From this material you will learn how to increase the draft in the boiler, what to do if the draft in the boiler suddenly disappears, we will consider only the most effective methods of increasing the draft in heating boilers.

Draft in a furnace or boiler is the main process that provides heating to any room. If there is no draft, then the heat will only come from the combustion of fuel in the combustion chamber, and the spread of heat, that is, convection, will be weak, as a result, “the heat will leave” and erode. In this case, the average person is faced with a difficult question: how to increase the draft in the boiler? There is an answer to this question and it is very simple.

No draft in the boiler? There are ways to solve this problem:

If there is no draft in the boiler, then there are several simple and effective means to ensure that the draft increases significantly and heating circulates freely throughout the entire area of the house through heating registers:

- One of the old, but effective methods is calcination of the boiler, that is, overheating the boiler and retaining the heat in one volume, after which it is necessary to sharply open the damper between the combustion chamber and the boiler, in which case a large amount of heat leaves through the damper and begins to circulate in the necessary directions . The method is applicable if the entire “system” has passed the seal test;

- improving boiler sealing. Lack of draft occurs if there are any voids, “holes” and heat leaks from the boiler. In this case, the heat circulation is not carried out at full capacity and a small amount of heat goes into the boiler, which does not satisfy the heating needs;

- modernization of the boiler and installation of a second venting boiler. In this case, the heat begins to circulate and “stretch” through two pipeline lines: one is a heating line, the second is a return line to the boiler, where a vacuum is formed during combustion. In this case, the heating of the boiler or furnace will take slightly longer than in a boiler without a drain boiler;

- The design of the chimney also significantly affects the draft state. If a large-diameter chimney is installed with a low-power boiler, then there will simply be no draft. These data must be taken into account during the initial laying and construction.

Sometimes the lack of draft leads to a complete replacement of the boiler, when all possible solutions to the problem turned out to be invalid. In some cases, low-power compressors and heat convectors are installed for a short period of time, which are designed to “heat up” the boiler and establish heat convection and draft, but such options are applicable only for home masonry stoves.

What to do if the boiler goes out Remedies

It is recommended to trust the installation of professional equipment to professional craftsmen. The Neva geyser goes out during operation if there is a small leak or the chimney is clogged. After eliminating the problems, durable equipment will delight its owners for a long time with proper operation. When the column goes out when you turn on the shower, the cause may be either low water pressure or clogged filters. You need to call the utility service and find out why there is low water pressure in the water supply. Filters must be cleaned and replaced if necessary.

Installing a special damper will help prevent the gas boiler from extinguishing in windy weather. Expensive models equipped with a special hood that can increase air flow do not have problems with a lack of oxygen necessary for combustion.

A water filter will allow you to clean dirty water entering the column, and a stabilizer will effectively solve the problem with voltage drops.

If an AEG geyser, equipped with an automatic regulator for water flow, goes out and does not turn on, then it is possible that the solenoid valve for turning on the gas is faulty. After replacement, the equipment will work properly again.

How to check the draft in the chimney of a gas boiler

Burner flame color and shape

The simplest, but not the most accurate visual method for checking draft in a gas boiler. It is enough to look into the technical window of the boiler, located closer to the bottom of the boiler, the burner module (on some models you will need to remove the facing panel).

If the color of the flame periodically changes to red, this indicates insufficient draft; the boiler does not have enough oxygen to fully burn the gas. If the burner flame constantly changes shape and direction, the sounds of turbulence and drafts are heard, there is reverse draft, that is, the movement of air masses in the opposite direction, caused by errors in the design of the chimney and gusts of wind.

With a lit match

A more informative and proven method. To check the draft in the chimney of a gas boiler, bring a lit match to the technical opening (window) of the boiler unit:

- If the flame of a match clearly tends inward, the draft is present and, most likely, corresponds to the norm.

- If the shape of the match flame remains unchanged, there is no draft and action must be taken.

- If the flame turns in the direction opposite to the boiler, there is a reverse draft.

Using the same principle, you can check using a thin sheet of paper.

Anemometer

A professional device for measuring the speed of movement of air masses, it is also called a “wind meter”. This is the most accurate and informative method of measurement, but the cost of the device starts from 2 thousand rubles. Therefore, it is advisable to use it only if it is possible to take it for temporary use.

Normally, thrust indicators should be from 10 to 20 Pa.

Boilers with a closed combustion chamber, as a rule, do not need draft measurements. In case of any violations, combustion in them is simply impossible: the flow of air is not carried out without pressurization by a fan, the automation always reports problems in its operation.

