Why is it necessary to insulate slopes?

Often, after replacing windows, they are limited to only decorative finishing of the slopes, which is wrong and can lead to problems in the near future, because:

- The seams between the wall and the glass unit are filled with polyurethane foam. But this material is not sufficiently resistant to high humidity, ultraviolet radiation and low temperatures. Very quickly, unprotected polyurethane foam will begin to deteriorate under the influence of weather conditions , which will lead to heat loss through voids in the seams.

- Numerous cracks on untreated surfaces of slopes are a common cause of heat leakage from a room.

- Moisture can accumulate in the voids between the wall and decorative panels , which means condensation may form.

Plaster slopes become damp in winter

Plastering slopes without additional insulation is a kind of “first aid”. This finishing method will help you out for a while if, immediately after installing double-glazed windows, you do not have the opportunity and time to do quality work. But in the long run this is not the best solution. Small cracks will form on such a surface, which will require constant minor adjustments. In addition, such slopes do not have good thermal insulation. We will soon have to return to the issue of serious insulation.

It is advisable to carry out the work immediately after installing the windows in the warm season. During the cold season, this will be more problematic, since many adhesives and sealants can only be worked at a certain temperature.

Protection for polyurethane foam

PSUL (abbreviation for self-expanding tape) is glued to the frame before installing it in the window opening. Within about half an hour (depending on the ambient temperature), it increases in volume, filling the space at the outer junction of the edge of the opening with the window frame.

PSUL tape serves as reliable protection for polyurethane foam from all possible destructive processes, because it:

- does not rot;

- moisture resistant;

- does not deteriorate from exposure to sunlight;

- has good vapor permeability;

- when expanded, it perfectly fills small protrusions and irregularities;

- retains its protective functions at temperatures from -50 to +90.

The service life of the self-expanding tape is 50 years and, in theory, its protection is sufficient for external slopes. But, unfortunately, there are no ideal finishing materials.

Therefore, the self-expanding tape also needs protection, and such finishing protection can be the installation of external slopes.

Materials used

The range of materials used to insulate slopes on your own is quite diverse. Each of them has its own advantages and differs in installation and operation features:

- Mineral wool (not to be confused with glass wool - this material is highly undesirable to use for interior work). The main advantages are excellent heat and sound insulation properties. Disadvantage: high moisture absorption. If you notice that the windows are “sweating”, then it is better to abandon this type of insulation, as over time this can lead to the formation of mold and fungi.

The easiest way to insulate using mineral wool

- Styrofoam. The material is inexpensive and easy to work with, which is why it is popular in various types of work.

- Penoplex. It has improved performance characteristics compared to polystyrene foam, but it is also more expensive.

- Sandwich panels. Modern and most convenient type of material. Already includes thermal insulation and protective layers. It harmoniously complements plastic windows and usually fits into any room design. Cons: relatively expensive.

The choice of the preferred material is made based on climatic conditions, the general condition of the walls of the house, the material capabilities of the owner, and the skill level of workers.

Select the required thickness of insulation.

What other insulation options are there?

It is worth noting that there are other ways to protect your home from the cold. Let's take a look at some of them.

Method No. 1. Wool blinds

A non-standard method of thermal insulation of a window structure, but quite effective. Ordinary blinds must be wrapped with strips of woolen fabric, which will prevent the cold from entering the room.

Method No. 2. Window sill insulation

Cold air can also penetrate through the joints between the elements of the window sill. Therefore, these joints should be carefully sealed. In addition, in case of improper installation, “black holes” may appear under the window sill itself, which means that the element must be dismantled, and the gaps between the block and the slab must be carefully processed.

For this purpose, the plugs are opened, the window sill is unscrewed with a screwdriver, and there you will find all the cracks (if any) that allow cold air to pass through.

Method number 3. Application of heat-saving film

A double-glazed window can also be thermally insulated using heat-saving film - a cheap but at the same time effective material. It must be glued in such a way that no air bubbles remain under it, since not only the aesthetic indicators of the entire structure, but also the thermal insulation properties will depend on this.

