When building a roof, special attention is always paid to the structure of the attic. After all, it is important that its covering is done technologically correctly, does not put unnecessary pressure on the walls and is able to withstand the load from things stored under the roof and sometimes an entire set of furniture.

Therefore, in this article we will understand in detail how an attic floor on wooden beams should be installed correctly: the features of its installation, calculation of loads and fastening. And our detailed illustrations will help you.

What is an attic ceiling?

The ceiling is a horizontal load-bearing structure that separates the living floor from the attic space, and at the same time takes on the load from the weight of everything that is under the roof.

The floor itself is a necessary element of rigidity, which also provides stability to the entire structure. Among all the others, today we will highlight the attic floor, namely its specific type. Note that the general rules apply to all types, but there are still some technical features in the arrangement of attic floors along beams.

The first of these is rigidity and strength. Those. the overlap should be:

- Capable of withstanding design loads and not bending or collapsing. For example, the permissible deflection is only 1 in 250 of the span length.

- Secondly, the attic floor should not be flimsy, and in no case should it vibrate when objects are moved on it or people move on it.

- And finally, soundproofed to avoid unpleasant squeaks when someone climbs into the attic.

In private construction, two types of floors are mainly used: wooden and reinforced concrete. The former are built on strong wooden beams, and the latter – on beams, slabs and in a monolithic version. Also, the beams themselves can be steel if it is necessary to cover fairly large spans. But it is precisely in private housing construction that the choice of flooring material is most often influenced by the economic factor.

The cost of installing floors usually amounts to up to 20% of the estimate for the entire construction of a house, and labor costs - as much as 25%. Therefore, the construction of a wooden attic floor is still quite popular - all thanks to its high performance characteristics and good sound insulation.

And one more important point: when making wooden attic floors, you do not need heavy lifting equipment, especially a concrete pump.

Lighting

In order for natural light to freely enter the rooms under the roof, translucent structures are needed. In this case, the only correct solution would be to install skylights. An important point in the process of preparing to install a window into the roof slopes is the manufacture of a strong wooden frame on the inside, which will help hold the window frames and prevent possible deformation. The frame is installed between the rafter legs, so the width is ordered taking into account this distance and the thickness of the beams. Windows can be installed on gables or directly in the roof of the house. What are the advantages of roof windows?

- Saving on energy costs. Such windows allow you to increase the transmission of natural light by 40%.

- Exquisite design. Windows help create a unique atmosphere in the room under the roof; they organically complement the design, creating spaciousness in the room.

- Functionality. Manufacturers offer various configurations and functional loads of windows for attic spaces.

Dormer windows are an excellent source of daylight

As for wiring into the attic to create high-quality artificial lighting, there are several proven methods:

- laying wires over the walls, hiding them in special plastic boxes;

- arrangement of hidden electrical wiring by laying the wires under the inner lining.

The first method is the simplest; you can do it quickly and easily with your own hands. The second method is more technically complex, since the fire safety standards and requirements for a private home must be taken into account. Hidden electrical wiring is installed during the installation of the frame, wall and ceiling cladding.

When the electrical wiring is installed in the attic, all sockets and switches are placed in their places, you can begin the most exciting stage - interior planning. Flights of imagination are welcome here! You can choose classic style solutions, cozy Country or gentle Provence. For young people you can create an urban room under a roof in the Loft style, and for children - a fabulous dream island.

The easiest way to highlight the beauty of your attic interior is through thoughtful lighting.

Transforming a dusty and dark attic into a cozy and spacious room under the roof itself is a labor-intensive process and requires financial costs. Knowing the secrets and tricks, following the rules and advice of experts, you can quickly transform an uninhabited cold attic under the roof into additional living space.

Transforming an Abandoned Attic

Advantages and calculation of beam floors

The entire structure consists of beams and boards, which are called rough. The beams themselves can be load-bearing, located simply next to each other, or fixed in a special way, which is much more reliable. The standard sizes of beams are 20-40 centimeters in height and 15 meters long, plus 8-20 centimeters in width.