Typical problems of double-circuit boilers

Double-circuit modifications of gas boilers, intended for the preparation of coolant and hot water, can also fade for all the reasons described above. But if there are no signs of the above breakdowns, perhaps the problem is caused by the specific features of the unit.

These include those that arise due to the operation of the water overheating protection system, namely:

- mixing hot and cold running water;

- thinning of the walls of the gearbox membrane.

The instructions for boilers with an additional heat exchanger for domestic hot water usually warn that two taps cannot be opened at the same time. It is better to initially select the most suitable temperature for heating hot sanitary water in the settings.

Read also: Schisandra what to do with it

The fact is that when cold water is turned on, the consumption of hot water decreases, and heat is generated in the same mode, overheating the heat exchanger. Due to overheating, the automatic system is activated, which shuts off the gas supply and blocks the operation of the boiler.

There are many more reasons why a DHW boiler goes out due to the peculiarities of its design. The problem can be solved quite simply: to avoid overheating, choose a comfortable water temperature by changing the regulator on the control panel

If operation is carried out according to the instructions, but the dual-circuit unit still turns off, you need to change the gasket of the water unit. Most likely it is worn out.

What threatens the lack of normal vacuum in the furnace?

Modern, even the simplest gas heating equipment does not allow combustion with reverse draft or its complete absence. However, with insufficient, poor draft, not all boiler models interrupt combustion, and this is fraught with:

- the spread of natural gas throughout the room due to its under-combustion due to lack of oxygen. In this case, there is always a characteristic smell of gas;

- the entry of toxic combustion products into the room, sometimes, especially in small quantities, they are not noticeable by smell;

- increased soot formation, which leads to accelerated clogging of the chimney, heat exchanger and combustion chamber of the boiler.

Reducing the chimney diameter

Not in all cases, a large pipe diameter is good for the system. To ensure proper traction, the following conditions must be met:

- the required amount of oxygen in the place where combustion occurs;

- increasing the temperature to a level of 600 degrees, necessary for complete combustion of the gas mixture;

- increase in temperature on the walls of the chimney.

The last point is the most important and is present in systems made from a material with a low level of thermal conductivity, such as brick.

In the case of a large diameter chimney pipe, whatever the material used to construct the chimney, it is necessary to heat large volumes of air so that the walls begin to heat up.

In addition, the wide pipe allows the hot air to mix with the cold air flow coming from outside. This slows down the heating process of the walls and the desired level of thrust is not achieved.

The easiest way to make the diameter of the chimney opening smaller is to install a pipe of the required diameter inside the existing one. Due to this, heat loss will decrease and the rate of heating of the walls will increase. As a result, when the device is ignited, the draft begins to rise very quickly.

It is also worth checking the ventilation system, which may cause a lack of combustion oxygen consumed by the boiler from the boiler room. A slot at the bottom of the door will help improve ventilation.

Ways to recover and increase traction

The reasons for decreased traction are usually understandable and easily eliminated:

- Chimney blockage . This can occur due to soot formation or the ingress of dust and dirt from outside. Regular cleaning of the chimney, even under the most favorable operating conditions, is the norm. This can be done, for example, with a metal brush on a long wire. The walls of the chimney must be as clean as possible and have a smooth surface.

- Insufficient thermal insulation of the chimney . If insulation is insufficient, most of the chimney is cooled, as a result of which there is no longer a significant temperature difference necessary for sufficient vacuum.

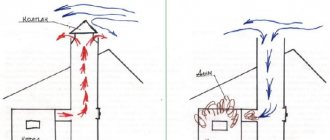

- Errors in chimney design . Most often, its height is insufficient; it should be at least 5 m. There are also height standards relative to the roof ridge (see photo below). Weak draft is also possible if the chimney diameter is insufficient, there are an excessive number of bends, or leaks.

The optimal height of the chimney according to SNiP 41-01-2003.

Separately, it is worth noting the reverse draft belt phenomena that extinguishes the boiler burner, which arise not only due to the incorrect height of the chimney, but also the lack of a well-chosen wind-protecting deflector on it.

An unpleasant burning smell, smoke in the room, poor combustion of wood - all these are consequences of reverse draft in the chimney . This is a problem faced by many owners of fireplaces, stoves, solid fuel boilers and other wood-burning heating devices.

Further in the article we will look at the main causes of poor draft in a chimney , and also provide simple recommendations for eliminating this problem.

Causes of poor traction

First you need to figure out why there is poor draft in the furnace. Problems can arise from the very beginning and during operation. Below are the most common reasons

:

- Clogging of the channel (with soot on the walls or all sorts of debris that has fallen from the street).

