What happens if you combine a fireplace and stove into one? What are the advantages of such a home heating system? Or maybe there are disadvantages? The answers are in this article.

How pleasant it is to spend an evening in your own home in front of the fireplace, enjoying the play of the flames and the relaxing warmth. Indeed, a fireplace can create a special atmosphere in the house. What if you add a stove to the fireplace, in which you can bake real bread or cook borscht, and in addition it will give warmth to the whole house. So such an opportunity exists in the form of a stove-fireplace design.

Description of the fireplace stove

A fireplace stove is a combined fireplace and stove that combines all the advantages and purpose. A fireplace can heat a room in a short time and create comfort due to the visible flame. The stove, although it takes longer to warm up than a fireplace, gives off heat for a long time, even after the fire has died out. In addition, the oven is used for cooking and heating food.

Main types

In words it is quite simple to explain the principle of unification according to which the fireplace stove is built. The real device is complicated by the fact that today it is customary to equip it with additional functions. Thus, there are models with ovens, hobs, niches for drying fruit, barbecues, barbecues, etc.

- Ancient traditions are embodied in modern stoves with benches. Of course, the stove has somewhat lost its purpose, and the stove bench serves, for the most part, to add some color, but it is functional. You can climb on it at any time and warm up. Such stove options require a dedicated area of the room. So think about where you can install it.

- Due to its shape, a wall-mounted wood-burning stove-fireplace does not take up very much space, but it allows you to heat two adjacent rooms at once. It is mounted so that its firebox opens into one room, and the back wall is part of the partition. In a small house, this design will provide warmth in any weather.

- A real center that can gather everyone around it is a stove with an oven and a hob. It can zone a room, allocating space for a full kitchen and a hallway. To welcome guests and prepare a festive dinner, it is enough to light only one firebox. As a result, you can get a warm room, a great view of the burning flame and a lot of cooking possibilities.

Home while working

Fireplace stove design

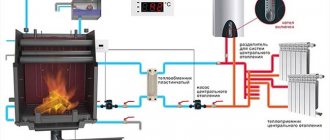

The fireplace stove system is quite complex; each element has its own characteristics that are clearly different from each other. The fireplace has a large open firebox, this allows you to create a large air draft, which means the fire will quickly flare up and warm the room. And in order to remove combustion products without delay, the fireplace has a straight exhaust pipe. But as soon as the flame goes out, the heat stops flowing into the house. The oven has a completely different principle of operation. It does not require a large firebox and strong draft, so the fuel does not burn, but rather smolders, gradually heating the stove. The heat accumulates and warms the house for a very long time, even without fire in the firebox. And the winding exhaust pipe only contributes to this, trapping hot gases.

The stove makers managed to combine the stove and fireplace together. You can’t heat all the fireboxes at once, but if there is a need for this, you should light the fireplace and then the stove. Since the fireplace has a more powerful air draft.

Reason #2 – poor ventilation

Incorrect air exchange, in one of the rooms or in the entire building, is also a factor explaining why there is no draft in the stove of a house or bathhouse. Combustion products are not removed properly and/or in full if:

- In the boiler room/room, windows are constantly or often open, which are also installed at a level significantly higher than the firebox door.

- There are strong drafts that disrupt the usual movement of gas masses through the rooms.

- There is no flow of fresh air, and the sleeve seems to “suck” it from the street so that a vacuum is not created.

The difficulty and even danger here is that these shortcomings may not manifest themselves for a long time, and then lead to the release of exhaust gas, and this is fraught with carbon monoxide poisoning.

If a new stove smokes, most likely during the process of laying it some technological regulations and standards were violated. Perhaps the chimney openings were too narrow or the design of the furnace wells was damaged. Unfortunately, it is not possible to get rid of this with your own hands. The oven will have to be rebuilt.

Models of fireplace stoves

They build different models of the stove-fireplace system. The differences are in the material, which affects the performance of the equipment. There are also fireplace stoves of different shapes, which allows you to install them in the house based on the internal layout. There are corner, island and wall-mounted ones. Their shape affects the external design, for example, a corner one does not need decorative cladding on the sides of the walls. The main materials for the production of fireplace stoves are cast iron or steel and brick. Brick ones have a lot of weight and size, so they need to strengthen the foundation. They accumulate heat well and share it for a long time. A brick fireplace stove can be installed so that the fireboxes open into different rooms. This will not spoil the interior and will have a positive effect on heating the house.

Cast iron or steel are produced as a monoblock, which is convenient for installation. The properties of cast iron are that it has a lower heat capacity than brick. When heated, cast iron emits infrared heat, warming people and objects, rather than airspace, and does not create air currents that raise dust particles.

