By properly insulating the floor under a concrete screed, you can significantly save on space heating. This is much more effective than installing expensive heating systems, which negatively affect not only the budget, but also the natural microclimate of the premises. Heat loss through the floor, depending on its design, can be up to 30%. In addition, a cold coating provokes the growth of fungus and mold, causes a constant feeling of chilliness and is dangerous for small children who spend most of their time on it.

Rough screed using beacons

If the screed is made with a cement-sand mortar, then metal beacons are required, which are shown, and their installation in the room is shown.

The beacons are installed along a horizontal line previously drawn for the subfloor. To level them horizontally, use a ruler-level and place the same solution under them as for the screed. The distance between the beacons determines the length of the rule with which the solution will be distributed between the beacons. However, in the absence of experience, this distance should not be greater than 1.5 m. Composition of the solution: 1 part M300 cement, 3 parts sand, 1/10 part lime paste. Water must be added in such an amount that the solution is thick and does not spontaneously spread over the surface. No more than 2 hours should pass from preparing the solution to its use.

The ready-made mixture for screed can be purchased at a retail chain; it is prepared according to the attached instructions.

https://kuhnyamoya.ru/youtu.be/Jtw7-0XAyQo

Lay the mortar with a shovel, starting from the wall. Liquid cement is first applied to the surface. The solution should rise slightly above the beacons and occupy an area of approximately 1 m2. Distribute the solution, removing the top layer, using the rule rack shown. The lath near the wall is removed, the place is filled with mortar, smoothing it with a trowel. The areas of the beacons to be removed are also filled with solution.

The hardening time of the screed is approximately 1.5 days. After that, you can walk on it, but you can lay the insulation on the rough screed in a week.

If in a newly built house the concrete floor of the room does not require leveling, then the subfloor is not made. It is enough to properly seal the cracks, remove debris from the floor and wipe with a damp cloth to remove dust.

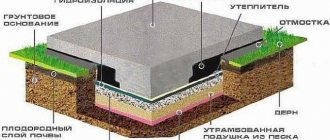

If insulation is done during the construction process, then there is no need for all the operations described above. Polyethylene film is laid overlapping on the concrete slab, sealing its joints with tape. Then the foam is laid and waterproofing is placed on top of it again.

Next, a reinforced cement screed is made. The dimensions of the reinforcing mesh are 100×100 mm or 150×150 mm. If the thickness of the screed is no more than 5 cm, then the mesh must be raised so that it does not touch the waterproofing.

https://kuhnyamoya.ru/youtu.be/RRaZfW17rNw

Thus, if insulation is done during the construction of a house, then it is not difficult to complete this work yourself. It is much more difficult to insulate the floor in an already built house, especially if it was built a long time ago and has shrinked a lot.

How to lay insulation on the concrete floor of the first floor?

First of all, the base under the insulation is thoroughly cleaned. Sometimes, depending on the type of flooring, thermal insulation material is placed between the ribs of a metal or wooden frame. When the installation is completed, a cement-sand screed is made on the insulating material.

When insulating a concrete floor in a private house, you need to choose the right insulation and strictly follow the technology for its installation. Expanded polystyrene is much easier to use than mineral wool, and the protection against it is no worse. During the construction phase, there will be large expenses, which will more than pay for themselves during operation - you will save on heating and repairs.

Expanded clay as insulation

This insulation is filled in and porous. It has been used for a long time. This material is easy to install. Expanded clay chips are placed on the prepared surface. The thickness of the embankment is 150-300 mm. Beacons are installed at a distance of a maximum of 80 mm from each other - this is necessary for precise insulation of the floor at the desired level.

In order to simultaneously carry out waterproofing, a polyethylene film is applied near the wall. You can install an insulated floor using a more progressive method - using a screed. Then the film is not used, because the layer is made only from a binder solution and water. This makes it possible to protect the structure from moisture.

Isolon as a method of arranging thermal insulation

This material can easily be used to insulate the bottom of a concrete floor in a private wooden house, and in this case roll materials are not required. Izlon is a foil material. It is laid on a concrete surface, directly on the insulation or on the attic wooden floor. The waterproofing seal is glued to the main structure.

It is moisture-proof, but a small gap is left before the coating for ventilation purposes, which will prevent the material from shrinking. To form such a cavity, the bars must be laid at a distance of 0.5 m from each other. The material is glued, after which the remaining layers containing foil and logs are mounted. To ensure that the floor always remains warm, a heating system is laid on the surface along the izlon.

Floor insulation with foam

The method eliminates the use of other insulation materials, since only foam insulation allows for maximum leveling of the floor surface. The foam will not shrink even after several years, since during its installation the beacons are first built by assembling guide profiles. Then foam is applied and the remaining layers of the floor covering are laid, thus thoroughly insulating the floor.

If you need to install thermal insulation for an already completed floor covering, then the production time and the amount of work are reduced. The structure is disassembled, foam is sprayed, and the top layer is installed on it as it swells. For partial repairs, without disassembling the structure, two or three boards are lifted and foam is poured under the floor.

Safe material – ecowool

A special dispenser allows for uniform application of ecowool when sprayed. This is a significant reason for specialists to recommend this material. It can also be laid manually if the amount of work is small. In this option, material consumption increases by as much as 50%.

After unpacking the material, it is placed in some container to be fluffed with a special apparatus. We must not forget that ecowool increases in volume. Then it is laid on the floor surface. It is worth noting that during the application process it is necessary to pause before laying the last layer of flooring - wait for a crust to form.

Floor insulation with polyurethane foam

This material is used if it is undesirable to allow the formation of thick seams or if it is necessary to cover the attic. Polyurethane foam perfectly stops the formation of condensation and prevents moisture from seeping through. In a short time it is possible to cover the entire floor at once, because all the ingredients are supplied only in liquid form.

To insulate a concrete floor in a house with high-quality polyurethane foam, it is necessary to calculate the loads acting on the base. The material is laid according to the rules for maximum longevity. Polyurethane foam does not have the ability to evaporate, therefore it is absolutely harmless to humans. It does not rot, does not mold.

To insulate the floor in a private house yourself, it is worth foreseeing in advance the loads that affect the design of the coating. The type and thickness of the insulation material is determined in accordance with the methodology - only in this way can the desired results be achieved when insulating the floor in a private house.

Advantages of polystyrene foam as floor insulation

It is popular to use polystyrene foam for heated floors because it has the following advantages:

- Excellent heat insulation and frost protection

. The thermal conductivity of the material is low due to its porous structure. In this regard, polystyrene foam perfectly retains heat in the room. - Good sound insulation

. The material absorbs both sound waves coming from the room and those coming from outside the building or its lower levels. The insulation layer reduces the level of vibration of the ceiling. - Fire resistance

. Polystyrene foam does not burn when exposed to direct fire, and to be more precise, it instantly extinguishes. It is worth noting that even during the shortest period of combustion, harmful volatile substances are released that pose a danger to the human body. It is not recommended to use such insulation in industrial facilities with an increased risk of fire. - Resistant to exposure and moisture penetration

. The resistance of polystyrene foam to moisture is very high, since the material does not absorb water. When using it, you can refuse to install waterproofing. - Long service life

. Foam sheets do not deform and are resistant to subsidence and rotting during operation.

Based on the foregoing, we can conclude that polystyrene foam is a universal material and can be used in the construction of a wide variety of buildings. Floors treated with foam plastic are reliably protected from the effects of cold air masses.

