The Russian stove, familiar to us from fairy tales and historical chronicles, has not lost its relevance to this day.

It is especially popular in rural areas and in the construction of country houses. A similar heating structure is used as a heat source for heating living rooms and kitchen areas. Thanks to the crucible's ability to retain heat for a long time, aromatic crumbly porridges, pastries and pies acquire an indescribable taste. This article is devoted to the construction of such a structure as an outdoor Russian stove. The process of constructing a structure is very labor-intensive and has many subtleties and nuances. But if you have the proper skills, abilities and desire, it is not something impossible.

It is considered rational to use heat-resistant bricks in the construction of an outdoor oven. In addition, we recommend providing a variety of cooking options. Such a device can be equipped in such a way that frying on the grill and skewers, baking, boiling, simmering and even smoking does not cause any difficulties.

Cladding an outdoor stove with bricks and making a smoke extractor (with photo)

The surface of the cornice is usually covered with clinker slabs, and its edges are decorated with facing bricks cut to the size of the end.

During facing work, it is necessary to ensure that the seams between the bricks are of the same width. After completing the masonry, use a narrow trowel to press the mortar into the seams so that they are completely sealed. Then smooth out the solution, let it dry, and then remove the seams.

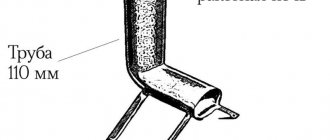

After completing work with the fireplace, you can proceed directly to the manufacture of the smoke extractor. Blanks made of sheet copper 1 mm thick should be pre-cut. The width of all allowances for creating the sides should be 29 mm, and the height of the pipe should be 50 cm. To make it, you will need four blanks, each 25 cm wide. On the two outer blanks on the left and right, you need to carefully bend the edges 25 mm wide at a right angle. After this, you need to attach the smoke eliminator hood to the fireclay insert guard. Instead of copper, you can use other sheet metal (stainless steel or galvanized iron) for the smoke eliminator.

To create the edges of thin sheet metal, you need to fix the workpiece between two pieces of hardwood, then use a rubber mallet and a mounting block to carefully bend the protruding edge. Then, on the workpieces at equal distances from each other, you should first make markings, and then drill holes with a diameter of 4 mm for the rivets. For a fastened smoke extractor, it is recommended to strengthen the edge of the hood using brass corners.

On top it is necessary to install a square chimney with a weather vane. You can simply put it on the cap, but it is still recommended to attach it using rivets. In this case, the pipe will definitely not be blown away by the wind.

The smoke extractor must be fixed to the furnace fence using galvanized steel brackets. Before this, they need to be bent and attached to the cap with rivets 12 mm long. In order to correctly mark the points for drilling holes for dowels, the cap with the pipe must be attached to the fireplace, determine the future location of the brackets, only then make the markings, remove the cap and drill the holes. The cap can then be placed and screwed on.

In the hearth there is a frame for hanging the grill grate and installing an ash pan. To make it you will need steel corners. They must be connected to each other with screws or welding. As supports for the grill grate, it is recommended to attach two vertical elements made of strip steel to the rear transverse element of the frame.

In addition, you will need a weather vane, which is a cap that crowns the chimney. It is necessary to prevent precipitation and birds from entering the mouth of the pipe and to protect it from moisture.

You can purchase a ready-made grill for cooking roast, but you can save money and weld it yourself from pieces of steel rod with a cross-section of 8 × 8 mm and a length of 540 mm each, having previously bent them. Do not forget that two pieces of such a rod will be needed for the grille frame, which is made first, and then the remaining rods (about 18 pieces) are welded onto it. Screws can be used instead of welding. After assembly, it is recommended to chrome plate the grille. Two similar pieces of rod must be attached to the longitudinal elements of the frame from above, which are used as guides for the retractable ash pan. The distance between them should be slightly larger than the width of the ash pan. The retractable ash pan itself is best made from black sheet metal 1.5 mm thick.

Watch step by step how to make an outdoor fireplace in the video below on this page:

Drying

After completing the laying of the Russian stove, it will be necessary to carry out the drying procedure. There are two ways. You can, for example, open the blower door, views, and valves (to create a draft). After 2 days, start heating the fireplace at the lowest power (if the fireplace is wood-burning, then use only dry pallets).

When drying, the stove should operate in a gentle manner: 2 times a day for 40-60 minutes daily, until the walls become dry to the touch and the mortar between the bricks becomes light in color.

It is worth considering that moisture from the damp solution will evaporate. It is necessary to thoroughly ventilate the premises after the drying procedure. If condensation appears on the walls, the water must be wiped off with a rag.

Depending on the size of the stove, drying lasts 4-7 days. Then you can start using the oven at full capacity. If you start turning on the fireplace at full power without first drying it, the walls will crack.

Design features

This design can have either one or two hearths. It consists of:

- internal combustion chamber for loading fuel;

- countertops for preparing dishes (optional);

- external hob;

- woodshed - a special compartment in which fuel is stored for drying (optional);

- space for a grate – can be combined with the internal combustion chamber.

