- December 14, 2019

- Floor

- Lyudmila Storozhenko

Electric underfloor heating systems are popular. They save energy and create comfort and coziness in your home. It is pleasant to walk on such a floor. It is important to note that operating the system is not difficult.

There are many options for underfloor heating. The choice of system depends on a number of factors. In this article we will look at which heated floor is best to choose for linoleum.

Features of electrical systems

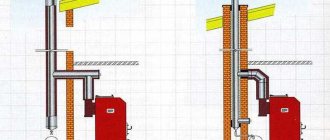

The easiest way to install the electrical system is under the linoleum. There are also water heated floors. They are mounted in a thick layer of screed, so the best covering for such systems is tile, as it has high heat transfer.

Linoleum is a thin polymer material. It is installed both in private houses and apartments. During the renovation process, homeowners are wondering which heated floor to choose for linoleum. There are several system options that are suitable in this case.

A heated floor powered by electricity consumes 120-180 W/m² at full power. When using a thermostat, this figure decreases. Moreover, such systems can be used to create both autonomous and additional heating. In the first option, there are no other heating devices in the room. The room is heated exclusively with underfloor heating. In this case, it is necessary to cover at least 70% of the room area with the heating system.

Additional heating assumes that there are other heaters operating in the room. In this case, the heated floor is installed only in certain areas, for example, near the bed, next to an armchair, sofa, or dining table.

Disadvantages and possibilities for their elimination

- Electricity costs

Although the floor consumes a relatively small amount of energy, its constant operation affects the meters. To reduce energy costs, you should control the temperature, prevent overheating, and set it to light warm-up when leaving for a long time.

- Trouble with power supply

A regular outlet will not work to supply electricity. Installation of a separate power line with increased power is required, as well as installation of a machine in the panel.

Heating cable

When considering which warm floor is best to choose for linoleum, it is worth paying attention to a number of features of its installation. If you are planning to do major renovations indoors, you may prefer a heating cable. It is mounted in a screed. The floor level in the room will rise by 7 cm or more.

This option is suitable for owners of their own houses and apartments with high ceilings. First, thermal insulation (expanded polystyrene) is laid on the prepared rough base. A reinforcing mesh and guides for the heating cable are laid out on top. The wire is then mounted on these guides. The laying step is 10-15 cm.

The wire is covered with a tie on top. Its thickness is at least 3 cm. If the pitch of the turns is wide, the screed should be even thicker. It is unacceptable for there to be air bubbles in it. When the screed dries (at least 3 weeks must pass), linoleum is laid on it.

Preparing the base

This is a general point and the quality requirements will be similar regardless of the floor covering. There are only two requirements - thermal insulation and smoothness.

For high-quality thermal insulation, a material is needed that, with low thermal conductivity, has high elasticity.

Of the entire range of materials offered, the ones best suited for our purpose are:

- Cork backing;

- Cross-linked polyethylene foam;

- Extruded polystyrene foam.

The difference between them is that the cork backing is laid on a plastic film to avoid exposure to residual moisture from the screed. In terms of thickness, it is best to use 4 mm material.

But the substrate must be laid only on a perfectly flat and smooth surface. The concrete base should be leveled with a quick-drying self-leveling screed. It gains strength throughout its entire thickness within 1-2 days. And what’s especially nice is that you can do without beacons. The mixture prepared according to the instructions will level itself to the horizon level. After the screed has matured, it is coated with a primer.

See also: Heated floor thermostat

Wood floors require a different approach. Moisture-resistant plywood, 18-20 mm thick, is best suited for leveling them. Before work, the sheets should be sanded from the bottom side. The sheets are laid end to end and screwed with self-tapping screws. There is an allowance of 1 cm between the wall and the covering. The frequency of fastening along the edge is 15-20 cm, and in the center 30-40 cm. The heads of the screws should be slightly recessed. After fixing the plywood, they go along the seams with a sander. This will allow you to even out minor elevation differences. The best test of reliability is your own feelings. Walk on the floor, jump in different places. If there is no creaking or vibration, then the base is ready for thermal insulation.

