When noises occur

The new boiler operates almost silently, no louder than a household kettle. But sometimes, over time, if the components are incorrectly installed, configured or worn out, the device beeps quietly or even makes noise like an airplane.

Loud noises in the heating boiler disturb users; the reasons may be the following:

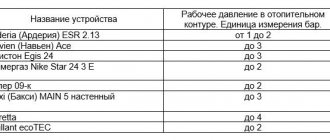

- The water in the system is highly oxygenated. When heated, air bubbles are released which produce noise. This happens most often in open heating systems. At the same time, not only the device itself vibrates, but also the wall radiators.

- The boiler puffs if a lot of air has accumulated in the coolant system.

- Scale in the heat exchanger. If the water is hard, over time lime will build up on the walls of the radiator pipes.

This also reduces equipment durability and efficiency. A sign of scale accumulation is that the device hisses like a kettle when it warms up.

- Strong noise can be produced by an incorrectly operating fan designed to remove combustion products. This can be caused by drying out of the lubricant inside its bearings, imbalance, or accumulation of dust and dirt on and around the blades.

- Perhaps it is not configured correctly, and that is why the gas valve or bypass is howling.

Bypass installation example - When operating at high power, a faulty gas meter rattles.

- If the equipment power exceeds the required, vibration occurs from excess pressure created by the pump. The device also cracks if there is too little coolant in the system.

- Often a loose valve or a valve inside it rattles.

Why does the heating boiler click? Why the heating boiler is noisy, let's figure it out together

A recently purchased gas boiler operates quietly, barely noticeable to humans. If during operation the unit suddenly begins to make noise, then this is a direct sign of the first malfunctions in the system.

The fan is out of order, the walls of the heat exchanger are clogged with scale, the components of the device are worn out or the boiler is not configured correctly - all these reasons lead to the device beeping, knocking, humming or making clicks

.

Why does a gas boiler make noise when heating?

There are many reasons

, causing alarming noise in a gas boiler.

Each problem requires a different approach

to fix it.

The fan located above the burner is faulty

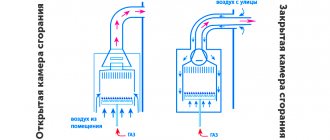

The fan provides ventilation in the system to remove and exhaust smoke, and also removes residual gas combustion products. Common Cause

Fan breakdowns occur

during operation.

The longer the boiler operates, the more parts of the system wear out.

Photo 1. This is what a fan looks like in a gas boiler. Its breakdown can cause unpleasant noise coming from the heating device.

Other causes of breakdowns:

- The fan located at the top above the burner

. Constantly being exposed to high temperatures burns out the bearing lubricant. This causes rapid wear. - The fan is full of dust

and residues from gas processing. - Manufacturing defects.

Reference.

There are characteristic sounds that indicate a malfunction of the device.

Listen to the operation of the boiler. If it makes clicking sounds at short intervals

, the cause is the fan.

In order to repair

fan,

the following manipulations should be carried out:

- First, inspect

the fan and

clean it from the inside

: the main blades are located on the inside of the housing, you need to free them from accumulated dust and dirt, and then lubricate the bearings. - If the problem has not been solved and the boiler is still noisy, you can replace the valves with ball valves

or install a rubber gasket. - If the previous measures did not help, then you should reinstall the cooler

. To do this, you need to call a technician and replace the worn-out device with a new one.

Scale in the heat exchanger

A heat exchanger is a boiler component that plays the role of an intermediary between the thermal energy of gas and water

, which heats up from it. Because of it, scale appears and lime accumulates both on the walls of the radiator pipes and in the entire heating system.

Photo 2. Heat exchanger from a gas boiler

Reasons for the formation of sounds and pops

Sharp sounds and pops have the following causes:

Semi-automatic boiler wick

Popping and clicking noises when igniting

When starting an Ariston or another brand of boiler, do you hear knocking and popping noises? The problem requires an immediate solution.

Three-way valve

The part is used to switch the operation of the unit from heating hot water supply (DHW) to heating, and vice versa. A faulty valve will click every time it is ignited. In this case, it needs replacement.

Ignition block

A loud bang occurs when the spark ignites for a long time. Then a lot of gas accumulates, which flares up when ignited. It is necessary to carry out diagnostics of the unit: burner, igniter, electrode, contacts and connections.

Wick clogged

When ignited, the product bangs, which indicates a clogged wick or chimney. The problem is typical for semi-automatic models. Inspect the wick: if clogged, clean it.

To make sure that the chimney shaft is clogged, check for draft:

- Place a lit match near an inspection window or vent.

- If the flame deviates to the side, the draft is normal; if it burns evenly, it needs cleaning.

For your part, you can clean out the mine. But to completely remove contaminants, it is better to contact utility services.

In models with automatic ignition, the electrode may become clogged. Clean the part and install it 3-4 mm from the burner.

The injectors are clogged

When heating, a noise is heard, ignition does not occur, or the flame bursts out in jerks. Turn off the gas supply and clean the holes with a thin wire.

Incorrect installation

If the calculation and mounting of the device body is incorrect, the sounds of metal impacts appear. When the cladding heats up, the metal expands, and when it cools, it returns to its previous position, which leads to extraneous sounds.

