Expanded clay blocks are a relatively new, but already gaining popularity building material: strong, durable, non-flammable, environmentally friendly, quite budget-friendly, with good sound insulation.

However, due to the porosity of the structure, expanded clay concrete has reduced frost resistance, so the question of insulating walls made from this building material often arises.

Is this really necessary?

Expanded clay blocks are produced with different density indicators , which directly affects the thermal conductivity of the material: the higher it is, the worse the material retains heat, and its energy-saving properties deteriorate.

Thus, the facades of houses with a wall thickness of up to 0.7 m from blocks with a density of less than 1 ton/m3 can be simply covered with finishing material, but if the density reaches 1.2 t/m3 with a standard wall thickness of 2 blocks (40 cm), then for comfortable living conditions a layer of thermal insulation is required.

In addition to creating heat in the house, insulating expanded clay concrete walls helps solve the following problems:

- improve waterproofing, protect the house from dampness, mold and mildew;

- increase the service life, maximizing the integrity and strength of the masonry, protecting it from negative external climatic influences;

- save on heating with small thickness of walls and foundation.

Reference . In northern latitudes, all houses made of expanded clay blocks in Russia require mandatory insulation, and the thickness of the thermal insulation layer must be at least 100 mm.

Consequences of absence

If you do not insulate your home's walls, foundation or basement, you may face significant heating costs during the cold season.

In the absence of an insulating layer, the likelihood of cracks increases , which can lead to high costs for façade repairs.

Considering the fact that a sufficient level of insulation helps prevent infection of the interior surfaces of the room by fungus and mold, an attempt to save on it may result in additional costs for interior decoration and disinfection.

Subtleties and useful tips for insulating a house made of expanded clay concrete

Each case has its own nuances, which professionals, as a rule, are in no hurry to share. Using solid experience in communicating with manufacturers and building insulation specialists, we have accumulated a sufficient arsenal of information that may be useful. So, here's what you need to remember when calculating the plan for insulating a house from KBB: 1Integrated approach It is most justified to carry out insulation of the entire house as a complex, without losing sight of the foundation. If this is not possible, do everything gradually. 2 Location of insulation The main thermal insulation systems should be located outside the building. 3 Insulation inside the house Sometimes you can complete the insulation with individual components from the inside. But this requires a professional and balanced approach.4 Work procedure The facade of individual construction accounts for a fifth of all heat losses. It’s better to start with the roof, then work on the walls and finish with communications and the foundation. 5 Alternative If you want to do without insulation, build a wall thickness of 600 mm or more. 6 Professional help Illiteracy in insulating a house made of expanded clay blocks is fraught with significant financial losses and disappointment. Work with companies that thoroughly know the materials and professionally fulfill their obligations. Remember: whatever insulation you choose, the construction result largely depends on the quality of the source materials. At the KBLOK site you will find reliable expanded clay concrete manufacturers who will not only be able to give professional advice on laying walls from KBB, but also, by individual agreement, provide the services of specialists in construction and insulation. We personally check the products of all suppliers from our catalog, so we are sure that they are not afraid to entrust projects of any level of complexity.

When do you need to insulate the outside and inside?

At the stage of constructing a house made of expanded clay concrete, construction experts recommend using the option of double insulation - external and internal, this will maximize heat retention and protect the walls and foundation from dampness.

If funds are limited and you need to choose only one type of insulation, the first step is to protect the outer layer of the walls of the house. However, in some cases, this is not possible:

- a ready-made tiled house is purchased;

- it is rarely used (and is quickly heated at the right time);

- The housing is located in a high-rise apartment building.

In such situations, only internal insulation is available. It has several negative points:

- reduction of useful living space in rooms (at least 10 cm on each wall);

- the house from the outside remains unprotected from the aggressive external environment and temperature changes;

- The dew point remains inside the new structure (between the cold wall and the warm layer of insulation), which can cause mold to develop.

Considering the disadvantages of the internal insulation method, when building a house from scratch, it is better to avoid it.

Properties of expanded clay as insulation

The main indicator of this material is its natural clay composition. After high-temperature treatment, it becomes quite strong and reliable. It is worth noting that by using it in garages and basements, you can forget about such a problem as rodents. At an average cost, it has a long service life. And in comparison, for example, with wood, it is significantly better, since it does not rot, does not create a favorable environment for insects, and is not at all afraid of humidity and even prolonged exposure to water.

