosion layer.

- Low connection life. This criterion applies only to prefabricated sectional radiators (those assembled from separate sections). The number of joints has a direct impact on the duration of their operation (the more joints, the higher the likelihood of leakage).

- Sensitivity to alkali. If the acidity level of the coolant for some reason exceeds 7 units, a chemical reaction begins resulting in the release of hydrogen. An increase in internal pressure will cause the metal to burst. Therefore, if you are planning to purchase a radiator for a central heating system in an apartment building (or another in which it is not possible to control the chemical composition of the working fluid), give preference to a convector made of a different metal.

Healthy! An exception may be aluminum radiators with a blower.

- Possibility of damage due to water hammer. This disadvantage is also associated with the use of batteries in central heating systems. The possibility of metal rupture occurs when the system is filled in the fall or when it is purged in order to eliminate air pockets.

Healthy! The problem can be solved by installing a hydraulic compensator.

The disadvantage of aluminum radiators is their fragility Source rssrv.ru

Confirmation of quantitative characteristics is carried out through laboratory studies at the stage of their manufacture. The obtained result is a fundamental factor in certifying the product in accordance with established international standards.

The list of analyzed characteristics, methods and criteria of the tests carried out are given in the regulatory documentation of the following nature:

- GOST or GOST R - for Russia.

- EN 442-2, valid in the European Union countries.

Also, detailed conditions can be published in the direct technical conditions (TS) for the use of the product.

Number of sections

Modern aluminum radiators are assembled from several sections that can be disconnected as needed. Thanks to this, it is possible to select the optimal power required to heat a room of a given area.

Therefore, you can purchase a ready-made (assembled) radiator with the required characteristics or assemble it from several sections purchased separately. The individual components are connected via a nipple connection.

The number of sections is calculated taking into account the thermal power of each element. This is done according to the formula, N = 100 x (S / P), where the decoding of the abbreviation looks like this:

- N is the number of aluminum radiator sections required to heat one room.

- S is the area of a specific room (written in square meters).

- P – heat transfer power of one section (indicated in Watts).

How to calculate the number of sections for a specific room Source kotelstroi.com

Healthy! The average heat flux value for one aluminum section is 150-200 W.

An example of independent calculation by area

An example of calculating the number of radiator sections for a studio with an area of 25 m2 (taking into account the climatic features of Moscow and the Moscow region):

- According to the previously presented formula, to determine it is necessary to divide the area of the room by the power of one section. We get 25 / 200 = 0.125.

- Then the resulting value should be multiplied by 100. 0.125 * 100 = 12.5.

- The result is that to heat a room with an area of 25 m2, you will need 12.5 sections with a standard heat flow power (200 W).

Thus, rounding the result obtained, you will need to purchase 13 sections.

Important! This example of independent calculation is averaged, since it does not take into account the thermal insulation properties of the walls of the room.

The second method of calculating the number of sections of an aluminum radiator involves carrying out a calculation based on the spatial volume of the room. As an example, we took a room measuring 4.5 x 3.5 m, with a ceiling height of 2.7 m.

- The volume is determined by multiplying the length, width and height. The result is 42.5 m3.

- For Moscow and the Moscow region, high-quality heating of one cubic meter of living space requires 45-50 W of thermal energy. This value applies to brick buildings; when designing a modern cottage built from a material with good thermal insulation characteristics, the figure can drop to 30 W.

- The required amount of thermal energy is calculated by multiplying the above ratio by the volume: Taking the minimum 30 W and multiplying by the volume of 42.5 m3, the result is 1,275 W.

- Subsequent steps are performed similarly to the method described above. Dividing the total heat volume by the thermal power of the radiator (1,275 / 200), the result is 6.375. Rounding up we get 7 sections.

- Thus, for high-quality heating of a room with the specified characteristics, you will need 7 sections of an aluminum radiator.

