At the moment, the most common heating device in our country is the MS-140 cast iron heating radiator. The reliability, durability and practicality of this device have been tested in practice for many decades. The production technologies of these batteries are already outdated, but they still heat tens of thousands of homes, administrative, office, commercial, industrial and public buildings throughout Russia.

Our citizens have been familiar with these heating devices for a very long time.

Total information

Batteries offered by manufacturers differ in the number of sections.

They are made:

- in 10-section form;

- in 7-section design;

- in 4-section form.

Note! A different number of sections allows you to install cast iron radiators in rooms of different sizes. That is, you can choose a device that will be optimally suited for a particular room.

Types of MC batteries

MS-140-500 have a flat surface and are painted in different colors.

To compete with more modern types of devices, manufacturers of cast iron heating batteries had to expand this product line.

The following models are currently available on the Russian market.

- Cast iron heating radiators MS-140-500 are produced by the Republic of Belarus. This device has undergone several improvements. Now its surface, as a rule, has a flat appearance. In addition, the product comes already painted in different colors.

- Battery MS-140-500 with 7 heating elements. This is a frontal variation of the previous model.

- Analogue MS-140-300. This device has a gap between nipples of 300 millimeters.

- The MS-140-108 model does not require significant care and does not require constant maintenance.

Difference between different device models.

- Cast iron heating radiators grade MS-140-180 and 98 have gaps between nipples of 108 and 98 millimeters. The devices, like the previous one, are produced in Russia and Ukraine.

Thanks to such a wide selection of products, property owners can optimally arrange heating in their home.

Calculation of the number of sections

Accurately determining the number of sections in a heating battery is a long process. You need to take into account the region, the material of the walls, what kind of windows and doors there are, how many windows are in the room, what their area is, whether the room below is warm or cold, etc. If you need an exact calculation method, look here, but you can roughly calculate based on the area of the room. It is believed that on average 100 W of heat is required to heat 1 m2 of area. Knowing the area of your room, determine how much heat will be needed: multiply the area by 100 W. Then divide by the thermal power of the selected radiator model.

For example, in a room of 12 m2 we will install MS-140M-500-0.9 from the Bryansk plant. Thermal power of the section is 160 W. Calculation:

- Total heat required is 12m2 * 100 W = 1200 W

- How many sections are needed 1200 W / 160 W = 7.5 pcs. We round (always up - it’s better if it’s warmer) and we get 8 pieces.

Qualities and characteristics

The described heating devices are designed to transfer thermal energy from the heating system to the premises of public, residential, industrial and other buildings. They are designed for coolant temperatures up to +130 degrees and operating (excess) pressure of the medium up to 0.9 MPa. Products are manufactured in accordance with GOST No. 31311/2005, as well as TU No. 4935/005/00288372/05.

Advantages of cast iron batteries

- High degree of corrosion resistance . This quality of cast iron is explained by the fact that during operation “dry rust” grows on its surface. It protects the material from corrosion.

- Cast iron has good wear resistance . Dirt and debris inside the system do not harm it.

- Excellent level of thermal inertia . Cast iron batteries, 60 minutes after turning off the heating, retain about 30 percent of the heat. For steel analogues, this parameter is only 15 percent.

- Very long service life . A high-quality device can last about 100 years. Manufacturers guarantee 15/25 years of trouble-free service.

The thermal photo shows that part of the battery is clogged with debris, which means it needs to be cleaned.

- Large cross-section of the internal space of the sections . Thanks to this, the batteries only need to be cleaned once every few years.

Note! Cast iron, due to its structure, cannot be a catalyst for electrochemical corrosion. In other words, the material does not conflict with steel and plastic heating pipes.

- The price of such heating devices is relatively small.

