When installing a heating system, the main attention is paid to the quality of the radiators. Aluminum batteries have the best price/quality ratio.

It is their pros and cons that we will consider below - varieties, calculations, connection options, technical criteria and selection tips.

- Thermal power

- Calculation of the number of sections for each room

- Russian products

- with side connection

Design and operating principle

Aluminum batteries can be solid or sectional. For strength and corrosion resistance, silicon, zinc, and titanium are added to aluminum during the manufacturing process.

The sections are connected by threaded connecting elements. The connections are sealed with silicone gaskets. To prevent ruptures, the inside of the radiators is coated with polymer materials.

Types of aluminum radiators by manufacturing technology

According to the production method, they can be sectional (cast) or solid (extrusion).

Cast

Each radiator section is manufactured using injection molding. This method guarantees accurate dimensions and a smooth surface of the product.

The sections are connected into a block using nipples. Such batteries are more expensive than extrusion batteries, but their reliability is higher.

Extrusion

One-piece models are made from recycled aluminum by extrusion. It consists of pressing a melt of material through forming heads (dies) to obtain the desired profile.

Steel profiles are used as dies. The blanks obtained in this way are welded together. The result is one-piece products that cannot be increased or decreased.

Sometimes, to reduce their cost, individual parts are not welded, but glued together with composite adhesives. However, such a replacement significantly worsens the characteristics of the products.

Heat dissipation and power

These two characteristics of aluminum radiators are almost always given as identical values and are used as synonyms in many articles. At the same time, each of them still has its own nuances, which follow from their physical definition:

- Heat dissipation

– this is a thermodynamic process, which consists of transferring heat from a solid body (radiator surface) to the environment through a coolant;It occurs in two ways - convection and radiation. For an aluminum heating device, the ratio of convection and radiation is approximately 50:50

- Power

is a physical quantity that shows how much heat a particular device can produce per unit time. The more powerful the radiator, the larger the area it can heat.

An aluminum radiator installed in an apartment.

In fact, an aluminum radiator performs useful work in heating a certain area, which depends on its power, due to the phenomenon of heat transfer. Both quantities discussed are measured in watts (W) or kilowatts (kW) and are often equated. Although it would be more correct to use the concept of power, which determines the amount of energy transmitted, and not the transmission process itself. We will use both expressions, according to recent practice.

Main technical characteristics

Aluminum batteries are attractive precisely because of their high technical characteristics at an affordable price. Wherein:

- weight of one section – 1…1.5 kg;

- capacity – 0.25…0.46 l;

- distance between axles – 20/35/50/80 cm;

- Guaranteed service life is 10...20 years.

The manufacturer indicates all the main characteristics in the device passport.

Thermal power

Thermal power (heat transfer) refers to the amount of heat produced by one section of the radiator.

The output coefficient for the standard section is 82...212 W. It depends on the temperature of the coolant. The total thermal power depends on the number of sections in the battery.

Operating pressure

There are two types of aluminum radiators:

- normal - with a working pressure of up to 6 atmospheres;

- reinforced - up to 16 atmospheres

Since the working pressure in multi-storey buildings is 10...15 atmospheres, and in houses with an autonomous heating system - less than 1.4 atmospheres, the first option is suitable for installation in private houses, and the second - in high-rise buildings.

Test pressure

To maintain the functionality of the system, it must be subjected to pressure testing annually, the pressure of which is 20...50 atmospheres.

Coolant parameters

The temperature of coolants in aluminum radiators can reach up to 120 °C, but usually it does not exceed 70 °C, and this is the temperature that is taken when calculating the thermal power.

What does it mean and how is the heat transfer rate of heating radiators calculated?

Heat transfer is an indicator that indicates how much heat the radiator transfers to the air per unit of time, at a certain temperature of the coolant in it (usually, according to GOST - at 70°C). Also called thermal power, it is measured in Watts (W). Sometimes in the passport of a heating device you can also find the designation “heat flow power”, the units of measurement of which are cal/hour: 1 W = 859.845 cal/hour.