The properties of expanded clay as insulation are multifunctional both in winter and summer. It is considered the most versatile material, which has a high level of frost resistance and copes well with exposure to high temperatures.

The main property of this material is the complete absence of toxicity.

Also, importantly, expanded clay does not create a favorable environment for mold, mildew and other pathogenic bacteria. Due to the fact that it does not enter into chemical reactions with aggressive substances, such a coating completely eliminates the possibility of the formation of harmful vapors that can adversely affect human health

Pie wall

External insulation of expanded clay concrete walls can be carried out in several ways, depending on this, the sequence and thickness of the layers in the wall “pie” can vary .

So, when using the “wet facade” technique, the materials go in the following sequence:

- wall made of expanded clay blocks;

- adhesive layer;

- insulation placed on special dowel mushrooms;

- leveling solution;

- reinforcing mesh (optional);

- final adhesive layer;

- plaster;

- primer;

- painting/exterior finishing.

When insulating using the “dry facade” method, the layers alternate in this way:

- expanded clay concrete masonry;

- vapor barrier membrane;

- sheathing frame made of slats up to 2 cm thick to create an air gap;

- thermal insulation layer;

- waterproofing;

- layer of external finishing.

With the rather rare “well” method of insulating expanded clay walls under construction (this option is not applicable for an already built building), the insulation is simply placed between two layers of expanded clay concrete blocks.

You can calculate the required thickness of the insulating layer yourself , knowing the thermal conductivity coefficient of the expanded clay block (0.17 W/m) and the minimum thickness of the block. Calculations can also be carried out in special programs, such as “Teremok”.

So, with a standard block thickness of 40 cm (when laying in a bandage) and with a required thermal conductivity of 0.05 W/m degrees Celsius, the insulating layer of polystyrene foam or glass wool will be 5 cm thick, and of polystyrene foam and facing bricks - 19 cm.

If you build from large expanded clay blocks 29 cm thick, then such walls will require an insulating layer of foam foam at least 10 cm wide.

Note ! When forced to carry out internal insulation of expanded clay concrete walls, in order to avoid the formation of condensation, material with the lowest vapor barrier properties should be placed closer to the heated room.

This is exactly what ordinary plaster made of cement and sand or gypsum is; it is similar in chemical composition to expanded clay concrete, therefore it ensures good adhesion and closure of microcracks in the wall, through which heat escapes from the room.

What are expanded clay concrete blocks according to GOST

Expanded clay concrete is classified as lightweight concrete. A porous material, expanded clay, is used as a filler. These are round granules made of baked clay. The composition of expanded clay concrete is cement, sand, expanded clay and water. When preparing the mixture, more water is poured than in ordinary heavy concrete, since expanded clay is hygroscopic and absorbs liquid. When producing blocks, the finished mixture is poured into molds, left until initial hardening, after which they are removed from the mold. In principle, the blocks are ready, but they cannot be used until they reach their design strength.

A house made of expanded clay concrete blocks can be built quickly

There are two technologies for bringing products to normal strength at the factory - in an autoclave and by vibration pressing. In the first case, the blocks are sent to an autoclave, where the material is treated with steam under pressure. This makes expanded clay concrete blocks more durable. The second method is vibration with simultaneous pressure. When vibrating, all voids disappear, the solution becomes more homogeneous and fluid, enveloping each of the expanded clay granules. The result is high strength indicators.

In artisanal production, the blocks are simply left to “ripen.” In theory, it takes at least 28 days until the concrete gains strength. But they can sell it earlier so as not to take up space. Nobody guarantees durability.

Round granules of expanded clay can be seen on the surface of the block. Depending on the brand, they can be of different sizes, in larger or smaller quantities

The fact is that for cement to gain normal strength, it is necessary to create a certain heat and humidity regime. In this regard, expanded clay concrete is more capricious than ordinary concrete. Due to the high absorption capacity of expanded clay, it can take up too much water. And the liquid will not be enough for the concrete stone to gain strength and not just dry out. Therefore, it is advisable to water the finished blocks and cover them with film at least for several days after production. They cannot be kept in the sun and the temperature should not be lower than +20°C. Otherwise, expanded clay blocks will never gain the required strength and will crumble even under light loads and impacts.

When it comes to price, factory units are more expensive. But still. If you are building a house, and not a utility block or barn, you should not save money and buy “garage”-made blocks. Quality is a big question here.