Lay a substrate on the prepared base. It can be fixed with double-sided tape. In this case, the adhesive tape must be pasted in such a way that the edges of adjacent sections of the substrate fall on one strip.

IMPORTANT: the direction of laying the substrate must be perpendicular to the strips of the heating film.

Pay special attention to the joints between adjacent strips of insulation. OVERLAPPING IS NOT ACCEPTABLE!

On top, sections of heat insulation are taped along the seam.

Heating mat

When installing an electric heated floor under linoleum, you can consider another option. This system is called a heating mat. It is a polymer mesh on which the heating wire is laid out. It is thin, so it does not require installation of a screed. Heating mats are laid in tile adhesive, the thickness of which is at least 7 mm.

If the installation is carried out on the second and subsequent floors, the insulation does not need to be laid on the base of the subfloor. Heat loss in this case will be minimal. If the heated floor is installed in a private house or on the first floor of a high-rise building, thermal insulation must be installed. A layer of screed at least 3 cm thick is poured on top. When it dries, the mat is installed.

A thin heating wire is more suitable for installing tiles. When laying it under linoleum, you will have to perform a number of additional works. The cost of repairs in this case will be high. Such a system has been in operation for 40-50 years.

Heating mats for linoleum

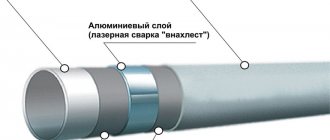

TP designs of this type are used only for additional heating. The design is reminiscent of heating cable heating technology, with the addition of a protective shell. The conductor is attached to a non-metallic mesh. The top is covered with a protective layer of rubber and PVC fibers.

Heating cable mat from a 220 V mains voltage.

Heat is transferred to the floor material through the aluminum shell. Advantages

this method TP:

- easy installation that does not require skilled hands;

- simple calculation of the required amount of material;

- high heating rate of decorative material;

- automatic process control.

The downside is the relatively high price.

As with the heating cable method, the working conductor comes in two types: single- and double-core. The latter type is more often used for residential premises. Can be laid on any flat surface (including wood). For a single-core element, concrete preparation is required.

It is important that the interfloor covering is warm. That is, adjacent to another warm room. If this is a cold base of a basement, balcony, loggia, it is necessary to insulate it and prepare it for laying the TP - make a cement-sand screed. This work is easy to do with your own hands. TP made from heating mats is installed in the following sequence:

- Drill a hole in the wall of the required diameter for a junction box and a corrugated tube for leads from the system to the thermostat.

- Prepare the surface: remove dust, prime.

- Spread foil-type thermal insulation. Connect the edges with aluminum tape.

- Lay the heating system strips according to the preliminary plan.

- Make a fine in the monolithic base according to the markings. Lay a corrugation for the temperature sensor.

- Place the sensor into the corrugation. Seal the fine with mortar.

- Connect the mats to cold conductors. Lead their ends through the pipe to the junction box.

- Place waterproofing made of polyethylene film with the edges on the wall.

- Measure the resistance of the mats (instructions are included with the purchase). Check the operation of the circuit.

- Pour a cement-sand mortar screed with a thickness of at least 30 mm.

- After complete drying, lay the material.

Pouring a heating cable with concrete

If you do not immediately get a smooth surface of the screed, it can be leveled using a thin layer of self-leveling floors.

The device of the tape with a two-core conductor is made in the same way. Sometimes it is proposed to lay sheets of plywood or OSB over the heating system. This method involves rigid fastening of the flooring. When fixing with self-tapping screws, screws or dowel nails (depending on the material of the subfloor), the heating element can be damaged.

With the heating method with a two-core conductor, the connection to the external network occurs at one end of the cable. A coupling is put on the far end as a plug.

Laying diagram of a two-core heating cable

Video will help you do the job correctly and quickly. The execution algorithm is suitable for laying any material.