Note! The larger the combustion chamber, the larger the dimensions of the structure itself and, accordingly, the greater the functionality. But remember that heating up an oven that is too large will take a long time, as will it take a long time to cool down.

Handy tools

A set of necessary tools is also collected in advance. It should consist of:

- Angle grinders 230;

- Angle grinders 125 (not necessary, but preferable so as not to rearrange the wheel and cup);

- extension cord with a tee (so as not to switch sockets);

- level 80 cm;

- level 30 cm;

- metal ruler 1 m;

- tape measures 3m;

- masonry trowel;

- regular and rubber hammer;

- a mixer with a nozzle for preparing a solution or a drill with adjustable speed;

- buckets for mixing the solution;

- containers for soaking bricks;

- hand and brick rags;

- concrete mixers (although you can mix by hand);

- shovels.

Accommodation

If you decide to install a barbecue stove on your property, then regardless of the type of stove you choose, you first need to think about fire safety - the place where it will be installed. It should be understood that any device with an open flame, if neglected in its placement and rules of use, threatens serious burns, large fires, which result in harm to human health (often fatal), surrounding buildings and nature.

It is safest to place a resting place with a barbecue on an area that is located at a considerable distance from the main buildings (country house, outbuildings, premises with animals and birds). But this is not always convenient, especially for an open outdoor brazier and those models that are under a roof, but do not have electricity, running water and other amenities of civilization.

Gazebos with barbecues can be placed on the same foundation as the house and under the same roof. But in this case, you must adhere to all fire safety requirements for buildings and residential premises.

It is not recommended to place such devices in the following places:

- near the storage area for firewood, hay, lumber and their waste;

- near dry grass, fire hazardous debris;

- close to fences and walls;

- directly under trees and overhanging branches.

When installing a collapsible barbecue in the garden or on the street, you need to take into account the speed and direction of the wind. Smoke should not go towards neighboring buildings and houses, and in cases of installing a stationary outdoor barbecue (including in a gazebo), you should take an interest in the local “wind rose” and build a protective screen on the side of the most possible “wind blower”. Special portable protective screens are available for sale, which is the best option for solving the problem of wind direction.

You also need to take care of the convenience of using the stove in the selected location of the site.

The following questions must be addressed here:

- a free approach to the device from at least two sides, because it is always more convenient and fun to cook with an assistant;

- there should be space for a table and seats nearby;

- the ability to provide a recreation area with clean water and lighting;

- Convenient access to the place from the house.

The following points should also be considered:

- how much time is expected to be spent at the dacha (this means constantly or only in the summer) - the installation of the stove indoors or in an open gazebo depends on this;

- how many people the recreation area is designed for;

- what design to choose for the barbecue area and gazebo.

Each owner will probably have a lot of questions about the design and selection of stoves, but they can already be solved in the process of creating the interior.

Memo

for those who still decide to install it themselves

- Decide on the type of stove to be installed outdoors.

- Decide on the location where the stove will be installed.

- Prepare a drawing of your future stove.

- Make a list of the necessary materials and tools, analyze the building materials market, and based on it, make a cost estimate.

- Develop a step-by-step plan for installing the furnace; this will help you navigate the time frame that construction will take.

- Start construction! And may your stove please you and your loved ones for a long time with delicious dishes cooked on it.

Installation of an outdoor stove

An ordinary garden stove in the classical sense is a stove made of brick or stone with one or two hearths.

It contains:

- internal firebox where firewood is stored;

- external hob;

- in more thoughtful designs there are places for smoking (usually in the chimney);

- places for a barbecue grill or grill, they can be combined with an internal firebox, or can be made separately;

- stoves come with two internal fireboxes - one open, the other closed;

- many stoves are equipped with a woodshed - a section or niche where firewood is stored for drying;

- For ease of use, there should be a countertop for preparing dishes (flat surface, ledge) on the front side of the oven.

The more spacious the firebox, the larger the oven itself, the more functionality the oven will have. But do not forget that a stove that is too large has great inertia - it takes a long time to heat up and takes a long time to cool down.

fire-resistant fireclay and decorative veneer, heat-resistant insulation, choosing bricks for laying stoves

The chimney can be made of brick, or a metal pipe of suitable dimensions can be used. There are also completely metal stove designs. Most of them are lined with brickwork during installation.

Materials

Projects for garden hearths usually contain a list of required materials. The foundation of a brick stove requires a solid foundation, which is poured over the formwork with concrete. If the foundation is deepened into the ground, a cushion of sand and crushed stone is required. To strengthen the base under the stove, reinforcement with metal fittings is used. Simple brickwork of the furnace firebox is done with fireclay bricks, but the best option is stove bricks. The remaining parts of the stove are made of red brick, since silicate brick is not used in the stove business. The ordering is carried out using a clay solution, which you prepare yourself or purchase a ready-made dry mixture. Construction cement-sand mortar is also used.