Replacing a brick pipe with a metal one

If a brick chimney is not enough, it can be further extended using a metal pipe. The task is labor-intensive, but completely achievable

It is important to approach it with full responsibility

To begin with, a flat steel platform with a pipe is made. Moreover, its diameter should be the same as the diameter of the metal pipe that is planned to be used. The platform must be securely secured. It is fixed with dowels and screws. Sealing will add additional reliability.

Work order:

On the brickwork you need to mark the points at which the fastening will be installed. They cannot be placed on a masonry seam. It is advisable to place them closer to the center of the brick, and not on its edge. Holes are drilled in the marked places to place dowels. At the same points, holes are made on the flat surface; the self-tapping screws will go there. Fireproof sealant is applied to the brick base, then a steel platform is placed there. Self-tapping screws are screwed into dowels

It is important to ensure tight fit and uniformity. Now all that remains is to wait for the sealant to dry completely and proceed directly to extending the chimney using a metal pipe

Important installation details:

The decision on how to insulate a metal chimney pipe should be made based on the budget, as well as the needs of the structure.

It is important to approach the task as responsibly as possible, performing work in full compliance with all standards and nuances. Then the chimney insulation will last a long time without complaints.

PC orders

Stoves and fireplaces designed and built by Georgy Reznik are distinguished by high thermal qualities and a precise design, which is based on the image of a traditional Russian stove. You can once again be convinced of this by familiarizing yourself with the new order of the heating stove-fireplace.

The design of the proposed fireplace stove is intended for heating a room with an area of up to 30 m2 and a ceiling height of about 250 cm. If the fireplace stove is installed in a hall (large room), it should be turned with the stove part towards the wall or partition with a distance of at least 125 cm. This distance is sufficient for working near the stove. The fireplace stove can also be installed in the opening of a wall or partition between the living room and the kitchen. In the heating and cooking furnace, the convective system is a bell-pack system, which allows you to install a low mounted pipe. For a one-story building, this is important, since there is no need to raise the pipe high above the roof. The oven has two modes - summer and winter. When the summer valve is open, flue gases enter the chimney, bypassing the hoods and without heating the furnace mass. A ventilation valve is installed in the upper part of the cooking chamber. The stove is equipped with an oven.

The main mass of the fireplace stove is made of stove (Vitebsk) brick. Both fireboxes (stove and fireplace) and parts of the adjacent chimneys are made of fireclay. For a more expressive design, decorative elements (shelves, arches, skirt, bottom sill) can be made from solid brick, the color of which differs from the main color of the stove (for example, from Pobeda Knauf brick). You can further decorate the stove by covering the shelves with ceramic tiles or natural stone.

MATERIALS AND DEVICES REQUIRED FOR CONSTRUCTION OF STOVE-FIREPLACE Red brick M-200 - 1200 pcs. - "- fireclay Sh-8 - 170 pcs.; Fireclay clay - 50 kg. Crushed fireclay - 50 kg. Smoke valve 26×13 cm - 3 pcs.; —“— 13×13 cm — 1 pc. Cast iron two-burner stove 58.5×34 cm - 1 pc.; Fire door 21×25 cm -1 piece; -“- blower 13×25 cm -1 piece; -“- for cleaning 7×13 cm -3 pcs. Grate 25×30 cm - 2 pcs. Oven 35x28x25 cm - 1 pc. Steel strip 50x5 mm -8 m. Steel angle 60x60x6 mm -2.5 m. Clay, mountain sand - as needed.

Reason #2 – poor ventilation

Incorrect air exchange, in one of the rooms or in the entire building, is also a factor explaining why there is no draft in the stove of a house or bathhouse. Combustion products are not removed properly and/or in full if:

- In the boiler room/room, windows are constantly or often open, which are also installed at a level significantly higher than the firebox door.

- There are strong drafts that disrupt the usual movement of gas masses through the rooms.

- There is no flow of fresh air, and the sleeve seems to “suck” it from the street so that a vacuum is not created.

The difficulty and even danger here is that these shortcomings may not manifest themselves for a long time, and then lead to the release of exhaust gas, and this is fraught with carbon monoxide poisoning.

If a new stove smokes, most likely during the process of laying it some technological regulations and standards were violated. Perhaps the chimney openings were too narrow or the design of the furnace wells was damaged. Unfortunately, it is not possible to get rid of this with your own hands. The oven will have to be rebuilt.