Important! These values may be different depending on changes in one or more criteria: room volume, thermal power of the convector, thermal insulation properties of the load-bearing walls of the room and other factors.

Heat dissipation

The heat transfer coefficient is measured in watts (W) and serves for the above-mentioned method to calculate the number of sections required for high-quality heating of a particular room. According to the content of GOST 31311-2005, the value of the nominal heat flow under normal operating conditions is equal to the following values:

- The difference between the room temperature and heating of the coolant is 70°C.

- Atmospheric pressure – 760 mm Hg. Art.

- The amount of coolant flowing through the radiator per second is 0.1 kg.

- The direction of movement of the coolant is according to the “top-down” pattern.

Formula for independent calculation of heat transfer from an aluminum radiator Source 1-teplodom.ru

Healthy! On some models there is a designation of the corresponding thermal power at different coolant temperatures.

External heating surface area

This value determines the summed surface area of the radiator sections in contact with ambient air. Moreover, not only wide edges are included here, but also side, narrow edges.

Regarding the area of the external surfaces, in most cases it is equal to one of the following values:

- For radiators where the center distance is 350 mm - from 0.3 to 0.4 m2.

- For radiators where the center distance is 500 mm - from 0.4 to 0.5 m2.

Battery selection criteria

It is not difficult to purchase high-quality aluminum radiators; you just need to know certain features.

Experts recommend adhering to the following tips:

- You need to choose a proven, well-known brand. This serves as a kind of guarantee that the radiators will last a long time and without problems.

- Cost also plays a role. As a rule, if the equipment is really high-quality, then it definitely won’t be cheap.

- Aluminum batteries are not made in Germany, no matter what the seller claims. The fact is that panel steel appliances are installed in this country.

- When purchasing, you should study the product data sheet. It must necessarily indicate power characteristics taking into account the specific temperature of the coolant.

As you can see, there are not many criteria for a competent choice. In any case, you need to be careful with the characteristics so as not to make mistakes.

Is it worth buying Chinese-made products?

When choosing heating devices, you need to be attentive to their cost and quality. At the moment, there are many manufacturers of radiators, but most often their products are made in China. Of course, these products have an attractive price, but the quality may be inferior to European devices.

When purchasing devices from China, you need to pay attention to the following nuances:

- Battery weight. Often, in order to reduce the cost of products, manufacturers use less metal than necessary. This significantly reduces the cost of the product, but at the same time its quality decreases. When purchasing, make sure that the back wall of the batteries and the side ribs are thick enough. If the thickness is small, then the radiator will have a lower power rating, and pressure surges can completely rupture such a device.

- To reduce cost, the diameter of the vertical collector is reduced. Because of this, more plaque will begin to be deposited on the internal surfaces of the batteries, which will interfere with the free passage of the coolant. After 5 years of operation, the hole may become completely overgrown, that is, such batteries will no longer perform their task. Therefore, the diameter of the collector, which is indicated in the passport of a specific model, is so important.

Of course, you can use Chinese radiators, but not for as long as you would like.

Qualitative characteristics

No less important are the values of the quality characteristics of aluminum heating radiators. It also needs to be taken into account at the time of drawing up the project and purchasing the main components.

Properties of coolants

Aluminum radiators can be used with two types of coolants: water or special antifreeze. The choice of the latter is determined depending on their characteristics and chemical composition:

- Salt - mainly used in heating systems with a secondary circuit. Able to withstand temperatures of -20°C and below. It differs from other antifreezes in its low viscosity level. The main disadvantage of the salt composition is its high anti-corrosion activity, which decreases depending on the temperature.

- Ethylene glycol and propylene glycol - capable of functioning in temperature ranges from -20 to +130°C. Regardless of the degree of heating or cooling, they remain in the same viscosity state. Ethylene glycol antifreeze is considered more popular. The popularity is explained by the lower cost and level of toxicity inherent in this composition.

