Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

To avoid troubles during operation, it is necessary to carefully consider the thermal protection of the building. Very often during design, a decision is made to use prefabricated or monolithic reinforced concrete floors. If the building does not have a heated basement or basement, it will be necessary to insulate the concrete floor on the ground floor in a private house.

Why is insulation performed?

Before insulating a concrete floor, it is necessary to understand the feasibility of this measure. Concrete has high thermal conductivity. This means that it transmits heat well through itself and removes it from the room. To prevent heat loss, materials with better thermal conductivity are used.

Laying insulation as an additional layer in a private house on the ground floor floor prevents the following problems:

- condensation on a cold surface from the warm air side;

- the appearance of mold, mildew and other microorganisms dangerous to humans;

- violation of the temperature and humidity conditions of the room;

- high heating costs.

If you leave a concrete floor in a private house without insulation, then in addition to the fact that it will be uncomfortable to use, the structure will soon require serious repairs.

The process of insulating slabs

When working with floors that are located above basements, you should start from the floor. First, a cement screed is laid on top of the reinforced concrete slabs - it is used as a base. In some cases, they do without it, simply sealing the seams between the slabs.

An important element are wooden logs, which are mounted on thin chipboard or fiberboard pads. The thickness of the gaskets is usually about 25 mm.

Logs are also used for insulation - material is placed in the space between them to prevent the penetration of cold and heat loss. Most often, mineral wool, Izol series products, various dry backfills and soft basalt slabs are used for this. The next layer is used to prevent steam penetration. This can be a roll material of a certain type - from glassine to ordinary roofing felt.

Insulation is required not only for horizontal surfaces, but also for the vertical parts of the slabs - for example, their ends. It is these elements that are most exposed to frost during the cold season.

To prevent a negative effect, construction waste is used (you can fill the brick fragments remaining after construction into the holes in the ends). The holes are then filled with solvent. The space between the end and the masonry is also filled with insulating material, the role of which can be played by mineral wool, basalt insulation and polystyrene foam.

Methods for insulating a concrete floor

Insulation of a concrete floor on the ground floor can be carried out both from above and from below the ceiling. The most commonly used method is from above. You can understand why this is so by considering the disadvantages and advantages of each of them.

Insulation of concrete floors from below (from the basement or underground)

Advantages of bottom insulation:

- high efficiency;

- protection of the concrete floor structure from freezing;

- Condensation is expected to occur from the basement side;

- does not reduce the height of the room on the ground floor when clean;

- The base for the flooring is a durable concrete slab, rather than porous insulation.

Insulation of a concrete floor from the cold air side is more efficient, but in the case of a horizontal structure it becomes more complicated. It is quite difficult to carry out work in a low technical underground, constantly raising your head up. Because of this drawback, in the vast majority of cases, the floors in the house are insulated from the warm air side.

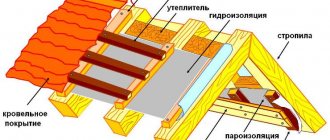

Pie of foam insulation on a reinforced concrete slab

Insulation over the ceiling has the following features:

- the dew point (condensation) is located inside the floor structure;

- the supporting structure is not protected from freezing;

- in addition to the vapor barrier of the insulation on the warm air side, waterproofing will be required on the cold air side;

- it is necessary to install a reinforced cement-sand screed on top of the insulation;

- The clean height of the first floor premises is significantly reduced.

Currently, screed reinforcement can be avoided by using insulation materials with increased strength, specifically designed for use in floor construction.

Cracked structure

Sometimes during construction it is discovered that the floor slab has cracked before it has even been laid. The cause of such a defect is improper storage or transportation. This building material must be stored in a certain way, observing the basic rules.

Structural elements must be stacked without touching the ground. Under the lower one, you need to place a non-wetting and non-rotting base, high enough and strong enough. It is advisable to lay the slabs in a horizontal position and install spacers made of wooden slats between them. The distance from the slats to the edge of the product should be 20-40 cm.