Brick stove-fireplace. Phased construction

Analyzing the thermal performance of heating centers, both newly built and in operation for many years, I came to certain conclusions. To some, my comments will not seem new, but they will be useful for owners of country houses with stove heating, as well as for workers who have some experience in constructing brick fireplace stoves.

Brick stove-fireplace construction

Let's start with the foundation. Its depth should be below the calculated freezing depth. It is strictly forbidden to connect the foundations of the stove and the house. It is necessary to perform double waterproofing: the first - at the soil-air boundary, the second - 10 cm before the level of the subfloor.

What materials should I use? Red clay brick. Before laying, it should be soaked in water for better adhesion to the clay-sand mortar.

The strength of the masonry depends on the fat content of the clay. To eliminate shrinkage, sand is added to the clay. The best clay is the one that has been left in the cold. The sand grain size should be 1…1.5 mm. This will make it possible to make the masonry stronger due to thin seams.

The old masters said about sand: “Which sand crunches in your hands and does not make stains when poured onto a white scarf, is suitable for the structure of a furnace.”

The firebox of a brick fireplace stove must match the fuel being burned. But in all cases, slopes are laid from the grate to the walls of the firebox, which helps coals or unburned firewood to roll onto the grate and “finish burning.”

Soot and condensation. To combat the loss of condensate and soot on the walls of chimneys and pipes, a suction channel (“ram”) is installed, which is a small window 70x70 mm made from the firebox into the last channel.

The stove must have good constant draft. This is achieved by smooth outlines of turns, narrowings and expansions of chimneys. The height of the pipe from the level of the grate to the head must be at least 5 m. Weak draft leads to soot deposition.

It must be remembered that burning a stove with chimneys on which soot particles have settled requires much more fuel and time.

A layer of soot 3 mm thick reduces the heat transfer of the masonry by 2 times. Birch firewood produces the most soot, while aspen firewood produces the least amount of soot.

Some innovators in the furnace industry insert 070 mm metal pipes into vertical smoke ducts to accelerate heat transfer from the furnace. The ends of the pipes, bent at the top and bottom, go out. Due to air convection, the room warms up faster.

How often and for how long to light a brick fireplace? - many developers ask. The heating and cooking stove is heated for 1.5 hours, the heating stove - up to 2 hours, the sauna stove - up to 4 hours. But if you need to get more heat, then it is more profitable to heat the stove twice with a break of 5-6 hours than continuously and for a long time. Fuel savings are also achieved through proper operation.

Stoves combined with fireplaces do not always have uniform heating of all masonry walls, but if such a fireplace is installed in one large room or the partitions adjacent to the heating structure are correctly constructed, then maximum comfort can be obtained.

When developing any design, you have to take into account many factors: the size and location of the rooms, the presence of a foundation, and if there is one, then its

dimensions

I had to develop an oven with a single burner stove and an oven for drying vegetables and berries. The stove had to be installed in a room with an area of 30 m2 and be used at any time of the year, so it was necessary to provide two fire modes: summer and winter. In addition, the customer wanted to have a built-in fireplace. The matter was complicated by the fact that the area of the existing foundation was only 1x1 m.

To develop the design and calculate materials, a kit for prototyping stoves and fireplaces was used. In this case, a completely new design of a compact heating and cooking stove combined with a fireplace was obtained.

The pictures show sections and arrangements of a brick fireplace stove.

Formation of condensation in the chimney

Moisture in the chimney impairs draft; this is easy to notice with constant use. Sticky soot blocks the pipe. In the masonry of brick chimneys, smudges appear at the seams, the bricks are saturated and destroyed.

At the bottom of the channel the temperature of the exhaust gases is maximum. Moving upward, the flow cools, lingering at the bends, and settles in drops on the cold surface of the chimney. Metal pipes that are not insulated cool down in a few minutes (when switching to a smoldering combustion mode), brick and ceramics give off heat more slowly. Hence the ability of the metal to collect drops of moisture on itself.

Insulating the pipe helps keep the temperature of the exhaust gases above the “dew point”. With a “lined” chimney, the space between the masonry and the pipe is filled or filled with non-flammable insulation (expanded clay, stone or glass wool). The top and bottom of the gap are sealed with a plug.

If the diameter allows, it is reasonable to assemble an analogue of the sandwich system. Having insulated the outside of the existing metal pipe with a layer of 5-10 cm of mineral wool, it is necessary to protect the entire structure on top with metal sheets or a pipe of a suitable diameter. On the outside, the channel experiences less stress, so a more aesthetic material can be chosen.

