If you want your garage to always be comfortable, there is a reason to think about installing a heated floor in it. There are several options for its installation, and each of them is replete with a large number of pitfalls. But don’t be in a hurry to lose heart: all the nuances in this article will be safely brought to the surface, and useful tips will help you make the right choice. We talk about all types of heated floors in the garage, the advantages and disadvantages of each system, and also provide prices and technological algorithms for productive work.

Advantages and disadvantages

When choosing a heating type, pay attention to the pros and cons of the chosen technology. Warm floors are attractive due to:

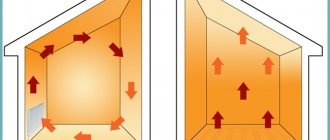

- uniform heating of the floor surface. Repair work is often carried out in the garage, and it may be necessary to inspect the bottom of the car. It is comfortable and not dangerous to your health to lie on a heated floor;

- energy savings if you use gas and solid fuel boilers for heating;

- Simple insulation of the walls and roof is sufficient so that in winter the temperature does not drop below 15 ° C, which is the lowest possible temperature, according to sanitary standards, for car parking areas. A microclimate is created that prevents the formation of rust on the body and other damage. The layer of air closest to the car warms up;

- variety of floor heating systems.

Although heated floors maintain room temperature well, they have technical disadvantages:

- load distribution - the floor in the garage is constantly under increased pressure due to the weight of the car. It is necessary to carefully calculate the load and mount it correctly so that the pressure from the wheels does not disrupt its operation;

- repair problem. The entire heating system is located under the floor, and in the event of a breakdown it will have to be completely dismantled.

Some tips

- When performing work on laying porcelain stoneware, it is necessary to take breaks.

- It should be taken into account that the tiles laid earlier will be located lower than those that are being installed now.

- As a rule, the adhesive for porcelain tiles hardens within 24 hours, after which you can begin grouting. At the same time, the floor cannot be used yet, otherwise it will become unusable.

- It is advisable to let the glue sit for two weeks.

Laying porcelain tiles is a complex and troublesome type of work and can only be carried out if the recommendations and advice of specialists are followed.

What exist, their characteristics

There are two types of heated floors, differing in the material used for heating. Both types are immured in a screed. Having studied their characteristics, the best heating systems for a particular case are selected.

Electrical

The heating system is built on the basis of an electric cable and a special fabric placed inside the screed. The advantages of electrical systems are:

- security. The floor is equipped with temperature sensors that signal short circuits and overheating of individual areas - they are necessary to control heating and regulate temperature;

- ease of installation and lack of additional equipment;

- service life is more than 50 years.

A serious drawback of this system is its high power consumption. You can save money by installing high-quality insulation and insulation of the garage walls - this way heat loss will be minimal. It is not recommended to install in rooms with high humidity.

Mermen

This is a system of metal-plastic pipes closed in a single circuit to the boiler. The pipes are filled with water or, alternatively, antifreeze. This type is best suited for rooms where a gas-type or fuel-fired boiler is already installed. Heating from electricity is not optimal. The advantages of the system include:

- ease of installation - the operating principle resembles conventional heating radiators, and such a system is easy to assemble with your own hands;

- uniform heating of concrete;

- energy saving.

They have a number of disadvantages:

- if the floors are not turned on in winter, the water in the system may freeze, which will lead to leaking pipes and failure of the entire system;

- it is necessary to additionally purchase a boiler and pump.

Rules for preparing the base

Most often, there is soil under the garage floor, so before making heated floors from water heating or electricity, you should pay attention to thermal insulation. The fact is that improper insulation can lead to significant heat losses, up to 30%, which are associated with warming up the soil.

vinyl wallpaper for the room with non-woven backing

The insulation process is as follows:

What tools and materials will be needed

The design of the heated floor resembles a layer cake. For its construction you will need:

- sand-cement mixture;

- reinforcing mesh 8-10 millimeters thick, with cells 15x15 centimeters;

- pipes and boiler or electrical cable and infrared film;

- a set of plastic clamps and supports for fixing the heating;

- hydro- and heat insulator (thick film, roofing felt, reinforced foil and other similar materials);

- finished floor covering: wood, tiles, painting.

The required tools are: a concrete mixer, a level, beacons, a rule and other available tools. It is advisable to make a drawing of the pipes or wires before installation. It is important that the car does not drive through cable laying areas.

Electrical installation

Work on installing the floor begins after the subfloor is completed. To do this, the soil is cleaned to a depth of up to half a meter, a layer of sand and crushed stone is poured in and concrete is poured. Electric floor heating does not require a high screed, but its optimal height is 10 centimeters.

Attention! It is recommended to lay a regular floor in places where wheels pass. And the cable can be covered with plasterboard, laminate or other covering.

Do-it-yourself work is performed in the following order:

- Laying waterproofing. Groundwater should not get onto the cable. To do this, use roofing felt or thick film.

- Creating a thermal insulation layer to prevent heat from escaping into the ground. It is not recommended to use foil as an insulator.

- Laying reinforced mesh and fixing it.

- Laying the cable and tying it to the sheathing. Calculate the required cable length in advance. Choose a solid wire, without solders. Heating mats can replace the wire.

- Installation of temperature sensors, especially in the area near the machine, where it is necessary to maintain a certain temperature.

- Connecting the cable to a separate panel and test switching on.

- If everything works properly, a layer of screed is poured over the grate, allowed to dry, and the finished floor is installed.

The system does not require special maintenance.