Unlike reinforced concrete attic floors, wooden ones are installed dry. It is much lighter in weight, so in private construction it is better to use just such an overlap. On the other hand, wooden floors are the least soundproofed, so you will have to spend money on additional measures.

The beams are located at a distance of 60 centimeters to 1.5 meters. Of course, the more often you install them, the greater the load the attic will be able to withstand in the future, but the foundation of the house will also have to endure a greater load.

Light partitions are usually mounted on a wooden attic floor - most often frame ones, to which the attic rafters are directly attached. They need to be installed perpendicular to the beams or edgewise.

But if for some reason the internal walls of the attic have to be placed parallel to the ribs or beams, which is not at all according to the rules, then the structures in these places must be strengthened. Most often, fragments of boards are used as such elements, which are attached perpendicular to the ribs of the floor.

And this graph will help you calculate the required number of beams and the load on them:

Space layout

Often the roof is attached closely to the mauerlat, so using this space is almost impossible. In such cases, the walls of the attic room are shifted towards the ridge of the roof from the walls of the building. Often this technique deprives the room of visual space, so walls are not installed in the attic. Installing furniture in such a room is more difficult, but it looks very interesting.

To make the attic a full-fledged living space, additional windows are installed. Most often this is done in the gables of the house, but if there are transverse walls in the attic this is impossible. In such a situation, windows that cut into the roof slope are used. Similar techniques are often used in Western architecture and can give the house an unusual look.

When planning an attic, it is often difficult to organize the entrance area. To do this, use compact folding or spiral staircases.

Options for installing attic beams depending on its type

Many people ask the question: where is the correct place to install wooden floor beams? Into the walls, onto the walls, or even bring them out a little? It depends on what type of attic you have and whether you will use it as a living space in the future. The attic is very popular today!

So, here is an economical option that allows you to convert the attic into an attic in the future without any problems. True, very tight:

Therefore, if you have such plans and even now you are not sure whether there is another place in the project for a personal office or a billiard room, then make the walls higher in order to install the floor beams lower.

What will it give? In such an attic there will be much more usable space, fewer sharp corners and it will be much warmer:

But if in your project the attic was initially planned as a separate and spacious room, as if built on top of the house, then the attic beams need to be installed as strong as in the interfloor ceiling, and also secured to anchors in the reinforced belt:

Here is an excellent step-by-step example of how such attics are built and how strong such a floor should be:

Roof slopes

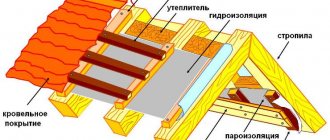

Roof slopes need to be insulated only if the attic space is planned to be made residential. This is a rather problematic solution - organizing an attic requires excellent knowledge of building physics and intense attention to each layer of the roof structure.

The air in a living room is saturated with moisture vapor that rises. If moisture penetrates into the thickness of the insulation - almost any! – its thermal insulation properties will deteriorate, so there must be a high-quality vapor barrier in the path of warm air. It is necessary to ensure that the joints of its panels and the junctions with the walls are carefully taped with special tapes. The other side of the coin is that absolute vapor tightness leads to disruption of the comfortable microclimate, so in attics it is preferable to use more expensive and modern diffusion membranes. Or often (and in fact, almost constantly!) ventilate the room. Another point that is extremely important when organizing an attic is the presence of a ventilation gap that helps remove moisture from the insulation if it does get there.

If the attic was initially included in the project, then in the vast majority of cases the roof insulation is carried out from the outside, before the installation of the finishing coating. There is a vulnerable point in this technology - when the insulation layer is laid, but not yet covered with roofing material, sudden rains are very dangerous. If the owner wants to avoid this risk, then it is advisable to lay thermal insulation material from the inside. This solution has a lot of advantages - in particular, it will be possible to do insulation after the end of the main construction season, in bad weather.

Insulation of the roof outside the house

To insulate the attic from the inside, it is necessary to place strips between the rafters that will hold slabs or rolls of insulation. The step between them should be 40-50 cm. The thermal insulation material is carefully placed in the resulting “pockets”, the sheathing slats are nailed, which will finally fix the insulation, the vapor barrier layer is installed and its joints are carefully glued.