When using such insulation, floors do not lose their strength and reliability, which means that the presentability of the selected finishing coating is not affected. The owner will be pleased to present his home in a photo and personally show it to guests, who will be surprised not only by the appearance, but also by the warmth of the floors.

How to choose insulation for floor screed

It has been verified that the insulated floor is not only very comfortable to use, but also practical. In order for it to serve as long as possible and the result to meet expectations, it is necessary to choose the right insulation for the floor screed.

The main purpose of insulation is to prevent cold from entering the room (in this case from below). By using insulation, a reduction in the cost of heating a room during the cold season is achieved.

Insulation process

To secure the thermal insulation material, it is best to use glue, especially for floating floors. When using glue, the risk of damage to the material is minimized. The glue should not be ordinary, but special, made specifically for the material used. The insulation must be laid as evenly as possible, and after applying the glue, press it carefully and wait a certain amount of time so that they have time to set.

Preparing the adhesive mass will not be difficult - just follow the instructions supplied with the product. To dilute the solution you will need a construction mixer. You can also use an ordinary drill, only in this case you will need to install a “mixer” attachment on it.

The process of insulating the floor under the screed begins not with the placement of slabs of material, but with the formation of sides along all four walls. They are made from the same material with which you will insulate the floor.

After this, it is necessary to accurately determine the height of the screed, taking into account the thickness of the insulating material. The sides mentioned above are installed precisely at this height.

If you use material in the form of slabs to insulate the floor under the screed, then they must be cut to the required size. These pieces are laid over the entire surface of the floor. At the same time, carefully ensure that the material is in good contact with the sides in the corners.

Thus, anyone can insulate the floor under the screed with their own hands. The main thing in this matter is to follow the sequence of actions and existing rules. Then you will be completely satisfied with the result, and your home will always be warm and cozy.

What types of insulation are there, their pros and cons

There are several types of floor insulation, each of them has advantages and disadvantages.

Based on their characteristics, as well as the characteristics of the premises in which they will be used, it is necessary to select a material for insulation.

You should start with the most common, well-known, but impractical and ineffective material - glass wool. It is rarely used for insulation of domestic premises; it is better known as thermal insulation for industrial purposes. Main disadvantages: absorbs moisture, which subsequently destroys its structure; elements in its composition cause irritation of the skin upon unprotected contact.

It may be interesting: How to insulate a floor with your own hands, detailed instructions.

The next stage in the development of insulating materials was mineral wool. It has characteristics similar to glass wool, but is more adapted for use in domestic conditions, although it belongs to the same group of insulation materials. It has a fibrous structure. The advantages include ease of use and a wide range of temperatures that the material can withstand from -60º to +450º C. The disadvantage is the ability to absorb and retain moisture.

Because of this, mold, mildew, and insects can form. The following materials have similar characteristics and structural structure:

- Slag;

- Stone wool.

This group of insulation materials is not recommended for use in rooms where moisture collects or there are prerequisites for its accumulation.

Expanded clay can be considered the next stage in the development of thermal insulation technologies. But it costs somewhat separately from other materials, since it is an additive. It is mixed with concrete.

Expanded clay is made mainly from clay; crushed stone, screenings, sand, and gravel can also serve as a base. Special technologies and equipment are used to produce the material. The final product has the form of pellets ranging in size from 5 to 40 mm.

Expanded clay has no practical disadvantages; it has excellent thermal and noise insulation, is resistant to temperature influences, does not absorb moisture, and has a high strength index. The material has only one drawback - it takes a long time to completely dry. But this quality can be considered a minus quite conditionally.

Along with mineral wool, polystyrene foam is very popular. This material is very often used for insulation. The reason for this popularity is its low cost, as well as high performance of a number of characteristics:

- Light weight, which makes it easy to transport and install;

- The granular structure makes it easier to process foam sheets. This can be done with any cutting object, for example, a stationery knife;

- Excellent insulation performance;

- Long service life, resistance to destructive factors.

Due to this combination of characteristics, foam plastic is widely used for insulating surfaces, including floors.

Polystyrene foam also has its disadvantages. The main one is certain difficulties during installation and installation. To create the most even surface possible, it is necessary to pour a layer of quartz sand onto the rough screed, and after laying out the foam sheets, you need to look for areas of swelling (this occurs due to the curvature of the foam) and carefully cut them into pieces, eliminating the bulges.

Other disadvantages: the toxicity of the material and its flammability. But they are very conditional, since fire and dangerous emissions are prevented by a layer of finishing screed.

Penoplex can be considered the most advanced among all the listed materials. It is made of polystyrene and has a porous structure. The cells in it are evenly spaced, making the material very durable and has high thermal conductivity. The small cell size helps improve these characteristics. This material will be discussed in more detail below.

Extruded polystyrene foam for screed

Compared to polystyrene foam, polystyrene foam has high strength and greater density. The closed structural cells of the material give expanded polystyrene foam almost complete protection from moisture. The material is difficult to burn, which makes it possible to use it when insulating wood floors.

A layer of crushed stone is poured and compacted. Sand bedding is made and compacted. The base should be as level as possible on a horizontal plane. Sheets of material are laid out on the prepared base at intervals. The joints are sealed with tape. A layer of waterproofing is required. A reinforcing mesh made of metal or plastic reinforcement is laid over it. The floor base prepared in this way is poured with concrete mortar.

Penoplex insulation

Penoplex is a polymer insulation, the structure of the material is closed cells. It is thanks to the penoplex structure that the insulation has high moisture-repellent properties and has high compressive strength. In addition, the material is fireproof, which allows the use of a heat insulator for insulating wooden floors.

Penoplex floor insulation technology

Linoleum, tiles, laminate and other finishing materials can be used as flooring.

Before laying the insulation, it is necessary to thoroughly compact the soil, pour a layer of crushed stone and make a sand cushion. Penoplex sheets are laid on the base prepared in this way. The insulation must be laid in a checkerboard pattern, and all joints between the insulating boards must be taped. A waterproofing film is mounted on top of the heat-insulating layer and a reinforcing mesh is installed, which ensures the resistance of the floor to dynamic and static loads. A layer of leveling screed is applied on top of the structure, the thickness of which should be 4 centimeters. After the screed has dried, the floor covering is laid. Linoleum, tiles, laminate and other finishing materials can be used as flooring.

Before pouring the screed, a temperature gap should be created. It is necessary to lay a buffer tape along the entire perimeter of the room, and the gap between the screed and the wall should be about 1 centimeter.

Nuances of arranging a “warm floor” system

The water system is more complex to arrange. It requires not only the installation of pipes under the screed, but also the installation of special equipment designed to heat and ensure forced circulation of water.

Nuances of arranging a “warm floor” system

The heating system is installed directly on top of the thermal insulation material

It is important that the insulation has a foil coating, due to which more heat will be reflected into the room. If there is no foil barrier, it is recommended to lay it manually

The system is installed according to the instructions provided by the manufacturer. After checking its performance, you can lay a reinforcing mesh to strengthen the structure and begin arranging the screed. When using a “warm floor” system, the solution can be prepared without crushed stone, expanded clay and other fillers.

Insulation with polyurethane foam

Liquid thermal insulator polyurethane foam is an ideal insulation material for floor insulation

Liquid heat insulator polyurethane foam is an ideal insulation material for floor thermal insulation, since it is sprayed directly onto the surface to be insulated and does not require the creation of additional vapor and waterproofing layers.