- Errors at the construction stage (a large number of bends and horizontal sections entail an increase in pressure losses along the length of the channel; in addition, the pipe must be of the same diameter along the entire length for uniform speed, which determines the formation of soot stagnation).

- Leakage of pipeline joints (this can occur both during the construction stage and over time, so it is necessary to periodically check the quality of the channel).

- Wind backlash (often it is because of the wind that a temporary overturning of the draft occurs, so it is advisable to very carefully choose the installation location of the chimney pipe).

- Incorrectly selected channel diameter relative to the stove power.

- Lack of supply air.

Causes of reverse thrust

To control the cleanliness of the smoke channel, you can mount a piece of pipe with a plug on the vertical part of the pipe from below, removing it periodically to get rid of most of the accumulated debris.

Chimney design

Important! The top of the chimney may fall into the zone of wind pressure; this possibility must be taken into account when choosing where the chimney exits to the roof.

The location of the chimney on the roof of the building is very important for the correct operation of the stove. Earlier in the article it was already mentioned that the height of the chimney should be at least 500 mm. But these are only general guidelines regarding a flat roof; in fact, the height of the chimney depends on the distance to the ridge and tall nearby buildings. Below are a few main rules for chimney height

:

- If the distance to the ridge of the building is less than 1.5 meters, the height of the chimney must also be at least 0.5 meters.

- If the chimney is located at a distance of 1.5 to 3 meters from the ridge, it is made no lower than the ridge, regardless of height.

- If the chimney is located more than three meters from the ridge, then it should be no lower than a line drawn from the ridge at an angle of 10 degrees to the horizon.

- If taller buildings are attached, the pipe must be installed above them.

- If there are exhaust ducts near the chimneys, the height of the hood should be no less than the height of these pipes.

Why is there no draft in the chimney?

The chimney is clogged with soot

Perhaps this is the most common and main reason for deterioration in traction.

During the burning of wood, soot is formed. It consists of particles of combustion products that stick together and settle on the inner walls of the chimney, which leads to a narrowing of its diameter. As a result, air movement becomes difficult.

Therefore, soot must be removed regularly. This way you will not only improve traction, but also increase the operating efficiency and fire safety of the heating device. To make the chimney walls less contaminated with soot, you can use fuel wood briquettes, which contain less moisture and other harmful impurities.

Insufficient air flow

When burning wood, the air needs to move from bottom to top. That is, from the room into the chimney and out into the street. To do this, in the room where the heating device is installed, there must be an air flow - draft.

Stabilizing devices

The reason for the lack of draft in a chimney located in a bathhouse in a residential building may be overheating of the outlet pipe, leading to a temperature difference and sedimentation of combustion products on the inner walls of the pipe in the form of condensate.

The stabilizing device consists of a regulator equipped with a temperature sensor and a fuse damper. When the temperature rises, the sensor gives a command to open the damper, and cold air flows through the hole, equalizing temperatures and pressures.

conclusions

So, how to increase draft in a chimney? Here are a few simple steps that don't require much time or money:

- Clean the chimney of soot. This is the first thing to do. You can do this yourself, with minimal investment of time, effort and money.

- Provide air flow. Open the window for 5-10 minutes before lighting the fire. This will create the correct movement of air in the room from bottom to top. The window can be closed after the fire has burned out.

- Insulate the chimney if it is not insulated. This will reduce the influence of cold air and also extend the life of the chimney.

As a rule, these simple actions are enough to increase chimney draft . If the problem is related to the design features of the chimney duct, then more serious resources will be required to solve it.

How to get rid of backdraft?

One of the ways to cope with backdraft is to use a deflector - a mechanical fan, the function of which is to suck smoke from the chimney (read: “How to make a deflector for a chimney with your own hands”).

Another chimney draft regulator is a damper, which is a special damper. One damper is usually fixed in the chimney duct, and the second either in the stove itself or in its door. By trying different options for their location, you can find the optimal one to solve the problem with traction. How to make a draft regulator with your own hands, details in the video:

Sometimes backdraft can be temporary, occurring for several days. This can happen at the beginning of the heating season, when in damp autumn weather the stove is lit after a long period of inactivity. In this case, the cold air accumulated in the pipe acts as a chimney draft limiter, and smoke, instead of going out into the street, begins to fill the room. To solve the problem of temporary backdraft, you need to find out the cause of its occurrence and then eliminate it.