If all the necessary conditions are met, with a solid base, the stack can have 8-10 rows, but should not have a height of more than 2.5 meters.

Materials for insulating concrete floors

The most common thermal insulation materials include mineral wool and expanded polystyrene . Recently, spray-on compounds have begun to gain popularity as an additional layer in a private home. When choosing an insulating material, more attention should be paid to the purpose of the room and the planned loads, since their thermal insulating properties are almost the same.

Features of using mineral wool

Manufacturers produce slabs designed specifically for floor insulation that are highly durable. Mineral wool has the following advantages:

- Resistant to high temperatures and fire.

- Vapor permeability.

- Resistance to fungus, mold and other microorganisms.

It is important that mineral wool is not highly resistant to water, so its use in wet areas is not recommended. When wet, the insulation sags and loses its useful properties.

Mineral wool is a soft material, so it is best to lay it between joists so that the insulation does not take on the load.

Insulation of the ceiling from above (a special case with logs)

Depending on the source raw material, mineral wool is divided into:

It is important to take precautions when working: small particles of material can enter the lungs and skin and cause health problems. When working with mineral wool, builders must be provided with protective clothing, gloves and masks.

Types of expanded polystyrene and its application

The cheapest option for insulation in a private house on the ground floor, not counting the simplest materials such as expanded clay, is polystyrene foam . It is highly efficient and resistant to moisture, but has its drawbacks:

- If the wetted foam is exposed to low temperatures, it will crumble into small balls and cease to perform its function.

- The material has a fairly low strength, so when insulating the floor, a reinforced cement-sand screed is used over it.

- Polystyrene foam is a moderately and slightly flammable material and, when burned, releases substances harmful to humans.

- Use with caution in damp areas.

Many of the disadvantages of foam insulation are avoided by the use of extruded polystyrene foam . In appearance it is similar to polystyrene foam, but differs in manufacturing technology.

What are the requirements for floors?

The question of whether it is necessary to insulate the attic can be answered positively. Yes, this is far from an unnecessary procedure. But usually the floor of a cold attic is insulated. That is, in cases where the roof was laid without a heat-insulating layer.

In other words, if the roof itself is warm, it can protect the premises from the cold. But if you just have a sheet roof, or materials without insulation, then insulating the attic floor will be the right decision.

In some cases, both the roof itself and the floor at the attic level are insulated.

A good and inexpensive solution would be to install roofing sandwich panels that will protect and insulate the roof itself. But additional care needs to be taken about insulating a cold attic. Roofing is one thing, but flooring is another area of work.

There are certain requirements for floors. The main one is sufficient strength. It is important to eliminate the possibility of the coating sagging under the weight of objects that are planned to be placed and stored in the attic for a long time.

The deflection norm is considered to be no more than 1/200 of the span. The maximum load per 1m2 is 105 kg.

Another point is related to fire safety. This parameter is related to the materials from which the ceiling is made. And each option has its own characteristics. For example, untreated wood will withstand no more than 5 minutes of exposure to flame. And concrete about 1 hour.

Therefore, when using wood, it is necessary to treat it with fire retardants and antiseptics.

And the last urgent requirement is the ability of the ceilings to trap heated air and not let it out of the house. In this case, proper insulation will help.

Laying insulation

Before starting work with polystyrene foam, you will need to prepare all the necessary tools. For installation you will need:

- knife for cutting material;

- glue;

- polyurethane foam;

- foil polyethylene as a vapor barrier;

- metal tape for gluing polyethylene sheets together.

How to insulate a concrete floor on the first floor correctly? It is important to carefully prepare the base for the insulation and clean it of dust and dirt. Depending on the type of flooring in the house, sometimes thermal insulation material is laid between the ribs of a wooden or metal frame. After installation is completed, a cement-sand screed .