The same thing happens with pipes that are walled into walls. When you turn on the heating and start hot water, the pipes expand slightly, which leads to knocking. When installing pipes into walls, it is necessary to leave a gap for thermal expansion.

Heat exchanger plates clogged

Then the boiler explodes when heated. And the plates can become clogged with dust, soot and soot. Remove the housing and clean the parts with a wire brush or a special vacuum cleaner.

The mesh located at the bottom of the case could become clogged with dust. In technology with an open combustion chamber, this leads to a decrease in thrust. Don't forget to clean.

Incorrect operation of the circulation pump

As a result of uneven operation, resonance occurs in the system, which leads to extraneous noise. Adjust pump settings.

Before starting any work, close the gas valve.

To reduce vibration, place a gasket under the housing. Regularly maintain the unit and clean parts from scale and dirt. This will allow you to operate the boiler safely and for a long time.

Loud noise when a gas boiler is operating may be a sign of a faulty heating system. Extraneous noise occurs as a result of some kind of malfunction, which definitely requires attention from a qualified specialist. Such a malfunction should not be ignored for a long time, as it can aggravate the problem and lead to an emergency stop. Loud noise from the boiler is a problem that can easily develop into the purchase of a new one. This is incredibly expensive and should be avoided.

If you notice that the gas boiler has become very noisy, the only and correct solution for you will be to invite our service engineer to study this problem in detail. An employee from our company is a highly qualified specialist who is needed in every home in the event of a problem in the operation of the central heating system, to carry out diagnostics to identify the malfunction.

Strong noise from the boiler is the reason for immediate contact with us and a reason to resort to the services of our engineers. There are many reasons that cause boiler noise during operation. Some problems are minor and can be eliminated during one visit of our technician, while some require financial expenses, especially where several breakdowns have occurred.

Our company offers clients the following services:

- heating boiler repair →

- heating boiler maintenance →

- installation and wiring of the boiler →

- heating system installation →

- flushing the heating system →

- flushing the boiler heat exchanger →

How to avoid noise

It is important to turn off the gas before making any repairs. If you suddenly feel that you smell of gas, immediately turn off the tap at the entrance to the house, turn off electrical appliances, ventilate and call the gas service.

During installation, you can install an elastic vibration-absorbing layer under the casing in all places where the boiler comes into contact with the wall.

Boiler cleaning

First of all, it is important to carry out regular maintenance of heating equipment, which includes cleaning components, removing dust and lubricating some elements. This will increase the lifespan of your boiler and eliminate noise before it even occurs.

In a closed system, you need to add water from time to time, monitoring the pressure gauge. In some devices, for example, Visman Vitopend, it is displayed on the control panel at the bottom of the case.

Let's figure out what to do when the device is already making strange sounds:

- If the cause is oxygen saturation of the water, the problem can be solved by converting the open system to a closed one. To do this, air vents are installed on the water heating boiler and the expansion tank is replaced with a membrane one.

- The fan should be inspected and cleaned. It is important to note that the main blades are located inside the housing under the casing. After cleaning the dust and dirt, additionally lubricate its bearings. If this does not help, the cooler needs to be replaced.

- When the heat exchanger howls, you need to clean the scale inside it. In order to remove it, the casing is removed and the pipes connected to it are unscrewed. It is best to pour a special anti-scale chemical inside, which is sold in hardware stores, and leave it for several hours. If removing the heat exchanger is too difficult, the product is poured inside using a flexible hose.

- If the gas valve whistles, you need to check its settings. The correct configuration is written in the operating instructions.

Automatic gas valve - When the pump power exceeds the need of the system, it is necessary to reduce its speed by changing the position of the white switch under the cover on the terminal block.

- Air from the heating system is discharged through a brass air vent on the front panel of the device.

- If there is a popping noise when igniting in semi-automatic models with piezo ignition, such as Bosch W, clean the nozzle and pilot tube, which is ignited by the starter, from dust and clogging.

- When an automatic boiler, for example Ariston Genius, turns on with a loud bang, you should clean the ignition electrodes and, if necessary, adjust their location. After this, the fire will proceed quietly.

- Noise from valves can be prevented by replacing them with ball valves or installing an additional rubber gasket.

- To get rid of the fact that the gas meter is clicking, you need to call the gas service to check it. Most likely, you will have to replace the device.

- In order to eliminate metallic knocking when the temperature of the radiators changes, you should move the wall mounts to places that coincide with their support points. Putting rubber gaskets on the brackets also solves the problem.

- When heating pipes built into the wall ring, you need to lay a special insulating material called Merelon around them. It is advisable to think about this at the time of installation, so as not to spoil the repair later.

If it is difficult to localize the sound, let the boiler operate in different modes. For example, if you have a double-circuit device, for example Ferroli Atlas, and you don’t understand what and why it’s humming, turn off the hot water supply. Next, note at what time interval the extraneous sound appears, when the boiler is just starting up or at high temperatures, after it overheats.

Other Possible Causes

A gas boiler may hum for technical reasons related to wear of loaded parts of heating equipment. For example, rolling bearings hum if maintenance has not been performed correctly. In this case, the gas boiler begins to hum already at startup, even before the burner is turned on and the combustion front of the gas fuel appears.