Functions of an outdoor stove

A well-functioning oven provides the following types of cooking:

- cooking;

- baking;

- frying;

- stewing;

- smoking;

- cooking kebabs (barbecue, grill, barbecue).

Well-made stoves also have the ability to heat water for various purposes. This could be a small fireplace for heating water for household needs, or it could be a built-in boiler with a storage tank. Most often, a garden stove is placed under a reliable canopy, but some options may be without it, simply having protective canopies on top.

In addition to cooking, great attention is paid to the opportunity to sit comfortably next to the stove and admire the living flames of the fire. Such stoves are classified into the group of fireplace stoves

Some types of stoves can be used to heat greenhouses or other buildings. There are also furnaces for various types of crafts - firing clay products, hardening iron parts. We will not consider them in this article; they are more related to industrial facilities than to household ones. Although, if you wish, you can burn a homemade cup in a simple oven or heat a stone for household needs.

Drying the lined stove

To prepare a newly built stove for the first fire, its entire structure must be completely freed from moisture. Drying fresh masonry will take about a week, during which a small fire is lit in the oven every day. The main thing is not to exceed the temperature of the outer walls (maximum +50 °C).

All parts of the oven are dried separately with a small fire made of torches and paper. The flame in the main firebox is lit when loading no more than 10% of the volume of firewood. Drying is complete if there are no wet spots anywhere on the surface and condensation does not appear on cast iron parts.

Types of structures

In the open air, when a summer cottage is being arranged, it is enough to install the simplest version of an outdoor barbecue. This device, made of bricks 5 or 6 rows high, two and a half bricks wide and four bricks long, is a temporary structure. It weighs little, so no foundation is required. For such a stove, you should find a flat area with dry soil (but not sand), compact it to good density and lay out brick walls without any binding materials.

You can place a thin reinforced concrete or cast iron slab on the bottom of the resulting oven. Air will flow to the fire through leaks in the brickwork. The fireplace is located inside; kebab sticks are placed on top directly on the walls of the masonry or on the barbecue grill. The grill allows you to cook simple dishes in a frying pan or in a saucepan. It is advisable to build a canopy over such a device to protect the fryer from precipitation and wind.

Often, outdoor cast-iron stoves with a roof are installed at dachas. The roof is built after the “cast iron” with a pipe is installed. If you do the opposite, you will either have to cut through the roof for the pipe, or run the pipe around the canopy (with elbows). This remark is true for any stove devices in rooms or sheds.

The most popular among summer residents are the designs of barbecues in gazebos. Some of these ideas may be of interest to most summer residents.

Prefabricated furnace complex. Suitable for large arbors with the prospect of winter living in the country. The complex includes a stove, barbecue and auxiliary devices: a countertop, a sink, built-in compartments for firewood or coal, shelves for utensils and accessories for frying, cooking, as well as a corner for placing fireplace accessories. A unique oven, a tandoor, is sometimes introduced into the complex. Using such a device, you can bake not only delicious Asian flatbreads - it can replace a barbecue, kebab grill, and even a smokehouse.

- Stove-grill with the design and functions of a Russian stove. A very complex design that only a professional stove maker can complete. It is best to arrange it in a permanent building with a good foundation and a reliable roof.

- An expensive stove model with three fireboxes. This device is a compact two-level option, characterized by convenience and practicality. Suitable for spacious and high gazebos. Here are combined options for cooking stoves with fireboxes of various functions: barbecue and smokehouse, barbecue and smokehouse, barbecue and Pompeii oven (pizza oven).

- The factory-assembled metal model is inexpensive. It can be used both permanently in gazebos and portablely outdoors. When these stoves are used indoors only, they are often lined with brick for safety and a beautiful design.

- Fireplaces have the same structure as stove fireboxes, but they have a different purpose. Fireplace stove models are a good solution for combining the functions of cooking and heating a room. Such models with a chimney exist only for closed outdoor gazebos. For open gazebos and terraces, these devices are impractical - the heat from the fireplace will not be retained in windy weather.

Models of ready-made stoves with barbecues have different solutions - they can be outdoor, garden, with or without awnings. You can also find options with chimneys of different designs, with and without pipes, expensive and budget ones. But if the owner has the hands and the material, then equipping his dacha with a beautiful and convenient stove device will not be difficult.

General Tips

- When laying out the firebox, the thickness of the seams should not be more than 3 mm (lining).

- It is easier to erect any ceilings when using a collapsible wooden frame.

- Lay out all rows neatly and evenly, immediately remove excess solution.

- It is better to place the door on a wire, which should be walled into the masonry, leaving the ends for a tie. With them you can easily and firmly pull the fire door frame into place.

- If you need to install a damper in the chimney or install a sink instead of a countertop, do not forget to make the necessary changes to the masonry.

- If the chimney is on the roof of a gazebo or shed, insulate it with a layer of asbestos or other non-combustible material, and the entire stove must comply with fire safety rules.

- Select the clay mortar required for masonry in advance. It should be too fatty, but it should also have the necessary plasticity. As an option, you can buy ready-made masonry mortar in hardware stores, but it will cost more.