Radiator characteristics

Now a little about the technical properties of these products. They are slightly different for all MS brand models. As an example, we give data on MS-140-98 batteries.

| Parameter | Meaning |

| Manufacturer country | Russia Ukraine |

| Coolant temperature, maximum | +130 degrees Celsius |

| Working pressure, maximum | 9 bar |

| Pressure (testing) | 15 bar |

| Battery Type | sectional |

| Number of channels in one section | 2 |

| Coolant volume in one section | 1.35 liters |

| Thermal output of one section | 175 W |

| Mass of one element | 6.2 kg |

| Width of one section | 98 mm |

| Nipple hole section | 5/4 inch |

| Material of gaskets between sections | heat resistant rubber type |

| Material of plugs and sections | gray cast iron SCh/10 (according to State Standard No. 1412) |

| Nipple material | malleable cast iron KCh/30/6F (according to State Standard No. 1215) or steel 08/KP, 08/PS (according to State Standard No. 1050) |

| Nipple hole thread | G-1 at 1/4" |

Note! The instructions say that due to the thinness of the walls of the radiator elements, it is strictly forbidden to throw heating devices. Due to shocks during transportation, the devices may have loose nipple connections.

Based on this, before starting the heating system, it is necessary to carry out pressure testing (hydraulic testing) of the batteries yourself. If they leak anywhere, the nipples will need to be tightened in those places.

Pass-through plug.

Radiators are always equipped with two plugs (through) with a right-hand thread and two plugs (blind) with a left-hand thread, half an inch. Upon special order, the configuration can be changed.

Cast iron heating radiators MS 140: technical characteristics

Despite the emergence of many new models of radiators and heating convectors, manufactured using modern technologies using modified materials, cast iron batteries do not lose their widespread popularity today. Due to a number of positive qualities, many owners of apartments and private houses prefer them.

Cast iron heating radiators MS 140 technical characteristics

Cast iron heating radiators MS 140, the technical characteristics of which will be discussed in detail below, have both positive qualities and disadvantages. It should be noted that today these elements of the heating system have been significantly improved - their technical properties have been improved and they have a more aesthetic appearance, although old versions, familiar to everyone from Soviet times, are also sold.

A brief history of the creation of cast iron radiators

Not many people know that cast iron batteries have been used for more than 150 years. The first of them was cast in St. Petersburg, in 1855, at the factory of Franz San Galli, a Russian entrepreneur of German origin. The plant specialized in the development and production of equipment for water supply and heating.

The “father” of the cast iron radiator is considered to be Franz San Galli, a Russian entrepreneur

The first name for a cast iron radiator is “heizkörper”, that is, “hot box”. Such a “box” consisted of vertically installed disks and large-diameter pipes.

Until today, the basic manufacturing technology of cast iron radiators has not undergone any fundamental changes - they are cast from gray cast iron in clay-sand molds.

The outstanding qualities of this heating device have been appreciated by many generations, and in honor of the 150th anniversary of the cast-iron radiator in 2005, a commemorative bas-relief was installed for it at the Samara State District Power Plant.

Monument in honor of the 150th anniversary of the cast iron radiator

The sculptural composition can be called a “folk work”, since it was made by master N. Kuklev based on a photo competition, most of which depicted installed radiators and pets basking on them.

Advantages and disadvantages of cast iron heating radiators

Agree that if a device model has been used for such a long time and is still in demand by consumers, this certainly speaks about its quality and efficiency, and also about the fact that a better option in this “line” has never been invented. However, like any device, cast iron batteries have not only undeniable advantages, but also disadvantages.

Positive qualities of cast iron radiators

- The main advantage of cast iron appliances would be their unconditional reliability. Manufacturers set their service life at 50 years, but, as is known, they can work for a longer time, especially in cases where they are properly maintained regularly.

If we look at history, the oldest battery that functions to this day is a radiator installed 110 years ago in one of the princely houses in Tsarskoe Selo.

- Due to the high heat capacity of cast iron, the design features and massiveness of such heating devices, they are able to retain heat for quite a long time after the heating of the coolant has been turned off.

- Cast iron batteries are installed in both central and autonomous heating systems, as they can withstand pressure up to 9 ÷ 12 atmospheres. This is especially important for devices installed in a central heating system, where water hammer often occurs, which can damage batteries that have thin walls. That is why the cast iron version is so widely used for installation in multi-storey buildings.

- This type of radiator, when assembled well, can easily withstand elevated coolant temperatures, reaching up to 100 ÷ 130 degrees.

- Resistance to coolant of any quality, which also allows the installation of heating devices in a central heating system. The fact is that water, heated at a thermal power plant, is driven through heating mains, and along the way the coolant becomes contaminated from old pipes and enters apartments in the form of an environment that is aggressive to metal, which can cause corrosion of any metal except cast iron.