Insulating the attic from the inside

In addition to slab and roll insulation, you can use various sprayed materials. They are also effective, however, their application requires expensive professional equipment and appropriate skills. We examined insulation for pitched roofs in more detail in this article.

Types of floor structures

There are several types of attic floors with wooden beams. Each of them has its own purpose and its own pros and cons.

Platform: for a cold attic

As for frame houses, the floors in them are recommended using the “platform” system. That is, after installing the walls, beams are laid and a certain platform is created, as it were, and a working foundation for the future floor of the attic at the same time. It is important here not to put unnecessary pressure on fragile walls, so the attic covering will also not be designed for a piano in the corner.

In this case, the beams are installed on a strapping beam, which is used as a power plate:

Rigid board: for uniform shrinkage

But in a house with walls made of logs or timber, according to the rules, a rigid shield is installed as an attic floor, which, when the walls shrink, will smoothly lower with them, and always evenly.

Economy flooring: to save time

Prefabricated wooden floors should be highlighted as a separate type of attic floors. Their main feature is the use of special fasteners, which are made of galvanized steel. Their thickness and quality are calculated depending on the level of future loads on the floor.

Standard attic floors on beams with beams and wooden joists appeared at the end of the 20th century, and after them floors made of wide boards became more fashionable.

Ready-made trusses: for a residential attic

Today, special ready-made companies for arranging attic floors are also in fashion. In fact, this is not a new thing in the construction market; such companies appeared at the end of the 16th century and found their rebirth at the end of the 20th century. Canadian companies that were involved in construction developed special calculation programs for such companies and their exact shapes with assembly lines.

Ribbed beam floor: for private housing construction

In our country, new types of wooden floors are beginning to appear, which until now were popular only abroad. These are light wooden floors. They are relevant for private construction, when a fairly light wooden frame is used as a system.

The essence of the overlap is that “ribs” are installed every 30-60 centimeters, and they are covered with sheathing. Wooden beams with a height of about 20 and 28 centimeters, a thickness of 45 centimeters, and a length of up to 5 meters are taken as “ribs”. They are made from natural wood and connected with special bundles of boards, covered with chipboard or fiberboard sheathing.

Therefore, we highlight quick and simple installation as the main advantages of a ribbed attic floor. Of the minuses: the need for treatment with a fire retardant, less strength and low sound insulation properties. And, of course, such boards are more sensitive to sudden fluctuations in humidity and temperature. And also, if a fungus or some insect decides to eat such a ceiling in a few years, it will eat it much faster than thick beams.

From below, this structure is covered with a suspended ceiling made of plasterboard slabs. Mineral wool is placed between the ribs on top. It is this that will provide fire resistance and sound insulation to the entire wooden floor.

Ribbed attic floors are much cheaper than beam floors - this is quite reasonable and rational if you do not insulate a non-residential premises and make a residential attic out of it. Then you don’t have to worry about the load-bearing capacity of such a foundation. The only negative is that beams are more common for Russian houses, and the ribbed ceiling is almost no different in appearance from the monolithic one. Therefore, in Russian houses, ribbed beam attic floors are more often installed.

The beam for constructing such an attic floor must be taken in a rectangular shape, and strictly, and not in a diamond shape. And be sure, when buying such timber, take with you the most common school ruler, because it often happens that many people are going to build a floor from 15x15 cm timber, but in the end they are built from 14x14 cm timber. And then, on your site, be sure to prepare a place for storage such timber and its processing.

By the way, today many even install ordinary timber in a wooden floor on its edge. The fact is that even a ruler, no matter what material it is made of, easily bends along its entire length, but if you place it edgewise, it will be almost impossible to bend it:

Lay a finished floor on the rough floor made of boards, and install a suspended ceiling underneath. But often the wooden floor of the attic is left without additional finishing on purpose, in view of the interior design concept, but then all its details are done very carefully and even with a decorative slope:

The suspended ceiling itself imparts a certain rigidity to the ribbed ceiling.

Attic space definition Safety Portal

If a residential building has a pitched roof, then a space will be formed under it, which can be called an attic or attic. You need to know the difference between an attic and an attic.