And this video shows the process of installing polystyrene foam screeds:

Tools and materials needed to work with mineral wool :

- waterproofing (for example, durable polyethylene film);

- vapor barrier (for example, vapor barrier membrane);

- tape for gluing joints of film and membrane materials;

- tool for cutting insulation boards.

Insulating a concrete floor in a house requires a careful approach, the correct choice of insulation and adherence to the technology for its installation. Working with expanded polystyrene is much easier than with mineral wool, and it protects no worse. Costs at the construction stage will easily pay off during operation (savings on repairs and heating).

In this video, experts talk in detail about all the nuances that you need to keep in mind when installing a floor.

Buildings with reinforced concrete floors, regardless of purpose and number of storeys, require insulation. The thermal characteristics of the structure will depend on the quality of thermal insulation and the choice of insulation.

You can insulate floors made of reinforced concrete slabs yourself, following a proven algorithm.

What types of floors are there?

Before insulating the attic in a house with a cold roof, you need to determine which design option you are dealing with.

The main criterion for classification is the material of manufacture. And here there are 2 main options.

- Concrete (reinforced concrete)

. Such bases are made in the form of a monolithic base or hollow slabs. The structures are durable and also fire resistant. But installation is more complicated. Walls are subject to increased strength requirements. Special equipment required;

- Tree

. Usually these are beams made of timber, logs or large boards. No equipment required for installation. The wall requirements are below. Therefore, this option is most often chosen in private construction. Let's talk separately about insulating the attic floor using wooden beams.

Thermal insulation material is laid on top of the base, and then the final stage occurs. This is the finishing. And that's it, the attic is ready.

Where to start installing thermal insulation

It is correct to begin insulation by sealing seams and joints in the area of the ends, grinding the surface of the slabs and seams. A layer of vapor barrier material is mounted on a smooth, treated surface, and only after that the insulation is attached.

An important point is the calculation of the thickness of the insulation for reinforced concrete floors. The easiest way to do this is to use a free online calculator by entering the required values. It is possible to calculate the required thickness manually using formulas, but the process will take more time, and in this case, errors are possible.

The functionality of the thermal insulation layer will depend on how correct the thickness of the insulation is. An erroneous choice in favor of a thinner covering material than required will lead to increased heat loss and shorten the service life of the insulation layer.

If it is not possible to buy insulation of a suitable thickness, you can use an alternative method - lay the thermal insulation in half, keeping the joints staggered.

Upon completion of the work on installing the heat-insulating layer, it would be correct to proceed to one of the final stages of insulation - a cement screed with a reinforcing mesh with 10x10 cm cells. After drying, the finished surface is leveled with a special leveling compound and protected from moisture with waterproofing mixtures. The finished screed is covered with floor covering. It could be:

- linoleum;

- laminate;

- carpet;

- parquet board or parquet, etc.

To ensure reliable and durable insulation, it is important not only to follow the work algorithm, but also to choose the right insulation. What options are suitable for insulating reinforced concrete floors and why? More on this below.

Fixes

Of course, it is always better to prevent a problem than to correct its consequences. But if measures were not applied on time and freezing nevertheless began, you need to start correcting the mistakes as quickly as possible. There are a number of different methods for correcting wall freezing problems.

Depending on the reasons and locations

Floor slab laying diagram.

The appearance of dampness and black spots in the area of the top floors, as a rule, occurs if the installation of attic floor insulation is insufficient or poor quality. First of all, defects in the joints between the slabs are eliminated, which reduces the appearance of moisture on the internal walls. Typically, expanded clay is used as insulation in attic floors. According to the standards, for its productive action it must be at least 30 cm.

Be sure to check if there are any problems with the ventilation of the attic space. The lack of high-quality air exchange leads to the appearance of condensation and overcooling of the floor slabs. Check the roof for leaks. Problems can also arise due to poor-quality sealing of joints in walls and balcony slabs. Moisture can get into the joints between the wall and the slabs, causing damp spots. You should dry the walls as soon as possible and seal any moisture ingress.