What is the best way to insulate?

Any insulation from the following list will be good thermal insulation for expanded clay blocks:

- glass wool;

- mineral wool;

- Styrofoam;

- expanded polystyrene (penoplex);

- polyurethane foam;

- liquid materials.

Glass wool is one of the most traditional and cheapest insulation materials . Its advantages are frost resistance and air non-conductivity. The disadvantages are low environmental friendliness and the risk of injury if installed incorrectly.

Mineral wool made from basalt or slag does not have these disadvantages: it is more environmentally friendly, is not flammable and retains heat better. However, it costs more than glass wool and is susceptible to moisture stagnation.

Polystyrene foam as insulation is relatively cheap , it is lightweight and very easy to attach to walls. Its disadvantage is rapid deterioration under the influence of moisture, insects, rodents and birds (to avoid this, it must be reinforced with mesh).

Expanded polystyrene is similar to polystyrene foam in terms of thermal protection, but this material is not susceptible to rodents, so it is more expensive. It is considered one of the most suitable materials for thermal insulation of expanded clay walls. It minimizes the number of cold bridges between blocks and is also easy to install. The material is dense and durable, not afraid of moisture.

Polyurethane foam copes well with protection from dampness , since it has a high degree of water resistance and retains heat well. However, it is quite expensive and requires special equipment and tools for installation.

Liquid insulation consists of two components - polyurethane foam and penoizol. This composition retains moisture and air and is easily applied by spraying onto a special sheathing. The downside is the cost, as well as the inability to immediately begin plastering work - after all, the finish must be fixed with a frame.

Useful video

In the video we will look at an example of insulating the ceiling of an extension of a private wooden house with expanded clay backfill:

You can cope with this work yourself at some stages of the preparatory work. Laying utility networks: ventilation, electrical wiring, plumbing - trust the builders who perform a range of construction and installation works.

(2 ratings, average: 5.00 out of 5)

- Features of thermal insulation

- Advantages and disadvantages

- Insulation technology

- Preparatory work

- Installation instructions

- Surface finishing

Ceiling insulation with expanded clay is an excellent alternative to using traditional thermal insulators like foam plastic or mineral wool. It makes it possible to provide high-quality heat conservation in any type of room. In addition, this method does not require significant costs.

Step by step procedure

All work begins with the preparation of wall surfaces - they are cleaned of dust and debris, covered with a layer of plaster (to increase adhesion), and primed.

From the inside

The following sequence of actions is used in the work:

- laying the insulating layer and fastening it to dowels;

- installation of a frame made of galvanized profile under polystyrene foam or drywall, you must remember to leave a gap of up to 2 cm between the wall and the insulation for air circulation;

- strengthen the insulation sheets - in this case, the distances between the logs should not exceed 0.5-0.6 m between horizontally mounted sheets; polystyrene foam is attached “in tension”;

- perform final finishing.

Additional Information . Where the outer walls of the house come into contact with the ceiling, an overlap must be left when using roll insulation.

Outside

After preparation, a vapor barrier is carried out - with special materials or another layer of plaster.

The next step is to prepare the adhesive composition, which is applied to the entire perimeter of the sheets of insulating material (plus a mound in the center). The glue is applied with a notched trowel over the entire surface of the slab without gaps.

The main point is the fastening of the plates. It is recommended to do it starting from the lower left corner. Having finished the bottom row, the second is laid, shifting it half a slab to the side (like brickwork). It is advisable to adjust the edge slabs to the size of the wall in advance, so that you do not have to deliver them in short strips in the corners.

It is advisable to lay out the entire perimeter row by row , rather than working with just one wall - this will give the glue time to harden and the top row of insulation will not move the bottom one.

After treating the entire surface, check the tightness of the material and seal the cracks with polyurethane foam.

If glass or mineral wool is used as the material, then dowels are used instead of glue, which are mounted on a special wooden frame. Also, such insulation is covered with a moisture-proof film with an overlap of 0.1-0.15 m, and the joints are taped.

Installation of reinforcing mesh is the next stage of work . The mesh is placed on a layer of plaster, pressing it firmly and quickly into the wall.

The insulation work is completed by finishing with brick, siding or decorative plaster.

Read more about insulating the outside of walls made of expanded clay concrete blocks here.

In the bath

The insulation of a bath includes thermal insulation of the walls, floor and ceiling - in such a room a “thermos” effect is formed.