This is necessary not only to understand the functionality of the under-roof space, but also to ensure that you do not have problems during the registration of the house, since the total and living area of the house can differ significantly depending on the purpose of the space under the roof.

- Attic floor

- Attic space

- Differences

Difference between attic and attic

The top end of the house can be an attic or loft. Each of these types of premises has its own characteristics. What are these features and how does an attic differ from an attic? Let's consider the issue in detail.

articles

Attic is an attic space used as a residential space, the facades of which are also the slopes of the roof of the building.

Attic

The attic is the space between the roof and the ceiling of the last (or only) floor.

Attic

How to embed attic beams into walls made of different materials?

Today there are several ways to attach attic beams. Basically, installation is required perpendicular to the support beam, which is equal to the maximum length of the floor beams. If the design does not provide for additional stiffening beams, then the attic floor beams should lie along the axes of the load-bearing wall posts. According to standards, floor beams must rest on the top frame of the walls and are attached to it with two nails 3.5x100 millimeters on each side.

But often in construction it is also necessary to use special fastening methods, and in order for you to better understand them, we have prepared high-quality master classes for you.

It is necessary to design a wooden attic floor based on the loads that will affect it. But keep this point in mind. Quite often, residential buildings are built with the expectation that they will be enough for the whole family. And such loads are divided into distributed and concentrated.

When designing an attic floor, you need to take into account distributed loads, and you can learn more about them from modern SNiPs. Concentrated loads should only be taken into account if you are definitely going to install some objects with a large mass in the attic.

For example, today it has become fashionable to arrange SPA salons, a billiard room, dance floors and rooms for musical training under the roof. But in practice it often turns out that 10 rooms in a house is not enough. And under the roof there is excellent ventilation, a beautiful and quiet space to set up your personal office there.

The need to use special fasteners depends on what technology for arranging the attic floor you have chosen in general. So the most reliable way is to support the beams on the load-bearing surfaces of the walls or on the floor beams. Then there is no need or sense at all to use metal elements - the beams are fastened with self-tapping screws or nails. In all other cases, it is necessary to secure the attic floor.

Therefore, we advise you to initially make such a strong attic floor that in a couple of years you can rebuild it into an attic with a clear conscience. And our special tables and computer programs will help you make special calculations. Your task is to correctly select the optimal cross-section of beams and their pitch. Everything else is just details.

Is a reinforced belt required?

First of all, decide whether you need an armored belt to install attic floor beams. Armopoyas is a reinforced belt, which is a closed structure along the entire contour of the building. The task of such an element is to distribute loads.

When installing wooden beams of the attic floor, it is necessary to install an armored belt only if:

- The walls of your house are built from gas block or foam block. After all, such material has a rather fragile structure, and at the same time the wooden beam floor has considerable weight. Due to its design, it always creates a point pressure on the blocks. And our task is to distribute this pressure and make it linear. So that the Mauerlat takes on the entire load.

- Also, whether the foundation for your house is prefabricated FBS blocks, or the foundation itself is shallow, it is also important to correctly distribute the load from the attic over the entire base area of the house.

In all other cases, you can safely do without an armored belt.

Fastening beams to beams or frame

When floor beams are attached to a log frame or rounded logs, the easiest way is to use the frying pan technology. In simple terms, simply insert beams into the walls, like parts of a construction set.

Please note that the floor beams are fastened together with metal brackets:

Attaching to a metal I-beam

If you have to split floor beams along their length, then their parts should be joined with an overlap or with the help of special overlays, and spacers will also be needed between the beams themselves.

And if we are talking about planning a large area, then it is better to use a steel I-beam or a particularly strong one made of laminated wood as a support for the beams. In this case, be sure to leave a gap of 10 millimeters between the attic beams and the steel I-beam. It is important that the steel beam does not touch the ceiling sheathing. To prevent the floor beams from creaking in the future, lay additional soundproofing material or make the ceiling sheathing quite dense:

If you use auxiliary beams, they do not have to be placed inside the floor. These can be easily built into the wall or even used independently. And the beams themselves need to be mounted on so-called beam shoes:

The first step for such beams is to make a strapping. Moreover, it is not at all necessary to attach the harness itself to the walls of the first floor, as many people think.