Correct installation of the chimney is important. The joints of the insulation and pipes should be staggered. The metal is connected with heat-resistant sealant and fasteners, and the entire structure is tightly fixed with clamps. If the joints in a homemade or purchased sandwich system are not sealed, condensation will seep in and destroy the insulation. In response, the temperature and fire danger will increase. The chimney will more often than not be damp and clogged.

Conditions under which excess condensation forms:

- burning with raw wood;

- cold chimney (not insulated or not used for a long time);

- weak combustion of fuel (with a lack of air, too weak draft or too strong), for example, in boilers in smoldering mode.

In a poorly calculated chimney design, the escaping gases also cool quickly. Channels with high heights, complex bends or narrowing diameters slow down and cool the smoke. If the cross-section is larger than optimal, then the draft weakens and condensation also forms.

Wood-burning stoves with 5-7 channels are difficult to warm up with a small load. The smoke will go into the chimney cold. To warm the smoke and reduce the amount of moisture, the design makes a thin direct connection between the firebox and the upper last channel. Also, previously, firewood was sprinkled with rock salt before the firebox - it removed some of the condensation. An ancient method of prevention.

Merging options

There are several approaches to solving the problem of combining two structures. Their type depends on the stage at which such a decision was made. The most popular are two ways to accomplish the task.

- Installation of two fireboxes in one housing. As a rule, already at the stage of pouring the foundation it becomes known that the future structure will perform two types of tasks. The body of the fireplace is laid out according to a certain pattern, in which two fireboxes are formed. One firebox belongs to the stove, and the second to the fireplace. Common models are those that are a stove on one side and a fireplace on the other. These devices heat different rooms, and it seems that they function separately.

- Equipping the furnace firebox with a glass door. This allows you to turn a stove into a fireplace with a minimal investment of money, preserving all the functional features of the original device. Thus, a fireplace stove is obtained thanks to an elementary addition.

Undoubtedly, if two devices are combined into one, then there are only one advantages, however, in the case when the originally built stove was built by your predecessors and you want to make two functional devices out of it, you will have to call a professional craftsman. Even if you plan to carry out all the work yourself, you need a clearly developed plan. It will tell you exactly how to implement the join.

How we are working

- You contact us by phone or send a request by mail. We expect the following information from you:

- the type and purpose of the stove or stove complex, the desired size and appearance of the stove, whether the stove will be operated continuously or only on weekends (dacha option);

- the area of heated premises, the height of the ceilings of all floors, the thickness of interfloor ceilings, the height to the ridge and the degree of slope of the roof, what material the house / gazebo is built from, what material the roof is made of;

- information about the foundation, dimensions, thickness, height to the finished floor level. The foundation must bear the load of the furnace with an average weight of 7-11 tons. The weight of the barbecue complex, depending on the configuration, is up to 15 tons.

detailed plan of the house / gazebo where the stove or stove complex will be located;

Is it allowed to connect two stoves or two fireplaces to one chimney?

Tight dampers can solve the problem of smoke getting into any of the rooms, but you cannot operate two stoves at the same time. Poor draft of the second stove and smoke on the second floor are the consequences that can occur, but the main question is air exchange in the house: how to regulate the combustion modes of wood and draft? How is supply ventilation arranged in each room? What are the air exchange conditions in the house (are the rooms connected via a flight of stairs or is it completely insulated)? In this case, there will be more questions than solutions. Therefore, each stove must have a separate chimney device.

Diagram of a two-pipe chimney.

In Europe, it is allowed to connect several gas appliances to one common chimney. All furnace work is carried out either by specialized companies or by licensed professionals. There are no universal recommendations or solutions in this case; everything must be considered individually. The situation with apartment heating (use of gas) and the removal of combustion products into a common similar device is somewhat different. Gas closed boilers are equipped with an automatic system for regulating combustion and operation in the event of a drop in gas pressure. Modern wood-burning fireplaces and inserts do not have such functions.

If two fireplaces are connected to a single smoke duct on the same floor, the distance between the connection pipes must be at least 1 m, and the cross-section of the chimney will need to be increased.

Simultaneous operation in this case will not cause problems. First, you should melt a more powerful hearth.

Firebox walls

The walls of the firebox of fireplaces with increased heat transfer (Fig. 5.2, 1-3) are placed “on edge” with a distance of 6 cm from the fireplace body to form an air chamber behind the walls.