- The design of the radiator provides wide internal channels, thanks to which blockages rarely occur in the path of the coolant. Wide channels also help maintain the integrity of sections during water hammer.

- Radiant heating. Cast iron radiators are more capable than aluminum or steel ones of transferring heat to surrounding objects using infrared radiation, warming them up. Thus, heated objects transfer heat into the air space of the room, becoming an additional source of heating.

- This type of radiator is dismountable and prefabricated. That is, it is always possible to install a battery of the required thermal power, and, if necessary, make adjustments by adding or removing the required number of sections.

- The affordable price of sections of this type of cast iron batteries, which on average today is 400 ÷ 500 rubles.

The fact that some qualities called positive, from the point of view of other evaluation criteria, may look like shortcomings requires clarification:

— For example, wide channels inside the batteries are good for the free passage of contaminated coolant. But, at the same time, the heating system where such radiators are installed requires a large volume of heated water, which means that a larger amount of fuel will be consumed in the autonomous system, which leads to increased costs.

— High thermal inertia, that is, it takes a long time to warm up the radiator sections, compared to other types of batteries made of thin metal plates. Long warm-up leads to long-term non-stop operation of the boiler, which also means extra fuel costs. However, this negative factor is compensated by the prolonged cooling of the coolant and the batteries themselves when the heating is turned off.

The disadvantages cast iron radiators include the following:

- Large mass of heating devices - the weight of a section with an center distance of 500 mm is from 6 to 7.5 kg. The battery usually consists of 6 ÷ 10 sections, so its total weight will be approximately 36 to 75 kg. If the room has a large area, then sometimes it is necessary to make up a battery from a larger number of sections.

- The heavy weight complicates the installation of the heating system. If the radiators are hung on wall brackets (and in the vast majority of cases this is the case), then you first need to carefully evaluate the ability of the fence to withstand such a load, calculate the strength of the fastenings and install them at a certain depth in the wall, and then hang the heating elements on them.

- Despite the high resistance of cast iron to various negative factors, it is a fairly brittle alloy, so during installation it is necessary to avoid impacts and falling batteries, as sections can crack or burst.

Primed cast iron radiator MS-140

- Cast iron batteries MS-140 of the old model require periodic painting - once at least two or three years. Radiators are sold primed.

- In the opinion of many apartment owners, the appearance of batteries of old models is unaesthetic. This small drawback can be completely corrected with the help of removable screens, which can be selected to suit every taste.

Cast iron radiators MS-140

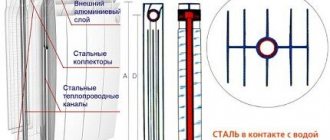

This brand of cast iron batteries can be called the most used, since they were previously installed in almost every private house or city apartment. The depth of one section of this radiator is 140 mm, the center height is 500 mm, the heat transfer power can reach up to 160 W - depending on the main mode of the boiler room. This type of radiator is marked MS 140-500.

The base material of manufacture is gray cast iron grade SCh-10. For connecting nipples, either ductile cast iron grade KCh - 30-6-F, or steel 08KP (08PS) is used. Gaskets are made of heat-resistant rubber brand TTS or PI. The thread of connecting nipples or plugs is 1¼ inches.

As a rule, radiators are supplied from the factory in assembled batteries of 7 or 4 sections. For construction organizations, delivery is practiced in “packages”, which include 9 seven-section and one four-section battery

They produce several versions of cast iron batteries MS 140:

- In addition to standard two-channel ones, MS 140 - 500 can have fins.

Cast iron radiator with fins

This type of radiator is considered the most effective, since additional fins installed between the two vertical channels of the section, when heated, sharply increase the active heat exchange area. The power of this battery option is higher than that of the “classic” type and can reach up to 195 W.

However, when installing this version of the radiator, you must remember that in order for it to work efficiently, its fins should be periodically cleaned of dirt and dust, otherwise the heat transfer drops by 25 ÷ 40 W.

- Radiator MC 140 ÷ 300

Cast iron radiator MS-140-300

This type of radiator has the same depth of 140 mm, but the height between the axes is only 300 mm, so one section produces about 120 W of thermal energy. This compact battery option is well suited for small rooms, or when the distance between the floor and the window sill is too small to accommodate a taller type of heating device.