Work to strengthen the walls is carried out in the following order :

- surface cleaning, drying;

- fastening the wooden frame to the walls, taking into account the air gap;

- laying insulation (fiberglass and mineral wool are strictly prohibited!);

- covering the frame with membrane insulation (foil or aluminum);

- wall cladding with finishing material.

Reference . It is best to use deciduous or coniferous wood for finishing - they have low thermal conductivity and have a pleasant aroma.

You will learn how to insulate a bathhouse made of expanded clay concrete blocks from this article.

Insulation during the construction phase

Blocks are an unsightly option and the external wall is rarely left unfinished. The laying of the outer layer of finishing brick can be combined with insulation. In this case, thermal insulation is laid between the load-bearing and decorative parts of the masonry.

For insulation use:

- Expanded clay;

- Expanded polystyrene;

- Basalt wool;

- Foamed polyurethane foam.

Expanded clay is a natural material obtained by sintering special types of clay. No additives are used in production. During the construction stage, the material is simply poured into the gap between the walls.

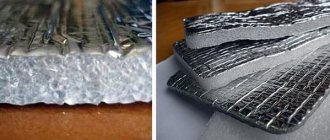

Expanded clay filled between the load-bearing wall and facade finishing

The advantages include environmental friendliness and low price. Among the disadvantages are not the best thermal conductivity and hygroscopicity.

Expanded polystyrene for construction comes in two types. Foamed - familiar polystyrene foam, and extruded - a material known under the names Penoplex, Penoplex, etc.

In terms of thermal conductivity, these materials are the same, but the price of the latter is 2-3 times higher. However, penoplex is rarely used for installation inside walls, since in a place protected from climatic conditions it does not have any advantages.

Installation of the slabs does not cause any difficulties - they are simply placed between the bricks.

The material is environmentally friendly and non-flammable. The damping time of the foam after the exposure to open fire has stopped is 4 seconds. Poisonous styrene from polystyrene foam is released when the slabs are heated to 80°C, which is only possible in the event of a fire. However, the insulation is in “packaged” form, so it is quite safe.

Another option for using polystyrene foam is to fill cavities with granules. This is the same polystyrene foam, but not in slabs, but in the form of balls (in bulk). The price of granules is 2000 rub. per cubic meter.

It is worth noting that foamed polystyrene foam is produced in 3 types, differing in density PSB-15, 25, 35. The numbers in the marking indicate the approximate weight of a cubic meter of material. The price directly depends on the density - 1500 rubles for density 15 and 3900 rubles. for 35 kg/m3. They produce polystyrene foam with a thickness of 10 to 200 mm. In retail sales, material thicknesses of 30, 40, 50 and 100 mm are more common. However, you can order slabs of any thickness from the manufacturer.

Important! Polystyrene foam with a density of 15 kg/m3 cannot bear a load, it cannot be plastered, but it is excellent as an inner layer in masonry.

*

Penoplex is produced with a specific gravity from 35 to 80 kg/m3. The price of extruded polystyrene is 4500 rubles/3, but it has no advantages as an inter-brick layer and is rarely used.

Basalt wool is a modern insulation material. Products are produced by sintering rock with the addition of fillers. Environmental friendliness and beneficial properties make stone wool a popular insulation material. They are produced in the form of slabs with a specific gravity from 30 to 200 kg/m3. Thermal insulation properties are close to foam plastic, but cotton wool has vapor permeability - the walls will “breathe”. When heated, some products may emit phenol and formaldehyde, but use inside sealed walls will not affect the health of residents. Just like polystyrene foam, toxic substances are released when heated. Installation consists of laying between layers of brick.

Basalt wool in masonry

Another option to insulate the masonry is to use polyurethane foam. The material is introduced between the load-bearing and facade walls through drilled holes, and after hardening it looks like foam glue. The method is rarely used due to its high cost - it is necessary to use special equipment. It is impossible to make insulation yourself.

The cost of polyurethane foam sheets is high, so there is no financial benefit to using it.

Insulation of masonry with polyurethane

The advantage of the material is the lowest thermal conductivity, but the cost negates all the advantages.