And if you decide to use such a film, then it is better to take care of gluing it before you begin installing the double-glazed windows themselves. Although, in principle, this can be done after installation is completed.

Method number 4. Curtains

This may sound ridiculous, but curtains can be another way to insulate double-glazed windows. These elements act as a barrier to air, which means it does not let it through in winter (if it does penetrate through the window structures). Moreover, the air passing through the curtains even warms up a little.

Preparatory work

Regardless of which insulation method and type of material are chosen, first of all it is necessary to conduct a visual inspection of the window structure and carefully check the condition of the installation seams. If the double-glazed window was installed a long time ago, and the installation seam was not protected, then most likely the foam has already begun to collapse and crumble. You can identify problem areas using a lighter. Run it along the entire perimeter of the window. Where the flame deflects is where the leak occurs. These areas need to be cleaned and re-foamed. After hardening, cut off excess polyurethane foam.

EuroStrip technology

Another name for this method is groove sealing. This insulation method is suitable exclusively for wooden windows. To implement this, all frames are removed from their hinges. Using a milling cutter, recesses are made around the perimeter of the sash, into which a special silicone sealant is placed with a roller. For reliable operation of the entire system, it is necessary to adjust the fittings, adjust the frame folds to each other with the smallest gaps, and fill cracks and crevices with silicone sealant. The result is high-quality, long-term insulation.

The downside is that the cost of such work can be almost the full cost of replacing a window with a plastic one.

Insulation of slopes inside with foam plastic or penoplex

Sheets of foam plastic or penoplex are the most common types of materials for insulating slopes. Work using them is carried out after installation of the double-glazed window in the following sequence:

- Slopes and areas between the frame and the wall, filled with polyurethane foam, must be plastered with cement mortar.

- After drying, treat the surface with an antibacterial compound.

- Cut the insulation to the required size. It is better to cut a larger piece - the excess can be easily trimmed after installation.

- Sand the surface with sandpaper. Coat with special glue for foam plastic. If you use foam, don't apply a lot of adhesive coating. This type of insulation expands when heated - in hot summer times, a thick layer of adhesive may crack and the coating will lose its thermal insulation properties. Apply the prepared insulation to the slope, partially covering the window frame.

- After the insulation has been glued, we fix it with plastic umbrellas.

- The next step will be mesh reinforcement.

- Then, we place the perforated corner on the putty and align it directly to the level.

- Apply a decorative coating to the front part of the insulation in accordance with the repair concept. This can be drywall followed by painting, plastic panels, colored plaster.

Also to help, a short video instruction:

Rough and finishing casing

Finish casing or quarter casing. It has a selection along the outer edge of the board. A window frame is placed in this contour. The window is located at the level of the external wall. It does not need to be additionally trimmed with slopes. Shutters are installed on the windows and trims are attached to protect the joints from moisture penetration.

A gap of 1-2 mm is left between the frame and the pigtail. Sometimes builders foam it. Professionals use insulation fabric as it is more durable.

To make a finishing pigtail, an array is taken. Glued boards are assembled from high-quality lamellas. Surfaces are polished. Therefore, the inside of the window frame does not need to be finished. Glued profiled boards for sidewalls are sometimes called Euro casing.

Exterior works

To more reliably protect the room from heat loss, it is necessary to insulate the window slopes from the outside as well. The best material for these purposes is penoplex. You will also need a special sealant for exterior use. In a private house, you can do the work yourself, but in a multi-story house it is better to use the services of professionals.

The technological sequence of operations is as follows:

- Clean the surfaces of external slopes from dust, dirt, paint residues, finishing and building materials.

- Level with cement mortar and allow the layer to dry.

- Cut the insulation into pieces of the required size.

- Coat the sheets with glue and install them on the slopes. Additionally secure in several places with dowels.

- Mount the corners. Do not neglect this stage. As a result, you will receive not only insulated, but also smooth slopes.

- Treat the front surface of the penoplex with special glue and secure the reinforcing mesh.

- Level with putty.

- After drying, apply water-based paint or other finishing materials.

The issue of slope insulation should not be ignored. The microclimate in the house and the size of the electricity bills depend on how well and timely this is done. Moreover, the whole process can be carried out independently.