Among all thermal insulation materials, polyurethane foam has the lowest thermal conductivity coefficient, which allows the insulation to be sprayed in a thin layer, significantly saving the usable area of the room.

Polyurethane foam has all the properties necessary to ensure high-quality thermal insulation of the floor. It is fireproof, environmentally friendly, chemically and biologically inert, and has high sound and moisture repellent properties. The high strength of the polyurethane foam layer allows you to apply a leveling screed on it without laying a reinforcing mesh.

The technology of spraying insulation makes it possible to easily and quickly insulate surfaces of even very complex configurations. The polyurethane foam thermal insulation layer hardens within 3-4 hours. Immediately after the thermal insulator has hardened, you can begin applying the leveling screed.

Using Penoplex

The name Penoplex itself is a brand. And the material itself is a high-density polystyrene board. For screed floors this is the best option.

- It has low thermal conductivity - 0.031 W/m K.

- It has a high density - 45 kg/m³, which affects the compressive strength. And for genders this is one of the important indicators.

- Does not absorb moisture.

- Does not allow steam to pass through.

- Chemically inert.

- Absolutely environmentally friendly.

- Easy to process.

Today, manufacturers produce foam boards with a tongue-and-groove connecting lock, which makes it possible to assemble a seamless coating on the floor base.

The process of insulation with penoplex is simple. It is necessary to lay the slabs over the entire surface of the concrete floor, connecting them together with a lock, then stretch the reinforcing synthetic mesh over the top, and only then you can pour the solution.

Estimation of the cost of screed with insulation

The only thing that will affect the cost of a poured floor screed with insulation is the price of the latter. Here are the prices for insulation materials that are used for thermal insulation of floor bases.

| Thermal insulation material | Characteristics | price, rub. |

| Mineral wool, m² | Thickness 50 mm | 75 |

| Expanded clay, m³ | Fraction 0-5 mm | 2400 |

| Penoplex, sheet | Thickness 50 mm. Dimensions 1200x600 mm. Density 30 kg/m³ | 170 |

| Penofol, m² | Thickness 10 mm. | 190-200 |

Extruded polystyrene foam

Expanded polystyrene foam is perfect for floor screeding, as this material meets all the requirements for high-quality insulation. Compared to polystyrene foam, it has better performance.

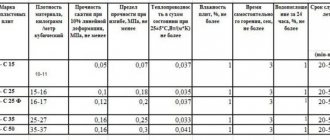

If we talk about choosing the right component composition of EPS, then you should be guided by the following indicators of various brands of expanded polystyrene.

| Name of insulation | Density, kg/m3 | Coefficient of thermal conductivity | Tensile strength, MPa | Hygroscopicity |

| Penoplex 35 | 28 – 38 | 0.030 W/m x C | 0,4 – 0,7 | 0,4% |

| Penoplex 45 | 40,1 — 47 | 0.030 W/m x C | 0,5 | 0,2% |

| Penoplex Foundation | 29 – 33 | 0.030 W/m x C | 0,27 | 0,4% |

| Penoplex Comfort | 25 – 35 | 0.030 W/m x C | 0,18 | 0,5% |

It is not recommended to choose polystyrene foam whose density is below 20 kg/m3, since such a base will not withstand the load from furniture. Based on this, the thickness of the sheets should be at least 30 mm for standard Penoplex boards and at least 7 mm for thin sheets (for example, Pufatherm).

There is also foil-coated polystyrene foam, which, thanks to the additional layer of foil, is the best option for insulating screeds for wooden floors and when installing heating systems. Foil can not only retain heat, but also reflect it. However, this material must be laid on the screed, and not under it.

Expanded clay

If we talk about insulation under the screed specifically for a concrete base, then expanded clay was originally created for this purpose. These are granules of foamed clay, which are simply scattered on the floor, leveled in thickness (usually within 7-20 cm) and covered with a semi-liquid concrete composition.

The thermal conductivity of expanded clay is 0.16 W/m K.

Rating of floor insulation

The formation of the TOP by the Vyborexperta.ru team was carried out by excluding from the list of nominees, which included 30 items, the least safe, convenient, durable and cheap heat insulators.

The rating was based on the following characteristics:

- Type of floor – wooden, concrete, warm;

- Type of material – polymer, mineral, wood chip;

- Type of insulation - cotton wool, polystyrene foam, etc.;

- Release form - sheets or rolls;

- Thickness and dimensions of the heat insulator;

- Density of sheets or rolls;

- Degree of heat and sound insulation;

- Water absorption level;

- Covered area;

- Vapor permeability;

- Insulation structure;

- Operating temperature;

- Flammability and fire safety group;

- Resistant to rodents and rot;

- Composition and absence of hazardous substances in it;

- Amount in a package.

The results of the analysis are presented taking into account the relationship between the cost and quality of thermal insulators and their prevalence in stores.

The best floor paints

Concrete floor base in a private house - features of a concrete slab

The floor is a critical element of the structure. Trying to increase the service life of a building, many people prefer concrete. After all, concrete surpasses most building materials in terms of performance characteristics. But along with a set of advantages, the material also has weaknesses.

Concrete has superior performance characteristics to most building materials.

Let's start with the main advantages of concrete floors, which include the following characteristics:

- increased safety margin. The concrete surface is able to withstand significant compressive loads, maintaining the structure and integrity of the mass;

- long period of use. The service life is commensurate with the service life of the building, thanks to the durability of the base;

- environmental cleanliness. The ingredients included in the concrete mixture are safe for health and do not harm the environment;

- ability to resist the accumulation of static electricity. Airborne dust is not attracted to the surface;

- Fire safety. The concrete base has increased fire resistance and is not destroyed by open fire;

- resistance to capillary penetration of moisture. Despite the reduced hygroscopicity, waterproofing the floor is a prerequisite;

- resistance to aggressive environments and chemicals. The concrete base is not destroyed upon contact with acids and alkaline compounds;

- maintainability. If necessary, it is easy to repair the damaged area.

Thinking about which insulation for a concrete floor is best, let’s look at the disadvantages of a concrete base. Main disadvantages:

- increased thermal conductivity. Without additional thermal insulation, significant heat loss occurs;

- condensation formation. Due to the increased temperature difference between the soil and the floor of the lower floor, moisture condenses on the concrete surface.

The concrete base has increased fire resistance

Condensation causes a number of negative factors;

- increased indoor humidity;

- deterioration of the internal microclimate;

- development of fungal colonies and mold;

- formation of dampness.

In addition, in winter, cold floors cause many inconveniences to residents:

- reduce indoor temperature;

- increase heating costs.

Laying heated floors on Penoplex

There are differences, but they only concern the laying of pipes or heating cables/mats. Preparation of the base, the first layers, including the waterproofing layer on Penoplex, were described above. A steel mesh is laid on the waterproofing film. It is needed to fix the cable or pipes in a given position. When using heating mats, they can be placed in a layer of tile adhesive - this is simpler and more effective, so this type of heating elements for the floor is rarely used at this stage (although no one prohibits it).

Which mesh should I use? Depends on the step at which you need to lay the pipe or cable. Can be laid 50*50 mm, 100*100 mm or 150*150 mm

It is important that the chosen scheme can be implemented. What is the thickness of the wire in the mesh? Not less than 3 mm

In the case of a cable, perhaps 2 mm is possible. And before pouring the screed, the pipes will be filled with coolant and need to be held in place, so a mesh made of 3-4 mm wire is needed.