Installation of heating mat

Thin heating wire

If you need to install a heated floor under linoleum on a wooden subfloor, you can choose a thin heating wire. It has a thickness of 3 mm, unfolds like a snake in increments of 7-10 cm. This installation is called dry. It does not involve the use of tile adhesive or screed.

The wire is laid out in grooves specially prepared for it. They are cut out of plywood or a special board is purchased for mounting the system. When the thin wire is laid in the grooves, it is covered with a sheet of plywood.

The peculiarity of linoleum is that it is a soft material. If you mount it directly on the wire, bumps will appear in these places. The wire will be subjected to increased mechanical stress and will quickly fail. Therefore, it must be covered with a layer of plywood. Its thickness should not be more than 1 cm. Electric heated floors under linoleum on a wooden floor can be installed using this method. This is economically beneficial, since the operation of the structure does not cause difficulties.

What do experts recommend?

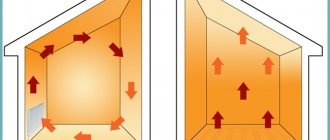

“Warm floor”, or heated floor, is an alternative method of heating a room. One of the advantages is the uniform distribution of warm air.

For those who decide to apply the method in their home, the question arises about choosing a floor covering. Many experts stop their eyes on ceramic tiles or laminate.

The issue of combining “warm floors” and linoleum also finds many supporters. Among the “advantages” are cost-effectiveness, ease of installation and dismantling, and a large selection of materials.

Not just any linoleum is suitable for heated floors - you need to purchase special models that are suitable for such a system

When they talk about the “cons,” they mention harm to health, fragility, and rapid deformation of linoleum when heated. To avoid such problems, when purchasing flooring you need to focus on the markings. It points to special additives that reduce ductility and increase the rigidity of the material.

Thus, the question about the possibility of laying linoleum on a “warm floor” can be answered positively. However, it is necessary to first study all the pitfalls when choosing a material and its installation.

Infrared heated floor

Experts agree that this option is one of the best when laying a heating system under linoleum. The system looks like a film, inside of which a special conductive paste is laminated.

It is advantageous to install infrared heated floors under linoleum for a number of reasons. This is the thinnest system. It does not need to be filled with screed and can be installed in literally 30-60 minutes. This is one of the most inexpensive types of electric heated floors. Its only drawback is its shorter service life. As a rule, it does not exceed 30 years.

The system heats the floor surface and interior items. The air in the room remains pleasantly cool. This is the main difference between the film and the heating wire. Since the thickness of the finishing material is small, tile adhesive and screed are not used. The surface heats up quickly. Literally in half an hour the system reaches the set temperature.

Properties

Let's consider the distinctive features of linoleum in comparison with other types of floor coverings.

Performance characteristics:

- ease of installation and dismantling;

- practicality in care and operation;

- wear resistance;

- water-repellent properties;

- resistance to dirt and stains;

- the presence of species that do not deform when exposed to high temperatures;

- good compatibility with other building materials;

- wide selection of products according to price indicators;

- linoleum made from natural materials has antistatic properties, low flammability, and resistance to acids and alkalis.

Linoleum has many advantages - it has a wide range of products and is resistant to moisture, temperature changes, and chemicals.

The list of positive properties is supplemented by minuses.

Among the shortcomings, experts note:

- instability to low temperatures;

- color change;

- erasure;

- exposure to mold and microorganisms;

- unpleasant smell of PVC linoleum.

A wide selection of products allows you to determine the ratio of price and quality of finishing materials.

If the linoleum is of poor quality, over time it may fade and wear out.

Start of film installation

Installation of heated floors under linoleum has a number of features. Manufacturers supply systems with instructions that must be read before starting work. In addition, you need to buy a thermostat. As a rule, these devices have a remote sensor that must be placed next to the heating system.

Film heated floors must be laid on a laminate base. It is best to choose hard materials, since linoleum is elastic and soft. You can use a cork backing. It will play the role of additional insulation.

In addition, massive protective elements are provided at the junction of the film and the wires. They need to be deepened into the lining material. They must not be allowed to rise above the level of the film. The linoleum in this area will quickly wear out.