Antifreeze for filling into heating radiators Source koffkindom.ru

Features of anodized batteries

Anodized systems are also included in the group of aluminum batteries. Their production uses aluminum that has undergone a high level of purification. Therefore, the metal has high technical indicators. Also, anodized radiators are treated with oxidation using an anode. Processing changes the structure of the material and increases its strength and resistance to corrosion. The internal surfaces of anodized systems are smooth because their parts are connected by external couplings. Such radiators have high heat transfer and operating pressure (50-70 atmospheres).

Manufacturing methods

The manufacturing process uses pure aluminum with the addition of silicon. The amount of the latter is determined depending on the type of radiator and the method of its manufacture.

Extrusion

Such radiators are a single structure, and the rigidity of the mounting connection is achieved by welding. The production of sections is carried out by the extrusion method - pushing (pressing) the molten composition through special molds.

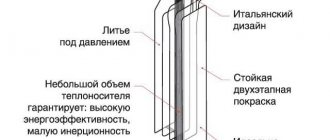

Difference between different production methods Source mynovostroika.ru

The advantages of aluminum radiators made by extrusion include:

- Lower cost.

- Relatively high heat transfer coefficient (in relation to cast analogues).

- Light weight for easy wall mounting.

- Smaller capacity of individual radiators. This property ensures the efficiency of the convector when used in conjunction with low-power boilers. In this case, there is a reduction in fuel consumption and optimization of the operation of the entire heating system.

Damage to one section and replacement of the entire radiator Source ytimg.com

The main disadvantage of pressed radiators is the aforementioned “solidity”. It is not possible to extend or detach one of the sections in them. For example, if a section is accidentally damaged, the entire radiator has to be replaced.

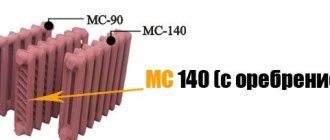

Cast

They are manufactured according to the principle of prefabricated structures. Production is carried out using high pressure and special molds. The connection of individual sections is carried out by nipples (threaded elements), which allows you to assemble the required number of sections into a single structure.

The tightness of the connections is ensured by high-temperature gaskets, the material of which is determined by the type of coolant. The most popular sealing elements are poranite, graphite, and high-temperature silicone.

Aluminum cast heating radiator Source kamburg.ru

Interesting! Cast split radiators can be provided as a single section or as boron structures consisting of 2-3 elements cast as one unit.

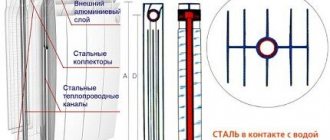

Combined

A kind of symbiosis in which the 2 above-mentioned manufacturing methods are used. Sections are manufactured using pressed profiles (obtained using the extrusion method), and the horizontal manifold is manufactured using the casting method. They are sold in different variations, in one section or as blocks.

Combined type radiator Source oboiman.ru

Anodized

Radiators made of anodized aluminum are a separate type of product. An alloy that is not at the molecular level is bombarded by anodes and receives different chemical and physical properties. In particular, a special protective layer is concentrated on its surface, reducing the hydraulic resistance of the metal.

Metal with protective anodizing Source img.alicdn.com

The advantages of radiators made of anodized aluminum include:

- Relatively high resistance to corrosion.

- Improved efficiency indicators (better transfer of heat to the room).

The disadvantage of such equipment is the price, which is significantly higher than the cost of radiators made from conventional aluminum.

Installation recommendations

In order for the installed radiator to effectively perform its function, you must adhere to certain installation rules.

The way the batteries are located is also important:

- distance from the device to the wall - from 2 to 5 cm;

- distance from the floor to the device - from 10 to 12 cm;

- the distance from the top to the window sill is about 10 cm.

When installing equipment, shut-off and control equipment must be provided at the inlet and outlet. This will allow you to manually or automatically (if there are thermostatic valves) regulate the heating temperature. This is also done so that the batteries can be disconnected later, for example, if they need to be disassembled, washed or replaced with new ones. If necessary, if a leak appears, so as not to completely replace the equipment, it can be soldered.