The main thing is to properly prepare such beams for installation. And to do this, they must be treated with an antiseptic (and at a temperature not lower than 5 degrees Celsius). Then leave them to soak for a day. Now cut and lay such boards and a supporting beam on a wooden Mauerlat, previously impregnated with its fire and bioprotection. All that remains is to secure all the floor beams to the shoes.

And, when the ceiling of the beams is ready, make a subfloor, at least so that it is convenient to move on it.

Fastening to brick walls

If we are talking about attaching a wooden beam to a brick wall, then it is necessary to create a nest in it, even at the stage of constructing the walls themselves. The nest should be located 160 mm inside the wall (this is the minimum), and on a special board.

When inserting a beam into the wall, you need to fill it with cement mortar or leave it open - everything here depends on the thickness of the wall:

- So, a closed version is necessary when the wall thickness is two bricks.

- Open - with a wall thickness of two and a half bricks.

In addition, the beam ceiling of the attic with brick walls must be reinforced with anchors in every third beam. The anchors should cover it from below and on the sides, and themselves should extend into the wall by 30–50 millimeters. It is also possible to connect beams to each other and on internal walls.

Beams should be attached to a brick wall using the following technology:

Attaching to fragile block walls

If you are attaching wooden beams to a block wall, then you will need to build a reinforced concrete lintel. This is the same reinforced belt that we talked about earlier. It needs to be installed under a beam, specifically under a wooden box that goes into the wall. The beam itself will need to be installed on a reinforced belt in the wall, also at a minimum of 160 mm. And do not forget also about such an important point as the insulation on the side of the block and the gap on the side of the beam, which will ensure the escape of moisture.

Therefore, in order for modern lightweight blocks to withstand the wooden beams of the attic floor, follow this scheme:

If the blocks are quite strong and their physical qualities are close to brick, then use the following installation scheme:

Floor installation in the attic

Attic is a living space located under the roof of a house.

To put it simply, this is a residential attic. The experience of arranging housing under the roof of a building came to us from France. At one time, residents of Paris began to develop attics, seeing the benefits of obtaining additional living space. In modern individual construction, home building owners willingly install attics under the roof of their homes. The floor in the attic is part of the floor structure. How to make an attic floor so that it meets modern requirements? We will talk about this in this article.

Which timber is better to choose for the ceiling?

If you have now smoothly approached the issue of installing an attic floor, the first problem you will have to face is finding good quality boards. It is very important that neither the beams nor the flooring have any flaws, are not weakened and certainly do not suffer from any mold. Otherwise, such overlaps are life-threatening for the lives of household members.

Option #1 - beams made from ordinary boards

Let's separately note which beams need to be used when constructing an attic floor. The best option is boards 20-30 centimeters wide. The material used is pine or larch, which work well for deflection. It is this kind of wood that is durable in terms of deformation and less susceptible to cracks. According to official estimates, when using such material, it is possible to reduce the consumption of all wood by as much as 20%.

Option #2 - beams made of laminated veneer lumber

Glued laminated timber is also often used today as beams, the strength of which is several times higher than that of ordinary wood. The thing is that any glued wooden products are stronger. The whole secret is that the glue that is used gets into the pores of the two parts being glued together and forms many strong threads between them - much stronger than the fibers of the wood itself. And therefore, laminated veneer lumber as beams is a completely normal option.

In appearance, they do not differ from solid wood, especially when, for aesthetic purposes, the best grade of wood is used in their outer layers. Such beams are made from lamella boards, which are cleaned of defects and glued together. The main advantage of this method is that the total length of the beams can now be up to 12 meters, and it will be much stronger, just with a wooden beam with the same parameters.

What many also don't take into account is that solid wood can have hidden problems that may show up a few years later in the form of a beam breaking down the middle. For example, such a cause is often rot or parasitic insects, which at the time of purchase of the beam have not yet had time to develop. Second point: it is quite difficult to find an absolutely flawless long beam made of pure wood, without knots and other problems. And the knots themselves are bad because in these places the wood does not work well in tension, it is denser, and as a result the beam, with the constant dynamic stress that contributes, reacts to it unevenly along its entire length.