If the gap is no more than 8 cm, then polyurethane foam can be used. To use it, you must first clean the edges of the crack from concrete crumbs. Polyethylene and silicone surfaces require additional treatment with acetone. The foam hardens within 24 hours. Then the excess foam must be cut off, using a utility knife, and the surface should be plastered, thereby closing the bridge of cold. If the gap at the joint is more than 8 cm, then you will have to use thick cement mortar.

Check the effectiveness of balcony drains. If the sealing of seam joints is broken, it is best to re-seal it using newer and higher quality materials. The strength of the building structure largely depends on the quality of filling of the joints. Proper sealing should be carried out only after thorough surface preparation:

- repair the external surfaces of wall panels;

- dry all wet and damp areas;

- Remove all damaged sealant before applying a new coat.

Under no circumstances should mastic be allowed to be applied to wet and untreated areas. It is best to carry out joint repairs in above-zero and dry weather. If an imbalance in the thermal protection of walls is detected, insulation should be addressed by expanding them.

How to insulate and what is the choice of insulation based on?

To insulate reinforced concrete type floors, you can use wooden flooring on logs made of timber with optimal cross-sectional parameters of 50×50 or 120×120 mm. To increase the level of sound insulation, the logs are additionally attached to small rubber pads fixed to a reinforced concrete base. A layer of insulation for insulation is laid between the joists, and a wooden floor is mounted on top.

Materials for thermal insulation of reinforced concrete floors are selected with high levels of resistance to mechanical stress. These must be strong, reliable insulation materials that are not subject to deformation due to temperature changes. Mineral wool-based materials are better suited for these purposes than others. They are practical, resistant to various kinds of tests, and durable.

Mineral wool insulation is produced additionally using the following materials:

Also, manufacturers of budget insulation options allow the addition of sedimentary rocks and industrial waste to the overall composition.

There are several options of mineral wool slabs available in the market. These can be soft, hard, or slabs with increased rigidity. The main advantages of the material include:

- low level of thermal conductivity (the slabs have a special fibrous structure with an air layer that prevents heat loss);

- excellent sound insulation;

- resistance to moisture;

- vapor permeability;

- resistance to fire, chemicals and mechanical damage;

- durability;

- safety.

Wall freezing factors

Installation diagram of a reinforced concrete floor slab.

- Incorrect filling of joints between slabs. Poorly filled seams lead to a violation of the heat-insulating properties of the floors. Increases the chance of cracks forming. Through them the stove absorbs moisture.

- Poor quality solution in the production of products. Choosing cheap or diluted solutions results in frequent moisture penetration. They usually have a very loose structure and cannot withstand pressure.

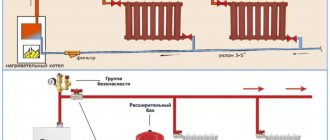

- Errors in the design of the heating system. Poorly heated rooms are much more susceptible to frostbite on the walls. After moisture accumulates, they begin to freeze both on the outside and on the inside.

- Subcooling of metal reinforcement elements and anchors. When various cracks appear, moisture begins to enter the metal components of hollow core slabs. As a result, corrosion may occur. The structure of such slabs softens and is more susceptible to decay from low temperatures.

- Exhaust pipes collect condensate. With weak draft, moisture accumulates inside the exhaust pipes, which leads to their freezing and reduced efficiency. At the same time, poor air circulation contributes to the accumulation of unnecessary moisture.

- Small wall thickness. The thickness of the walls is not taken into account for their use in the climatic conditions of this region.

- Low thermal qualities of the materials used. When choosing materials, the scales generally tip towards strength, while often when installing insulation, the low level of thermal insulation is simply not taken into account.

- Insufficient cross ventilation. In poorly ventilated rooms, the outer walls freeze much more strongly, losing their heat-shielding properties. Unsatisfactory internal waterproofing between the wall and the insulation leads to freezing of the outer surface, and then to the destruction of the masonry.