In multi-storey buildings, heating devices are most often installed using a single-pipe system. But such a system does not provide temperature control devices.

When installing batteries, under no circumstances should they be hung on pipes. The device is mounted to the wall in such a way that the hooks of the brackets are located between the sections, and its lower part rests on the fasteners. To prevent future leaks, the connecting surfaces do not need to be cleaned.

While the device is being filled with coolant, the shut-off and control equipment must open smoothly, otherwise a water hammer may occur. Before installing radiators, each element of the system must be thoroughly washed. Do not use products that contain alkali.

For each aluminum radiator, an automatic device or manual valve should be provided to bleed air. During the work, you must adhere to the instructions that come with the device.

Comparison with radiators made of other metals

Let's consider the main characteristics of aluminum radiators against the background of other, no less popular in Russia, convectors made of other metals. For ease of perception of information, all information is presented as a comparative table.

The presented table makes it clear that in many performance indicators, aluminum radiators differ significantly from analogues made from other materials:

- The spread in temperature of the working fluid is approximately the same, but this condition will be interesting only if antifreeze is used as a coolant. In most residential buildings and apartments, the temperature of the water circulating in the system does not exceed 80-90°C.

- The magnitude of the operating pressures introduces a kind of scatter. Cast iron does not tolerate stretching well, so it has a low index. Steel is slightly higher, bimetal has the highest value.

- In terms of efficiency, aluminum radiators can be called optimal in terms of price-result ratio. They emit much less heat than copper ones, but they are also much cheaper.

- An equally important factor is the weight of the radiator. This issue is most relevant when designing a heating system for a building built from porous aerated concrete. Lightweight bimetal and aluminum will not put excessive stress on the bracket like their steel or cast iron counterparts. Also, as already mentioned, lower weight facilitates the process of transporting and installing equipment.

Choosing a suitable radiator Source oboiman.ru

How to choose an aluminum radiator

This question worries many buyers, because it is quite difficult for an inexperienced person to make the right choice. In order to simplify things, Komsomolskaya Pravda has prepared some tips.

Design

As we previously wrote, aluminum radiators are divided into three types: extruded, cast and anodized. The most preferable option would be a cast device. It is able to withstand any pressure drops in the system. It can also work in absolutely any conditions, including high temperature differences.

Assembly

Note that it is best to purchase the radiator assembled and with the required number of sections. Factory assembly will be more reliable. It is best to purchase the device in a specialized store.

Review of manufacturers

This review of leading manufacturers of aluminum heating radiators is presented for informational purposes. It should not be regarded as a kind of rating.

Lammin is a Russian company, one of the leading domestic manufacturers of plumbing equipment for heating and water supply. Specializes in the manufacture of radiators from high-quality aluminum alloys. The internal volume of each section is covered with zirconium, which provides additional protection against rust and sedimentation of small dispersive particles contained in water.

Aluminum radiator Lammin Source www.termokit.ru

Oasis is a holding company whose full name is Oasis Investment Company. It is owned by one of the largest conglomerates in the UAE. Specializes in the production of household heating equipment with sales on the market of Russia and some countries of the Eurasian Economic Union. Production is established in China and the Russian Federation. Known for inexpensive and relatively good quality products.

Aluminum radiator from Oasis Source sima-land.com

Tropic is another Russian manufacturer of household heating equipment. The products sold under this brand are highly efficient, reliable and fully adapted to operating conditions in Russia.

Aluminum radiator Tropic Source pstm42.ru

Halsen is a Russian manufacturer of aluminum batteries based in Volgograd. The company specializes in the production of household heating equipment that meets all the requirements of domestic and international standards.