Manufacturers of cast iron radiators MS-140

The production of MS-140 cast iron batteries is carried out by factories in several countries, and their products may differ slightly in technical characteristics.

In Russia, radiators are produced by the following enterprises:

- Boiler and Radiator Plant, Nizhny Tagil;

- OJSC "Santekhlit", pos. Lyubokhna Bryansk region;

- LLC "Descartes", Novosibirsk.

In the Republic of Belarus, the production of radiators is carried out by the heating equipment plant in Minsk.

In addition, cast iron batteries produced at the foundry and mechanical plant in Lugansk are presented on the Russian market.

MS-140 radiators with and without fins, and, for comparison, MS-90 radiator

In addition to the MS 140 radiators, these enterprises produce another variety that has a shallower depth - it is labeled MS-90.

Boiler and Radiator Plant, Nizhny Tagil

The plant produces products according to the ISO 9001:2008 standard in the “Russian Register” certification; they also use a certificate from the GOST R and IQNet systems.

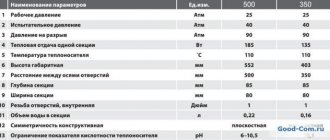

Drawing of radiator MS-140 M2-500

The batteries are designed for coolant temperatures of up to 125-130 degrees and for operating pressures of no more than 12 atm. The main characteristics are presented in the table:

| Radiator model | Distance between axles (mm) | Radiator dimensions (mm) | Section thermal power (W) | Section volume (l) | Section weight (kg) | ||

| section width | depth | height | |||||

| MS-140-M2-500 | 500 | 94 | 140 | 580 | 160 | 1.45 | 6.65 |

| MS-140M-300 | 300 | 104 | 140 | 388 | 117 | 1.11 | 5.4 |

| MS-90 | 500 | 90 | 90 | 580 | 130 | 1.15 | 5.48 |

OJSC "Santekhlit", pos. Lyubohna Bryansk region

This manufacturer produces batteries marked MS-140; MS-100 and MS-85.

Radiators meet the following parameters:

— working pressure for MS-140÷ 9 atm., MS-100 and 85 ÷ 12 atm.;

— coolant temperature — up to 130 degrees.

| Radiator model | Distance between axles (mm) | Radiator dimensions (mm) | Section thermal power (W) | Section volume (l) | Section weight (kg) | ||

| section width | depth | height | |||||

| MS-140M-500-0.9 | 500 | 93 | 140 | 588 | 160 | 1.45 | 7.1 |

| MS-140-300-0.9 | 300 | 93 | 140 | 388 | 120 | 1.11 | 6.1 |

| MS-110-500-1.2 | 500 | 82 | 110 | 588 | 125 | 0.85 | 5.6 |

| MS-110-300-1.2 | 300 | 82 | 100 | 381.4 | 79 | 0.63 | 4.45 |

| MS-85-500 | 500 | 76 | 85 | 581.4 | 115 | 1 | 4.45 |

Drawing of radiator MS-140-300

LLC "Descartes", Novosibirsk

Novosibirsk manufacturers produce cast iron batteries designed for a working pressure of 9 atm. and coolant temperature up to 130 degrees.

| Radiator model | Distance between axles (mm) | Radiator dimensions (mm) | Section thermal power (W) | Section volume (l) | Section weight (kg) | ||

| section width | depth | height | |||||

| MS-140/500 | 500 | 93 | 140 | 588 | 160 | 1.45 | 7.1 |

| MS-140/300 | 300 | 93 | 140 | 388 | 120 | 1.11 | 6.1 |

| MS-90/500 | 500 | 71 | 90 | 581 | 130 | 1.45 | 6.5 |

Products of the Minsk Heating Equipment Plant

This company produces cast iron batteries marked MS-140÷500, as well as modified three-channel BZ-140÷300.