- Foundations with poor waterproofing, especially in houses without basements.

- Violation of the vapor barrier structure in attic floors. Poorly executed thermal insulation of the ceiling transfers its functions to the cement screed. The concrete surface collects moisture, accumulating condensation, and moisturizes the insulation. The heat-protective material begins to lose its original properties, which are significantly reduced, as a result of which the floor slabs begin to freeze. The insulation also increases its weight due to the accumulated liquid.

- Often flooded basements.

- The blind areas are made incorrectly or are missing.

- Vertical waterproofing of basement walls was done incorrectly. Low air circulation leads to mold and condensation.

- Poor compaction of concrete during production. The frost resistance and water resistance of the structure of manufactured hollow core slabs depends on the quality of concrete compaction. A poorly compacted compound becomes too porous and the protection of the substrate is significantly reduced.

- Installation of insufficient thickness of the finishing layer.

By saving on the finishing layer, you can end up with global destruction.

When the air temperature fluctuates, the cladding gradually crumbles, reducing the wall's protection from getting wet and frost. And as a result, the strength of the entire structure is compromised, increasing the chances of emergency situations.

How to insulate a concrete ceiling

Houses that were built 20-30 years ago were designed taking into account maintaining heat in the house with excessive consumption of thermal energy . This is due to the fact that gas and electricity were cheap, and therefore the requirements for thermal conductivity of building panels were low. But the times of cheap energy consumption are over; houses still operate with heat losses, for which the owners pay.

The natural desire to reduce heat loss is to insulate the building . There are enough methods and materials for this.

But if putty is supposed to be applied over the material, this condition is not necessary.

In the course of the work that you will now see, decide what tool and material you need.

1. Preparing the ceiling. Remove the peeling plaster, seal the cracks and cracks with cement mortar. Apply two coats of primer perpendicular to each other.

2. Leveling the ceiling : using a thin layer of putty if the ceiling is flat, or immediately after priming, level the ceiling with a 50 x 50 or 50 x 70 mm beam along the location of the slabs and at a distance so that the joint falls on the central axis of the beam.

The primer is applied with a roller or brush. If the ceiling is smooth and covered with a thin layer of putty, then make notches with a spatula, clean it and prime it with a spray bottle: this additionally blows away dust from the ceiling, and the primer under pressure penetrates deeper into the pores of the concrete slab.

3. Then apply a sheet of insulation , mark the boundaries of the sheet and apply a layer of 1-2 mm KNAUF Sevener plaster-adhesive mixture and smooth it with a comb spatula.

4. Glue the sheet .

On the second and subsequent sheets at the joints, apply glue , apply it and try to ensure that the panel fits tightly to both the ceiling and the panel, without leaving a gap. Then we fix each panel with plastic umbrellas in the corners and center of the panel with 75 mm self-tapping screws. The umbrellas should be slightly recessed into the surface of the panel, and the recesses should be leveled with the mixture. Then we prepare the surface for reinforcement with rolled mesh. The mesh width is 1 m, apply a layer of glue to the foam from wall to wall.

5. Apply the mesh to the putty. Glue and iron with a spatula.

6. After reinforcement with mesh, putty is applied with a mixture of “Knauf Finish” . This work is done by master finishers. After complete drying, grout the entire surface of the ceiling with a special board with mesh No. 120.

7. Next work is carried out: wiping the ceiling from dust with a damp sponge, applying a primer to reduce paint consumption. Painting with latex paint. And this is what ended up happening.

- has been soundproofed . A damping layer of putty is applied between the ceiling and the foam;

- The ceiling was insulated with 20 mm thick foam plastic;

- The ceiling is painted with moisture-resistant paint. This means that the insulation is protected from moisture.

Sealing joints

A joint or rustle is where the long sides meet. To obtain a strong and solid ceiling, all rustications must be filled with mortar. Round-hollow flooring materials have locks on the sides, which look like round recesses. During the process of pouring rustications, the recesses are filled with concrete and the slabs are securely connected to each other.