Keep in mind that the characteristics may indicate the heat transfer of both 1 section of the device and the radiator as a whole, if it is sold as a set of 4, 6, 8 or 10 sections. With a power of one section of 624 W, a device of 4 sections will have a power of 4 * 624 = 2.496 kW.

Heat transfer standards for space heating

Heat exchange of a wall-mounted heating radiator.

According to practice, to heat a room with a ceiling height not exceeding 3 meters, one external wall and one window, 1 kW of heat for every 10 square meters of area is sufficient.

To more accurately calculate the heat transfer of heating radiators, it is necessary to make an adjustment for the climatic zone in which the house is located: for northern regions, 1.4-1.6 kW of power is required for comfortable heating of 10 m2 of space; for southern regions - 0.8-0.9 kW. For the Moscow region, amendments are not needed. However, both for the Moscow region and for other regions, it is recommended to leave a power reserve of 15% (multiplying the calculated values by 1.15).

Example: the premises of a house in the Moscow region have an area of 34 m2, respectively, requiring 34/10 * 1.15 = 3.91 kW of power. If a room with the same area belongs to a house in the northern region of the country, where heat loss due to the climate is much higher, for its comfortable heating you will need radiators with a heat output of 34/10 * 1.4 * 1.15 = 5.474 kW.

There are also more professional assessment methods, described below, but for a rough assessment and convenience, this method is quite sufficient. Radiators may turn out to be slightly more powerful than the minimum standard, but the quality of the heating system will only increase: more precise temperature settings and low-temperature heating modes will be possible.

Complete formula for exact calculation

A detailed formula allows you to take into account all possible options for heat loss and the characteristics of the room.

Q = 1000 W/m2*S*k1*k2*k3…*k10,

- where Q is the heat transfer index;

- S – total area of the room;

- k1-k10 – coefficients that take into account heat loss and installation features of radiators.

Show coefficient values k1-k10

k1 – number of external walls in the premises (walls bordering the street):

- one – k1=1.0;

- two – k1=1.2;

- three – k1-1.3.

k2 – room orientation (sunny or shady side):

- north, northeast or east – k2=1.1;

- south, southwest or west – k2=1.0.

k3 – coefficient of thermal insulation of room walls:

- simple, non-insulated walls – 1.17;

- masonry with 2 bricks or light insulation – 1.0;

- high-quality design thermal insulation – 0.85.

k4 – detailed accounting of the climatic conditions of the location (outdoor air temperature in the coldest week of winter):

- -35°C or less – 1.4;

- from -25°С to -34°С – 1.25;

- from -20°С to -24°С – 1.2;

- from -15°С to -19°С – 1.1;

- from -10°С to -14°С – 0.9;

- no colder than -10°C – 0.7.

k5 – coefficient taking into account the ceiling height:

- up to 2.7 m – 1.0;

- 2.8 - 3.0 m - 1.02;

- 3.1 - 3.9 m - 1.08;

- 4 m or more – 1.15.

k6 – coefficient taking into account heat loss from the ceiling (what is located above the ceiling):

- cold, unheated room/attic – 1.0;

- insulated attic/attic – 0.9;

- heated living space - 0.8.

k7 – accounting for heat loss from windows (type and number of double-glazed windows):

ordinary (including wooden) double windows – 1.17;- windows with double glazing (2 air chambers) – 1.0;

- double glazing with argon filling or triple glazing (3 air chambers) – 0.85.

k8 – accounting for the total glazing area (total window area: room area):

- less than 0.1 – k8 = 0.8;

- 0.11-0.2 – k8 = 0.9;

- 0.21-0.3 – k8 = 1.0;

- 0.31-0.4 – k8 = 1.05;

- 0.41-0.5 – k8 = 1.15.

k9 – taking into account the method of connecting radiators:

- diagonal, where feed is from above, return from below – 1.0;

- one-way, where feed is from above, return from below – 1.03;

- double-sided bottom, where both supply and return are from below – 1.1;

- diagonal, where feed is from below, return from above – 1.2;

- one-way, where feed is from below, return from above – 1.28;

- one-sided bottom, where both supply and return are from below - 1.28.

k10 – taking into account the location of the battery and the presence of a screen:

- practically not covered by a window sill, not covered by a screen – 0.9;

- covered by a window sill or wall projection – 1.0;

- covered with a decorative casing only on the outside - 1.05;

- completely covered by a screen – 1.15.