Aluminum cast radiator Halsen Source st26.stpulscen.ru

Royal Thermo is an industrial company that produces radiators, boiler equipment, smoke removal systems and a wide range of other equipment for domestic and industrial use. It is the largest brand in Eurasia specializing in the manufacture of goods in this category. It has its own production site in Russia.

Aluminum radiator Royal Thermo Source images.by.prom.st

Radena is a company engaged in the production of aluminum sectional radiators using Italian technology with an eye to operation in Russian conditions. The presented equipment complies with European and domestic standards and regulations.

Carefully read the characteristics Source aqua-santehnika.ru

We remind you that this review should not be considered as a rating.

Self-installation of an aluminum radiator Source eurosantehnik.ru

Manufacturers: black and white list

Of the main manufacturers whose products are deservedly popular, many Italian companies can be noted:

- Global;

- Fondital;

- Nova;

- Florada;

- Radiatori;

- Sira.

Nami also deserve attention .

Among domestic companies, it is worth noting radiators from Ankor , Rifar (under Global license) and Thermal .

Some Chinese manufacturers operating under a Global license were also included in the white list: Alltermo , Tianrun .

Also, we would like to draw your attention to the list of companies (mostly Chinese), about whose products we found the most negative reviews:

- Oasis;

- Conner;

- Radena;

- Warma.

In addition, during tests carried out in 2022 in the Moscow Vitaterm laboratory, discrepancies between real parameters and declared indicators from 22% to 34.75% were found in the products of the listed companies.

Corrosion, oxidation and service life

Aluminum radiators cannot be considered the best heating systems. The reason for this is the characteristics of the metal used: - the appearance of a chemical reaction between aluminum and copper entering through the coolant. With an increase in electrical conductivity, rapid destruction of aluminum radiators is observed when in contact with a heat exchanger or copper pipes. To neutralize this effect, it is advisable to use plastic pipes; — the constantly changing alkaline composition in water (increased pH) becomes a consequence of the reaction of aluminum with acids and alkalis. This releases hydrogen, which accumulates inside the housing. This is dangerous because such reactions act quickly and can explode the battery. Because of this, the radiator kit includes a special valve, which, when opened, can periodically remove hydrogen; — mechanical impurities, scale, stones and sand present in pipes lead to rapid destruction. Internal protective film and lead to metal corrosion; — the softness of aluminum can lead to mechanical damage to the battery. Such indicators are common in municipal heating systems. In private real estate, where it is possible to control the parameters of the coolant, the listed problems can be resolved.

Radiator care

The activity of convection currents ensures that there is practically no dust inside the heating device. Therefore, aluminum radiators do not require special care. But the implementation of simple rules will extend the life of the equipment. Due to the reaction of aluminum with copper, the walls of the devices wear out and electrical corrosion occurs. It is better to equip closed systems with plastic pipes. It is better to entrust the installation of a heating system to professionals. Aluminum is not resistant to damage, and you do not need to put any effort into tightening the tap. If the operating pressure exceeds 7-9 atmospheres, the system will depressurize.

Calculation of the required number of sections

As a rule, one radiator section is designed to heat 1.5-2 m2 of area.

But in reality this is not always the case, because it is necessary to take into account other characteristics of the room: - location (end room or not); - the thickness of each wall; — degree of freezing of the external wall; — characteristics of double-glazed windows; - type of roofing material; — roof condition, etc. Important technical parameters of aluminum radiators are operating pressure and heat transfer. Thermal output reflects the amount of heat generated by using one section of the battery. This indicator correlates with the operating temperature of the heating system. Basically, with dimensions of 100*600*80 mm, the heat transfer is 180 W. Under normal conditions, this volume of heat is enough to heat 1.4 m2. The operating pressure shows the degree of exposure to the coolant that the radiator can withstand. In a centralized heating system, the operating pressure exceeds 6 atm. But sometimes, when the load is exceeded, radiators fail.

Therefore, you should buy high-quality radiators and follow the installation rules. This will help minimize the risk of breakdowns.