Video on the topic:

How to insulate the slopes of plastic windows? This question worries many owners of modern window designs. However, not all owners care about insulation, but only deal with decorative and protective finishing of slopes, which is a significant mistake. After all, this procedure is one of the most important, which must be given close attention at the stage of window installation.

The most popular methods

How to insulate wooden windows using improvised means? To ensure that the window or window sashes fit snugly against each other, you can use a special rubber window seal, which is sold at any hardware store. This product has a self-adhesive base, which allows you to insulate windows yourself without calling a professional. In addition, the seal is inexpensive. The only drawback is poor fixation in the cold; for a more reliable fixation, the tape needs to be warmed up well.

How to insulate windows for the winter and seal large cracks? If there is a gap between the sashes, you can seal it with ordinary cotton wool. The material is placed tightly between the frames and in places where the wooden structure adjoins the slope or window sill. The top of the cotton wool is sealed with white tape; if the gaps are small, you can simply cover them with masking tape.

You can protect your windows from the wind for the winter with your own hands using self-adhesive foam rubber. The insulating material on one side has an adhesive base, which allows you to securely fix the tape in places where the window frame, vents, or between the sashes do not fit tightly. This product is also sold in construction stores in any city and is inexpensive.

In ordinary wooden windows there is always a gap between the glass and the frame. To seal the cracks, it is necessary to treat the contact areas with sealant. This must be done at above-zero temperatures; the surfaces must first be washed and wiped dry. It is best to use transparent sealant; it will not be noticeable and will not spoil the appearance of the windows. The glazing beads are sealed on top with wood putty.

Why insulate?

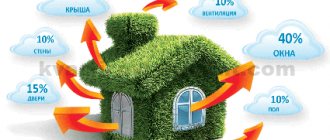

There are many reasons that prove the need for high-quality insulation of slopes, namely:

Traditional method

Previously, windows had to be insulated for winter. For this, strips of thick paper, cotton wool and paste were prepared.

This type of window insulation may make many people smile today, but it has many advantages. Cotton wool, soap and paper can always be found at home. The process of pasting paper strips takes little time, and heat loss is significantly reduced.

Perhaps in new apartments this type of insulation will look unnatural. But in dachas and rural houses this method of insulating windows is still used today. How to cover windows:

- cut strips of thick paper;

- We prepare a paste from flour or soap;

- Using a knife, we close the cracks with technical wool;

- Glue prepared strips of paper over the cracks.

If you do not have suitable paper, a roll of thick paper for covering windows can be purchased cheaply at any hardware store. The process of insulating window openings can be simplified if you buy tape with an adhesive surface. You simply caulk the cracks and stick a special film on top.

Condensation on windows and mold on slopes: causes and solution to the problem

Plastic windows “crying” in winter are a negative phenomenon familiar to many city residents and owners of private houses.

The second problem is mold that appears on the slopes or windowsill.

How to avoid this? To answer this question, you need to understand the mechanism of this phenomenon. With the classic heating and natural ventilation scheme, radiators are placed below the window.

The radiator captures cold air and raises the heated flow upward. Near a cold window, in winter, part of this flow cools and goes down.

Modern plastic windows, unlike old structures through which cold, dry air from the street constantly penetrated, are sealed. If there is a wide window sill at the bottom of the window (covering the radiator), or the radiator is mounted in a niche.

This prevents the natural mixing (exchange) of air masses and a stagnation zone forms near the window.

As a result, the glass blowing is disrupted. Warm air saturated with water vapor comes into contact with the cold glass unit, cools and condenses. This moisture flows down the window. It drips on the windowsill, accumulates in corners, etc.

Dismantling

Insulation of window sills begins with removing them from under the window. The operation is carried out using one of two dismantling options.

First method

It is necessary to very carefully remove the layer of plaster located under the slab. When wallpaper is pasted on the surface, remove it after soaking it in water.

Algorithm:

- The material is knocked down to the base of the wall. This gives full access to the structure, and it becomes easy to find cracks and chips.

- Dismantling requires breaking off the plaster near the window sill and slope.

