- Pipe cleaning

Many have wondered why condensation forms in the chimney pipe of a gas boiler and how to reduce its volume or eliminate it altogether. It is necessary to comprehensively consider the problem: determine what determines its scale, how to prevent it. You will not only be convinced that preventive measures are useful, but you will also be able to implement them in a timely manner (after all, some of them need to be introduced at the building design stage).

What it is

When burning any fuel - gas, coal, peat, coke and others, in addition to heat, steam is also released. As it rises, it cools upon contact with air of a lower temperature, and part of it turns into condensation in the smoke channel, that is, into moisture flowing down the walls. This is a natural, but negative and even dangerous physical phenomenon that can result in the most harmful consequences for the entire heating system (below, in a separate section, we will tell you exactly what they are).

Types of boilers by number of heating circuits

Condensing gas boilers, the operating principle and design of which were created on the basis of traditional models, are divided into two types according to the number of heating circuits. Features of single-circuit devices are as follows:

- They are intended for space heating only.

Single-circuit model with a power of up to 35 kW Source ark-eng.ru

- Single-circuit units are capable of producing water for domestic hot water supply. Most boilers can be connected to an external indirect heating boiler; The storage tank is selected taking into account the needs for hot water. The boiler will maintain the desired temperature, there will always be hot water in the house, which will not affect the heating system.

Double-circuit boilers provide both home heating and hot water supply. In the latest generation models, these processes are synchronized and do not interfere with one another. However, there are enough boilers whose operation is set to DHW priority. That is, if you decide to take a shower or wash the dishes, the moment you open the hot water tap, the automation stops heating the coolant in the heating system.

Also, dual-circuit units are characterized by a rather low productivity of hot water for domestic needs. If there are several water points in the house, then when they are used simultaneously, the water temperature will begin to drop. This feature can hardly be called comfortable.

Double-circuit boiler built into a niche in the kitchen Source gradusplus.com

Causes and factors influencing the formation of condensation

Let us immediately note that they are given in random order, and not in order of importance. So this is:

- The temperature of the steam (exhaust gas leaving the furnace head) does not exceed 100 °C. This is a typical drawback for a significant part of modern heating units.

- The pipe is too long - the smoke cools quickly and strongly in its upper part.

- The selected fuel is either damp (saturated with moisture during storage) or simply poorly suitable (initially contains a large percentage of water).

- The hog's clearance has narrowed due to a decrease in traction caused by the accumulation of soot deposits.

- The pipeline is not insulated enough and/or made of the wrong material (for example, one layer of zinc).

- The air outside is much colder than the escaping steam and, due to a serious temperature difference, condensate in the chimney of a private house collects quickly and in large volumes.

- Exhaust gas is retained by rough walls.

- The flow of fresh air to the stove is absent or insufficient, as a result of which the draft is too low, the fuel burns slowly and is not completely burned.

- The outlet channel already contains some amount of liquid that has entered there due to precipitation or for some other reason.

- The pipe has defects and/or design flaws - it has too inclined or even horizontal sections, its cross-sectional area differs from the design one (up or down), and the like.

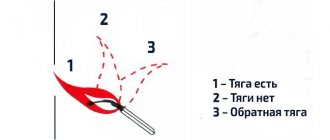

- Poor draft - the faster the gas leaves the system, the better, the less time remains for cooling and moisture formation.

- The stove is not built correctly - a significant part of the released energy is spent on its heating (and not on heating the room). This leads to a low outgoing steam temperature, and we have already discussed the consequences of this above.

All these factors provoke the appearance of fluid, but they act to varying degrees: some are stronger, others are weaker.

Briefly about the main thing

In some European countries, more than half of the heating boilers installed in private homes are condensing, but they are much less common on the Russian market.

Condensing boilers use the latent heat of condensation, that is, the thermal energy that in conventional devices simply flies out into the pipe. Therefore, the design of the units includes an additional heat exchanger, where combustion products transfer heat to the coolant. The solution significantly increases the efficiency of the boiler, which allows reducing gas consumption by 10%.

Convection systems differ in the type of installation (wall-mounted, floor-mounted) and in the number of heating circuits (single- and double-circuit). The combination of these parameters affects the performance characteristics, which must be taken into account when choosing a suitable model.

Influence of material on the occurrence of condensation

A gas boiler differs from an electric or solid fuel boiler in that it operates in such a way that some amount of moisture always forms in the system. Therefore, when purchasing and installing it, it is especially important to think about the issue of insulation and decide what the chimney will be made of. The service life and safety of heating equipment depends on the correct choice.

Brick

Well assembled (without cracks or crevices), it will be able to effectively retain heat, which will allow its walls not to cool down for a long time, and therefore will help maintain normal traction. On the other hand, it needs to be heated for a long time, and while the temperature remains low, the liquid accumulates relatively actively.