You can use Penoplex under a warm water floor without any problems

To prevent the mesh with coolant from moving when filled, it must be attached to the Penoplex. There are several options:

- Plastic clips that are driven into the insulation. But the thickness of the mesh rods is at least 4 mm.

- The metal tie is aimed at the insulation on both sides of the mesh cell.

- Special harpoon clamps.

- Special tires, but they are expensive.

- A mat with bosses is laid on top of the Penoplex. Then the grid is not needed. But these mats are also expensive.

After the mesh is secured, we attach the pipes or cable. The easiest way is with plastic ties, or knitting wire. But the wire can theoretically fray a pipe or cable as it increases or decreases in size (from heating and cooling) during operation. Therefore, if knitted with wire, it is in a plastic sheath. Manufacturers of pipes for heated floors have it.

Actually, that's all. Then they pour the screed, level it, and wait until the concrete gains strength.

https://youtube.com/watch?v=sZfkUVlJ93M

Slab thermal insulation

Slab thermal insulation materials include polystyrene foam and its derivatives (expanded polystyrene), as well as all those insulation materials that are produced in the form of slabs. With their help, you can quickly and affordably insulate cold concrete floors.

https://youtube.com/watch?v=t8KsPa1GeXc

Laying the slabs is carried out according to the principle of false floors by pinning them onto pin “beacons”. In this case, the finishing screed must be at least 50 mm and must be reinforced with mesh or fiberglass, which is added to the solution.

Before laying the slabs, the base of the floor is leveled with a thin layer of sand. The advantage of slab insulation is its soundproofing properties and resistance to fire, but it is worth knowing that during the smoldering process, expanded polystyrene and foam release caustic toxic substances.

Having studied all the advantages and disadvantages of thermal insulation materials, as well as having considered the methods of their installation, there will be no problems with how to insulate a concrete floor. The main thing is that the insulation has a high degree of compressive strength and at the same time is resistant to deformation.

Insulating the floor with penoplex under a screed with your own hands - how to insulate the floor with penoplex

Floor insulation is the most important element of repair work. After all, heat loss through this surface is 15%.

There are several ways to retain heat; one of the best is considered to be insulating the floor with penoplex under a screed with your own hands.

This is a very effective and simple method and does not require much effort or skill. The technology is unchanged and does not depend on the type of surface.

Features of penoplex

Penoplex is insulation made from extruded polystyrene foam. There are several options that suit the specific building conditions

This is why it is very important to make the right choice. For floor insulation, only penoplex with a density of 35 and 45 kg/m3 is suitable

"Penoplex 35" is suitable for thermal insulation of external walls, floors and foundations. This material has good characteristics:

- Average density 28 – 38 kg/m3;

- Low thermal conductivity;

- Low hygroscopicity;

- Low flammability index G1. The material can be considered absolutely fireproof thanks to the heat-resistant concrete screed, which will be laid on the insulation;

- The noise absorption rate reaches 41 dB;

- Operating temperature – -50º +75º C.

This material is perfect for a concrete floor under a screed. Additionally, you can install a “warm floor” system.

"Penoplex 45" has the highest density and is ideal for insulating floors on the ground. This material is even used for runways. Its characteristics are superior to Penoplex 35:

- High density. In the range from 40 to 47 kg/m3;

- Minimal hygroscopicity;

- Strength is 0.4-0.7 MPa;

- Fire resistance is G4.

Required tools and materials

To insulate the floor you will need the following materials:

- Penoplex;

- Polyethylene film;

- Cement;

- Sand;

- Glue;

- Primer;

- Sealant;

- Ribbon;

- Repair solution;

- Guide profiles for beacons.

In addition to the necessary materials, it is recommended to have the following tools available:

- Putty knife;

- Rule;

- Roller;

- Construction mixer;

- Container for mixing the solution;

- Level;

- Roulette;

- Knife.

Installation of insulated concrete floor

To carry out high-quality floor insulation, preliminary preparation is necessary:

- The floor surface is thoroughly cleaned of dirt and dust;

- All cracks and chips are eliminated;

- The floor is leveled if there is an urgent need for it;

- The primer is being prepared.

Penoplex is laid under the floor screed in several stages. After the base of the floor has completely dried, you can begin laying plastic film. It is better to cover the floor with film overlapping by 10 cm, and carefully glue the joints for additional vapor barrier.

The damper tape is cut and laid around the entire perimeter of the room. For better fixation, glue is applied to the tape pointwise, and the tape itself is pressed firmly to the floor. It is better to prime the area between the wall and the floor.

Damper tape plays a huge role in the operation of the floor.

In addition to enhancing thermal insulation, the tape, due to its elasticity, prevents the formation of cracks in the screed during its expansion due to changes in temperature and humidity.

There are usually no difficulties in laying penoplex itself.

It is important that the sheets lie flat and neat, and it is recommended to treat the joints with sealant. Even tape will work for this.

After that, a layer of film for vapor barrier is laid on the penoplex, a metal mesh is placed on top and secured with concrete mortar. It is better to pour the solution in parts.

Screed concrete is prepared from cement and sand in a ratio of 1:3. The most convenient and optimal option for work looks like this: half a liter of water, 1 kg of cement, 3 kg of sand. It is better to use containers larger than 20 liters.

If you use ready-made dry mixtures, then first add water, then add the dry mixture.

Then everything is thoroughly mixed. Afterwards, the resulting homogeneous mass is mixed with a construction mixer for another five minutes.

The finished solution can be safely poured starting from the far corner opposite the floor. The mass is thrown up to the level of the guide beacons, distributed with a trowel, the excess is removed by the rule, leveling the surface. After filling the first strip, you can start the next one.

At the stage when you can already walk on the screed (usually on the second day), the guides are carefully removed, and the resulting empty spaces are sealed with concrete mortar.

The final drying of the screed will not occur earlier than after three weeks. And only then can you place furniture.

Installation features: on the floor, on the wall, under the screed

Let's take a closer look at the sequence of actions when working on different surfaces. Penoplex is a multi-profile insulation, so you need to look at all the installation features.

Under a concrete screed on the ground

Here, the base will be a pillow of gravel with sand, 30 and 10 cm respectively. Penoplex sheets are placed directly on top, and if the thickness is insufficient, a second layer is built up. We make sure that the seams of different planes do not coincide, this worsens the waterproofing properties of the insulation.

The second row, for greater solidity of the structure, can be glued together at the ends. At the top, the seams are closed with tape. Then comes the covering film, laid on the wall with an allowance, and the reinforcing mesh. Now the installation of penoplex on the floor under the screed is almost complete, all that remains is to fill the resulting cake with a solution at least 5 cm thick. A cement-sand mixture is also used to create a heated floor, in this case, the size of the concrete layer depends on the location of the components of the heating system.

On the wall

Laying penoplex on the wall is not always recommended indoors, but it is ideal for loggias and outdoor installation. The installation process is much easier compared to floor insulation. Sequentially it looks like this:

This is interesting: Men's hairstyles for medium hair 2022

- Cleaning the wall from oil stains, crumbling plaster, paint;

- Prime the base with a compound containing an antiseptic;

- Prepare holes for fastening dowels;

- After drying, start gluing the insulation from the bottom corner. Place the sheet with the adhesive mixture against the wall, move it slightly to distribute the solution, press firmly in the desired position;

- Treat the ends of the workpiece with sealant and glue the next layer;

- Having assembled the bottom row, proceed to install the remaining plates, which you do in a checkerboard pattern;

- Final fixation with disc dowels in previously prepared holes. This is carried out only after the glue has hardened.