- To complete the process, you need to get rid of the foam remaining from the initial installation of the object.

Afterwards, just pull the window sill slightly towards you and down. Do not use great force when removing - damage to the “sensitive” plastic coating may occur.

Another dismantling method

It is possible to remove the window sill of a plastic window using a fine-toothed hacksaw with a long and stiff blade.

Instructions:

The hacksaw is inserted under the object, then the old foam is cut along the entire length of the window sill. On the sides of the slopes, the sealant is cut, which created reinforced fastening of the structure. Carefully and slowly, the window sill rises upward and then extends towards itself.

To complete the dismantling, you need to clean the base of the window. Any dust collector will remove debris and expose all existing chips and cracks in the space. They are first covered with new insulation.

How to avoid the appearance of fungus on slopes

For example, there is a wall made of aerated concrete. There is no insulation of the facade. The temperature outside the house is minus, and the temperature inside is positive. Let’s say it’s 26°C outside and + 20°C indoors. Window installed.

In this design, a window (even a high-quality one with several cameras and energy efficient) is a cold bridge. Those. where the window is installed, the thermal contour of the wall is weakened, and the effective thickness of the aerated concrete (which affects the thermal resistance of the entire structure) is actually reduced, and the slope freezes. This can be visualized like this:

Because of this, part of the slope with the window frame ends up in the so-called zone. dew point. This in turn leads to condensation in this place.

The problem is aggravated by the fact that the slope is not covered with vapor-permeable material. Warm water vapor contained in the air of a living space tends to escape and easily penetrates into cold slopes, and conditions for moisture condensation are created in the structure. The slopes become waterlogged and mold and mildew appear on them.

Thus, although there are conditions for moisture condensation in the wall, there is no water vapor in the colder zone. The wall remains dry and “healthy” even at sub-zero temperatures.

Repairing small cracks

If small cracks are discovered, then the owners have to take action immediately. There are several main ways to eliminate them from the inside.

Paper, clay, chalk

To create paper putty, you need to shred paper—newspaper works best. They are soaked in water, part of clay and two parts of powdered chalk are added. All gaps are sealed with the resulting composition.

The putty will be plastic and will clog even the smallest gaps. It is more convenient to work with a knife or a small metal spatula.

For protection, window tape or special adhesive paper is glued on top, or fabric strips pre-lubricated with soap can be used.

Such insulation will be simple but reliable protection before the onset of warming, but afterwards there will be unsightly stripes that will need to be washed.

The process of insulating aged wooden windows can be carried out with cotton wool and fabric. Cotton wool is a unique alternative to paper and newspapers. Technical wool is pushed into the cracks, sealed on top with heavily soaped strips of fabric.

This method is used more often and is quite inexpensive to implement. You can replace the fabric with modern heat-insulating tapes, which, after removal, will not spoil the paint.

Sealant

Silicone sealant for wooden frames is rarely used. In severe frost it will quickly lose its properties, so with the onset of warmer weather the procedure will have to be repeated.

Working with sealant

Putty

This method has come down to us since Soviet times. It was almost the only effective method for maintaining heat. Modern putty can also guarantee protection against drafts. It is used to seal the areas where the frame meets the wall. A special window composition or ordinary plasticine is used.

Materials are applied from the outside of the window - into the joints. First, small pieces are kneaded with your fingers, forming thin sausages and recessing them into the gaps.

The main disadvantages are the destruction of the putty due to frost or melting due to extreme heat.

Polyethylene

This is one of the most accessible and easiest ways. Polyethylene has the following advantages:

- low price;

- ease of installation;

- ease of care.

But its disadvantages should be especially noted, namely:

- insufficient thermal insulation;

- a lot of dust sticks to it.

The film is attached in the following sequence:

- Measure the required length of material according to the size of the window.

- Preparing the frame.

- Fasten the film with tape or pushpins; there should be no gaps left so that warm air does not penetrate.

Foam rubber

Foam rubber is a suitable material for thermal insulation of large gaps.

Special foam rubber

Sometimes wooden window sashes become so dry that they no longer fit tightly to the frame. But using only technical wool will not help. For insulation, foam rubber is glued around the entire perimeter. Thanks to it, the joints become airtight when closed.