Sometimes you come across defective products that have incorrectly made sides with locks. When they are connected, the notch is at the bottom, and the top fits tightly together. As a result, it seems that it will be difficult to fill such rust with concrete. In fact, the scheme of operation is quite simple. To repair defective rust, it is necessary to connect the ceiling elements not end-to-end, but to leave a small gap - 2-3 cm. It should be located in the upper part. At the bottom, along the length of the rustication, you need to tie up a wooden board, which will serve as formwork for pouring concrete. The solution, which is not thick in consistency, is poured into the rustication through the upper gap. After the solution has hardened, the work can be considered completed.

Insulation of the ceiling in the basement of an apartment building

The choice of insulation method depends on the purpose of the basement:

- Premises for storing agricultural products;

- Placement of heating and plumbing equipment;

- Arrangements for gyms, billiard rooms;

- Premises for other purposes.

Of these, it is necessary to designate: heated and unheated basements. This is important for residents of the first floors of apartment buildings. As a rule, residents insulate concrete floor slabs with basements by installing additional thermal insulation on the floor side . It is not only effective, but also cheaper.

In most cases, it is necessary to open the floors down to the cement screed and eliminate defects (potholes, cracks); You can additionally pour a thin layer of self-leveling cement mortar, and after hardening, make a substrate from the thermal insulating material Parkolag from ICOPAL - a Finnish thermal insulating substrate for laminate, linoleum, parquet.

This substrate is laid on a flat surface of a cement screed without waterproofing or vapor barrier, because the bottom layer of the substrate has micro-gaps with the floor and this achieves ventilation between the laminate and the concrete floor.

In another case, storage facilities for agricultural products . In addition to maintaining a certain temperature, such cellars must be dry so that the food lasts longer. Warm air, rising upward, encounters a barrier in the form of a cold cement slab, where it cools to the “dew point” on its surface and falls in the form of droplets from the ceiling. To prevent this from happening, you must prevent warm air from coming into contact with the stove. Installing ventilation with temperature control will solve this problem, but we need to look at what energy consumption occurs.

A simple “vent” device, natural ventilation , directs the convection flow in the desired direction and prevents air vapor from depositing on the surface of the slab. Another thing is maintaining the temperature. This is where it is necessary to insulate the ceiling, and possibly the entire basement room, in order to increase the temperature inside. The insulation method is not new - it is the same as for walls:

- Additional beams are attached to the ceiling, from wall to wall: an edged board 20 mm thick and 100 mm wide, impregnated with an antiseptic solution, is attached to the ceiling with an edge using corners along the entire length with a distance of 50-60 cm between each other.

- The junctions with the ceiling are foamed with polyurethane foam. Between the beams prepared in this way, roll insulation is laid, then a vapor barrier is fastened with a stapler, and the seams are taped.

- Then a spacer strip 10-15 mm thick is nailed along the beams.

- They cut sheets of gypsum board or gypsum board "Knauf", you can use moisture-resistant plywood and sew them to the slats.

You can use a stainless metal profile, attaching it to the ceiling on hangers and also laying thermal insulation with subsequent filing of gypsum boards.

Wall insulation options

For example, using a layer of brickwork you can clad the outside of a wall. This can be done without special skills. For this you will need:

Wall insulation scheme.

- bricks;

- level, tape measure and order, if the wall needs to be built high;

- sand-cement mortar in a ratio of 4:1 or adhesive mortar for masonry;

- drill with mixer;

- trowel and solution container;

- access to electricity.

You can also insulate the walls with plaster insulation on reinforcing mesh. To do this, use dowels to install the reinforcing mesh to the wall. The latter does not have to be metal. Plaster is applied between the wall and the mesh and on top. This can be a cement mortar or a ready-made dry mixture for wet rooms. Moisture-resistant solutions are more expensive, but last much longer than usual, since they have special additives in their composition.