Classification of linoleum

To make the right choice, you need to understand the characteristics of the flooring. The construction market offers a huge range of this product. To focus on the offered products only by price means making a mistake. What should you pay attention to when choosing linoleum?

The main task of the floor is to preserve the functional purpose of the room. First of all, let's pay attention to the classification of linoleum according to the tasks it is designed to perform.

There are three groups of flooring:

- household - for the operation of residential premises, with a relatively small flow of people and insignificant load;

- semi-commercial - intended for use in commercial premises, where the load level is defined as “medium”;

- commercial - meets the needs of public buildings and has significant thickness and strength.

There are three types of linoleum, and for residential premises, as a rule, household linoleum is used

An important characteristic is the chemical composition and structure of linoleum.

Based on their components, there are five types of linoleum.

| View | Description |

Natural linoleum | The natural material is made from wood flour, limestone, and cork tree bark. The composition is held together by linseed oil and pine resin. Dyes of natural origin are used in the production of linoleum. Organic components ensure the environmental friendliness of the material and the absence of toxic effects on the human body and pets during operation. Manufacturers note the antibacterial properties of the coating due to the linseed oil included in the composition. Consumers are also attracted by the safety of using a natural product - antistatic properties and high fire resistance. Wear resistance and indifference to chemicals ensure long service life. Disadvantages include fragility during transportation, the requirement for a flat subfloor, relatively low resistance to high humidity, and high cost. Natural material is painted in solid colors. |

PVC linoleum | PVC linoleum can have a different base structure: fabric, foam, non-woven. Such linoleum can be made without a base. Manufacturers offer materials consisting of 1-5 layers. Disadvantages of the product: it deforms due to temperature changes, emits a strong unpleasant odor, and is not resistant to chemicals. PVC linoleum is not safe from the point of view of fire requirements. When ignited, the material ignites easily and actively supports combustion. Experts do not recommend using such material for installing “warm floors”. At high temperatures it can release toxic substances. |

Glypthal (alkyd) linoleum | Made from alkyd resins, pigments and fillers. The production process includes the use of natural oils (linseed, cottonseed, sunflower and others). This increases the final cost of products and limits supply on the construction goods market. The product refers to coverings with a fabric base. It has good thermal insulation and creates acoustic comfort. The manufacturing technology of alkyd linoleum makes it possible to obtain materials of different colors and patterns. During operation, it can deform in length and width, develop cracks and breaks. It reacts poorly to temperature changes, which explains its increased fragility during transportation in the cold season. |

Rubber linoleum | Rubber linoleum is based on rubber. Products are made from recycled materials. The coating consists of two layers and is characterized by plasticity and water resistance. The advantage over other types of linoleum is its anti-slip effect. The properties of the material are used in the decoration of public spaces, sports and even medical buildings. Wide application is possible due to antistatic properties, resistance to low temperatures, and minimal slip. |

Colloxylin linoleum (nitrolinoleum) | Colloxylin linoleum is single-layer. It is made on the basis of technical nitrocellulose. The small thickness of the material explains the pros and cons of its operation. The thinness of linoleum ensures its plasticity, flexibility, and low weight. However, this also leads to low heat and sound insulation. Installation of such linoleum is possible only on an ideal subfloor and includes the stage of gluing the material to the base. The coating is characterized by increased flammability and sensitivity to acidic environments. |

Consumers note the material’s resistance to sunlight and pleasant shine.

As you can see, each product has a number of important characteristics. The choice must be made after carefully studying the proposals of the construction market.

Connection

The film must be cut based on the size and configuration of the room. Heating systems are not installed under furniture. The film is supplied in rolls, the width of which is standard and is 50 cm. Manufacturers provide the ability to cut it in the right places to make pieces of the heating film of the required size. Some make a dotted line along which a cut can be made at a distance of 50 cm, others - 10 cm.

Having cut pieces of the appropriate length, you need to connect the power wires to them. There are contacts on both sides of the film. These are silver strips to which metal terminals are connected. The clamps must pierce the contacts to create a proper connection.