Special foam rubber has an adhesive layer on one side. When such materials were not commercially available, foam rubber was attached using the smallest nails. With proper use, the product can serve for 3 years, but then deformation occurs. It is better to seal the top of the strip with tape. In the spring, the tape is removed, and the foam rubber can be left in its place.

Thermal reflective film

The use of heat-reflecting film is a modern method of eliminating cold bridges. The principle of operation of the material is based on the fact that it allows light to enter the house, and infrared radiation does not escape outside, thus retaining heat in the rooms.

The membrane has two parts - two sides. One is shiny, the other is ordinary. The main thing is to make sure that the shiny side faces the street.

The film is overlapped onto the frames with tape. When placed correctly and carefully, the thermal insulation is not noticeable. The membrane is suitable for PVC windows.

Rubber compressor

Rubber is used to create two types of belts:

- sealing;

- self-adhesive.

Self-adhesive material is used more often; it is made from synthetic rubber, therefore it has all its advantages:

- elasticity;

- resistance to temperature changes;

- resistance to aggressive environments;

- long-term operation.

How to make a “warm” window installation yourself

The technology of insulating slopes with extruded polystyrene foam is excellent for an ordinary country house. But, installing windows in energy-efficient homes requires a more advanced option. The thermal characteristics of the wall-window assembly can be improved by using the so-called system. "warm" installation.

These can be EPPS, PIR board, foam glass. The technology for “warm” installation of a window with facing brickwork is as follows, you need:

- Insulate the upper, right and left slopes with EPS.

- The base under the window is also insulated with EPS. But first, in the thermal insulation, you need to make a rigid support under the frame (under plastic support pads/wedges) to transfer the load to the wall, which will be discussed below.

- Additionally protect the mounting foam - from the inside with a vapor barrier, and from the outside with a vapor-permeable moisture-UV and windproof sealing material .

Now let's take a closer look at the lower heat-insulating part made of EPS. The nuance is this: the window must rest and transfer the load from its weight to a reliable, rigid base. When installing a window on aerated concrete, brick, concrete or a wooden lintel in the frame, no problems arise.

The window is mounted like this: under each vertical element of the frame, support blocks/wedges made of durable plastic are placed, and not, as some “masters” do, wooden chips or scraps from boards that come to hand are placed.

But extruded polystyrene foam, although a relatively strong material (it is laid under the foundation, for example, USHP), does not withstand local crushing well. Those. point load from the support block.

To install a window using the “warm” installation technology you need:

- Pre-drill holes with a diameter of about 25 mm in the EPS, which is placed under the window.

- Insert pieces of thick-walled polypropylene water pipes into extruded polystyrene foam.

- Fill the inserts with polyurethane foam.

The height of the inserts in the EPS is selected according to the thickness of the thermal insulation. The installation locations for the inserts are where the support wedges are placed. Next, the window is mounted as usual and secured to the wall with mounting/anchor plates.

Installation of windows and doors in wooden houses

Myths and speculation

The first myth. The jamb is needed to prevent the load on the window frame or door frame from logs during the shrinkage of the house.

If you invited a master to your place and he tells you the same thing, say goodbye to him immediately. It is not true. By and large, a frame is only needed to insert a narrow window or door into wide walls; this is an ordinary box, which can be made in a slightly reinforced version. And the gap between the jamb and the top crown should compensate for the shrinkage of the wooden walls. Ideally, only the force of the compressed seal should act on the top (the top board of the pigtail), and it, as you understand, is quite insignificant. If the gap is chosen too small, then you have three possible consequences:

- a gap of several centimeters is formed between the crown and the window, with all the consequences for the decoration of internal and external walls;

- the frame will not withstand the load and the window will become deformed;

- the error was only a few millimeters and there will be no visible consequences.