Another of the highest quality methods is the installation of vapor barrier material and insulation on the inside of the concrete wall. Installation is carried out by installing a frame lined with tiled insulation. To make such a frame and fill the distance with insulation between the wall and the finishing material, you can use various fasteners and hardware. These can be mounting brackets, plastic “fungi” dowels, and glue, both in finished form and in the form of a dry mixture that requires preparation. After that, be sure to finish it with plaster or any other finishing material.

Materials for frame and insulation:

- metal profiles or wooden slats;

- screws for metal or wood;

- sealant and polyurethane foam;

- vapor barrier membrane or aluminum foil on isofilm;

- sheet insulation, mineral or fiberglass wool;

- dry mixture for plaster.

Tools for installing the frame and insulation:

- grinder with circles for cutting metal or special scissors;

- drill with mixer attachment;

- screwdrivers or screwdriver;

- tape measure, level and pencil;

- spatulas and graters for grinding;

- solution container.

Scheme for insulating the wall of a frame house.

Between the frame and the wall you need to leave a space of about 50 mm and fill it with expanded clay. This material will perfectly absorb remaining moisture from the wall and stop the appearance of mold. Thus, the wall thickness increases by 150 mm. There are 80 mm foam blocks that successfully replace such frame structures. Installation is carried out using ordinary cement-sand mortar (1:4).

On particularly cold and damp walls, you can install a system called “warm floor”, or install a warm baseboard around the perimeter. This solution is best suited for corner rooms. When choosing a method for heating walls, the most suitable option is electric film or infrared flooring. You should not install it yourself. To heat the seam under the baseboard, you can use a heated floor, where a cable is used as a heating element.

Installing a stationary wall-mounted electric heater will not completely solve the problem of poor-quality insulation between the slabs, but you can install it yourself.

For this you will need:

- drill or hammer drill;

- anchors or dowels;

- hammer;

- socket.

Whatever the reason for freezing of hollow core slabs, it is necessary to significantly reduce the humidity in the premises, be sure to check the efficiency of the ventilation and monitor the quality operation of the heating system. All work to repair the building and eliminate the causes of freezing should be carried out carefully and accurately. If you forget about some detail, you risk encountering this problem again, and very soon.

Insulation of a concrete ceiling in the basement of a private house

Additional rooms for various uses are being built in the basements of private houses. The insulation of agricultural product storage premises is similar to that for the basements of apartment buildings. It’s another matter when basements are insulated for the purpose of additional space for living activities.

Such rooms are usually always heated. Their heat is insulated when the basement is located under a terrace, garage or other unheated premises. The method of insulation is the same as for apartments with attic floors, if it is not possible to insulate from the outside.

Prevention measures

To protect floor slabs from freezing, you need to take the following measures:

Diagram of a floor slab with waterproofing.

- Carefully and airtightly fill the space between the plates.

- High-quality installation of joint sealing must be waterproof (thanks to sealing mastics) and heat-protective (using insulating bags). With air protection, the distance between the plates is filled with sealing gaskets. The compression of the material of such gaskets should be at least 30-50%.

- Monitor and check the operation of the building ventilation as often as possible.

- Poor indoor air circulation contributes to long-term drying of thermal insulation layers, accumulation of excess moisture and the appearance of mold. The heaving soil under the foundation and the walls of the basement should not be allowed to freeze, and the air temperature on the basement should not be allowed to drop below zero.

- If the building does not have a basement, then it is necessary to install horizontal waterproofing between the ground and the surface of the basement.

- Increase the layer of thermal insulation on the attic floors.

- Maintain blind areas and drainage devices in good condition. Reducing the likelihood of freezing of hollow core slabs depends on the efficiency of their work.

- During the first 3 years of operation of the building, it is necessary to clean the drainage systems at least twice a year, and subsequently - once every three years.

- Carry out drying on damp areas of the walls without worsening their condition.