An interesting model produced by the Minsk plant

The model range of this company, in addition, includes both hanging versions of radiators and those installed on the floor, which have special stands for this purpose. By purchasing such models, you can get rid of the problems associated with drilling walls, installing brackets and hanging the batteries themselves.

| Radiator model | Distance between axles (mm) | Radiator dimensions (mm) | Section thermal power (W) | Section volume (l) | Section weight (kg) | ||

| section width | depth | height | |||||

| MS-140M | 500 | 108 | 140 | 588 | 160 | 1.45 | 6.7 |

| BZ-140-300 | 300 | 98 | 140 | 376 | 120 | 1.27 | 5.4 |

The plant's designers also worked on the appearance of the radiators. Therefore, this manufacturer’s product range includes models made in a retro style, on the surface of which relief designs are placed.

You can choose models with a relief molded pattern

In addition, batteries are produced that are designed for modern interiors - with flat front plates. These models are even somewhat reminiscent of aluminum or bimetallic radiators in design.

It should be noted that the products of this Belarusian enterprise are of high quality and have earned the best customer reviews.

Foundry-mechanical plant Lugansk

This plant produces radiators marked MS-140, MS-100 and RD-100; they are designed for operating pressures up to 12 atm. and temperatures up to 130 degrees.

| Radiator model | Distance between axles (mm) | Radiator dimensions (mm) | Section thermal power (W) | Section volume (l) | Section weight (kg) | ||

| section width | depth | height | |||||

| MS-140M4-500-0.9 | 500 | 102 | 140 | 588 | 184 | 1.33 | 6.74 |

| MS-140 M1-300-0.9 | 300 | 102 | 140 | 388 | 120 | 1 | 5.5 |

| MS-100 M1 3KP 500 | 500 | 63 | 100 | 570 | 135 | 0.7 | 5.4 |

| MS-1003KP 300-1.2 | 300 | 63 | 100 | 372 | 95 | 0.55 | 3.23 |

| RD- 100 500 -1.2 | 500 | 60 | 100 | 585 | 120 | 0.8 | 4.6 |

In addition to classic cast-iron radiators, the manufacturer produces batteries for modern interiors, which do not require painting, as they have a high-quality enamel coating. This table shows their characteristics and markings - RD-100 500÷1.2.

Nuances of installing cast iron batteries

As everyone knows, any type of heating device is mounted under a window opening. According to experts, this is the optimal area for blocking cold air coming from the window, since the heat rising upward from the radiator creates a kind of curtain.

For a cast iron battery to work effectively, it must be moved away from the wall by at least 40 ÷ 50 mm, raised from the floor by 70 ÷ 100 mm and located 50 mm below the window sill.

To prevent some of the heat from being lost to warming up the cold wall, it is recommended to secure foil insulation behind the radiator, turning its aluminum covering towards the room. Thus, this material will reflect heat towards the room, enhancing the heat transfer effect.

Foil screen on the wall behind the radiator

Since cast iron batteries are very heavy, it is very important to prepare reliable fastenings for them if the devices will be hung on the wall. The brackets must be located every four ÷ five sections of the radiator and recessed into the wall by at least 130 ÷ 140 mm.

To do this, holes are drilled in a stone or concrete wall into which the brackets are mounted on a concrete mortar. A hole with a slightly smaller diameter than the thickness of the bracket is drilled in the wooden fence, then it is carefully driven or screwed into the wall.

Simple hammer-in bracket for cast iron radiator canopy

It is very important to correctly mark the wall and determine the location of the brackets. The radiator must be located exactly horizontally, so the first thing to do is to draw a level line for the brackets, according to the dimensions previously taken from the heater. To avoid mistakes, you can make an exact template from cardboard, on which you can mark the location of the sections and the locations of the fasteners.

Prices for cast iron radiators from different manufacturers

cast iron radiator

Disassembling and assembling a cast iron radiator

For long-term operation of radiators and for their high-quality functioning, it is sometimes necessary to carry out preventive measures to clean individual sections. To do this, you will have to disassemble the radiator or its individual parts.

First of all, you need to become more familiar with the design of the sections connecting.

Interconnection diagram of cast iron radiator sections

1 – housing of the cast iron section of the radiator.

2 – connecting nipple.

3 – end plug.