Please also note that brick is quite easily destroyed when in contact with acid solutions and temperature changes. So it's classic and expensive (if made from good brick), but not the best choice.

Stainless steel pipes

The material itself, the surface of which is perfectly smooth, resists corrosion and aggressive environments. Now about the constructive solution.

In order not to see condensation flowing from the chimney, it is necessary to use a double-walled one rather than a single-walled one. The sandwich manufacturing technology involves double rings of different diameters, between which lies a layer of insulation made of non-flammable basalt fiber. With such additional insulation, stainless steel will not only warm up quickly, but also take a long time to cool down. And this without the accumulation of moisture and soot inside.

Ceramic pipes

They are quite durable and have the following advantages:

- warm up quickly and cool down slowly, which means they effectively retain heat;

- universal, do not depend on the type of fuel of the stoves;

- easy to maintain and therefore can be used for decades;

- fireproof - they are not afraid of soot fires.

There are also disadvantages, they consist in the large weight of the structure, which can lead to installation difficulties and high cost.

Furanflex chimneys

You can also consider this composite material so as not to think that condensation from the pipe of a gas boiler or furnace can damage the heating system. Moisture will not collect on the walls of the channel, since they will be made of polymer resin reinforced with fiberglass.

The finished furanflex sleeve can be of any length, diameter and, if installed correctly, will be completely sealed. Say a categorical “no” to leaks and a confident “yes” to consistently powerful traction. Installation is quick and clean, without demolishing walls, ceilings, parts of the roof, supporting structures, and is easy to carry out even after finishing work. The material is not damaged even when the steam temperature reaches 250 °C.

The main disadvantages of furanflex are its high price (2-3 times higher than stainless steel chimneys) and expensive installation. If the sleeve is damaged, sealing the element is difficult to achieve, and purchasing the entire system can significantly hit your pocket.

Asbestos-cement chimneys

Previously used everywhere, today, with the development of technology, they are considered obsolete. Having settled on this option, you will think not only about why condensation forms in the chimney, but also how to eliminate the consequences of inhaling asbestos dust. And it will be released during the heating process (when the acids contained in the flue gases begin to destroy the channel), settle in the room, and then enter your lungs when you inhale.

This material also has other disadvantages: it is not airtight enough, does not retain heat well, and relatively actively absorbs liquids. Add here the roughness of the surface (which, as we found out above, is bad), high porosity and tendency to crack under the influence of high temperatures, a threshold of 300 ° C, above which there is a threat of explosion.

Steel and galvanized pipes (single wall)

They are light and inexpensive - a sleeve will be 50-80% cheaper than a brick one, not to mention the rest. But there are drawbacks, and the main one is that the channel quickly burns out. This is due to the inability to withstand the effects of condensation and high temperatures. Steel may rust as it has poor corrosion resistance. And zinc, when heated above 419°C, releases toxic substances, so rolled metal products made from it can only be used at a low temperature of the exhaust gases.

Thus, we recommend choosing insulated stainless steel chimneys.

In addition to choosing the appropriate material, it is necessary to carry out installation according to the instructions. Irregularities during pipe assembly can lead to condensation and soot deposits.

Our production

Single wall chimneys

Double wall chimneys

Mounting elements

The appearance of moisture in double-circuit boilers

In addition to the chimney, condensation can occur in the water pipes of 2-circuit gas boilers. It's all about the temperature difference, due to which the pipe can rust and fail.

The problem may occur for one of the following reasons:

- Ventilation is not working correctly (the exhaust power is insufficient).

- The climate in the room is unfavorable - the humidity level is consistently exceeded.

- The equipment operates in an incorrect (erroneously calculated) mode.

Unfortunately, the features of the boiler do not allow you to completely get rid of condensate, but insulating the pipes and insulating the chimney can reduce the rate of moisture accumulation.

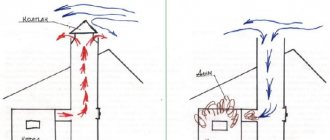

Chimney design requirements

They are determined by the provisions of SNiP 41-01-2003 and boil down to the following:

- channel height at least 5 m;

- the pipe rises above the flat roof by at least 1 m, above the pitched roof - depending on the distance between the ridge and the roof (by 0.5 mm, level or at an angle of up to 10 0);

- horizontal sleeve no more than 1 m long;

- the sum of the projections of inclined and horizontal zones is strictly up to 2 m, and the vertical sections also increase by the same length.

We found out why condensation collects in the chimney, and now let's see how to prevent it. First of all, correct installation of the pipe helps prevent the appearance of excess moisture.