- Try to reduce humidity in rooms with poor ventilation. In any room, air humidity should not exceed 60%.

Insulation of a concrete ceiling in a private house

If it is possible to insulate the ceiling from above, then the scheme is as follows.

On the side of the heated basement, in order to preserve heat, it is recommended to insulate the walls , and the ceiling is more insulated for sound insulation purposes, so high-density foam plastic is attached to the ceiling with an adhesive solution. Extruded polystyrene foam (XPS) boards can also be attached. This material has a dense structure and high thermal insulation and sound insulation properties.

In addition to the above methods, a more expensive method may be suitable - applying a polyurethane foam (PPU) layer to the insulated surface . Without special equipment, high-quality components for foam formation, mixing and application technology, it is impossible to make thermal insulation yourself.

So, to successfully insulate your basement, determine the cause of heat loss, the location of the leak, and the formation of condensation in the insulation.

The situation urgently needs to be corrected. For questions regarding thermal insulation of basements, please contact specialized construction organizations . A specialist will determine the method of thermal insulation of a particular room. Additional waterproofing or installation of drainage systems may be required. This will be determined by a specialist from a company engaged in complex work on thermal insulation and ventilation of premises. Only a professional approach to this problem will reduce the costs of this work.

Laying with insufficient width

Floor slab installation diagram.

During the process of laying slabs, it may turn out that the dimensions of the room do not correspond to their dimensions. As a result, gaps appear between the floor elements or between them and the wall. There is a simple solution to this problem.

The size of the gap must be divided into two equal parts. In this case, the first slab is laid at a certain distance from the wall, which is equal to the width of one of the resulting parts. All other structures are mounted end-to-end. As a result, a gap forms between the slab and the last wall, where it is necessary to poke a cinder block. It is securely fixed, as it rests against the slab. You need to lay the cinder block so that its holes point to the sides, and not down or up. The outer wall of the building will additionally secure it. This design may not seem reliable at first glance, but in reality it is quite durable.

There is another technology for bridging the gap, when its size is distributed between the plates. Then, under each gap, a board is tied, which acts as formwork, into which reinforcement is laid and concrete is poured.

Work order

- First of all, you need to remove the old thermal insulation (if any), thoroughly cleaning the room from its remains.

- The under-roof space should be dried, so it is better to carry out work on warm, dry days.

- Load-bearing structures are checked for damage and areas of rot. If necessary, replace or clean with fire-bioprotection treatment.

- If the beams are located below the ceiling plane or far from each other, install additional ones.

- Wooden structures must be treated with antiseptic and fire retardant impregnation. It is more convenient to do this using a spray gun. You can also use a garden sprayer. The impregnation must dry for at least the time indicated on the packaging.

- The vapor barrier is laid over the entire area of the ceiling of the underlying room, with an overlap of 100-150 mm. A construction stapler is used for fixation, and the joints are carefully taped with Paranet vapor barrier tape. Along the perimeter, the membrane should be placed (overlapping the walls with sealant) onto the enclosing surfaces by 200 mm.

- The first layer of Izover Profi thermal insulation is rolled out.

- The bars of the second tier are attached to the lower logs, perpendicular to them, in increments of 600 mm.

- The next layer of insulation is laid.

- For the convenience of carrying out repairs and inspecting the under-roof space along its perimeter (or crosswise through it), you can lay transitional walkways from OSB, gypsum fiber boards or analogues.

- If the attic is used (that is, with a floor), then a ventilation gap of 50-100 mm should be left above the mineral wool. If necessary, you can protect the mineral wool from debris and spills of liquids by covering it on top with Vetranet hydro-wind protection. it allows the material to “breathe”, evaporating excess moisture (be sure to ensure the tightness of the underlying vapor barrier layer).

Insulation carried out in accordance with the requirements of the technology will reliably protect the house from heat loss and, in the presence of heating and sufficient ventilation, will make staying in it comfortable all year round.