In this situation, the culprit for the hum is usually the pump. In order to verify this, you need to remove the front panel and place your hand on the body while the pumping apparatus is operating. If the reason is in the bearings, then you will feel strong vibration.

Can a gas burner make noise?

This is the most difficult case to diagnose correctly. Only an experienced specialist can recognize the sound of a malfunctioning burner. The pitch of the sound changes depending on the set heating power; it is masked by extraneous noise and interference.

The removed front panel will help to distinguish the noise of the gas burner more clearly - the hum from the operating burner will become more audible. A normally operating device makes almost no noise. If a hum or whistle is heard, this means that gas combustion occurs in an off-design mode.

The input or output of pipes on a gas boiler is humming

Often it is not the gas boiler itself that hums, but the supply pipe at the inlet to the pressure regulator. This means that inside this section or tap at the inlet there is interference, due to which liquid vibrations form in the pipe. This is what old water valves sound like when they open.

You can try to fix the problem by replacing the tap with a model with a larger flow area.

Have you encountered a similar problem?

There was noise in the gas boiler, I fixed it myself.

62.5%

When the gas boiler was humming, I called the gas workers, and they fixed everything.

25%

I have fairly new equipment, so far it works flawlessly.

0%

I don't have a gas boiler.

12.5%

Voted: 8

Causes of noise

There are actually not so many reasons for knocking in heating pipes when heating. Some noise can be ignored - it does not harm the system or heating devices. But noises such as buzzing, crackling, knocking, gurgling, and howling should give reason to think and take urgent action.

- air pockets in the system;

- clogging or overgrowing of pipes due to poor-quality coolant;

- leaks in the pipeline;

- violation of installation work when installing taps, valves and laying pipes;

- failure or wear of working equipment;

- cavitation, an increase in pressure in places where the diameter of pipes increases (decreases);

- incorrect calculation or non-compliance with design recommendations when installing the heating system.

These circumstances arise in private closed-loop systems and make us think about their urgent elimination.

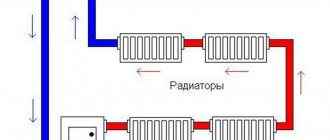

The circulation pump in the heating circuit system promotes forced movement of water, which leads to uniform heating and displacement of accumulated air from the system.

If the heating in a house or apartment is connected to a central pipeline, then startup, accompanied by similar sounds, is normal. Water, filling the general system, pushes out air, and, flowing along the contour, is accompanied by gurgling, knocking and crackling sounds.

As soon as the equipment enters operating mode, the general adjustment of the system will end - the temperature of the batteries will increase, and everything will stop. This is clearly visible in the diagram of heat supply to consumers from the central boiler house.

Problems with the ignition system

They can appear on both new and long-used equipment. There may be several reasons, it is worth considering the main ones:

- Incorrect burner position

, which makes it difficult to turn it on. Such malfunctions must be resolved by specialists, since it is impossible to check the pressure in the gas system and the correct operation of the unit by eye.

- Wick clogged.

Over time, plaque can be deposited on the surface, making it difficult for the equipment to ignite gas. Sometimes it accumulates in the chamber and due to delayed ignition, a loud bang is heard every time it starts. This not only causes discomfort, but is also unsafe, as system elements may be damaged.

- Failure or power failure of the ignition unit

. In automatic models, it is responsible for igniting the fuel. If this happens at the wrong time or the spark is weak, a characteristic chirping noise is heard when starting. Usually the sounds are heard for a couple of seconds, but if the period increases, you will have to replace the ignition system; it will not be possible to repair it.

Sometimes the problem appears due to a clogged chimney in a private house or blown out by the wind. Then the flame will be uneven, sometimes it goes out and lights up again with characteristic pops or clicks.

Types of noise in pipes

The noises that accompany the general heating start-up differ from emergency ones - they are intermittent and are accompanied by gurgling or gurgling. In bimetallic or aluminum batteries, a crackling or buzzing noise may be heard - this is also normal.

It is clear that prolonged noise is unpleasant, so it is necessary to prevent the situation in a timely manner.

The knocking and hum that occurs in the room with increasing force give reason to be wary and take drastic measures:

- Check heating devices and temperature conditions in the circuit. If a pump is installed, then its operation.

- Pay attention to the valves - if they break, a characteristic whistle appears. Sometimes a small adjustment is all it takes to get the equipment working.

- Having discovered visible problems, you need to stop the coolant and turn off the heating devices. Having assessed the breakdown, proceed to eliminate the accident yourself or invite a specialist.

These are primary measures that can prevent the development of major destruction.

Sounds from heating devices

If you hear a howl in the middle of the night, then most likely the system has leaked. A cloud of steam and a characteristic whistle will immediately indicate a gust or a failed valve. In some cases, it is enough to close the tap to bring the heating system into working condition.

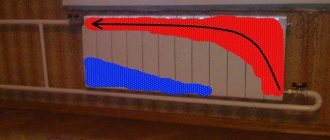

If no obvious causes are found, and the howling is accompanied by a crackling sound, it is necessary to check the pressure. Perhaps the flying scale blocked the free flow of the coolant, which caused increased pressure - it is urgent to stop the boiler, drain the water and look for the problem.