Additionally, you can also use a chimney draft stabilizer, which provides air supply and thereby optimizes the force of its movement along the chimney. The stabilizer is equipped with a safety valve that prevents the occurrence of excessive pressure. You can eliminate cold air in the pipe after a long break using plain paper. It is enough to burn a few sheets, slightly warmed air will begin to rise up the chimney and push out the cold air.

Typical problems of double-circuit boilers

Double-circuit modifications of gas boilers, intended for the preparation of coolant and hot water, can also fade for all the reasons described above. But if there are no signs of the above breakdowns, perhaps the problem is caused by the specific features of the unit.

These include those that arise due to the operation of the water overheating protection system, namely:

- mixing hot and cold running water;

- thinning of the walls of the gearbox membrane.

The instructions for boilers with an additional heat exchanger for domestic hot water usually warn that two taps cannot be opened at the same time. It is better to initially select the most suitable temperature for heating hot sanitary water in the settings.

The fact is that when cold water is turned on, the consumption of hot water decreases, and heat is generated in the same mode, overheating the heat exchanger. Due to overheating, the automatic system is activated, which shuts off the gas supply and blocks the operation of the boiler.

There are many more reasons why a DHW boiler goes out due to the peculiarities of its design. The problem can be solved quite simply: to avoid overheating, choose a comfortable water temperature by changing the regulator on the control panel

If operation is carried out according to the instructions, but the dual-circuit unit still turns off, you need to change the gasket of the water unit. Most likely it is worn out.

What else can cause an ignition failure?

Less common, but the following problems may occur that lead to blocking of the heating unit.

Short circuit

Another cause of failure may be a short circuit. This often happens when the boiler is chosen incorrectly; it does not fit the dimensions of the house (too small and its power is not enough to heat the room, or, on the contrary, too large).

Component mismatch

If the boiler has already been repaired and elements that are not suitable for the model are installed in it, for example, an air pressure switch, the boiler may see a signal unusual for its operation and therefore is blocked.

Inconsistency with the dimensions of the heating system

Boilers should be selected according to the size of your home's heating system and your likely demand for hot water. If the boiler is too powerful, it will produce more steam than it can condense, causing a short cycle. In the past, engineers typically installed boilers that were larger than required to compensate for high losses. Boilers today are much more efficient, so there is no need to overload the boiler.

Pressure too high

Too much boiler pressure will also cause the boiler's automatic safety precautions to kick in and shut down the boiler. As a rule, the pressure in the boiler should be between 1 and 2 bar. If reducing the pressure doesn't make any difference, try bleeding the radiators with excess air and water before calling a gas safety engineer.

How do you solve the problem of boiler attenuation? Do it yourself Call a specialist

Ventilation holes are faulty

All components in a gas boiler are important, and a malfunction of one will certainly lead to a blockage of the entire unit. In particular, ventilation is of particular importance for the correct operation of the boiler. If the vents are not working properly, air will be trapped in the system, increasing the pressure until the burner switches off at pressuretrol. They may need to be cleaned or replaced.

Thermostat is faulty or incorrectly calibrated

The thermostat may be faulty or in a cold draft, affecting its ability to accurately measure the monitor's temperature. Therefore, it is unacceptable for the unit to remain in a cold room for a long time. If the thermostat has a mercury switch and is not leveled, this can also cause the problem.

Boiler is the right size, but overheated

When a boiler overheats, it will produce a lot of steam in a short period of time, which will increase the pressure in the unit and cause it to shut down for safety reasons.

Why might the burner go out at all?

The boiler extinguishes as a result of the device’s automatic operation, which responds to the following disturbances in the operation of the system:

- the draft in the chimney has decreased or disappeared;

- the gas pressure in the supply line has dropped;

- The flame in the burner has gone out.

Moreover, these processes can occur both due to internal failure and due to the influence of external factors.

If we consider floor-standing models (manufacturers: Danko, Aton, ROSS, Zhitomir), then they have a primitive internal design. Therefore, if you look into them, there is nothing special to break in them. Attenuation in this case occurs most often due to strong wind outside or other external factors.

Floor-standing gas boilers are simple in design, so eliminating the cause of their attenuation will not be so difficult

But wall-mounted gas boilers in their design already resemble an autonomous mini-boiler room, and therefore there may be more options for stopping the operation of a gas boiler:

- the coolant circulation was interrupted or did not start after repairing the circuit (the flow sensor reacts);

- The air supply has decreased/stopped (the pressure switch is triggered);

- voltage drops occur;

- power outage.

If a mounted heat generator goes out, it is not easy to restore its operation. However, it is still quite possible to eliminate some malfunctions on your own. Find out how to do this below.