Comparative table of insulation for installation between walls.

| Material | Characteristics | ||

| Thermal conductivity, W/(m*K) | Density, kg/m3 | Price, m3 | |

| Expanded clay | 0,1-0,18 | 200-400, depending on the faction | 1300-2500, the larger the fraction, the cheaper |

| Foam plastic PSB-S-15 | 0,04 | 11-12 | 1500 |

| Foam granules | 0,045 | 9-12 | 2000 |

| Penoplex | 0,032-0,038 | 35-70 | 4800 |

| Basalt wool | 0,035-0,04 | 35-200 | 1700-5200 depending on density |

| Polyurethane | 0,019-0,03 | 50-300 | 9000-16000, Average price for insulation with a 50 mm layer – 500-1600 rub/m2 |

*

Elimination of cold bridges:

It is difficult to find a construction project that does not have deficiencies in thermal insulation.

Standard defects in heat conservation are parts of fencing structures of sufficient density and heat transfer capacity, for example, dressing fittings, opening lintels, seams, etc. Unfortunately, it is not possible to correct the shortcomings by eliminating one heat leak, but step-by-step adherence to the advice will allow you to reduce the heat transfer to a minimum level. Opening lintels and reinforced belts are the basis for problematic thermal insulation. Located above radiators, window openings, under the ceiling, and having a hollow structure, they are able to easily transfer accumulated heat. Heat loss can be reduced several times by dividing the array with a barrier of a more porous structure.

It follows from this that it is better to cast the lintels using profile trays. You can make lintels from expanded clay concrete structures. Due to the lack of expanded clay concrete construction, it is worth using aerated concrete trays or trays made of porous ceramics. Jumpers or armored belts can be cast onto the formwork, having previously reshaped the form with extruded polystyrene foam. The redistribution must be carried out longitudinally in two places.

Laying expanded clay concrete blocks

Another example of heat loss is wall areas made of solid blocks. According to the accepted technology, the open sides of the walls, edging of openings, T-shaped inserts and corners are laid in voidless blocks. As a result, the heat transfer process is disrupted, since hollow-free blocks transfer heat better than hollow ones. The next stage will be an uncontrolled shift in the dew point, which will lead to dampness on the external walls and internal corners. Separating the rows with slab polymer material in multi-row double-block masonry will help cope with this problem. When constructing two-story buildings, it is better to insulate a single-row wall from the outside, creating a facade blade.

Eliminating cold bridges plays an equally important role in solving the problem of thermal insulation. Seams in masonry and embedded reinforcement remove heat quickly enough. The problem can be solved by replacing steel reinforcement with polymer reinforcement and preparing a solution with the addition of air-entraining substances. It is worth considering the fact that the size of expanded clay concrete blocks allows for the application of an extremely thin layer of binder masonry.

The nuances of glazing a house made of expanded clay concrete blocks:

First, it’s worth understanding the difference between expanded clay concrete and expanded clay blocks. Expanded clay concrete block has low porosity, therefore it is used to lay a load-bearing array. Expanded clay blocks are lighter and are used to encircle buildings.

House made of expanded clay concrete blocks

Double-row masonry contributes to the implementation of many ideas regarding heat conservation. For example, an overlap of 2.5-3 cm of external thermal insulation masonry in window openings will promote greater adhesion of the window frame and minimize blowing.

The highly porous structure of external blocks can become the root cause of convective heat dissipation. Therefore, using waterproofing mastic, the outer sides of the opening should be treated with an overlap of 20-25 centimeters on the outer surface of the walls. The remaining aspects of the installation of window structures, which guarantee long service life and strong installation, are very typical: direct mounting through the frame, thick seams of polyurethane foam and support pads.

Mounted ventilation systems in the house:

Compared to porous ceramics, expanded clay concrete and expanded clay blocks have a dense structure, which allows the use of anchor and direct installation. Installation of a façade ventilation subsystem is possible since the pullout force of the anchor fasteners is not less than 40 kg.

Since expanded clay blocks are highly vapor permeable, this threatens heat loss as the insulation becomes damp. If you try not to release steam from the inside and due to accumulated moisture, you can render the building unusable. The problem can be solved by organizing an area for the vent near the outer surface of the wall. The hole is made small, and a wooden strip is attached along the facade, which prevents the insulation from “sticking” to the wall. The vapor barrier must have a limited throughput, which will ensure slow steam circulation and uniform temperature release.