Installation rules

It is important to make the system sealed, insulated, waterproof, and protected from the destructive effects of aggressive environments. To do this, you need to select suitable materials for arrangement and insulation, and then be guided by the following principles:

- The chimney assembly should be carried out along the “condensate”, and not through the “smoke”. For single-wall chimneys, when assembled “by condensate”, the upper end is inserted into the lower end. For sandwich-insulated structures, this rule applies to internal assembly. The outer part is collected “by smoke”.

- Treat each joint with a sealing compound.

- Do not deviate from the vertical by more than 30% (less serious deviations are acceptable).

- Make horizontal sections no longer than 1 m.

- Use components of the same cross-section (along the entire channel).

The installation must be carried out in compliance with technology and the correct choice of pipe material. Avoid using materials that are obsolete, hazardous (asbestos) or difficult to construct (such as brick). It is better to use ready-made chimney kits, which are presented on the website feflues.ru. Prices can be found in the price list.

What to do if the chimney pipe is leaking

Yes, it will not be possible to completely protect against moisture on the walls of the channel, but at least it is possible to reduce the volume of its occurrence, albeit at the stage of building construction and roofing. But what if the house is not new (for example, you bought it from someone), has been in use for a long time and already has this problem.

There are effective measures, and it is quite possible to take them even on your own. Below we will tell you several ways, but first answer a simple question: what are you going to heat with?

Focus not only on the price of the combustible material, but also on its environmental friendliness (after all, the health of you and your loved ones depends on it), cost-effectiveness of consumption and, attention, its natural humidity. After all, fuel oil or gas contains a lower percentage of water than wood. Also, consider how easily the fuel absorbs liquid. Any wood must be dried before use; peat or coal is strictly prohibited from getting wet.

Now let's move on to ways to fix the problem.

Pipe cleaning

How to avoid excess moisture and deal with condensation in the chimney? Remove soot in a timely manner. Because it settles on the walls of the channel, making the surface rough, and thereby worsens the draft - flue gases are retained in artificially created “depressions”.

The amount of soot depends on the fuel used and the design of the system. With a coal stove there will be a lot of it, with a gas boiler - not enough. But she will still be there. Therefore, it is important to clean the inside of the canal at least twice, and preferably three times a year. Choose any convenient method, mechanical or chemical, only in the first case act carefully so as not to damage the walls, and in the second use environmentally friendly and not too aggressive compounds.

Insulation

It is important to prevent the formation of excess condensation in the chimney even at the stage of building a house or bathhouse. For these purposes, it is necessary to use an insulated structure, namely:

- single-wall chimney in an insulated shaft;

- double wall chimney.

How to get rid of condensation in a chimney chimney if it is constantly cold? It is necessary to insulate it using modern thermal insulation materials. If you have a brick chimney, the best option to prevent condensation is to line it with a stainless steel sandwich.

Protecting the canal from precipitation

Achieved by installing components - you need to install:

- condensate drain for the chimney - a container for collecting condensate, usually made of stainless steel; such an element should be placed below the pipe so that it can be easily emptied if necessary;

- deflector (umbrella with wind protection) – installed at the end of the chimney (a cone is pre-attached to the sandwich), prevents precipitation from entering the pipe;

- visor - with or without a weather vane, in the shape of a mushroom (hippable roof), with an opening lid or not; but in any case it will protect from direct precipitation - raindrops and snowflakes.

These elements stabilize the draft, eliminate the possibility of blowing in and make the appearance of the roof more modern and aesthetic.

Installation of a walk-through collector

In the chimneys of gas boilers, condensate often forms in horizontal sections of the pipe. In order to solve this problem, a collector is installed as a pipe segment, to which a 90° angle is attached so that the chimney is inclined towards the boiler. This is done so that moisture flows down into the condensate trap.

Is it possible to calculate the probability of condensation occurring?

Yes, if it appears due to overheating of the walls due to too much steam emission. In this case, it is realistic to determine what the power of the operating equipment should be.

In general, the rate of heat release (per 10 m2 of room area) is 1 kW. If the ceilings in the room are no higher than 3 meters, the formula is as follows:

MK = S*UMK/10, where

MK is the design power of the boiler in kW; S – area of the room in which the heating unit operates; WMC is a specific indicator that depends on the climatic zone of residence and is equal to:

- 0.9 – for the south;

- 1.2 – for the middle band;

- 2 – for northern latitudes.

If a double-circuit boiler is used, the resulting MK figure must be multiplied by 0.25 (additional coefficient).

Dew point

The process by which water vapor in the chimney begins to precipitate and form condensation is called “dew point.” It depends on the indicators of absolute, maximum possible humidity, depending on the air temperature on that day, the actual air humidity at the moment and the difference between these indicators. You can find out at what temperature the dew point appears in the table below.