Next comes the finishing of the penoplex insulation with plaster with mesh reinforcement. We can assume that the work on laying the material is completed. Independent work with insulation will not be difficult.

The manufacturing technology of extruded polystyrene foam is one of the new, but widely used. It's all about the ease of installation and the variety of uses of insulation.

Filling the screed

The screed is made at above-zero temperatures. The entire area is poured at once. To prevent air voids from forming, it is necessary to pierce the surface in several places with a thin metal object, since the air itself cannot escape from under the heavy cement layer.

If the room area is large, after laying the heated floor, special beacons are installed, they are levels for pouring an even layer of mortar. Beacons are placed 0.5 meters from the wall, and from each other at a distance less than the size of the rule.

Concreting is done from the far corner to the door. The solution is poured between the beacons, evenly distributed and leveled, its level should not be higher than the beacons.

In order for the screed to come out of high quality, it requires care. To do this, 2-3 times a day for a week, its surface is moistened with water, since the solution must harden and not dry out. The heated floor system should be turned on after the laid screed has completely dried.

In general, the filling procedure is simple. If you follow the instructions and technology for making the solution, anyone can do everything with their own hands.

Styrofoam

Very often polystyrene foam is used for insulation. Its main advantages are:

- low cost;

- good thermal insulation characteristics;

- light weight;

- long service life;

- the material is easily cut using a regular stationery knife;

- resistance to combustion (if the heat-insulating layer is covered with a screed plate);

- moisture resistance and moisture resistance.

Among the disadvantages of foam plastic under floor screed is its toxicity. However, it all depends on the type of foam. Suitable for residential premises:

- PVC foam plastic. Polyvinyl chloride material is considered less harmful, since it contains a minimum of toxic substances.

- Polyurethane foam under the screed is foam rubber with good flexibility. This material is widely used in the production of furniture, so it is also safe for health. Thanks to the pores, polyurethane “breathes”, but it is flammable.

- Polyethylene foam for flooring under screed is completely non-toxic. This material is well known to everyone, since it is in it that various products are most often packaged.

In order for a floor screed with foam to have all the necessary parameters, it is necessary to select a material of a certain density. Therefore, when buying polystyrene foam, look at its markings - after the letters PPT there should be a number no lower than 25; such sheets are best suited for the heat-insulating layer of the screed. It is also worth paying attention to the PSB marking.

Another disadvantage that this material has is the complexity of its installation. In order for the foam floor screed to be durable, it is necessary to create the most even surface possible. To do this, quartz sand is first poured onto the rough screed, and only after that the insulation sheets are laid.

Healthy! For even cutting of insulation sheets, it is best to use a special construction cutter with a hot wire.

Foam sheets must be laid very carefully. If cracks or gaps have formed between the plates, they must be eliminated using polyurethane foam. Otherwise, the thermal insulation properties of the material will noticeably decrease.

If the foam screed will be located close to the foundation (first floor), then you should choose a material with a thickness of at least 10 cm, and for the upper floors slabs 5 cm thick will be sufficient.

Penoplex insulated ground screed

The soil base is fundamentally different from concrete and requires a different technology when insulating it with penoplex. Most often, this method of flooring is used for strip foundations in private homes. There are several conditions that allow you to use penoplex for screeding on the ground:

- No serious loads on the floor.

- The location of groundwater is below 5 meters.

- Presence of heating in the room.

Option for installing a floor on the ground

In addition to penoplex with an L-shaped edge to prevent the formation of cold bridges, you will need to purchase other materials for preparing the base and pouring the screed in the form of:

- Clean sand.

- Rubble.

- Waterproofing material (roll and mastic).

- Cement.

- Self-leveling mixture.

- Damper tape.

- Reinforcing mesh.

Insulation schemes

Before you begin installing the floor, you must choose one of three flooring schemes for laying the floor on the ground with polystyrene foam.

Scheme 1

The first scheme involves laying insulation directly on compacted sand located on the surface of a durable crushed stone cushion.

Scheme 2

The second scheme involves the installation of two screeds - rough and finishing, between which insulation with a waterproofing layer is laid on both sides. A “warm floor” system can be installed in the final screed.

Scheme 3

The third option differs from the second in the absence of a rough screed and the laying of penoplex directly on the sand cushion. This scheme differs from the first option only by the presence of waterproofing.

Mineral wool

It should be noted that of all the insulation offered under the screed, this is the most inconvenient. The thing is that mineral wool is a hygroscopic material. It quickly absorbs moisture, becoming practically unnecessary. Therefore, it must be covered on both sides: on the side of the concrete floor with a vapor barrier film, on the side of the screed with a waterproofing membrane. Therefore, the pouring process itself begins with the installation and laying of the lower protection.

- Typically, the film is laid in strips with edges overlapping within 10-15 cm, which must be secured with construction tape along the joint. Be sure to lay it over the walls, taking into account the thickness of the entire insulated pie plus the screed.

- Next, the thermal insulation material itself is laid out. It is better to use mats for the floor. They should be laid tightly to each other so that there are no gaps left, which can later become cold bridges.

- The top film is laid, like the bottom one, in strips with overlap and installation of tape.

- A reinforcing frame in the form of a metal or synthetic mesh must be applied to such a heat-insulating cake.

Please note that if mineral wool is laid in two layers, then the mats should be offset by half the panel. The seams between the thermal insulation elements must not coincide vertically.

Floor insulation with polystyrene foam: instructions

- Level and compact the soil as much as possible.

- Place a layer of fine crushed stone about 10 centimeters thick on top. It will also need to be compacted thoroughly.

- Fill this layer with sand on top and compact it again. The sand filling will hide the sharp edges of the crushed stone and compact the cushion made of it.

- Expanded polystyrene is laid on this soil base. If necessary, the material must be cut into pieces of the required size. The insulation should be laid as tightly as possible, without gaps or cracks. Most modern brands of this material now have special protrusions and cutouts that allow it to be laid in an even layer.

- The next layer is always a vapor barrier. The waterproofing film should overlap slightly, and to prevent the material from moving out, it should be fixed with mounting tape.

- For the strength of the concrete screed and uniform distribution of the load on the insulation, the next step is laying a mesh of reinforcement. It increases the strength of concrete and makes the floor durable.

- The concrete screed is made in the usual way. The sand-cement mixture is poured onto the reinforcement and leveled. The concrete layer should be no thinner than 5 centimeters so that it can withstand any load.

- After the concrete has hardened, it is leveled again and the final covering is installed on top - tiles, laminate, parquet, etc.

Please note that for thermal expansion of materials, it is necessary to leave a centimeter gap between the walls and the floor, which we talked about earlier. It needs to be sealed with foam. For reinforcement, you can use wooden logs rather than metal mesh or rods

They are placed below, and not on top of the layer of material. In this case, a wooden base is first mounted on a bed of crushed stone and sand, and then polystyrene foam is laid between its parts

For reinforcement, you can use wooden logs rather than metal mesh or rods. They are placed below, and not on top of the layer of material. In this case, a wooden base is first mounted on a cushion of crushed stone and sand, and then polystyrene foam is laid between its parts.