The side walls of the upper firebox 1, in accordance with the recommendations for the design of a classic fireplace, are installed at a slight angle relative to the side walls of the fireplace body. However, experience shows that it is not possible to find the optimal angular position of the walls (and, accordingly, find the angle that defines this position) in fireplaces of a small group (A = 51 cm and A = 63 cm) and the effect of their rotation remains practically zero. Let us remind you that turning the walls of the firebox is done to better reflect heat into the room. Some experts believe that it is better to use the rotation of the walls to maintain the fuel combustion process, so they try to concentrate this direction in the middle of the firebox. For this reason (due to low efficiency) in fireplace 2 (this is a fireplace A = 51 cm), the side walls of the firebox are placed without turning, they are parallel to the walls of the fireplace body. The picture is different in the firebox of fireplaces of the medium and large groups, as can be seen from the fireboxes on the right (4-6). But even in these cases, it is impractical to set in advance a specific angle that determines the position of the side walls of the firebox. It is clear that it will depend not only on the width of the portal (dimension A), but also on the selected depth of the fireplace body (and, accordingly, the depth of the firebox). For medium and large fireplaces these values can vary significantly. In our example, the depth of the fireplace body is 2.5 bricks; it could be 3.0 bricks, which could also affect the choice of the angular position of the firebox walls.

Therefore, for fireplaces of medium and large groups, it is also impractical to set the specified angle in advance; usually it is ~ 30 °. The decision is best left to the discretion of the designer or performer.

Rear wall of the firebox

The beginning of its laying (2 rows on edge for fireplaces on the left and 4 and 5 rows for fireboxes on the right) should be placed in a binder with the side walls of the firebox, this is somewhat difficult to do, but the problem is solved by appropriate trimming of the brick

Let us pay attention to the exception made with firebox No. 4: for laying the first 4 rows, halves of bricks were used, sawn lengthwise: 250 x 60 mm. This frees up an additional 6 cm of the depth of the firebox, or more precisely, its hearth, in favor of placing a fire pit (this is in conditions when the depth of the firebox, and therefore the hearth too, is made minimal)

Firebox No. 4 is the only one where the rear inclined wall is laid in horizontal rows, and the inclined surface of the wall is formed by an angular cut of the brick (20o from the vertical). Accordingly, the outer bricks are intertwined with the side walls, which are laid with a bevel. Due to this, the entire firebox receives strength properties: under temperature loads it does not form cracks and crevices, which, as the solution crumbles from them (with poor, low-quality solutions), can become through.

Pages: — — | — — | — — | — — | — — | — — | — —

Construction of an additional foundation

The Swedish stove with fireplace and boiler has a large mass due to the use of brick. In order for the structure to be distinguished by its strength, reliability and stability, it becomes necessary to install an additional foundation according to the following scheme:

- At the first stage, it is necessary to dig a fairly deep pit (at least 0.5-0.9 meters);

- The bottom of the dug hole is well and thoroughly compacted with a shovel and leveled;

- Pre-prepared sand with a fine fraction is laid in a layer of 10-13 centimeters and also compacted;

- The next layer of crushed stone is placed about 15-18 centimeters thick;

- In places where the ground is elevated, there is a need to install formwork;

- We create a monolithic layer and give it greater rigidity through the use of reinforcing mesh;

- Pour in a pre-prepared mixture based on cement and graphite. The second and subsequent layers should be mixed on the basis of cement and sand - this composition makes it more durable and reliable;

- We waterproof the completely dry surface with several sheets of roofing felt.

Components of an additional foundation

The first row is laid flat and sets the required shape of the fireplace

You can learn more about building a foundation by watching the video in this article.

Problems arising with one chimney and two fireplaces

Building two stoves or fireplaces and then venting them into one smoke duct can cause problems in the future. These include:

- poor traction;

- smoke on the top floor;

- a short pipe and, as a result, the inability to melt the upper device.

Large plumes of smoke from a second floor fireplace may be caused by an uneven chimney. If during masonry the formation of protrusions was allowed or the cross-section of the passage increased, then carbon monoxide does not exit correctly. Smoke entering an uneven section of the pipe begins to change its trajectory and form “vortices”. Then he finds himself in a second connected passage and follows it into the room. In this case, it will not be possible to build one chimney; you need to install two pipes. You can also make two outlet channels in one pipe or connect the upper chimney to the main pipe at an angle. Thanks to such solutions, smoke will be eliminated and normal draft will be maintained during operation of the upper stove.

Normalization of draft is achieved by igniting a fireplace that has large dimensions. To prevent smoke from getting from one stove to another, it is necessary to make several tight dampers instead of one and ensure that the pipe is hermetically sealed.

If the final decision was made to make one chimney for two fireplaces, stoves, barbecues, etc., then without the proper experience it will not be possible to fully do this. It is better to contact specialists who have the proper knowledge and experience in arranging such structures.