It happens that the batteries start to “shoot” - this is another reason to be wary. Such noise is typical for bimetallic batteries when the pressure in the system does not coincide with the calculated one.

When purchasing heating appliances, you need to take into account the operating parameters of the boiler and select the appropriate radiator. Otherwise, the problem may result in a rupture of the heating device due to water hammer, which is completely inappropriate in the winter cold.

Heated water is not able to compress; it needs to move freely along the contour. Banal deposits in pipes can provoke an increase in pressure and rupture of pipes due to water hammer.

Another reason is an air lock, which can be eliminated through the Mayevsky drain valves located at the ends of the batteries. The procedure is simple, and anyone can handle it.

Prevention measures

The design of modern boiler equipment does not allow the user to interfere with the operation of individual components and mechanisms. Only visual diagnosis and minor prevention are available.

Most problems with heating equipment are associated with three main components:

- fan with motor;

- heat exchanger;

- burner device.

The remaining components of the boiler - regulators, sensors, three-way valves - are too complex for independent diagnostics and maintenance.

Fan

If you remove the panel, the impeller with the motor becomes accessible for inspection. Inspection should only be carried out with the boiler turned off and de-energized. Optimally – 5 minutes after switching off.

First, without touching the contacts, we test the electric motor housing with our hands; the temperature should not be higher than 45 °C. Fingers should not experience discomfort from heating. If the housing is hot and you can even smell the wiring, it means the engine is overheating.

As a preventative measure, you need to lubricate the bearings and adjust the contacts.

Only special oil is used. The spindle, lock lubricant, and brake fluid will cause the motor winding to burn out.

If the design of the smoke exhauster allows it, you need to open the hatch on the fan housing. Any cleaning operations are performed with a soft brush or tweezers, without touching the impeller wheel. Otherwise the balance will be disrupted. The smoke exhauster will noisy louder than before.

Boiler furnace

Remove the outer lining of the combustion chamber. This will make it possible to inspect and clean the gas burner and boiler heat exchanger. At the same time, inspect the condition of the plates of the heat exchange equipment. There should be no melted areas, soot or soot deposits on them.

Often the fan picks up various debris from the air flow from the street. Therefore, you additionally need to remove the transition elbow from the body to the chimney and check whether there are any small twigs or leaves stuck there.

There are not many reasons why a gas boiler may hum. This situation is not a warranty case, and most often you have to deal with it on your own. If there is a suspicious hum or noise, it is better to contact a specialist.

Is the boiler making noise? Reasons, explanation, experiment: video.

Have you encountered a similar problem? What was the reason? Tell your story in the comments. Save the article to bookmarks and share it on social networks.

Pump noise

A common cause of problems is pump operation. Typically, it has three positions to raise the water column to a certain height, which depends on the power of the device. The uniform movement of the coolant along the thermal circuit is not accompanied by noise effects.

If you hear strange sounds that sound more like mechanical sounds, you should check the operation of the pump.

In case of failure:

- water gurgles in the heating pipes of a private house;

- a hum appears;

- cracking is possible;

- The boiler begins to make noise and knock.

In this case, you need to turn off the pump, and if the sounds stop, then the cause has been found. Cracking and noise are mechanical damage: this means that the graphite sliding bearings have worn out or dirt has gotten into the housing.

Scale settles on the inner walls of the pump due to poor-quality coolant and has a destructive effect on its components.

Checking is simple:

- it is enough to remove the pump;

- lower its working part into a container of water;

- when turned on, it must pump water; if this does not happen, it must be repaired.

Important! The pump cannot be turned on without water.

Types of noise and its diagnosis

If water makes noise in the heating pipes during heat supply operation, then there are certain reasons for this effect.

First you need to identify them, and then begin to reduce the noise or eliminate it completely. Why is the water noisy in heating pipes and how to correct this problem? Let's look at the main types of extraneous sounds. They point to the objective factors in the occurrence of an undesirable effect:

- Crackling in pipes. Occurs when the heating system is turned on;

- Clicking sounds that appear at regular intervals;

- Constant hum in transport highways;

- A barely audible knock.

All these extraneous effects - noise in the heating radiator or radiators - significantly reduce the comfort of living in the house. In addition, they may indicate improper operation of the heating supply. If action is not taken to correct the situation in time, some heating element may fail.

If the heating pump or other system component is noisy, you should first try to localize the cause of the extraneous sounds. To do this, it is recommended to use the following method:

- Monitor the frequency of occurrence of the effect.

- Try to identify the relationship - temperature increases in pipes, pressure surges, etc.

- Make sure that the noise in the heating boiler comes from it, and not from other objects located in the boiler room.

If it has been determined that the source is a component of the heating system, certain actions should be taken to eliminate this phenomenon.

Extraneous sounds in the heating boiler

Sometimes the heating of the boiler is also accompanied by some sounds. When cold equipment heats up and begins to crack, the characteristic clicks should not cause panic - metal makes such sounds when it warms up.

Gurgling and gurgling are also possible - this is also a normal phenomenon: the coolant began to heat up and set the system in motion. However, the same sounds can occur if there is insufficient coolant in the pipes. In this situation, it is enough to add water to ensure uniform heating.