Any garden stove is laid out approximately according to this plan. It is also possible to construct a furnace from iron materials. Craftsmen even make mobile ovens on wheels from iron barrels and old gas stoves. Such ovens are usually more mobile. But they burn out much faster. Of course, the industry does not stand still, and today you can find various types of stoves for your garden on sale.

Simple brick outdoor oven for bread and pizza

You can build an outdoor oven for bread and pizza from various materials - refractory bricks, concrete slabs or from special ready-made modules for the construction of ovens, which are assembled like a construction kit. It will take no more than three hours to build an outdoor pizza oven from ready-made parts, and more time is needed to build a house around it.

The location for the construction of an outdoor cooking stove should be chosen especially carefully. Although such a stove does not use open fire, it is still necessary to choose an area protected from the wind, away from wooden buildings and trees (at least 6 m), but not too far from the house, since you will have to carry food and dishes.

The mass of a simple outdoor stove is at least 400 kg, so a special foundation must be built at the site of its installation. To do this, you need to remove the soil to a depth of 20-40 cm and put a compacted sand-gravel mixture.

Reinforced paving slabs 5-10 cm thick must be laid on top. One row of brickwork should be laid on the foundation, which will serve as a support for the furnace walls. Then you need to build an underbowl - a frame made of 9x9 cm timber, overlapped with fastening bolts. A fireproof heat-insulating board 8 cm thick will be mounted on the finished frame.

The main part of a simple outdoor stove is the firebox, or crucible, which is a rectangular box where wood is burned. Food is also prepared in it. In the furnace there is a mouth for the exit of flue gases. Above it is a chimney. The depth of the furnace is usually 75-100 cm.

Brick or concrete slabs are used to build the furnace. In addition, you can purchase a ready-made construction kit for outdoor stoves, the parts of which are made of special heat-resistant concrete. This brick summer stove is easy to assemble as a construction set.

The finished blocks are connected to each other using a special heat-resistant mastic adhesive. Instead, you can use a solution of 2 parts ordinary cement, 4 parts heat-resistant cement and 4 parts mortar. Before laying, it is recommended to moisten the seams and then avoid gaps in the mortar layer. If you couldn’t get a ready-made kit for building a bread and pizza oven, you can build it yourself out of brick. For masonry, it is recommended to use normal fired red brick, and the firebox should be built from refractory brick. As a solution, it is best to use a mixture of refractory clay and sand (in a ratio of 1:2) and mix with water until the consistency of thick cream.

While the finished bread and pizza oven is drying, you can begin to protect it from precipitation. To do this, the rafters in the lower part must be fixed to the foundation slab and covered with clapboard formwork. In this case, you should leave at least 20 cm of space between the stove and the roof slope for further thermal insulation of the stove. The top of the roof should be covered with bitumen shingles, and the roof ridge with sheet steel.

The pipe should be inserted into a lead-lined sleeve filled with mineral wool. To protect the pipe from moisture penetration, it is necessary to fill the gap between the cuff and the pipe with high-temperature silicone. A layer of mineral wool should be laid between the pipe and the roof. Insulation is very important in outdoor ovens. Between the stove and the roof slope you need to pour a layer of non-combustible expanded clay 10 cm thick and lay mineral wool. This layer will protect the roof from overheating and create the optimal temperature for baking. In addition, high-quality thermal insulation will allow you to cook food even in the cold season - down to -10 C. At lower temperatures, it is not advisable to use an outdoor stove: a large amount of firewood will be consumed.

The roof overhang in front of the mouth of the furnace is a fire hazard, so it must be lined with fire-resistant slabs 30 mm thick. Due to the intense heat from the stove, it is recommended to build the pediment not from wood, but from cellular concrete 50 mm thick and tiled. For greater reliability, all wooden parts should be coated with a special protective compound - fire retardant. In addition, any open-air wooden structure must be protected from fungus, insects and rot. You can use special chemicals for this. The easiest way to protect wood is to apply moisture-resistant paint to the wooden parts of the structure.

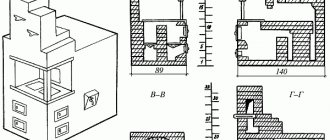

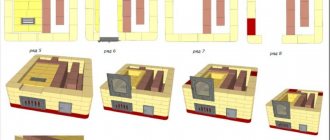

Laying order of rows

Since the first three levels are practically not subject to heating, it is allowed to use superheated bricks when performing them. However, if a Russian stove has bottom heating, it must be completely lined with high-quality refractory bricks.

First six rows

Since sweating is excluded, the foundation does not need a screed, and the masonry is carried out dry. Initially, the front left corner is made, where a three-quarter brick is placed with the butt facing outwards (in figure “a” under the number 1). With it, 12 full-sized bricks go in one row exactly up to the corner indicated by the number 2. In the first three levels of masonry, the seam remains expanded, which ensures the formation of a ledge in the fourth row.