After determining the values of all coefficients and substituting them into the formula, you can calculate the maximum reliable power level of the radiators. For greater convenience, below is a calculator where you can calculate the same values by quickly selecting the appropriate source data.

Calculator for quick and accurate calculations

How many kW in 1 section of aluminum radiator

The thermal power of aluminum batteries directly depends on its height. There are two types of products currently sold:

- conventional batteries (height 50 cm) – power of 1 section 0.18...0.23 kW;

- shortened (height 35 cm) – power of 1 section 0.08...0.16 kW.

Calculation of the number of sections for each room

It is believed that one section of an aluminum battery heats 1.5...2 square meters. meters of room. But there are many factors that reduce the heat resistance of residential premises.

Therefore, when calculating the number of sections, the following points should be taken into account:

- whether the room is corner or internal;

- how high is the degree of freezing of the walls, and what is their thickness;

- whether double-glazed windows are installed and how well they retain heat;

- what material is the roof made of and what is its condition.

If any of the listed factors is unfavorable, the number of sections must be increased compared to the standard calculation.

Calculation for non-standard rooms

This calculation option is suitable for non-standard rooms with too low or too high ceilings. The calculation is based on the statement that to warm up 1 m3 of living space you need about 41 W of battery power. That is, calculations are performed using a single formula that looks like this:

A=Bx41,

Where:

- A – the required number of sections of the heating battery;

- B is the volume of the room. It is calculated as the product of the length of the room by its width and height.

For example, consider a room 4 m long, 3.5 m wide and 3 m high. Its volume will be 42 m3.

We calculate the total thermal energy requirement of this room by multiplying its volume by the previously mentioned 41 W. The result is 1722 W. For example, let's take a battery, each section of which produces 160 W of thermal power. We calculate the required number of sections by dividing the total need for thermal power by the power value of each section. The result will be 10.8. As usual, we round to the nearest larger integer, i.e. until 11.

Important! If you bought batteries that were not divided into sections, divide the total heat requirement by the power of the whole battery (indicated in the accompanying technical documentation). This way you will know the required number of heating radiators.

It is recommended to round the calculated data upward for the reason that manufacturing companies often indicate in the technical documentation a power that is slightly higher than the actual value.

Calculation of the required number of radiators for heating

Advantages and disadvantages of aluminum models

The main advantage of these products is their compactness, light weight, and affordable price. In addition they:

- warm up quickly and quickly release heat; have an optimal “thermal power/cost” ratio;

- have a fairly long service life;

- thanks to the sectional design, they allow you to select the optimal length for each specific room and calculate its cost (when selling, the cost per section is indicated);

- have an attractive appearance and durable paint coating;

- they use a convection heating method, due to which dust does not accumulate;

- easy to install even on drywall;

- varied and interesting in design.

The disadvantage of these radiators is their susceptibility to corrosion, leading to deformation.

Corrosion resistance is enhanced by the internal polymer coating. In its absence, to prevent battery rupture, the taps on the coolant supply pipes must not be turned off.

In addition, the disadvantages are also:

- low resistance to acid solutions that can be added to coolants;

- poor tolerance to sudden changes in fluid pressure;

- relatively rapid formation of gases inside the product, creating the need for its regular removal.

Selection, installation and operation of cast iron heating batteries

Stages of installing a radiator to a heating system.

If the choice (lightweight radiators or cast iron) is made in favor of the latter, then you need to calculate the number of batteries in the room and the number of radiators in each of them. To do this, you need to know the technical characteristics of a particular model, first of all, the amount of heat generated. Another important task is to determine the location for installing the batteries and the method of mounting: wall or floor. Based on this, a specific sample is selected. Photos of almost most cast iron heating radiators can be found on the Internet. Cast iron radiators have different external volumes, including being quite voluminous or completely flat, and having different heights and widths.