Option #3 - OSB beams

To make strong beams from OSB boards, they are cut into strips of different widths and milled. Next, the blanks are glued together, and they form a long endless strip, from which templates of a certain length are made. The main advantage of using such beams for attic flooring is their low weight and excellent strength and bending resistance.

Option #4 - I-beams

Another type of beams popular in Russia is I-beams. This is one of the strongest types of beams, and any flooring can be installed on top of them, not just plywood. And the plasterboard is hemmed underneath. These beams are so strong that it is more appropriate to install them as an interfloor ceiling for fully residential rooms, not only for the attic, and even more so for a cold attic.

The so-called Canadian I-beams are also popular. They are made in a factory from wooden blocks, OSB boards, special moisture-resistant boards, laminated veneer lumber or coniferous wood.

Option #5 - beams from ready-made trusses

For example, one of the most recent developments is ready-made attic trusses. Their height is 350 millimeters. They are made from dry wood with a cross-section of 100x50 mm. In the factory, such elements are combined into one structure using a special press with metal plates. Moreover, during the manufacturing process of such trusses, engineering communications are even placed inside them.

Option #6 - LVL beams

It is also worth noting that a relatively new material on the domestic market is LVL beams. These are high-strength homogeneous materials that are made by gluing under special pressure. Several layers of veneer are used, and during the manufacturing process of the beams the fibers are arranged strictly parallel.

The characteristics of such beams are special. The main advantage is that which beams have a large selection of sizes. The material itself lends itself well to processing with almost any cutting tools. But given the price of LVL timber, we advise you to purchase it only if your attic floor will be located over a large span and your priority is quality and safety.

Option #7 - HTS beams

Another new type of attic beams is the German HTS. They are also an I-beam, where the top and bottom layers are made of wood, but the middle layer is made of OSB board.

Between these layers a profiled steel sheet 0.5 millimeters thick with a special polymer coating can also be inserted. Moreover, the steel itself has a wavy shape, due to which the beam has high load-bearing characteristics. And there may not even be one such wall, but two, which is even better for bending resistance. And to prevent the HTS beam from bending and twisting, hidden transverse connections are installed between the layers at a certain pitch.

Features of heated floors in the attic

Today it is important to install heated floors in the attic.

Of course, there is no talk of installing a water heating system. This is expensive and not practical.

However, options such as cable electric heating on a dry backfill floor or infrared heating are quite possible. For more information on how to make floors on the second floor, watch this video:

The least labor costs arise when installing infrared heating. IR elements are placed directly under the laminate flooring substrate.

| № | Type of heated floor | Advantages | Flaws |

| 1 | Electrical cable | Reliability, durability | Dry backfill device |

| 2 | IR heating | Easy to install | IR elements are sensitive to high humidity |

All the pros and cons of installing a particular type of underfloor heating depend on the totality of financial capabilities, technical accessibility and other circumstances.

Exterior works

A prerequisite is that the house is insulated in warm and dry weather. It all starts with an inspection of the surface. Next, all wooden components need to be treated with an antiseptic, and metal ones with an anticorrosive agent. It is also necessary to thoroughly dry damp areas. If the tree is damaged by insects, it is replaced.

In a log house, the rafter system is made of wooden beams. So the waterproofing film is glued directly to these joists, after which the lathing is created and the roof is installed. Insulation from the inside occurs by laying the material between the rafters with its fixation on top of the vapor barrier, as well as finishing with plasterboard. There is no need to compact fiber-type insulation - you need to cut out pieces of material with a small allowance and insert them between the rafters. If a soft roof is to be installed, then OSB boards or moisture-resistant plywood are laid directly on the sheathing, after which the roof is created.

Choice of insulation

When choosing a gasket for the floor on the attic floor, you need to avoid making the structure heavier.