The corner indicated by the number 2 is created using 2 three-quarter bricks, laid with the butts facing outwards. Further to corner a-3 there is a double level of full-length ones. The segment from a-3 to a-4 is laid according to the same pattern as a-1, as well as a-2.

In the front front part, a space is left empty, which subsequently forms the underlay. To do this, the laying of the first row is completed with two full-sized bricks, which will create an opening measuring 54 cm.

As can be seen in figure “b”, the pokes of the first row in the left and right corners are covered with spoon bricks. Each corner consists of two three-quarter blocks laid using spoons. One level of three-quarter bricks is laid on top of the full-size bricks of the opening. In this case, the seams must be tied.

The third row is designed similarly to the first row.

To complete the fourth level (Figure “d”), a brace is pulled, while the bricks are positioned in the same way as in the second row, and the seam is narrowed to 0.5 cm. As a result, a small ledge 2.5 cm wide is obtained on the sides of the stove. The work performed is checked by the level.

The diagram of the fifth row is shown in Figure “e”. 2 three-quarter bars are placed in corners 2 and 3. The back side consists of 2 spoon levels, and the side structural elements are made in bonded rows. The bricks used to lay the wall of the oven opening are pulled together under the heel of the arch. On top of the 5th level, circles of the arched lintel are installed on wooden supports. The sixth row is designed similarly to the fourth. The laying of the vault to cover the under-kiln begins here.

The first of the arches

When making arched lintels and vaults, the following conditions are met:

- all seams must be bandaged;

- their thickness decreases from the top of the arch to its base - from 1.3 cm to 0.5 cm;

- It is allowed to remove formwork and circles only when the solution is completely dry.

If the arch does not continue into the vault, it is not necessary to use formwork to lay it. The work is done directly in circles.

Rows 7 to 10

The order of laying the seventh level repeats the arrangement of the bricks of the fifth, and the eighth - the sixth row. On the inside, the butts are squeezed under the base of the arch. Starting from level 8, we lay the subfloor.

It is necessary to make three rows of full-sized bricks, laid with butts. In this case, the middle pin level is tucked under the arch of the arch.

By analogy with the seventh, the ninth row is also designed, but the second level of the sub-pile must be made with spoon bricks.

The masonry diagram of the tenth row is shown in the figure on the right. The corners are decorated with three-quarter bricks, the sides with full-size spoon bricks, and the front with full-size butt bricks. The front part of the furnace is laid out from three levels of full-sized bars, located butts deep. Each row consists of seven bars laid flat. It is they who subsequently form the sub-height.

Bedding

We use clay mortar mixed with broken bricks to fill the furnace. Please note that it must be stretched and compacted, as shown by the arrow in the image. It’s quite difficult to do a crooked job on your own. Not every stove maker is capable of such a task, therefore, without the proper skills, it is better not to take on this task.

Laying rows 11 to 17

Starting from 12, all even levels are performed according to the same scheme as the tenth. The odd ones are laid out on the sides with pokes, and at the back with spoons. It must be taken into account that the 15th and 16th rows should be tucked under the arched bases.

Upon completion of level 17, the masonry is interrupted until work is completed on the front side of the furnace up to the vertical part of the rear wall of the mouth.

Complex structural elements, as well as arches and vaults, are built using auxiliary wooden devices - circles. The side walls of the corner - the section of the hearth where hot coals are raked - are laid out the width of a brick, and the head and mouth - half a block. In this case, the base of the arch of the pharynx falls on the 15th row, and the mouth – on the 16th.

It can be difficult for non-professionals to smooth out the walls of the heil from the inside, because the view is very limited. A similar procedure is performed from above, and the correctness of its implementation is checked using a template.

Row 18 and beyond

In the figure shown above, you can see that the odd levels repeat the arrangement of the bricks of the 11th row, and the even ones - 10. In the event that you decide to make a floor on a clay basis, then all the bricks starting from the 19th level will have to be trimmed so that they lie on the the roof of the furnace.

Style and design

It is better to equip the summer kitchen area with a barbecue and cooking stove in the country house taking into account the already established natural landscape. Even a beautiful hedge with trees nearby can be a great starting point for stylishly decorating a seating area.

A view of a river or pond also suggests an original plan in relation to the surrounding view. The main thing in the arrangement is that the design of the recreation area should be in harmony with the surrounding landscape and match the design style of the house. If there is no house structure yet, then the plan for the kebab shop site needs to be developed in the same style as the plan for the future house and surrounding areas.

In more difficult circumstances, when there is neither a house nor the beauty of the landscape around, there is only one way out - to choose the style direction for arranging the site and housing to your liking. Landscape designs of smooth, flowing lines using natural wood and stone, as well as the Art Nouveau style with the obligatory presence of forged elements are now popular.

Gazebos can be of different shapes - from round to polygonal options, and barbecues - cast iron, wrought iron, brick or metal. The main thing is to maintain the chosen style.

Choosing a place

To decide on the place on the street where the stove will be installed, you need to take into account the following nuances:

- The stove should be close to the place where you plan to eat: in the summer kitchen, near the gazebo, not far from the dining table.