Water floor equipment

A water heated floor, like an electric one, is created on the basis of a rough screed. If the floor already exists, then remove its top layer, remove debris and level the surface. For this type of floor, the following work is performed:

- Installation of a waterproofing layer made of rolled material. Roofing material with seams coated with bitumen mastic is preferable, but can be replaced with a thick film.

- Organization of thermal insulation. Since the load on the floor is high, thin materials are used. They use a foil layer, laying it with the glossy side up, so that the heat from the pipes returns to the room and does not go down.

- A sheathing is placed on plastic supports to strengthen and prevent cracking of the screed. The optimal height is 3-4 centimeters above the insulation level.

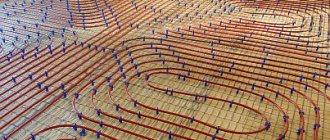

- The pipes are tied with clamps. It is possible to wire them according to the “snail” or “snake” scheme; you can make 1 or 2 circuits.

- Connection to the boiler, installation of a pump if necessary. Filling the system with water and test run.

- Filling the screed with a layer of 5 centimeters. Recommended thickness is 10-12 centimeters.

- Creating a finished floor.

When laying pipes, the minimum distance from the walls is 20 centimeters. You should not place them under cabinets and racks. Before starting work, a drawing of the future system is made.

Requirements

Before starting installation work, draw up a TP diagram . Based on it, the required amount of materials is determined and the power of the heating system is calculated. When designing it, the requirements for the installation of a heated floor and the materials used are taken into account.

Water floors:

- The heating circuit must be at least 15 cm away from the walls.

- According to SNiP 41-01-2003, clause 6.5.12, the temperature of TP for rooms with temporary presence of people should not exceed 31 ° C, with the constant presence of people - 25 ° C.

- According to SP 41-102-98, the temperature difference in different parts of the heating system should not exceed 10°C.

- According to SP 41-102-98 clause 3.5 a, the maximum permissible coolant temperature is 55°C.

- The surface on which the TP is laid must be flat. Differences within 5 mm are acceptable. Otherwise, there is a high risk of pipes becoming airborne.

- Before pouring the screed, a damper tape must be laid around the perimeter of the room, around columns and other elements rising above the lower floor.

- In order to prevent heat leakage towards the ground or into the lower room, a layer of thermal insulation is laid. The optimal choice is foil materials with a thickness of 5-10 mm.

- It is recommended to use any of two methods of laying loops: “single coil” or “spiral”. In the first option, the temperature distribution of the floor surface will be uneven. This method is optimal for local heating of any space in the garage (for example, in a parking area).

- Installation of pipes must be carried out in accordance with the markings applied to the heat insulator. To complete the task, anchor brackets are used, which are attached in increments of 30-40 cm.

- When pouring the screed, the pressure in the pipes must be 0.3 MPa.

Electric floors:

- Heating elements are placed at a distance of at least 5 cm from furniture, risers of a centralized heating system, household and other appliances.

- For maximum efficiency of the TP system, heating elements must cover at least 70% of the room area.

- The control unit is placed no lower than 90 cm from the floor.

Laying heated floors with antifreeze

The disadvantage of a water floor is that the freezing temperature of the coolant is quite high. If the room is not regularly heated in winter and water is not drained from the pipes, they may freeze and become damaged. The problem is solved by pouring antifreeze into the system. Depending on the additives, its freezing point is from -65 to -30 °C.

Laying the coating is no different from the work for a conventional water floor. Such a system requires the installation of a more efficient pump so that the liquid circulates freely. Antifreeze is used instead of water. The liquid is made from two substances: ethylene glycol or propylene glycol. The second one is more expensive.

Installing underfloor heating with antifreeze is more expensive than its water-based counterpart. The choice of more expensive equipment is required, but the system will pay for itself with “cheap” heating compared to other types.

Rules for choosing porcelain stoneware

Owners of garage buildings who have decided to lay porcelain stoneware on the floor are interested in the question of how to choose this material.

There are several rules that will help you make the right purchase.

- First of all, you need to read the reviews and opinions of those car enthusiasts who have already used this material.

- You need to learn to distinguish ceramic tiles from porcelain stoneware. This finishing material has a uniform structure. In contrast, the tile on top is painted in a certain color, which when cut is significantly different from the overall structure of the plate.

- To determine the high quality of porcelain stoneware, use a regular marker. They are passed over the surface of the product. After 5 minutes, the applied mark can be easily removed from high-quality tiles, otherwise the product should not be purchased.

- The weight of one square meter of finishing material is of no small importance. Such information is usually found in the accompanying documents for the products. In the absence of such documentation, the quality of the product should raise doubts.

- Porcelain tiles for the garage floor should be chosen with smooth, regularly shaped edges, without chips. This is what indicates its high quality. It is imperative to examine the reverse side of the material for the presence of depressions on it. Their depth is considered acceptable up to 1.5-2 centimeters.

- The product must indicate the country of origin of the product.

Safety precautions

Operation of heated floors, all installation work must be carried out strictly in accordance with the instructions from the manufacturers.

There are several risks when working with them:

- leakage – relevant for water and antifreeze floors. In the first case, the quality of heating is simply impaired and dampness increases. Leaks of ethylene glycol antifreeze can cause poisoning. This substance creates toxic fumes that cause various diseases. Propylene glycol is safer. Antifreeze is also fluid and leaks in the most unexpected places;

- short circuit, overheating - relevant for the electrical circuit. This type of floor does not like carpets and other coverings, as they retain heat and lead to overheating of the system. For this reason, the wheels should not rest on the cable.