If you are not carrying out work in a private house without a basement, then the construction technology does not change significantly. The concrete or wooden base is covered with insulating material, and the remaining layers are installed on top of it.

Insulation of concrete floor

In most cases, the floors in apartments in city high-rise buildings are reinforced concrete slabs. The concrete floor itself is very cold, but if you add to this the gaps between the slabs and insufficiently tight joints between the walls and the floor, then it becomes truly icy. Therefore, insulation of concrete surfaces is a top priority for residents of multi-storey buildings who seek to increase comfort in their apartments.

Each master involved in insulation develops his own formula for the ideal insulation “pie” on concrete slabs. Let's look at the most popular possible options.

Option No. 1 - insulation + screed

The thermal insulation properties of a concrete floor can be significantly improved by laying insulation between the floor slab and the cement leveling screed. In this case, floor insulation in the apartment is performed as follows. The first step is to remove the old floor covering and remove the screed. The surface of the slab is cleaned of debris, dust, and unevenness from cement screed residues is eliminated.

Insulating the floor in an apartment using thermal insulation material and reinforced screed

Then a vapor barrier is performed. A polyethylene or polypropylene film is laid on the concrete base, laying the strips overlapping by 15-20 cm and extending 3-5 cm onto the walls. The overlap joints are insulated with special tape. Foam plastic with a minimum thickness of 50 mm and a density of 25 mm is laid on the vapor barrier film. Instead of polystyrene foam, you can use polystyrene foam, mineral wool, etc. The insulation sheets are laid as closely as possible to each other so that cold bridges do not form in the seams. After this, another layer of vapor barrier is laid. If polystyrene foam or expanded polystyrene were used as insulation, then this step can be skipped.

Now lay a metal mesh with square cells (cell side – 50-100 mm). The mesh will act as a frame for the cement screed, making it more durable. A cement screed with a minimum thickness of 50 mm is poured over the mesh. A thinner screed will be unreliable - after a while it will begin to crack and crumble. The cement screed must dry, this will take about two weeks. After which, to strengthen the top layer, it is necessary to cover it with a primer. After all this, any decorative covering is laid on the screed.

Option No. 2 - insulation along joists, without the use of wet processes

This option is similar to insulating a wooden floor. The difference is that the thickness of the wooden floor initially contains logs, between which it is convenient to lay any type of insulation. In the case of concrete floors, these logs will have to be constructed independently.

Insulation of the concrete floor along the joists eliminates wet processes and does not burden the ceiling

Technology for insulating concrete floors using joists:

1. First of all, clean the concrete slab from old screed, debris and dust.

2. Arrange waterproofing. It is convenient to use ready-made waterproofing polymer-bitumen solutions, which are applied to the concrete surface with a roller or brush. Another option is to use a vapor barrier film for these purposes, which is laid out overlapping on the floor, extending onto the adjacent walls. If you want to save money, then the most suitable material for hydro- and vapor barrier would be ordinary polyethylene film.

3. Install the logs at a distance of no more than 0.9 m from each other; if you take a step larger, the floors will sag. Instead of logs, if you plan to use bulk material for insulation, metal beacons are attached to the floor.

Installation of wooden joists on a concrete floor

4. Lay the selected insulation. Both mineral wool and polystyrene foam, and any type of bulk thermal insulation materials are suitable. Insulation in the form of sheets or rolls is laid out tightly, without gaps between the joists. Bulk material (for example, expanded clay) is poured between the beacons and leveled to one level using a metal rule.

Insulation is placed in the space between the joists

5. Lay the floor. To do this, you can use sheets of plywood, gypsum fiber board, OSB, chipboard with a thickness of 10-15 mm. It is safer to lay them in two layers so that the seams of the lower sheets overlap the panels of the upper sheets. Thus, the floor covering will be seamless, which will eliminate the possibility of cold bridges. After laying, the layers of sheets are connected to each other and to the joists (beacons) using self-tapping screws.

Laying sheets of dense material (plywood, gypsum fiber board, etc.) on joists

6. Suitable for any finishing floor covering.

Laying laminate flooring on an insulated floor

This short video will clearly demonstrate the process of insulation using joists:

The use of lightweight heat-insulating screeds

Providing good thermal conductivity is achieved by using a similar material such as perlite sand in concrete screeds. Lightweight concrete with perlite sand is environmentally friendly, durable, and retains heat remarkably well.

The downside is that the perlite screed must be protected with moisture-repellent compounds. Perlite sand is a very hygroscopic material.

Selecting a heat insulator for a floor is a very complex process. The variety of materials and their characteristics require a careful selection approach. The price issue is also very important. Choose the optimal middle ground between purchasing qualities and cost.

Options for floor pie with screed

Insulation of the floor under the screed is carried out in several cases:

- on the floor slab - reducing heat loss in the basement or attic floor;

Thermal insulation on the floor slab.

- floor on the ground – reduction of heat loss into the ground;

Thermal insulation of the floor on the ground.

In addition, insulation is laid under the contours of a heated floor on any floor if a decision is made not to use a massive ceiling as a heat accumulator. Therefore, all options will be considered in detail.

There are three types of screeds, which also affects the choice of insulation. For example, in dry screeds, expanded clay sand is used, which has both heat-insulating and sound-proofing properties. For wet and semi-dry screeds, the same insulation materials and principles of hydro-, sound- and vapor barrier are used.

Material requirements

Insulation is a necessary part of the “pie” of any floor on the first floor of a private house. Especially if there is no heated basement below. In high-rise apartments, additional thermal insulation will also not be superfluous, performing not only a direct function, but also a noise-proofing function. It is also mandatory when installing heated floors, so that the system does not work in vain.

Of the many types of insulation, only a few are suitable for installation under a concrete screed. They must meet the following characteristics:

- High moisture resistance . When wet, the insulation may lose its insulating properties. Therefore, only water-resistant materials are used for pouring liquid concrete.

- Resistance to temperature changes . Floors on the ground or above an unheated basement in winter freeze on one side and are warmed up by heating devices or a “warm floor” system on the other. It is important that the material does not deform, causing cracking of the overlying layers.

- Light weight . The concrete screed itself is massive and its installation on existing floors, especially in high-rise buildings of the Stalinist and Khrushchev type, is the ultimate load. Light, but high-quality insulation will allow you to reduce the thickness of the top layer to a minimum and reduce the overall weight of the “pie”, without losing its insulating properties.

- Ecological cleanliness . Despite the fact that the owners of a house or apartment do not directly come into contact with the material, the influence of toxic substances, if any, cannot be completely excluded. It is better that every component of the floor is safe for health.

- Easy to install . This parameter is especially important for home craftsmen who fill the floor with their own hands.

- Compressive strength, elasticity, resistance to uneven loads. Insulation materials have the ability to compress under pressure. But if they start to “play,” for example, under point loads from cabinet furniture, this will lead to cracking of the concrete, as well as problems with the top coating, primarily with ceramic tiles.

- Biostability. Mold and fungus should not develop in the coating, which significantly accelerates its destruction.

- Acceptable price. Sometimes it is this factor that turns out to be decisive when choosing a heat insulator. But it is advisable to take into account the long-term perspective, because some materials can last for decades, helping to significantly save on repairs.