- It is better if there is a source of water nearby, as well as electricity.

- It is preferable to place the stove away from the cesspool, toilet, or livestock barn.

- The road, a source of harmful gases and dust, should be as far as possible from the stove.

Bricks for outdoor barbecue ovens

Many design projects for outdoor stoves and barbecues cannot do without modern building materials. Therefore, to add originality and sophistication to the facades of fireplaces, ceramic bricks that have appeared long ago are used. It is one of the types of facing bricks. And new shades and colors of brick will complement the uniqueness of this modern material and will allow you to easily decorate any barbecue complex project.

1) Clinker brick. During its production, a higher temperature is used, which makes it more durable and lasts longer. It is absolutely frost-resistant, extremely wear-resistant, has low porosity, and is easy to clean (a brush and water are enough to clean it). Clinker bricks can be figured; they are sometimes used in lining garden kiln complexes. Thanks to its varied shape, this type of brick is perfect for a variety of designs, allowing you to realize any fantasies. It combines perfectly with other materials and is environmentally friendly. There is also façade clinker brick, which is usually colored.

2) Kiln brick

Such a brick can withstand significant temperatures, it has a high thermal conductivity coefficient (it accumulates and releases heat well, which is very important for outdoor fireplaces, as well as garden barbecue stoves), and has an attractive appearance and color. This type of brick is indispensable for garden fireplaces where high temperatures are used.

Such bricks contain a large percentage of clay; sometimes graphite or coke powder or quartz are added to it, producing different types of bricks with fire-resistant properties. 3) Fireclay brick. Designed for the internal parts of barbecue fireboxes. It is obtained by firing fireclay and refractory clay, but it is important not to overcook the brick, otherwise a glassy film will form on it. Fireclay brick has a yellow color and a granular structure; it is used in laying out fuel chambers, hearths, stoves, fireplace inserts, and chimneys due to the fact that it is highly resistant to high temperatures. Before laying, the brick is checked for quality - they tap it (there should be a metallic sound) and try to break it (it should crack, not crumble).

4) Hollow facing brick. It comes in several types - hollow thermally efficient brick (it has an air layer, which prevents the walls from freezing and reduces the efficiency of heat exchange between the internal and external fireboxes of an outdoor fireplace), hollow ceramic brick, in addition to thermal insulation, retains moisture well, which has a beneficial effect on the future operation of the complex . Ceramic hollow bricks come in two types: glazed (glossy) and engobed (matte). They are used as a design solution in a variety of projects.

5) Textured brick. It has a number of advantages, which is why professionals are so interested in it. And already in its first use it proved its usefulness and reliability.

1. Unusual appearance. Ordinary building brick has always been a top seller, but it is very simple and unremarkable in appearance. Therefore, brick manufacturers decided to create a brick that would look like a work of art. Projects made from textured bricks are amazing and unique.

2. Technical characteristics. Having changed the appearance of the brick, its technical properties were not affected at all. Textured brick is also durable and practical, for which builders value it very much, since facing building materials are short-lived, and over time they deteriorate and crumble. And also this textured one protects the object from the negative effects of the environment.

4. Bricklaying. Some types of material are sometimes abandoned due to their complex masonry technology. A lot of experience or specialization in a certain field is required, so specialists are looking for other solutions. And although textured brick has changed in its design, the installation process remains the same as with ordinary bricks.

To summarize, ceramic brick is not a new product, and at the same time it remains the same good old brick.

Barbecue complexes. Video

Articles:

| Building a brick barbecue for a summer cottage is not always a complex construction; it all depends on the option chosen and your capabilities. The simplest project can be laid out on a platform or slab in a tower without using mortar, each row is laid with the seams bandaged, keeping the masonry vertical. Such a country house will be ready for use within a day. |

Trial fire

After drying is complete, perform a test fire in the following sequence:

- the combustion chamber is loaded as much as possible with dry wood, laying it in dense rows and set on fire. At this moment, the valve should be fully open, and the wellhead valve, on the contrary, should be tightly closed;

- after the first batch of firewood has burned out, the next portion of wood is loaded, but only 2/3 of the furnace is already filled;

- The intensity of fuel combustion is regulated using a valve;

- Complete closing of the valve is possible after all the firewood has burned out and the formed coals have gone out.

The next fire can be started only after the stove has completely cooled down.

Furnace designs and sizes

The design and size of an outdoor stove depends on its type.

Russian

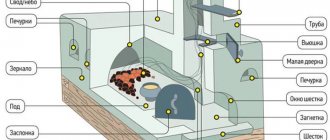

This option has the most complex design, which consists of the following parts:

- Opechek is a cavity intended for storing firewood.

- A stove is a recess for drying fuel.

- A shelf is a platform in front of the firebox for placing dishes before placing them in the oven or after preparing a dish.

- Under - the lower surface of the cooking chamber.

- The firebox is a cavity where firewood is stored.

- The overpipe is a place for collecting smoke from the firebox, which goes into the chimney.

- Dushnik is a small window that serves as a place for smoke exhaust. It also leads directly to the chimney.