Cotton

You can hear such sounds if the gas outlet pipes are clogged. This happens when the boiler is ignited: the accumulated gas, without having time to escape, creates a bang. This is dangerous, as a sudden burst of flame can cause burns or fire.

If the boiler is gas, then the reasons for such noise are clogged nozzles or a malfunction of the three-way valve. In this situation, it is necessary to clean the equipment from soot.

The occurrence of a knocking sound in the boiler indicates its incorrect installation or unregulated operation of the pumping equipment. If the pump operates unevenly, moving the coolant in jerks, resonance occurs between the boiler and the pump, accompanied by a characteristic knocking sound. In this case, it is necessary to regulate the operation of the pump.

Sounds in different boiler models

Noise can occur for a trivial reason, which lies in the boiler model itself. This is typical for gas boilers equipped with ventilation burners. To avoid such trouble, you need to choose boilers with atmospheric burners and an electronic control system.

When choosing a solid fuel or electric boiler model for heating your home, you should always familiarize yourself with the technical characteristics of the equipment. Often the cause of noise can be incorrectly selected equipment, as well as the presence of a fan in the boiler.

Double-circuit boilers also suffer from noisy operation: although not obvious, water overflows and filling of the system are always accompanied by sounds.

Answers to pressing questions

In what cases can air get into the heating system?

Air bubbles penetrate inside for a number of reasons, the most common of which include the damaged integrity of the ligaments, complete removal of water from the pipes and depressurization of equipment.

Why might the fan be faulty?

The main function of the fan is to remove combustion residues. As a result, it periodically becomes clogged with dust. Under the influence of high temperatures, its lubricant may dry out. All this together stimulates its wear and tear. Sometimes a faulty fan is a manufacturing defect.

What causes a whistle that sounds like a boiling kettle?

The most common reason for this phenomenon is the formation of scale with the subsequent narrowing of the passage of the device. In this case, whistling sounds appear approximately 20 minutes after starting the heating system.

Why do rattling sounds occur when the boiler is turned on?

Rattling occurs when the valve in the boiler wears out badly.

Why does the flame ignite jerkily when the boiler is turned on?

This happens when the injectors are severely clogged. The problem is solved by turning off the gas supply and then cleaning the cavities with a thin wire.

Regardless of the cause of the noise, the problem cannot be ignored. The sooner it is eliminated, the better.

How to remove an air lock with your own hands

Air in the system after a long stop is common. This problem arises not only in the private sector, but also in apartment buildings. It's quite easy to solve.

Heating radiators are equipped with Mayevsky taps located at the ends of the radiators. This could be a valve or a fitting with a notch for a screwdriver.

- armed with a small container (for draining water), you need to unscrew the tap and let out the air;

- Actions should be performed carefully so as not to get burned by the escaping steam;

- when water comes out of the hole, close the valve;

- Such manipulations are carried out on each battery.

This eliminates noise and allows the coolant to move freely through the system, evenly releasing heat.

Methods for cleaning radiators from dirt

During operation of the heating system, dirt accumulates in it: iron oxides, dissolved salts and possible mechanical impurities. But if water moves through the pipes at high speed, then in the radiators the process slows down and the sedimentation of suspended matter increases. Therefore, cleaning radiators is a must.

There are two methods: flushing the entire system together and disconnecting the batteries and cleaning using a compressor unit. Favorable conditions are created in the batteries for the accumulation of dirt, since the coolant slows down the movement in them. To flush, the radiator is connected to the compressor, and dirt is cleaned from it with water pressure.

If you carry out annual preventive maintenance of the entire system, then drastic measures will not be required. It is quite possible to limit yourself to a general flushing of the entire heating circuit with ordinary water. Chemical reagents are used in cases where the coolant does not meet the established parameters and significant deposits of salts and scale appear on the working elements.

After using chemicals, leaks may form in radiators and cracks may appear that were successfully covered with dirt.

To avoid an emergency, all equipment must be checked for functionality before starting the system.

Timely preventive maintenance of all components of the heating system will protect it from complex accidents and save the budget.

Video

By watching the video, you can find out why the circulation pump is noisy and what needs to be done.

Evgeniy Afanasyev chief editor

Author of publication 08.11.2018

Did you like the article? Save so you don't lose!

Knocking in the heating pipes of a private home is a common occurrence for owners with individual heating. Why the noise occurs and what influences it is necessary to understand.

The main indicator of trouble is poor-quality coolant containing dissolved salts and mechanical impurities.

Why does the heating boiler knock when heating up - circulation pump malfunction

This unit ensures the movement of the coolant, increasing the efficiency of the system. In this case, there may be several reasons:

- Unstable voltage in the network

. The equipment operates intermittently, and the malfunction is most often intermittent, sometimes it appears frequently, but can occur occasionally. The problem can be solved by installing a stabilizer that maintains stable performance.

- Presence of air pockets in the heating circuit

. If you do not ventilate the radiators at the beginning of the heating season, strange sounds occur during heating due to the large amount of air in the pipes, since the load on the impeller is uneven.

- Wear of individual components of the circulation pump

. Factory defects or long-term use provoke production. The shaft begins to vibrate, the impeller may become deformed or even partially collapse, which will lead to a loud knocking sound when the equipment is operating. Most often, in case of breakdowns, the pump is replaced, since most models are irreparable.