What should it be: requirements

According to building codes and regulations (SNiP), the minimum thickness of the floor screed is 20 mm. In everyday life, such a minimum is rarely installed. It increases significantly if you need to hide equipment located on the subfloor. Thus, the thickness of the screed when installing a warm water floor should be determined taking into account the basic parameters of the pipes.

It is well known that the layer of mortar above the heating system should not exceed 40 mm. With a greater thickness, the installation of a heated floor is ineffective, since the bulk of the heat received simply will not reach the consumer. The internal layers of the screed will heat up, and the floor covering will receive virtually no thermal energy. The simplest calculations show that the thickness of the screed for a pipe diameter of 25 mm should be in the range of 50-70 mm. A standard screed consists of several components or layers.

The order of installation from bottom to top is as follows:

- waterproofing;

- thermal insulation;

- fittings;

- warm floor;

- screed

Different heated floor designs require different screed layers.

In some cases, the subfloor is first leveled with a thin screed; sometimes the solution is laid directly on the insulation. Its thickness should not be less than 2 cm. The layer is given 1 month to dry, and only after it has completely dried can you begin installing the heated floor, subsequently covering the installed communications with another screed.

An electric heated floor requires a low screed, especially if film heating was chosen. Infrared film is ideal for installation under laminate, carpet and linoleum.

If you plan to cover the floor with tiles, you should use a heating cable. In this case, you will need a less thick screed than when creating a water floor.

Choice

Concrete screed is far from the only way to insulate and level floors, especially in a private home. Instead, wooden logs are often used, which are easier to install, do not require long exposure, allow you to create a mini-underfloor (technical space for laying communications and storage), and, importantly, are lightweight.

Almost any insulation is suitable for such structures - from traditional mineral wool to ultra-modern sprayed polyurethane foam. Since the space between the joists is filled with a heat insulator, and the top is covered with OSB or plywood, it does not bear any load. The method of laying all components of the floor is dry. Consequently, neither high strength nor moisture resistance is required from the insulating material. And the consumer has much wider choice.

Only two options are recommended for concrete screed: expanded polystyrene and expanded clay. Both work well in bending and compression, and have not only heat but also sound insulating properties. The materials are absolutely safe for health and are not affected by fungus. To make a specific choice, you need to become more familiar with each of them.

Expanded polystyrene

This type of insulation can be called improved polystyrene foam. Today it is recognized as a favorite in the construction industry. 98% of polystyrene foam consists of air enclosed in a thin polymer shell. Available in two versions: pressless (PSB) and extruded (EPS). There is also a loose variety, which is foam granules, but it is used extremely rarely.

PSB has a lower price, however, its water resistance and strength are also low. Builders prefer its analogue, which is produced at high pressure and therefore has improved characteristics. Extruded polystyrene foam is even used for runways and highways. Its compressive strength is considered the highest among existing thermal insulators.

EPPS is also characterized by:

Domestic products are popular on the Russian market. Therefore, extruded polystyrene foam is known to many under the name of this brand. EPPS is produced in slabs with dimensions of 1200x600 mm, thickness from 20 to 150 mm. They can be foil-coated on one or both sides, which enhances the heat-insulating and moisture-proof properties. The one-sided covering is placed “facing” the living space.

The disadvantages of polystyrene foam of all types include flammability. Manufacturers are working to improve the fire safety of the material, experimenting with various fire retardants, but so far no effective impregnations have been found. That is why it is recommended to “hide” polystyrene foam under concrete, which reliably protects it from open fire.

A screed with an EPS layer is called a floating screed. It is permissible to install heated floors in it - this is one of the most effective solutions. In order for the structural “pie” to last as long as possible, it is necessary to take into account all the subtleties of its arrangement; there are no “extra” actions here. There are two types of installation - for floors on the ground and on the ceiling.

Insulation on a reinforced concrete slab

The “pie” is made as follows:

If you plan to lay linoleum or laminate, it is better to make another layer under them - a self-leveling layer.

In multi-storey buildings of the old housing stock, where the floor is not monolithic, but prefabricated, there are often differences between the slabs that do not allow the polystyrene foam to be laid evenly. In this case, a rough concrete floor screed is first made. It is recommended to lay any waterproofing material under it - polyethylene or rolled bitumen, placing it on the walls. This will protect the lower floors from leakage.

It should be remembered that additional layers of flooring “eat up” the living space and it becomes uncomfortable to be in it. Therefore, they choose insulation with a thickness of no more than 50 mm, and the screed is made 30 - 50 mm high.

If there is an unheated basement below, waterproofing must be done under the insulation. It is even better to use a hydro-vapor barrier membrane, such as ONDUTIS, which protects against condensation. To reduce the humidity of the basement in winter, install small ventilation holes - vents, which are constantly kept open until the frost subsides. A plastic film is laid on the earthen floor or a layer of lean concrete about 50 mm high is poured. The load-bearing walls of the first floor in the lower part are insulated.

Ground installation

In private houses on a strip foundation without a basement, the floors should be insulated more thoroughly than usual. After all, there is no additional protection between the ground that freezes in winter and the living spaces on the first floor. To enhance the strength characteristics of the floor, it is recommended to make a rough screed. Its location varies depending on the groundwater level. But it is important that the finished floor is level with the threshold of the building.

The classic “pie” diagram looks like this (from bottom to top):

If groundwater lies below 2 m, the concrete base can be poured directly over the ground, removing the fertile soil layer and making a small sand and crushed stone backfill.

Expanded clay

The material is obtained by firing clay shales, which foam and form granules that are hollow inside. Expanded clay is the most environmentally friendly, lightest and cheapest type of insulation. It has noise-proof and anti-vibration properties, is easy to install, does not mold or be corroded by fungus. In addition, unlike expanded polystyrene, expanded clay does not burn.

But the ceramic granules themselves are fragile and absorb water well. If they are used as dry filler, falling asleep between the joists, no problems arise. But under the concrete, expanded clay must be poured with a liquid cement-sand mortar. It is better to buy a ready-made mixture that contains all the necessary proportions. And only after it has dried, make a clean concrete floor screed with reinforcement.

Expanded clay has a low heat capacity. Therefore, to ensure the proper level of insulation, it is poured in a thick layer. But this apparent minus turns into a plus in houses of old construction, when builders replace the wooden floor along the joists with a more modern and comfortable concrete screed. A high layer of expanded clay ideally compensates for the difference in height, without gaining critical mass with heavy concrete.

For floors on the ground, clay insulation is also considered a good option, more economical and functional than polystyrene foam. Another advantage is that it does not require a flat base.

Standard “pie” made of expanded clay:

Penofol

Foamed polyethylene, covered with foil on one or both sides, is a new word in the market of thermal insulation materials. Penofol is non-toxic, moisture resistant, does not allow sound, vibration and heat to pass through. It has a small thickness, which allows you to maintain the useful height of the premises and is produced in rolls - a significant advantage that facilitates installation. The only obstacle may be the cost of penofol. But its durability compensates for this “shortcoming”.

Most often, a new generation of heat insulator is used when installing water-heated floors:

It is highly undesirable to use penofol for electric heated floors, and the intra-apartment wiring system under the floor must be reliably insulated. Insulation is a conductive material.

Source

Features and types of foam

Externally, the foam is a white slab made from compressed polystyrene granules.

Expanded polystyrene or polystyrene foam

The dimensions of the slabs are usually 0.5x1.0 m, but can be 1.0x1.0 m.