- View - a damper for completely blocking the chimney. Inside there is a second damper that controls the draft of the stove.

- A lounger is a space above the firebox that is used as a sleeping place or for storing kitchen utensils.

The external dimensions of the stove may vary and are selected in accordance with the wishes of the homeowner and the size of the site on which the structure will be erected. In addition, you need to take into account the length of the lounger and the presence of additional functional features, for example, recesses for a cauldron, etc.

The depth of the foundation depends on the external dimensions of the furnace and the characteristics of the soil, but cannot be less than 50 cm. There are established standards for cast iron structural elements.

| Name | Size in cm | Quantity in pcs. | |

| Door | Firebox | 20x20.5 | 2 |

| — | Blowing | 25x14 | 2 |

| — | Ventilation | Arbitrary | 1 |

| Lattice | grate | 38x25 | 1 |

| Gate valve | 26x26 | 1 | |

| 18x14 | 1 | ||

| 14x14 | 1 | ||

| View | 23 | 1 | |

| Damper | Firebox | 45x38 | 1 |

| Water heating box | 50x12x28 | 1 | |

| Hob with two burners | 40x70 | 1 | |

| Steel rods | 100x5x1.2 | 1 | |

| 143x2.5x0.2 | 1 |

Fireplace

When building an outdoor fireplace stove, the draft is not calculated, since the device is not intended for heating. To organize the correct chimney, you only need to comply with the established standards for fireplace pipes. The cross-sectional area should not be less than 12% of the diameter of the firebox inlet.

Photo 1. Outdoor brick stove-fireplace. Installed under the roof of the gazebo, it additionally has countertops and a sink.

The external dimensions of the fireplace depend on the wishes of the homeowner, but when laying the foundation, it is made 50 cm larger than the future stove. The depth of the base is from 40 cm or more. For construction you will need:

| Name | Size | Magnitude | Quantity |

| Concrete plates | 75x50x5 | cm | 5 |

| 50x50x5 | cm | 2 | |

| Aerated concrete blocks | 65x40x10 | cm | 3 |

| Fireclay slab for firebox | Depends on the desired size of the firebox | 1 | |

| Copper sheet | 1 (thickness) | mm | 1 |

| Brass corner | 20x20x2 | mm | 1 |

| Mineral fiber board | 120x60x1.9 | cm | 1 |

| Brass rod | Arbitrary | 1 | |

| Galvanized steel brackets | 15x15x0.5 | cm | 10 |

| Facing brick | 230x114x65 or 250x120x65 | mm | Depends on the external dimensions of the fireplace |

| Clinker boards | 20x20 | cm | 20 |

| Square rod | 8x8 | mm | 1 |

Tandoor

The tandoor has a round shape, so the foundation is made the same. Since this is the lightest version of an outdoor stove, its depth can be from 20 cm.

The exact value is calculated taking into account the characteristics of the soil.

The optimal height of the tandoor is 100 cm.

The lower diameter can be increased at the request of the owner, but the ideal parameters are from 60 to 80 cm.

The upper part of the structure is narrowed to sizes from 40 to 60 cm.

Important! The amount of narrowing is indicated taking into account the optimal diameter of the tandoor - 60-80 cm. When laying the first tier of the stove, a blower is made

This could be a removable brick or a damper. The blower is designed to supply air when igniting fuel or increasing the temperature inside the furnace

When laying the first tier of the stove, a blower is made. This could be a removable brick or a damper. The blower is designed to supply air when igniting fuel or increasing the temperature inside the furnace.

Composition of the biosphere

Structure of the biosphere:

- Living matter

- the entire set of bodies of living organisms inhabiting the Earth, is physico-chemically unified, regardless of their systematic affiliation. The mass of living matter is relatively small and is estimated at 2.4...3.6 1012 (in dry weight) and is less than one millionth of the entire biosphere (about 3 1018 tons), which, in turn, is less than one thousandth mass of the Earth. But this is “one of the most powerful geochemical forces on our planet,” since living organisms do not just inhabit the earth’s crust, but transform the appearance of the Earth. Living organisms inhabit the earth's surface very unevenly. Their distribution depends on geographic latitude. - A biogenic substance

is a substance created and processed by a living organism. During organic evolution, living organisms passed through their organs, tissues, cells, and blood a thousand times over most of the atmosphere, the entire volume of the world's oceans, and a huge mass of minerals. This geological role of living matter can be imagined from deposits of coal, oil, carbonate rocks, etc. - Inert matter

is products formed without the participation of living organisms. - Bioinert substance

is a substance that is created simultaneously by living organisms and inert processes, representing dynamically equilibrium systems of both. These are soil, weathering crust, etc. Organisms play a leading role in them. - A substance undergoing radioactive decay.

- Scattered atoms, continuously created from all kinds of earthly matter under the influence of cosmic radiation.

- Substance of cosmic origin.