The natural question becomes: how to calculate the compensation gap from the top board of the frame to the top crown. The calculation for a log house with a natural humidity of 26-33%, on a jute inter-crown seal of 6-8 mm, will be 5-7%, that is, take the height of the window or door, for example 1.5 meters and multiply by 5% = 7.5 cm + tolerance for the seal , for example mineral wool. Thus, the gap between the top board of the frame and the top crown will be 10-14 cm with a window height of 1.5 meters. By the way, in those countries where they have already learned how to build rationally, the frame is made using a completely different technology and using other lumber, we will talk about this below.

Second myth. The gap between the crown and the pigtail can be sealed with polyurethane foam.

In fact, this cannot be done - since this unit is movable, during the shrinkage process the foam will come off one of the sides and a microcrack will appear, which is completely undesirable from the point of view of energy efficiency. When installing, I recommend using jute fabric 1 cm thick and as wide as the frame or larger, since later it will be necessary to caulk this joint. However, we definitely need mounting foam to seal and fix a window or door in the gap between the frame and the window or door itself.

You already understand that the correct installation of the window depends not so much on the thickness of the boards used to make the frame, but on the correctness of the chosen expansion gap. What does this gap depend on?

- From the material of the walls of a wooden house. Sawn timber can have one shrinkage, laminated timber another, and round timber has third shrinkage rates. The amount of shrinkage depends on the specific humidity of the timber at the time the buildings are covered with a roof.

- On the inter-crown sealing materials used and their thickness. Tow, mineral wool, moss, modern artificial insulation give different shrinkage.

- From the quality of the timber used. If the beam had minor unevenness along the planes, then they will begin to level out over time, which will certainly affect the amount of shrinkage.

- From the height of window and door openings. Here the dependence is directly proportional.

To begin with, let’s dispel a few strange statements that circulate on the Internet with enviable regularity.

The combination of these factors indicates that the architect who can accurately calculate the amount of shrinkage of a house has not yet been born; it is determined “by eye”, taking into account the experience of the master. As a rule, they all make a margin of 2–3 centimeters from the expected shrinkage, which does not allow the crowns to fully rest on the elements of the frame.

Types of pigtails

Taking into account the method of execution and the final purpose, there are several types of pigtails.

- A tenon in the opening, a groove in the frame.

- A groove in the opening, a tenon in the frame.

- The pigtail in the embedded block. Both the opening and the jamb have small grooves into which a planed guide block is installed. It is this technology that is used in developed countries; it allows reducing the consumption of lumber by almost three times, and hence reducing construction costs.

- Draft pigtail. The surface of the frame elements is not processed; the rough frame must be covered with finishing decorative elements.

- Clean pigtail. The quality of parts processing is at a high level; no additional processing is required.

Most domestic technologies involve using 100×150 mm timber for the pigtail; more economical technologies for producing the pigtail use a 35 mm thick board. There is a difference? But the construction effect is the same.

Pipe installation technology

The frame consists of two sidewalls, a top (upper lintel) and a threshold or window sill board. All elements are connected to each other in a tongue-and-groove pattern; such a connection requires a certain order when installing the elements in the opening.

- The dimensions of the tenons and grooves must be made in such a way that the structures can easily move during the shrinkage of the house; any available insulation can be placed in large gaps.

- First, the upper part of the pigtail (top) is put in place. Otherwise, you will then not be able to install the sidewall tenons into the grooves of the top. If the top does not hold itself in a horizontal position, secure it temporarily.

- The sidewalls are put on tenons (or inserted into grooves) and installed in a vertical position; if necessary, they also need to be insulated.

- The last operation is the installation of a window sill or threshold.

- Check the position of the structure, all angles must be 90°, remove the temporary fastening of the top.

- Use self-tapping screws or nails to secure the individual elements of the frame together.

Additionally, you need to caulk the existing cracks; the insulation material does not matter. Now you can start installing the window. Depending on the type and type of window, various decorative elements are used.

What should I say at the end of the article? When making a pigtail, adhere not only to existing traditions, but also listen to common sense, do not be afraid to use modern technologies, in many cases they not only speed up the process of building a house, but also reduce the overall estimated cost and improve its performance characteristics.

Video “How to insulate slopes”

In the video you can see what technological solutions are used by European developers of installation technologies. Watch the recording and find out how the process of insulating slopes and walls occurs, as well as what materials are needed for this.