There are many materials for insulating buildings on the market. Which one is optimal for insulating the attic floor should be examined in detail. We remember that the ceiling of the lower floor is also the basis for the attic. Therefore, heavy insulation materials should be avoided, as they place excessive stress on ceiling beams and floors. Experts recommend the following insulation materials: Polystyrene foam is the easiest way to insulate a floor. Advantages:

- affordability;

- excellent thermal conductivity;

- moisture resistance and biological stability;

- ease of installation.

In addition to the advantages of using polystyrene foam as insulation for floors in attics, there are also disadvantages. The material has low vapor permeability, little strength, and is also a fertile environment for rodents.

Extruded polystyrene. A representative of the modern generation of floor insulation, which has the following advantages:

- high levels of moisture resistance;

- low thermal conductivity threshold;

- groove fastening system.

The disadvantages include the high cost of the material and low vapor permeability.

Mineral wool is the best choice for insulating floors in the attic. Pros of use:

- the material is fireproof;

- has low thermal conductivity;

- moisture resistant;

- environmentally friendly for households.

The disadvantages include the high cost and the presence of joints during installation. The cracks and joints that may result from installation must be sealed with special mastics.

Expanded clay is one of the most effective materials for floor insulation. This insulation is a budget option with good characteristics. Pros:

- lightness;

- maximum filling of voids;

- minimal load and simple installation technology;

- environmental Safety.

Important! When choosing expanded clay for floor insulation in an apartment or semi-attic, you need to take into account its shrinkage, the coefficient is 1.15.

Glass wool is considered a classic insulation material. But, along with safer and more modern thermal insulation materials, its characteristics are not ideal. When choosing floor insulation, you need to proceed not only from financial capabilities, but also from the aspect of durability. As they say, the miser pays twice! Therefore, savings in measures to insulate the attic floor are not appropriate.

Main nuances of the procedure

- The wood rots, therefore, the steam rising from the house must pass freely. If you install a vapor barrier or use a material that does not “breathe,” the tree may soon collapse.

- Insulation with foil should be laid with it (foil) down to protect the wood from moisture.

You can see examples of correct and incorrect installation in the image below.

But here is a universal scheme - insulating the attic floor using any of the materials.

Video - thermal insulation of attic floors

As a result, we note that the thermal insulation of the attic floor will be most effective if the attic itself is reliably protected from moisture penetration from the outside. In other words, you also need to properly arrange the roof. Good luck with your work!

Functions

The design of the attic floor depends on the size of the house and the nature of the use of the under-roof space. The attic is a kind of air gap that separates the heated space of the first floor and the roof and thermally insulates it. Its floor performs the following functions:

- Carrier. The floors between the upper floor and the attic perform a load-bearing function, so they must be strong enough and reliable, because people move around it, equipment and storage areas are installed.

- Isolating. The room in an unheated attic has a temperature not much higher than the outside temperature. Therefore, the ceilings perform a thermal insulating function, preventing the heated residential floor from cooling down. To retain heat, they include a layer of insulation.

Remember that the temperature, comfort, and safety of living in the house depend on the correctness and quality of the work on arranging the attic. Therefore, it is better to entrust the design, installation or repair of floors to professional craftsmen.

Attic floor diagram

Sawdust

Sawdust is a natural material and has proven itself for thermal protection of wooden houses. This technology is somewhat more complicated than gluing with foam plastic. The main difficulty lies in the preparation, or more precisely, the manufacture of insulation, which is a cement-sawdust mixture.

Preparation of the composition

It is better to use medium-sized shavings. Thyrsa is not suitable for insulation. Its volume contains very little air. The sawdust should not be fresh. The raw materials are treated with antiseptic and antifungal compounds. The simplest solution to this problem is to soak wood chips in a solution of copper sulfate, after which it should be thoroughly dried.

The process of preparing a cement-sawdust mixture consists of the following steps:

- in a spacious container (a trough with sides 25-30 cm), prepare “cement milk” by mixing water with cement in a ratio of ten to one, and mix thoroughly;

- Sawdust is added to the resulting mixture, which during the mixing process should be evenly covered with a layer of solution.