Dew point determination table

It shows that if the air temperature is 5 degrees Celsius and the air humidity does not exceed 70%, then the dew point appears at a temperature of -5 °C and moisture will begin to appear on the walls of the chimney.

Consequences of condensation inside the chimney

Moisture is not just collected, but mixed with combustion products - aggressive acids (nitric, carbonic, sulfuric). Settling on the walls, these harmful compounds gradually destroy the channel (if it is made of brick, plain steel or other material with low corrosion resistance). Excessive condensation leads to the formation of soot, which clogs the hose, impairing draft, resulting in a risk of chimney fire and reverse draft.

Selecting quality fuel

You can also extend the life of your boiler and make it easier to clean if you use high-quality fuel - fuel with low humidity. Naturally, the most ideal fuel, with a moisture content of less than 10%, is pellets and other briquetted fuels. Briquetted fuel will also make it possible to obtain a longer burning time for one load of fuel. Pellets can only be used in a specialized pellet boiler. Thus, a pellet boiler and pellet fuel are an ideal pair that makes the life of the owner of such an automatic solid fuel boiler as easy as possible.

Preventive measures

We'll tell you how to get rid of the cause of condensation in the chimney. It’s simple: you need to prevent the emergence and development of moisture formation factors. To do this you need:

- competently design the heating system and equip it strictly according to the drawings;

- correctly install the chimney from a material resistant to aggressive environments and high temperatures;

- provide high-quality thermal insulation;

- maximize thrust - by installing deflectors, canopies, rotary turbines;

- use suitable and dry fuel;

- Carry out regular cleaning of the internal surfaces of the sleeve.

Now that you know why condensation forms in the chimney boiler pipe and how to eliminate it, you can extend the life of your heating system, as well as increase the convenience and efficiency of its use.

How does a thermostatic distribution valve work?

The thermostatic valve is installed on the supply in front of the bypass section (pipeline section) connecting the supply and return of the boiler in close proximity to the boiler. This creates a small coolant circulation circuit. The thermoflask, as mentioned above, is installed on the return pipeline in close proximity to the boiler.

At the moment of boiler startup, the coolant has a minimum temperature, the working fluid in the thermoflask occupies a minimum volume, there is no pressure on the thermohead rod, and the valve allows the coolant to flow only in one direction of circulation in a small circle.

As the coolant heats up, the volume of the working fluid in the thermoflask increases, the thermal head begins to put pressure on the valve stem, passing the cold coolant to the boiler, and the heated coolant into the general circulation circuit.

As a result of mixing cold water, the temperature in the return line decreases, and, therefore, the volume of the working fluid in the thermal flask decreases, which leads to a decrease in the pressure of the thermal head on the valve stem. This in turn leads to the cessation of the supply of cold water to the small circulation circuit.

The process continues until the entire coolant is heated to the required temperature. After which the valve blocks the movement of the coolant through the small circulation circuit, and the entire coolant begins to move through the large heating circle.

The thermostatic mixing valve works in the same way as a distribution valve, but it is installed not on the supply pipe, but on the return pipe. The valve is located in front of the bypass, connecting the supply and return and forming a small circle of coolant circulation. The thermostatic flask is mounted in the same place - on a section of the return pipeline in close proximity to the heating boiler.

While the coolant is cold, the valve allows it to flow only in a small circle. As the coolant heats up, the thermal head begins to put pressure on the valve stem, allowing part of the heated coolant to pass into the general circulation circuit of the boiler.

As you can see, the scheme is extremely simple, but at the same time effective and reliable.

The thermostatic valve and thermal head do not require electrical energy to operate; both devices are non-volatile. No additional devices or controllers are needed either. To heat the coolant circulating in a small circle, 15 minutes are enough, while heating the entire coolant in the boiler can take several hours.

This means that using a thermostatic valve, the duration of condensation formation in a solid fuel boiler is reduced several times, and along with it, the time of the destructive effects of acids on the boiler is reduced.

To protect a solid fuel boiler from condensation, it is necessary to properly piping it, using a thermostatic valve and creating a small coolant circulation circuit.

Condensation on the gas boiler pipe is formed due to the difference in ambient temperatures and the walls of the smoke channel. In winter, condensate freezes, and icicles form on the head of the pipe, and ice plugs in the chimney. Over time, the ice thaws, moisture flows down the pipe, the chimney and adjacent structures become wet and gradually collapse.

Condensation in the pipe of a gas boiler also leads to negative consequences. Water vapor contained in the products of fuel combustion condenses on the cold walls of the chimney. As a result, moisture is formed, which combines with the salts of the flue gases. This creates aggressive acids that destroy the chimney and other surfaces.