We recommend that you read

Finishing window slopes with sandwich panels - the final stage of installation

Instructions for installing slopes with your own hands

How to make high-quality finishing of external window slopes

Features of sealing plastic windows

If you want to know how to insulate plastic windows, then the structure is pretty shabby, since only the installed packages do not need additional sealing. Often the causes of drafts are:

- shrinkage of the wall and the appearance of cracks;

- wear of rubber gaskets or loss of their elasticity;

- violation of the seal between frames and slopes.

The following work may be required: insulating the window sill, adjusting fittings, replacing rubber seals, or installing slopes as described above.

The given recommendations and video with a step-by-step description of the work will allow you to enjoy the view from the window without feeling the cold and drafts.

Cover with sealant

This method is suitable if the gap between the window sill and the window frame is not very large.

In addition, compared to other methods of combating drafts, this is the cheapest. Defects are eliminated using a transparent sealant. Before using it, the gap should be cleaned of dust and dirt, degreased, and dried.

The gap between the frame and the window sill must be cleaned of dirt

Then, using the tube nozzle, apply the maximum possible amount of the substance until it is completely filled.

For the easiest way to eliminate a defect, use a sealant

To get a beautiful seam, run the edge of a 10-ruble coin along it. Do this in a continuous motion to avoid crooked seams.

The advantage of this method is that all the work takes a matter of minutes. Disadvantage: fragility. After two years, the sealant begins to peel off and darken.

Platbands

Platbands or casing for internal slopes for PVC windows can be made of different materials, but its functional purpose is the same - protecting the installation seam from destruction and giving the window opening an aesthetic appearance.

Types of platbands

Platbands differ in appearance and functionality:

| Flat platbands. This is the easiest and most inexpensive type of cash withdrawal. |

| Profiled platbands have a convex surface of different profiles, aimed at enhancing the decorative function of cashing. |

| Shaped platbands can have a complex relief and imitate natural wood. |

| Carved platband is the most expensive type of cash, made to order according to individual sizes. |

Materials for production

The most common material for making cash is sheet plastic. It is used for the manufacture of budget flat platbands, which can be used for finishing windows indoors and outdoors.

This material is not afraid of temperature changes, exposure to moisture or sunlight. Its surface can be laminated and take on any color or imitate various types of natural wood. Therefore, choosing cash to match the color of the window facade will not be difficult.

Plastic platbands are not prone to deformation due to temperature changes and exposure to moisture.

Profiled PVC trims have the same properties, but may have a shaped surface. They are also used for interior and exterior window decoration.

MDF trims can also be flat or profiled, but they are used exclusively indoors, since the properties of MDF do not allow them to be used outdoors under the influence of surrounding natural phenomena.

For external use, dense foam casing can be used. This material is easy to process and install. The most intricate and complex shapes can be cut from polystyrene foam. It can be decorated with any finishing materials. It has negligible weight, so it does not put any load on the wall.

Foam trim can be used for exterior window decoration

The most expensive window design option is the installation of wooden carved cash. Carving can be done manually or mechanized. Handmade is very expensive due to its individuality and exclusivity.

Profiled and shaped platbands made of natural wood, made on a machine, will cost less.

Wooden platbands require careful care, since wood, when used in conditions of exposure to the external environment, has some disadvantages:

- wood can become deformed when absorbing moisture or crack as a result of drying out;

- Such cashing looks harmonious on wooden windows or on timber facades. On modern facades such cashing will look ridiculous.

Fastening

Most often, when installing platbands on a plastic window, mounting elements are used that are fixed to the frame or wall.

Platband installation diagram

Safety precautions

During work, it is necessary to comply with safety rules and requirements. This will help avoid unpleasant consequences. The main attention should be paid to the properties of the insulating material :

- Mineral wool. You need to work with it in a well-ventilated area. The cutting tool must be well sharpened, gloves, a respirator and special glasses must be worn.

- Sandwich panel. If the material needs to be cut, the respiratory tract must be protected from dust. To do this, just wet the panel with water or put on a mask (respirator).

Important! Before starting work, be sure to familiarize yourself with the safety precautions for each type of insulating material.