A common place in a living room where you can install a battery is a niche located under the window sill. Its parameters dictate the size of the battery. The technical characteristics of this battery should provide 1 kW of heat per 10 m² of room area. Moreover, if the volume of the room is larger than usual due to the high ceiling, or there is a second window, then 1.2 kW of heat is needed for the same area. If the room occupies a corner position, it makes sense to add a few more extra sections, since there is more heat loss there.

The mounting method dictates both the weight of the battery and the strength of the wall near which it is placed. If it is hung on the wall, then it is worth remembering that at least three brackets are needed for each battery. Today, cast iron batteries often use floor mounts, and many models have ready-made legs. If the wall is made of wood, then you should use corner fasteners. Next, you need to carefully install the pipes supplying the coolant and screw them on, ensuring the tightness of the threads as much as possible. At the same time, do not overdo it in applying force so as not to tear it off, otherwise water will leak.

https://youtube.com/watch?v=8l2cyQIMvMQ

Repairing a cast iron battery most often consists of eliminating leaks at the connection points with the pipes. The question arises: how to wash the radiator from the inside? It also has a simple, albeit time-consuming solution. It is disconnected from the battery, and then with the help of a flexible brush and a hose with high water pressure, all accumulated dirt is easily washed out. Like repairs, this procedure is best left to a specialist. Independent steps can be quite successful, but they can also lead to damage.

Cast iron batteries will become an uninterrupted and reliable source of heat for you, your children and grandchildren.

Features of manufacturers - which are better?

The Russian market of radiators for heating systems includes products from both Russian and foreign manufacturers.

They differ in their characteristics, and their diversity allows each buyer to choose the appropriate option.

Russian products

Among domestic manufacturers, the company Rifar and. Rifar produces a series of heating devices under license from the Italian company Global. Models of this series Alum and Alum Ventil operate at a pressure in the heating system of up to 20 atm, and their power is 183 W per section.

These products can work when using household antifreeze in the coolant, but the pH value must be in the range of 7...9 units. These are relatively expensive batteries, the price per section is more than 400 rubles.

Thermal brand batteries have the same characteristics. Their main feature is their small thickness (60 mm), which allows them to be installed in niches, saving room space. However, this worsens the heat transfer, it is only 167 W. But their price is very attractive - about 250 rubles.

Italian brands

The products of Italian companies Fondital, Sira and Global are of high quality. Although the price of this type of product is the highest (from 400 rubles), it is very popular among buyers.

Global produces ISEO radiators with a power of 180 W and VOX - 195 W. Sira Industrie produces cast and extruded models. The Alux sectional model has a power of 190 W.

Hungarian products

The Hungarian company NAMI also produces high-quality products, although its quality is slightly inferior to that of Italian companies.

Two modifications of the product are sold in Russia: NAMI Classik and NAMI Grand. The power of the latter is 195 W, and it allows the pH of the coolant to be up to 12 units. The cost of products is slightly less than the cost of products from Italian companies.

Chinese appliances

Chinese companies Bilux and Konner also produce very good products. The product price is lower than its Italian and Hungarian counterparts.

The cost of these products is reduced due to material savings: the thickness of the side ribs and rear wall is reduced, and the diameter of the collector is reduced. This degrades the thermal output and reduces the longevity of the appliances.

What you need to know when choosing aluminum batteries

Aluminum radiators are very sensitive to the acidic environment in the heating system. Therefore, reliable, long-term operation is only possible at a pH of 6.5... 8.

You should also know that:

- the internal surface must be carefully processed, an oxide film must be applied;

- the radiator must have a passport with the characteristics specified in it, it is desirable that there is a test report;

- factory assembly is more reliable, so if possible, you should buy a ready-made battery from the required number of sections;

- You should not install a battery of more than 15 sections, it is better to install two;

- an unusual radiator design may impair its performance;

- Chinese-made NF/68 radiators should be avoided. They may contain asbestos, which is hazardous to health.