Surface preparation

Before you begin making insulation, you should prepare the area for its application. This preparation includes the following:

- dismantling the attic floor;

- cleaning the space between the joists from debris and other foreign objects;

- treatment of all available wooden floor structures with antifungal and antiseptic agents;

- laying a vapor barrier carpet (as insulation, you can use thick polyethylene film overlapped on the joists).

Application of insulating composition

Next, the prepared cement-sawdust mixture is scattered over the floor area and lightly compacted. The insulation must be evenly distributed between the floor joists. After complete drying, the resulting coating can be walked on.

One of the main advantages of this method of ceiling insulation is the low cost of materials. First of all, this concerns sawdust, which, with some effort, can be purchased for free.

How to calculate the thickness of the insulation layer

Before you insulate the ceiling in a private house from the attic side with sawdust or expanded clay with your own hands, you need to accurately calculate the height of the backfill layer and the amount of material required. This applies to foam plastic, mineral wool and penoplex to a lesser extent, but it would not be superfluous to determine the thickness of the slabs for them as well. If the calculated mass of bulk material can lead to collapse, choose a different type of insulation.

First of all, the homeowner will need a standardized value of the thermal resistance of the floors for calculation. The latter is established for each climatic region and is selected according to tabular data, multiplied by the thermal conductivity coefficient of the insulation to obtain the required thickness of the material. To compensate for possible calculation and installation errors, 20-50% is added to the obtained value.

Characteristics

The main characteristics of the panels as a thermal insulation material exceed those of the most popular insulation materials. If we compare the thermal conductivity, then for Teplofom it is in the range of 0.028-0.032 W/(m*°C). For comparison, this figure is: for foam plastic 0.033; glass wool - 0.04; mineral wool - 0.05 W/(m*°C). From which it follows that insulation with such panels will allow you to retain better heat in winter and coolness in summer.

An important characteristic for thermal insulation material in the attic is water absorption. It shows the ability of a material to absorb moisture and is measured as the percentage of water absorbed over a certain period of time when the sample is completely immersed. The indicator for Teplofom is 0.1%, which is significantly less than foam plastic (1.5-3.5%) and incomparably less than glass wool and mineral wool (up to 70%).

The following modifications of panels are suitable for insulating the attic:

- Teplofom+ can be used for indoor and outdoor spaces and does not require waterproofing or additional ventilation. The panel size is 250x50cm, thickness from 10 to 100mm, this makes it possible to select the necessary parameters for any use case;

- Teplofom+ SP - use a tongue-and-groove connection. This allows you to speed up installation work and create durable, securely bonded coatings with minimal effort.

- Teplofom+PL - a coating of moisture-resistant plywood on both sides allows the use of such panels to create an already insulated base for the roof and floors. This results in a surface completely ready for finishing with linoleum, parquet, laminate, etc.

Features of flooring in the attic

The process of arranging the attic floor has some features:

- Despite the fact that the attic floor does not come into contact with the cold external environment, it needs high-quality heat and sound insulation.

- The material for floor insulation should be light in weight so as not to burden the structure.

- The attic comes in different configurations, allowing you to open up new opportunities for realizing design ideas. Practice shows that making a room from an attic is cheaper than building a full second floor, despite the cost of insulating the room.

- Thanks to the variety of shapes and configurations of the structure, attics give an original look to the house.

- A high-quality floor depends on the quality of the materials for its manufacture and the technology of its construction process.

- When arranging the floor of log houses, the size of the relay and rafter beams must be the same and form a strong frame for attaching the mauerlat to it.

House with a residential attic

Waterproofing, vapor barrier

The attic, like any other room in the house, requires protection from moisture. And she can get into the attic in two ways. Through roof defects from the outside during precipitation and in the form of condensation when cold air comes into contact with warm air rising from the ceiling of a heated room. In addition to the fact that humidity in the attic can gradually destroy wooden rafters and create conditions for mold to grow, it reduces the thermal insulation properties of some insulation materials.

From the above it follows that in order for the thermal insulation system to perform its functions for a long time, it must be protected from moisture. This is ensured by the use of two protective layers:

- The vapor barrier is installed on the side where warm air enters to prevent water suspension from entering the insulation.

- Waterproofing protects against water entering from the outside; accordingly, it is laid between the insulation and the roof.