Do-it-yourself construction of a stove for burning garbage, cooking or decorating a site

In order to choose the right project for the construction of a furnace, the following conditions are calculated:

- functions are the main criterion; the type of device chosen and its features will completely depend on it; it is also better to immediately decide whether the stove will be used only for cooking or will also have a decorative function;

- availability of sufficient space - it is best if a separate area is allocated for the stove, where it will be convenient to place the devices themselves, and then put up a gazebo or canopy for relaxation;

- foundation - more compact varieties, for example, a stove under a cauldron will require only a special platform, larger and heavier devices are provided with a serious foundation;

- budget - depending on the amount of funds, more expensive and high-quality or more economical materials are used, the dimensions of the stove and decorative elements are also calculated.

After choosing the type of device, it is best to make a detailed drawing, taking into account the dimensions and costs of materials.

Materials

Refractory bricks are well suited for building a garden stove; for an economical option, fireclay bricks are used only for laying out the combustion chamber.

The walls of the furnace are made of ceramic bricks; you will also need a mortar made from a mixture of fire-resistant cement and sand.

It is recommended to use ready-made mixtures, which are sold in construction stores). The necessary parts are purchased - dampers, doors, hinges, most often made of cast iron.

Preparing the site

Installation of a garden stove is ideally planned at the same stage as the construction of a house. It is most advantageous to place it next to a relaxation terrace, a gazebo, or next to a convenient clearing or the shore of a pond, where it will be good to organize family evenings and relax with friends. The location near the house is most convenient, as it will save time in the future - it will be close to carrying food for cooking, fuel, and it will be easier to maintain equipment.

The foundation is made based on weight and dimensions. A pit is dug, at the bottom of which a cushion of crushed stone and sand is poured, formwork and a mesh of reinforcing rods are installed on it. Then the foundation is poured with concrete and left for a week to dry. The resulting platform protrudes above the ground by 10 - 15 cm.

Photo 1. Scheme of preparing the foundation for an outdoor stove with dimensions and explanations.

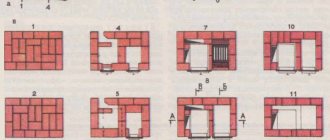

Step-by-step instructions for laying a stove. Order

Before starting, it is recommended to lay out the masonry according to the scheme without mortar, prepare and cut the bricks, mark them - this will greatly facilitate the work process and help avoid mistakes. Laying is carried out in the following order:

- Waterproofing is laid on the dried foundation.

- The base is laid out according to the diagram - while carefully monitoring the evenness of the rows (check with the building level).

- The combustion chamber is laid out - when using ceramic bricks, two rows are often made - an outer ceramic one and an inner one made of fireclay bricks. To lay out the device under the cauldron, bricks are cut according to the diagram to obtain beveled walls of the firebox.

- The cooking chamber is laid out - in models of two-chamber fireplaces.

- A chimney is laid out, and in some cases, smoke channels are laid out.

- Very often, garden stoves are lined to protect them from the elements, to better seal seams, and also for decoration.

Photo 2. Layout diagram from the first to the seventeenth row of a simple oven with one oven and a cutting table.

After construction is completed, the stove is left to dry, and after several days they begin to gradually heat it - first only with paper, then increasingly increasing the amount of fuel and heating temperature.

How to decorate a Russian stove in the house

To ensure that a Russian stove not only serves as a functional element, but also decorates the interior, a caring owner will pay attention to its appearance.

Methods for whitewashing a stove

Whitewashing is the easiest and cheapest way to maintain a stove. In peasant houses, the hearth was usually whitened annually. Now, in addition to recipes inherited from ancestors based on chalk or slaked lime, many specialized compositions of a new generation are available. To prevent the chalk coating from staining your hands and clothes, the solution is made with skim milk containing casein. You can add ready-made wood glue or liquid glass.

Plastering and painting

The stove is plastered with a solution based on fireclay clay, which is not afraid of heating. Now special dry mixtures with a pre-selected composition are available for sale. After the finished layer has naturally dried for 3-5 days, the oven is lit and the coating is checked for defects.

To apply drawings, special paints are used that are designed for use on heated surfaces. They are found in retail chains and are made on the basis of organosilicon polymers. A budget option is paint based on liquid glass.

First, the plaster is completely painted white. Then, using colored tints, designs are applied, the choice of which is limited only by the taste of the master. If you don’t have the ability to draw, printed stencils or a template printed on a printer will help.

Decorating the stove with tiles

Tiles are ceramic parts specially designed for decorating the surface of stoves. The tiles have a special box-shaped projection (rumpa) on the inside. An artistic layer of heat-resistant glaze is applied on the outside. Their installation must be provided for at the masonry stage in order to mount them to each other and to the surface.

Decorating the stove with tiles

Finishing with such elements belongs to the realm of art rather than construction.

Finishing a Russian stove with tiles

Ceramic tiles are quite suitable for external cladding of oven walls, because they are resistant to heat. To lay tiles on a vertical plane of the wall, nails are inserted into the masonry joints, each part is glued onto the mortar separately, leaving a wide joint to compensate for thermal expansion. The seams are rubbed with elastic mastic.