Characteristics of insulation material

Expanded clay was created specifically for insulation. And due to the list of its characteristics, it occupies a leading position among insulation materials. And the price is very pleasing. Let's look at the basic properties of the material to find out why it is so successful:

- The thermal conductivity coefficient of the material is 0.16 W/μ. This means that a layer of only 10 cm can compete with natural wood of 30 cm. This is 3 times less. And if you compare it with brick, then expanded clay is 6 times better;

- high strength index. If we consider different types of material, its density ranges from 250 to 600 kg m3;

- good level of sound insulation of insulation;

- I am also pleased with the durability of the material. Since expanded clay is solid clay, you can be sure that the service life of the insulated floor will be long, and will even survive construction;

- the material is resistant to chemicals;

- products are fireproof and heat-resistant;

- an excellent indicator of the frost resistance of expanded clay, it is not afraid of temperature changes;

- The light weight of expanded clay is also pleasing. To fill the floor, you do not need to create a frame or reinforced structure;

- the cost of the material is low. Wholesale prices for a 20 kg bag are $2.5 or more;

- Insulating with expanded clay is quite simple. There is no need to do any preparation.

Thermal calculation

When purchasing blocks, the manufacturer must always indicate their properties. The calculation determines the thickness; to perform it, a characteristic such as thermal conductivity will be required. There are two ways to perform this calculation:

- "manually";

- using special programs.

Reduced heat transfer resistance of a wall made of expanded clay concrete compared to other materials.

It is not difficult to perform an independent calculation, but it can cause difficulties for a person who does not have a construction education. It is best to use the simple Teremok program, which works in two modes:

- calculating the thickness of one of the layers of the wall structure;

- checking the heat transfer resistance if the thickness has already been selected.

To work with the software, you will need the following initial data:

- thermal conductivity of expanded clay concrete blocks;

- block width;

- thermal conductivity of insulation;

- insulation thickness (not needed if working with the program in the first mode).

Having selected the values, you can begin insulating the walls of the house.

Types of expanded clay fractions and selection criteria

For thermal protection of the walls of the house, an expanded clay mixture of granules of different sizes is used to ensure maximum packing density of the mass. They produce material of different fractions. When choosing a bulk insulator option, a number of factors are taken into account, including the features of the structure being insulated, the climatic conditions of the region, and the type of planned work.

Gravel

Products in the form of round or oval granules are produced on the basis of a clay mixture by firing in a high-temperature rotary kiln. There are 3 fractions of expanded clay gravel:

- 20-40 mm. Due to geometric features and size, expanded clay of this fraction has a low bulk density. The product is used to create a thick thermal insulation layer. The sample is mainly in demand when arranging foundation structures, is used in the construction of a cellar, and is suitable for thermal protection of attic floors;

- 10-20 mm. As an option with optimal characteristics, expanded clay of this category is widely used in the insulation of external walls of brick houses using the well masonry method, and is used in the formation of floors and roofing piecing;

- 5-10 mm. Fine gravel is in demand as effective thermal insulation when installing underfloor heating systems.

The sample is also relevant when insulating the facade from the outside: fine-grained expanded clay is included in the cement mortar for pouring between the masonry and the cladding.

Sand

The material is produced by crushing expanded clay in shaft furnaces. Sand is also obtained by screening out large fractions of raw materials.

Types and application:

- up to 3 mm. Expanded clay sand with a fraction of up to 3 mm is mainly used as a “warm” masonry mortar;

- up to 5 mm. The solution is intended, among other things, for making a cement screed when arranging a floor pie.

Depending on the planned work, the thickness of the screed layer with expanded clay filler varies up to 20 cm.

Crushed stone

The sample is obtained by crushing baked pieces of clay-shale mixture. Expanded clay crushed stone is in demand in the production of concrete structures with low specific density and serves as a heat-insulating filler.

When choosing expanded clay, the following points are taken into account:

- bulk density and strength of granules. To enhance the strength characteristics during the production of expanded clay, the clay-shale mixture is enriched with special additives;

- heat and sound insulation properties. Depending on the characteristics of the insulated structure, an option with optimal characteristics of resistance to heat transfer and noise absorption capabilities is selected;

- moisture absorption parameters. Priority is given to material with a correlation coefficient of 0.46%, otherwise the granules absorb moisture and retain it, which indicates violations of the product production technology;

- price. The material is presented in a democratic segment. Moreover, prices vary depending on the type of expanded clay; the smaller the fraction, the more expensive.

Different types of expanded clay

Also, when choosing expanded clay as a thermal insulation filler for the external walls of wooden or brick houses, properties such as non-flammability, resistance to fungus and mold, and unattractiveness to mice are taken into account.