Less often, extraneous sounds may occur due to errors when installing heating in a private home. The absence of an expansion tank provokes an increase in cavitation loads and the system will make noise during operation, especially during heating. After installing it the noise will disappear

Causes of noise

There are actually not so many reasons for knocking in heating pipes when heating. Some noise can be ignored - it does not harm the system or heating devices. But noises such as buzzing, crackling, knocking, gurgling, and howling should give reason to think and take urgent action.

- air pockets in the system;

- clogging or overgrowing of pipes due to poor-quality coolant;

- leaks in the pipeline;

- violation of installation work when installing taps, valves and laying pipes;

- failure or wear of working equipment;

- cavitation, an increase in pressure in places where the diameter of pipes increases (decreases);

- incorrect calculation or non-compliance with design recommendations when installing the heating system.

These circumstances arise in private closed-loop systems and make us think about their urgent elimination.

The circulation pump in the heating circuit system promotes forced movement of water, which leads to uniform heating and displacement of accumulated air from the system.

If the heating in a house or apartment is connected to a central pipeline, then startup, accompanied by similar sounds, is normal. Water, filling the general system, pushes out air, and, flowing along the contour, is accompanied by gurgling, knocking and crackling sounds.

As soon as the equipment enters operating mode, the general adjustment of the system will end - the temperature of the batteries will increase, and everything will stop. This is clearly visible in the diagram of heat supply to consumers from the central boiler house.

Main causes of noise and solutions

Any equipment that contains electric motors, pumps, fans, water and gas circuits through which flows of water and gas move makes noise and even hums. Gas boiler developers make every effort to reduce the sound level to a minimum.

Ideally, during operating mode there will be no noise or buzzing. Another thing is during startup, when all the components and assemblies of the gas boiler are heating up. If the gas boiler hums when turned on, it requires maintenance and cleaning.

The main reasons why equipment makes extraneous sounds during operation:

- abnormal fan operation;

- malfunction of the burner device;

- the flow of liquid in the pipes and heat exchanger may hum;

- malfunction of the chimney or pump.

There may be more reasons for the noise. It doesn’t make sense to respond to all of them, since quiet and not ringing sounds are a consequence of the normal operation of the automation. Noise may occur due to worn parts of the gas boiler.

A cause for concern may be a situation when the gas boiler hums with a low vibrating bass, or sharp, ringing sounds appear in the noise.

Fan fault

The blower of a gas boiler has several operating modes, so the sounds from the impeller operation are usually low and rustling. If it is damaged, the sound will change to a loud crackling sound. The impeller can also hum when the balance is out of balance, for example, after unsuccessful cleaning of a gas boiler, or if a foreign object has gotten inside.

The electric motor may hum if the shaft on which the impeller is mounted has been hit. The engine will operate with a hum in any mode of the gas boiler, while the propeller will change tone depending on the rotation speed.

The problem can be resolved by replacing the impeller or electric motor.

Oversaturation of water with oxygen

The water flow moving through the pipes inside the gas boiler can hum. Often, a booming low sound appears during the process of heating water in the secondary heat exchanger.

The reason why a gas boiler hums when heating water is the release of oxygen dissolved in the water flow. Gas absorption occurs during operation of a high-pressure pump from a well or a centralized water supply pumping station.

Cold water dissolves oxygen well at low temperatures. When heated in the heat exchanger, gas is released, and at a certain temperature the bubbles collapse with a hum. This is something like how a kettle of water hums on the stove before the boiling process begins.

Nitrogen is less soluble in water than oxygen. Most of it remains “overboard” even at the stage of pumping water into the pipeline system with a well or substation pump. Therefore, a water stream saturated predominantly with oxygen enters the gas boiler. It is because of its collapsing bubbles that the primary heat exchanger burns out and the secondary heat exchanger rusts.

Reduced pressure

A low sound, even a hum, can occur when there is insufficient water pressure in the heating system. A floor-standing gas boiler, which does not have a smoke exhauster or circulation pump, often hums. Typically, such heating systems operate in an open circuit with gravity flow.

Oxygen from the air dissolves freely even at room temperature. The pressure in the heating circuit is slightly higher than atmospheric pressure, so the process of releasing bubbles during heating occurs slowly when the water is heated in the heat exchanger.

A double-circuit boiler may hum when the water pressure in the hot heating circuit is less than the safe minimum of 1 bar. This is a dangerous mode for the boiler. The situation may arise if the pressure sensor fails or the settings on the control board are incorrectly set.

The boiler hums at a high pitch. When water pressure is low, a zone of cavitation or cold boiling of the liquid forms around the impeller of the circulation pump. The force of cavitation easily destroys the bronze of ship propellers, and can destroy a plastic pump impeller in a matter of hours. Therefore, if the boiler is humming in the pump area, you need to urgently stop the gas equipment before it completely fails.

The boiler pump may make a loud noise when starting up new gas equipment for the first time. In this case, the issue is not cavitation, but rather debris that got inside the pipes during the assembly of the heating system by unscrupulous installers.

Sediment on gas boiler elements

Noises and extraneous sounds often appear when scale is deposited on the inner surface of the heat exchanger. Approximately once every five years, the heat exchanger must be washed using special liquids.