When the terminals are connected, a wire is connected to them. Usually all the necessary components are sold as a kit. Many manufacturers supply additional parts separately.

Contact insulation

In the process of installing a film heated floor under linoleum, it is necessary to perform high-quality insulation of the contacts. This is necessary for the safe operation of the structure, as well as its effective functioning. When the wire clamps are connected to the contacts, they must be properly insulated.

For this purpose, the installation kit includes special gaskets. They are made from bitumen mixture. They cover the contacts by placing squares on top of the terminals. Then the paper on which the insulating material was applied is removed. This creates high-quality insulation.

Bitumen mastic does not allow water and dirt to pass to the contacts. This allows them to remain in working condition for a long time. To further protect the contacts from mechanical damage, they are covered with plastic covers. They are also included in the kit. The thickness of the protective caps can be up to 5 mm. Therefore, under them, recesses of the appropriate shape are cut out in the lining.

Thermostat sensor

Having decided which heated floor is best to choose for linoleum, you should pay attention to the installation of a thermostat. It controls the heating level. Without it, the system will consume more electricity.

The remote sensor is mounted in the floor next to the film. You don’t have to put it in a corrugated pipe if the system is installed dry. An appropriate recess is made in the lining so that the sensor does not protrude above the floor surface.

Compliance with thermal conditions

To select a high-quality floor covering, no special knowledge is required, because in the instructions the manufacturer indicates the possibility of using this material in the construction of heated floors. This information can be found near the marking; the permissible heating level is also reflected there; it is 27 degrees.

For your information! If the temperature is exceeded, the floor product will be damaged.

PVC linoleum can withstand +30, but there is no guarantee that the material will not be damaged, and the release of harmful substances is also possible.

To monitor compliance with the temperature regime, you will need a high-quality thermostat, ideally digital. Then, the temperature level will be maintained automatically.

Installation of a thermostat

For this device, a recess is made in the wall. The thermostat is installed next to the outlet. A round hole is drilled for it, as for a regular switch. On the reverse side of the thermostat there are several terminals (the number depends on the model).

Two of them are intended for connecting a remote sensor. Two more are needed to connect the wires to the infrared film. There are also terminals for connecting the phase and neutral of the network. Some models also have a seventh terminal. It is intended for grounding connection.

Completion of installation

Having connected the thermostat, an RCD must be installed in the system. Check performance with a multimeter. The resistance is indicated on the packaging. If everything is fine, lay linoleum. It is secured with a plinth around the perimeter of the room. If desired, you can eventually remove the floor covering (carpet) and lay it in another room.

We hope the information provided in the article will help you decide which heated floor is best to choose for linoleum. If you install the system correctly, it will be effective, durable, and will easily create a cozy atmosphere in your home.

Recommendations for laying linoleum

Linoleum is not laminate. You can't put it directly on film. You need a flat, solid base. To do this, you need to put a flooring made of plywood, OSB, fiberboard or flat slate on the film. You cannot attach it to the base of the floor through a film - there is a high probability of getting into live strips. Linoleum is laid on them. The technology is simple:

Attention: if the flooring has a seam, a waterproofing film made of polyethylene must be laid under the flooring. For a single piece, waterproofing is not necessary.

- a roll of linoleum for a warm floor is brought into the room and rolled out. It is cut to length and width with a margin of 10 cm (it has the unusual property of increasing in size in the cold);

- Leave it rolled out for 2-3 days - it should level out. You can speed up the process by turning on the “warm floor”;

- The floor covering is laid for further use. Experts recommend attaching it to the flooring with glue or double-sided tape. According to the editors of the StroyGuru website, the glue is more reliable - the flooring adheres to the flooring more tightly and does not heat up as much. For a felt base, “Gumilax” is suitable, for material without a backing - “Bustilat”;

Trimming linoleum near walls.

- When laying two strips, the seam at the bottom is glued with tape so that there is a tight fit, and then everything is glued. The glue is spread on both the flooring and the coating;

- Along the perimeter, the linoleum is secured with skirting boards.