Radiator power components

What the thermal energy of the heating system should be depends on many factors:

- Area and volume of the room: parameters taken into account - length, width and height of the ceiling

- Radiator type: bimetallic, steel, cast iron, aluminum

- Number of sections: from one to fourteen

- Region of residence: for southern places the power is 40 - 45 W for heating one cubic meter of air, and in the northern regions - 60 W.

- Air temperature chart

- Rose of Wind

- Which side do the windows face and what quality are they?

- Thermal insulation of walls, floors and ceilings

- Number of doors in the room.

In the southern region, for a room with a volume of 45 cubic meters with windows facing southeast and one door, the calculation of the heating radiator power will look like this:

3x5x3x40 = 1800 W. In the northern region, heating an office of equal volume and conditions will require 2700 W. Based on the calculations made, a heating system is selected, consisting of thermal equipment, which includes various types of radiators.

Cast iron battery

This time-tested heating device is good because it has prefabricated sections with a power of approximately 160 Watts, is not afraid of water hammer, and is suitable for any coolant.

Cast iron is less susceptible to corrosion and tends to maintain temperature for a long time, therefore it is famous for its maximum heat transfer. The disadvantages are quite large weight and dimensions.

Steel radiator

Cheapness, light weight, ease of installation, fast heating and a ready-made table of the power of heating radiators at optimal temperatures are the advantages of a steel battery.

- The disadvantages are that it is impossible to regulate the number of components yourself, fragility, and rapid cooling.

- They have a panel (solid) or tubular (collapsible) design.

The power of panel heating radiators is indicated in the technical data sheet of each product; on average, it has a value of 85 W.

Bimetallic convector

Each of its compartments consists of corrosion-resistant steel structures inside and an aluminum coating on the outside, which has high heat transfer. Thanks to this combination, the durability of the battery is increased. The heating device looks modern, stylish and has a high cost.

The power of bimetallic heating radiators is indicated per section and is approximately equal to 180 W; to calculate the power of the entire convector, it is necessary to multiply this figure by the number of sections.

Aluminum radiator

It has all the characteristics of an old cast iron battery, except for heavy weight, excellent heat transfer and low cost. A modern heating device with a pleasant design comes on sale in a one-piece or collapsible design, which makes it possible to independently install the required number of elements.

The disadvantages of this type include susceptibility to oxygen corrosion.

Connection options

The most effective is a diagonal connection, in which heat loss is only 2%.

However, the appearance of this connection somewhat spoils the surrounding design, so they often give preference to products with side and bottom connections, which look more aesthetically pleasing.

with side connection

With a side connection, the inlet and outlet pipes are connected from above and below to the section on one side of the radiator, which ensures uniform heating of all sections.

This connection can be used with a large number of sections - up to 15.

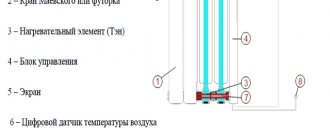

The influence of the placement and method of connecting radiators on heat transfer

The best location for the radiator is under the light openings, since the greatest heat loss occurs through the window, no matter how insulated it is. In addition, hot air from the heating device creates a thermal curtain: cold air from the window does not spread throughout the room, circulation improves.

Changes in the thermal power of the radiator depending on the placement and presence of a screen.

If you decide to hide radiators under screens or decorative panels, this will lead to a loss of power. Sometimes such measures are resorted to in order to purposefully reduce the strength of the heat flow by 10-15%.

Reduced thermal power with different connection methods.

The method of connecting radiators also has a significant impact:

- Bilateral or unilateral . Connecting pipes from different sides helps to increase the heat transfer of the battery; with this connection, the power of the device corresponds to the declared maximum. However, for radiators with less than 20 sections, it is better to install pipes from one side.

- Top or bottom . The supply of coolant to the upper part of the battery, when removed through the lower part, has a minimal effect on heat transfer. Feeding from bottom to top reduces the indicator by 20-22%.