The heat exchanger is dismantled and washed on a special stand under pressure. Any attempts to remove scale using artisanal methods usually lead to burnout of the copper wall.

Types of noise in pipes

The noises that accompany the general heating start-up differ from emergency ones - they are intermittent and are accompanied by gurgling or gurgling. In bimetallic or aluminum batteries, a crackling or buzzing noise may be heard - this is also normal.

It is clear that prolonged noise is unpleasant, so it is necessary to prevent the situation in a timely manner.

The knocking and hum that occurs in the room with increasing force give reason to be wary and take drastic measures:

- Check heating devices and temperature conditions in the circuit. If a pump is installed, then its operation.

- Pay attention to the valves - if they break, a characteristic whistle appears. Sometimes a small adjustment is all it takes to get the equipment working.

- Having discovered visible problems, you need to stop the coolant and turn off the heating devices. Having assessed the breakdown, proceed to eliminate the accident yourself or invite a specialist.

These are primary measures that can prevent the development of major destruction.

Sounds from heating devices

If you hear a howl in the middle of the night, then most likely the system has leaked. A cloud of steam and a characteristic whistle will immediately indicate a gust or a failed valve. In some cases, it is enough to close the tap to bring the heating system into working condition.

If no obvious causes are found, and the howling is accompanied by a crackling sound, it is necessary to check the pressure. Perhaps the flying scale blocked the free flow of the coolant, which caused increased pressure - it is urgent to stop the boiler, drain the water and look for the problem.

It happens that the batteries start to “shoot” - this is another reason to be wary. Such noise is typical for bimetallic batteries when the pressure in the system does not coincide with the calculated one.

When purchasing heating appliances, you need to take into account the operating parameters of the boiler and select the appropriate radiator. Otherwise, the problem may result in a rupture of the heating device due to water hammer, which is completely inappropriate in the winter cold.

Excessive pressure in the heating pump

The pump provides high pressure; it is necessary to adjust its settings. Excessively high pressure in the system can provoke an emergency.

A low amount of water in the system may cause the device to overheat. Try lowering the thermostat. You may need to add water to the device to the required level.

Heating pump

- If the boiler seems to “howl”, the gas valve may be set incorrectly, check the jumpers.

- At high power, the source of extraneous sounds may be the gas meter.

- The valve was worn out and began to rattle. It needs to be replaced. If the problem is not solved and the boiler is still noisy, you can replace the valves with ball valves and install a rubber gasket.

- If the above measures do not help, you may need to replace the cooler.

Pump noise

A common cause of problems is pump operation. Typically, it has three positions to raise the water column to a certain height, which depends on the power of the device. The uniform movement of the coolant along the thermal circuit is not accompanied by noise effects.

If you hear strange sounds that sound more like mechanical sounds, you should check the operation of the pump.

In case of failure:

- water gurgles in the heating pipes of a private house;

- a hum appears;

- cracking is possible;

- The boiler begins to make noise and knock.

In this case, you need to turn off the pump, and if the sounds stop, then the cause has been found. Cracking and noise are mechanical damage: this means that the graphite sliding bearings have worn out or dirt has gotten into the housing.

Scale settles on the inner walls of the pump due to poor-quality coolant and has a destructive effect on its components.

Checking is simple:

- it is enough to remove the pump;

- lower its working part into a container of water;

- when turned on, it must pump water; if this does not happen, it must be repaired.

Important! The pump cannot be turned on without water.

Some tips

To eliminate knocking noises, you can also try the following:

- Install a closed water supply system (more precisely, change the corresponding open one). In this case, it will not boil as intensely and, accordingly, there will be less sounds from the boiler.

- In any gas boiler, soot (dirt) accumulates, which increases the temperature on the walls of the gas boiler. In particularly advanced cases, this can even lead to an explosion, and not just knocking. For this reason, the walls, heat exchanger, and water supply pipes must be cleaned regularly.

Well, you can purchase a wall-mounted boiler, water heater, pump, heated floors and much other equipment from our company.

Extraneous sounds in the heating boiler

Sometimes the heating of the boiler is also accompanied by some sounds. When cold equipment heats up and begins to crack, the characteristic clicks should not cause panic - metal makes such sounds when it warms up.

Gurgling and gurgling are also possible - this is also a normal phenomenon: the coolant began to heat up and set the system in motion. However, the same sounds can occur if there is insufficient coolant in the pipes. In this situation, it is enough to add water to ensure uniform heating.

Cotton

You can hear such sounds if the gas outlet pipes are clogged. This happens when the boiler is ignited: the accumulated gas, without having time to escape, creates a bang. This is dangerous, as a sudden burst of flame can cause burns or fire.

If the boiler is gas, then the reasons for such noise are clogged nozzles or a malfunction of the three-way valve. In this situation, it is necessary to clean the equipment from soot.

The occurrence of a knocking sound in the boiler indicates its incorrect installation or unregulated operation of the pumping equipment. If the pump operates unevenly, moving the coolant in jerks, resonance occurs between the boiler and the pump, accompanied by a characteristic knocking sound. In this case, it is necessary to regulate the operation of the pump.