4 – shows the protrusions on the inner surface of the nipple, for which the working part of the nipple wrench is engaged (item 5)

The main elements required for installing the sections into a single battery:

What is needed to assemble sections into a battery

a – nipple. It is a cast iron or steel cylinder. There are two 1¼-inch threaded sections cut on both sides of the outside. The direction of the threads is the opposite. Similarly, on cast iron sections, left-hand and right-hand threads are cut on opposite sides. Thus, when the nipple is rotated with a wrench in one direction, the nipple is simultaneously screwed into both sections (when dismantled, it is unscrewed, respectively). The figure shows the ribs for gripping the nipple with the working head of the wrench.

b – rubber or paronite gaskets that are installed between sections and under plugs.

c – blind plug. Depending on the installation location, it may have either a left-handed or right-handed thread.

g – passage plug. External thread - the same as on a blind plug, left or right. Internal - right, used for packing the supply or return pipe or fitting.

The work of disassembling the radiator is carried out step by step in the following order:

- If it is necessary to carry out work on radiators connected to the central heating system, then the first thing to do is shut off the coolant supply and then drain the water from the radiators located in the apartment.

In an autonomous heating system, you just need to free the pipes and radiators from the coolant contained in them.

- Next, using a wrench of the required size, the fittings are unscrewed on both sides of the radiator, and it is removed from the brackets. Place the device on a previously prepared sheet of plywood so as not to damage or stain the floor covering.

- The next step is to unscrew the blind side plugs from the battery.

- Then, a radiator key of the required size is inserted into the opened side hole of the battery and turned - for this, a crossbar can be welded to the rod. If not, then turn it with a gas wrench. This is how the nipple connecting the sections is unscrewed. Work must be carried out in parallel with the upper and lower nipple.

Unscrewing the nipple

- In order not to make a mistake with the location of the required nipple, you should estimate in advance the depth of insertion of the key into the battery and make a corresponding mark on the rod.

Many craftsmen use convenient wrenches that have a movable clutch. It not only clearly positions the working head of the wrench on the desired nipple, but also centers the rod, preventing it from skewing when forces are applied during unwinding or assembly.

- Unfortunately, it also happens that if the batteries have not been disassembled for a long time, then the protrusions in the nipple intended for the key are “eaten up” by corrosion. The key turns, and it is impossible to disassemble the battery in the normal way. In this case, you have to resort to drastic measures - the nipple between the sections is very carefully cut along the gasket line with a grinder. Then its threaded parts are heated with a blowtorch and each half of the nipple is unscrewed separately.

- The battery is reassembled in the reverse order. Naturally, the gaskets should be changed. It is worth immediately assessing the safety of the nipples - it may be advisable to replace them with new ones.

Video: dismantling and assembling a cast iron battery

Calculation of the required number of sections of a cast iron battery

The simplest method for determining the required number of sections for heating a room is to take into account only the area of the room.

With great simplification, it is believed that heating 1 m² of area on average requires 100 W of thermal energy. Knowing the area of the room, it needs to be multiplied by 100 and then divided by the thermal power of the radiator model.

For example, a room has an area of 16 m², and a radiator model MS-140-M2-500 is purchased, each section of which has a thermal power of 160 W. In this case, the calculation is made as follows:

- 16 m² × 100 W = 1600 W – heat will be required to heat this room.

- 1600 W : 160 W = 10 pcs. - this is the number of sections required.

If the calculation results in a non-integer number, it is rounded up to a whole number.

However, this technique is overly simplified and does not take into account many criteria.

To make a more in-depth calculation of the required number of sections, you need to take into account many parameters - the level of winter temperatures in the region, the quality and material of the windows, their number in the room and the total area, the degree of wall insulation, and more. Even the connection diagram of radiators and their location in the room matter. This calculation is usually carried out by specialists, and it is not easy to cope with it yourself.

However, our reader is given this opportunity - at his service is a special calculator, which takes into account most of the factors affecting the size of the heating radiator. Just provide the requested information and get the desired result.

Calculator for calculating a cast iron battery

Go to calculations

Although cast iron batteries have the same MS-140 marking, they may have slightly different characteristics, since they are produced according to industry standards of the countries in which they are produced. However, it should be noted that this fact rather plays into the hands of the consumer, since he has the opportunity to choose the appropriate option, especially since some of the parameters vary quite significantly. Learn how to heat a house without gas inexpensively on our website.

You might be interested in information on how to choose an electric boiler