Advantages of expanded polystyrene:

- affordable price - this is practically the cheapest insulation for floors or walls;

- has good thermal insulation ability, 15-20% better than mineral wool;

- not afraid of moisture;

- has good elasticity, although it largely depends on its density (grade);

- has very low weight;

- it is simple to install and easy to cut; if necessary, adjust the size of the slab in the desired location of the floor base.

Flaws:

- Flammability - ordinary polystyrene foam burns with the release of very harmful substances. But there is a variety of it that practically does not burn - this is the so-called self-extinguishing foam. On its marking there is an additional letter C (for example, PSB-S). Although when using polystyrene foam under a screed, especially on a concrete base or soil, its flammability is not a big drawback.

- Contacts with gasoline or some other organic solvents, releasing harmful substances. Therefore, when working with polystyrene foam, it is necessary to ensure that it does not come into contact with solvents of this type. And they can be, for example, in coating waterproofing solutions.

- May be damaged by rodents.

- Decomposes when exposed to ultraviolet radiation. Although for the insulation under the screed this factor does not play a special role, since it is closed from sunlight.

Foam boards differ in density or grade. Most often, you can find polystyrene foam with a density from 15 to 50 on sale. The higher its density, the greater its elasticity and ability to withstand mechanical loads.

And this quality for floor insulation, which is laid under a screed, is quite important, since it will subsequently be subject to the load from the weight of the screed itself, the floor covering, as well as furniture, objects and people. Therefore, to insulate the floor under the screed, it is best to use foam with a maximum density, but not less than 35. Of course, another type of polystyrene foam would be best suited for this purpose - extruded (penoplex or extruded), but its cost is 2-2.5 higher, that's why many people choose the regular one

We have already talked about insulating the base of the floor with penoplex (extruded polystyrene foam) in another article in this section, but here we will talk about ordinary polystyrene foam or polystyrene foam and its use when insulating the floor under the screed

Of course, another type of polystyrene foam would be best suited for this purpose - extruded (penoplex or extruded), but its cost is 2-2.5 times higher, which is why many choose regular one. We have already talked about insulating the base of the floor with penoplex (extruded polystyrene foam) in another article in this section, but here we will talk about ordinary polystyrene foam or polystyrene foam and its use when insulating the floor under the screed.

Insulation with expanded clay

Expanded clay is a highly environmentally friendly, fire-resistant material.

Expanded clay is a highly environmentally friendly, fire-resistant material. Polystyrene foam granules are highly porous, which increases the water absorption of the material; in addition, expanded clay is a fragile insulation material, so backfilling of the expanded clay thermal insulation layer should be done carefully.

In order for the floor to withstand significant loads, the thickness of the expanded clay layer must be at least 15 centimeters. This thickness entails an increase in the floor level, so expanded clay is not used for insulating rooms with low ceiling heights.

The expanded clay thermal insulation layer should be carefully insulated from moisture penetration, and before applying the concrete screed, the structure must be additionally reinforced.

Manufacturers and prices

It is not difficult to insulate a concrete floor today, since the range of thermal insulation materials is very large. But you can only trust the following manufacturers in terms of choosing quality:

- Ekomix (extruded polystyrene foam) - price 1300 rubles per package.

- Isolon (foil insulation) - price 1200 rubles per roll.

- Paroc (mineral wool) – price 800-850 rubles.

- Rockwool (mineral wool) – price 1000 rubles.

- Neman (glass wool) – price 1200 rubles.

Insulation is one of the important processes in the field of construction, with which you can make any home warm and cozy

When choosing a material for thermal insulation of a concrete floor, you need to pay attention to the composition of the material, its thermal conductivity, moisture permeability and service life

The best insulation for wooden floors

Insulation of wooden floors is carried out from below, under the main boards, which are subsequently finished with the main coating. This reduces the risk of swelling of the top layer. For such surfaces, penoplex, stone wool, etc. are used. Before understanding which insulation is best for the floor of a wooden house, 10 nominees were analyzed taking into account their safety, ease of installation and durability.

Penoplex Comfort 118.5 x 58.5 cm 50 mm

A new generation of heat-insulating material used for finishing not only floors, but also walls, roofs, and foundations. Extruded polystyrene foam is suitable for both external and internal work. It comes in the form of slabs measuring 118.5 x 58.5 cm, which makes the installation process convenient and quick. The model can be used without consequences in a wide temperature range – from -50 to +75°C.

Penoplex has a good density - 25 kg/m³, so it reliably retains heat and at the same time has some soundproofing properties. In this regard, it is also relevant for finishing interfloor ceilings in a house. Due to water absorption at the level of 0.4%, the accumulation of liquid inside and the appearance of unpleasant odors is eliminated, but the vapor barrier should not be completely ignored. The insulation is durable in compression and can withstand high mechanical loads.

Advantages:

- The area covered by one sheet is 0.7 m²;

- Good waterproofing;

- Ease of installation;

- Long service life (up to 40 years);

- Low thermal conductivity – 0.033 W/(m⋅K).

Flaws:

- Sometimes attacked by rodents.

Sheets are produced with a thickness of 5 cm and a density of 25 kg/m³, which is sufficient for a wooden (frame or log) house, including an attic. At the same time, they do not take up space and are relevant for low ceiling heights.

TechnoNIKOL Rocklight 1200 x 600 x 50 mm

When trying to decide what kind of insulation to put on the floor, it should be noted that stone wool is supplied in slabs, which makes it easier to install. This material does not burn and can withstand temperatures up to 870ºC. It has, along with heat-insulating, sound-absorbing properties due to its dense structure - 35 kg/m³. This option is suitable for installation between joists under laminate, parquet, linoleum, and solid boards.

TechnoNIKOL Rocklight has low heat losses - 0.041 W/(m⋅K), which reduces home heating costs. The insulation is resistant to compression, allowing it to be used in areas with high traffic. It practically does not absorb moisture - its absorption coefficient does not exceed 2%. Thanks to this, the material can be used when arranging floors on lower floors, including above the basement.

Advantages:

- Resistance to rotting;

- Not affected by mold;

- The optimal sheet area is 0.72 m²;

- 8 sheets per pack.

Flaws:

- Weighs 10.28 kg.

Stone wool does not lose its performance characteristics over a wide temperature range: from -180 to +700 degrees. Due to this, it can be used for thermal insulation in rooms with high fire safety requirements.

Isolon 500 3020 AV/AH 1m 20 mm

A universal material used in construction for steam, sound and heat insulation. The insulation is produced in the form of a slab 1 m wide. It covers an area of 2 square meters. m, which allows for quick installation. Its density of 33 kg/m³ makes it possible to thermally insulate a room with a concrete floor, including under a screed. Izolon is also relevant for finishing above the basement.

Isolon 500 3020 AV/AH has a low thermal conductivity coefficient of 0.036 W/(m⋅K), which reduces the need for additional heating. The use of a slab significantly reduces the thickness of the interfloor “pie” and eliminates excessive pressure on the load-bearing parts of the building. This is a fireproof material that does not support combustion. Good steam and moisture protection make it possible to install the material in Finnish saunas, rooms with a swimming pool, and baths.

Advantages:

- Eliminates leakage through the floor;

- Reflects heat;

- Protected from UV rays;

- 15 sheets per pack;

- Suitable for outdoor use.

Flaws:

- Not detected.