Sounds in different boiler models

Noise can occur for a trivial reason, which lies in the boiler model itself. This is typical for gas boilers equipped with ventilation burners. To avoid such trouble, you need to choose boilers with atmospheric burners and an electronic control system.

When choosing a solid fuel or electric boiler model for heating your home, you should always familiarize yourself with the technical characteristics of the equipment. Often the cause of noise can be incorrectly selected equipment, as well as the presence of a fan in the boiler.

Double-circuit boilers also suffer from noisy operation: although not obvious, water overflows and filling of the system are always accompanied by sounds.

ZOTA boilers are very sensitive to the quality of the coolant, so unpleasant effects can be caused by:

- clogged mud trap;

- oxygenated water;

- scale on working elements;

- Broken bearings on the fan.

Therefore, it is worth choosing single-circuit models and purchasing a boiler to heat hot water.

Prices for ZOTA boilers

Prevention

Timely prevention of all components of boiler equipment can minimize the likelihood of noise.

Thus, flushing the system once a year is a prerequisite for trouble-free operation. Moreover, this is becoming a mandatory requirement of many resource supply organizations in preparation for the heating season.

You can flush the system yourself or use the services of specialists.

Depending on the coolant, the type of cleaning is selected:

- Washing with water under pressure generated by the compressor. Sometimes this is enough.

- For iron oxide deposits on pipes, appropriate chemicals are used. They eliminate the problem and additionally create a protective barrier from further exposure to an aggressive environment.

- You can use the services of a specialized organization that has the equipment and tools to perform the work.

Each operating manual for heating equipment provides a recommendation for preventive inspection and cleaning of the working parts of the boiler from corrosion and all kinds of contaminants with partial disassembly - at least once a year. If maintenance is not carried out, the manufacturer withdraws its warranty obligations.

Possible causes of extraneous sounds

Knocking and clanging in the boiler can be caused by both indirect and completely understandable reasons. In the first case, we may be talking about a broken installation, wear of components and incorrect settings.

The following factors can also provoke the appearance of extraneous sounds:

- Formation of scale layers on the walls of the heat exchanger . This happens due to the large amount of salts in the water. To prevent the problem, it is necessary to cleanse it once a year using specialized products.

- Increased pressure in the water pump or lack of water in the system . Under unfavorable conditions, these phenomena lead to an emergency situation.

- Oversaturation with air . In this case, the problem will be accompanied by the appearance of a characteristic knocking sound. To stabilize the situation, it is enough to release excess air from the system.

- Fan malfunction . This occurs due to the accumulation of dirt or drying out of the grease in the bearings.

- A clogged chimney or wick is a common problem with semi-automatic boilers. Diagnostics consists of checking the presence of traction. To do this, you need to bring a burning match to the ventilation window. If the flame burns evenly, it means the mine needs to be cleaned. It is advisable to contact utility services for these purposes.

- Malfunctions in the three-way valve . With this problem, a characteristic crackling sound will be observed every time you ignite. To correct the situation, the valve must be replaced.

- Incorrect installation of the gas burner in the boiler . In this case, whistling or tapping sounds will occur. To prevent this problem, you need to compare whether the gas pressure level matches the parameters indicated in the technical data sheet as recommended.

- Violation of the system installation technique may result in sounds of impacts on a metal surface occurring in the device body . They are provoked by the expansion of the pipe when the heating system is turned on. This problem is typical for pipes embedded in the wall without leaving a gap specifically for thermal expansion.

- Clogging of the heat exchanger plates with soot and dust . Parts must be cleaned regularly using a specialized vacuum cleaner.

How to remove an air lock with your own hands

Air in the system after a long stop is common. This problem arises not only in the private sector, but also in apartment buildings. It's quite easy to solve.

Heating radiators are equipped with Mayevsky taps located at the ends of the radiators. This could be a valve or a fitting with a notch for a screwdriver.

- armed with a small container (for draining water), you need to unscrew the tap and let out the air;

- Actions should be performed carefully so as not to get burned by the escaping steam;

- when water comes out of the hole, close the valve;

- Such manipulations are carried out on each battery.

This eliminates noise and allows the coolant to move freely through the system, evenly releasing heat.

Methods for cleaning radiators from dirt

During operation of the heating system, dirt accumulates in it: iron oxides, dissolved salts and possible mechanical impurities. But if water moves through the pipes at high speed, then in the radiators the process slows down and the sedimentation of suspended matter increases. Therefore, cleaning radiators is a must.

There are two methods: flushing the entire system together and disconnecting the batteries and cleaning using a compressor unit. Favorable conditions are created in the batteries for the accumulation of dirt, since the coolant slows down the movement in them. To flush, the radiator is connected to the compressor, and dirt is cleaned from it with water pressure.

If you carry out annual preventive maintenance of the entire system, then drastic measures will not be required. It is quite possible to limit yourself to a general flushing of the entire heating circuit with ordinary water. Chemical reagents are used in cases where the coolant does not meet the established parameters and significant deposits of salts and scale appear on the working elements.

After using chemicals, leaks may form in radiators and cracks may appear that were successfully covered with dirt.

To avoid an emergency, all equipment must be checked for functionality before starting the system.

Timely preventive maintenance of all components of the heating system will protect it from complex accidents and save the budget.