One of the important stages in creating a partition cake is ensuring that the structure is perfectly dry. In such cases, vapor barrier of the walls of a frame house comes to the rescue. Such a structure, like no other, requires the creation of a water-repellent layer. This is exactly what we will talk about in today’s article, and also consider the features of this insulator and which one will be better in a particular case.

Walls in a frame house that need vapor barrier Source eco-kotly.ru

Vapor barriers - what they are and its features

Vapor barrier is one of the layers that is necessarily used when constructing the walls of a frame structure. For this, a special material is used, which is a membrane; it is smooth on one side and rough on the other (both can be rough).

With the help of such a layer, excess moisture is removed from the inside and does not enter from the outside. The layer itself inside has a porous complex structure. Such material must be installed strictly as stated in the instructions (they always specify which side the vapor barrier should be on the outside and which side should be on the inside).

Vapor barrier for exterior walls of a frame house Source remontnik.ru

If it is a material with both sides the same, then there is no difference in the arrangement. There are also special purpose options. These are intended for certain conditions: for example, with high humidity (bathhouse, sauna), for non-residential premises or for houses with a harsh climate.

Installation technology

Most often, vapor barrier materials with foil are used to equip a cold attic and a warm attic. In the first case, the insulation system must be installed along the ceiling, in the second - along the slopes.

To install a vapor barrier correctly , you need to adhere to generally accepted construction rules:

It is worth noting that accessories for foil insulation must be selected from the same manufacturer as the material. Of course, you can find universal tape on sale that is suitable for joining materials of any kind, but in the case of foil structures, you need to remember about tightness. Therefore, here it is better not to experiment with options for adhesive tape for gluing, but to take it from the same company that produces the foil sheets themselves.

What types of vapor barriers exist

In most cases, the construction of frame houses cannot be done without installing a vapor barrier. But these materials are classified into:

- universal type films;

- films with a reflective layer;

- diffuse membranes of vapor barrier type.

Universal films are produced from production with or without reinforcement. Such a barrier not only blocks the movement of steam, but also the movement of large particles of water.

Wall pie in a frame house with a vapor barrier device Source inmoversion.es

If the film has a special layer (this can be foil or any other type of material that reflects infrared radiation. This insulation option is only performed for rooms in which it is necessary to preserve internal heat as much as possible and prevent the appearance of rot in the walls, for example, in steam rooms or saunas

Diffuse layers are membranes of variable action, and they work as a classic vapor barrier. In case moisture forms in the existing insulation, the vapor barrier will remove it indoors. With such steam removal, a ventilation gap must be provided. All moisture will be removed into it. An even greater effect will be achieved by a special drainage and ventilation duct designed to remove condensed steam.

Foil vapor barrier material for walls in a frame house Source energiewende.baden-wuerttemberg.de

Also, vapor barrier materials that are placed on surfaces and partitions are divided into:

- Impenetrable. They are polyethylene with an ordinary structure (they try to use this for covering greenhouses). But for a frame structure, it is best to give preference to dense materials - approximately 200 microns. This one does not allow steam and moisture to pass through on either side. But, if during insulation there is still moisture left in the partition or ceiling layer, it will not come out anywhere and will negatively affect the internal layers, causing the formation of fungi and mold.

- With variable permeability. In other words, such films are called adaptive and are classified as a relatively new type of insulator. Such layers perfectly remove moisture from the air. They are mainly used as a component for insulating attic roofs or interfloor ceilings. Designed only for use in rooms with constant temperatures.

On a note! Do not confuse ordinary films with waterproofing windproof membranes. They have the main difference - impenetrability.

Film vapor barrier for frame-type houses Source tur.sika.com

Materials

The main material of the multilayer system is insulation. The fact that inclined surfaces have to be insulated dictates its own conditions for this material. Preference is given to semi-rigid and rigid thermal insulation materials in the form of slabs. Most often used:

- Polyfoam has good thermal insulation properties, low weight, ease of cutting and installation. Its price is low, which makes it popular. There are disadvantages that need to be taken into account. It is highly flammable and, when burned, releases toxic substances, is not protected from rodents, does not allow air to pass through well and contributes to the formation of condensation.

- Mineral wool. Another type of inexpensive insulation. Installation of mineral wool slabs is quite simple. It is not subject to rotting, does not form condensation, and is resistant to fire. The slabs are laid in several layers, creating a protective layer of 20-25 cm. Such layers require additional measures against sagging.

- Foamed polyurethane foam. This material is gaining popularity due to its ability to create a thermal insulation layer on any surface. It is produced in liquid form and is saturated with gas using special equipment. This mixture is applied to the surface and hardens, creating a uniform coating with a high thermal insulation coefficient. The disadvantage of the material is its high cost, the need for special equipment and installation by qualified specialists.

- It is worth considering very carefully a modern version of a thermal insulation material that can replace a bulky multilayer structure. We are talking about Teplofom thermal insulation panels. Designed to create the most effective combination of layers at a small thickness, the panels have a thermal insulation layer of extruded polystyrene, covered with a durable layer of polymer cement and reinforced with fiberglass mesh. This design gives them advantages in many ways, such as:

- high thermal insulation characteristics, a layer of material 10 cm thick is capable of retaining heat on a par with one and a half meter walls made of hollow brick, 60 cm of aerated concrete or 40 cm of pine boards;

- vapor tightness;

- moisture resistance;

- strength combined with flexibility, which allows it to be used to create curved surfaces;

- durability, panels made using this technology have withstood a service life of more than 30 years;

- versatility in use, the material can withstand a wide temperature range (from -50 to 75 degrees Celsius) and is suitable for interior and exterior decoration, walls, floors, ceilings;

- ease of installation, not requiring professional skills;

- Full readiness for finishing without additional measures

Installation of insulation pie with vapor barrier

There are cases when the vapor barrier layer in the wall pie is installed in the wrong place where it should be. As a result, problems arise with the functionality of this layer. To prevent such mistakes, we recommend that in this section we consider how a wall is constructed in a frame structure using all materials.

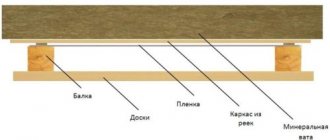

The correct insulation cake is performed as follows:

- interior decoration;

- a gap of 20-30 mm, necessary for air circulation inside;

- vapor barrier;

- thermal insulation material (its thickness will be individual in each individual case, since everything depends on thermal conductivity;

- diffuse membrane;

- ventilation gap of at least 50 mm;

- sheathing or frame made of beams;

- drywall (if it's a wall) or roofing (if it's a roof).

Ventilation gaps are mandatory, since thanks to them air can circulate freely, maintaining a dry microclimate in the cake.

Internal wall pie with vapor barrier in a frame house Source eco-kotly.ru

Mechanism of condensation formation

Before deciding which vapor barrier to choose for an attic roof, you need to understand the mechanism of formation and movement of water vapor. There are two principles of transfer and formation of condensate:

- Diffusion is the movement of steam from an area of high pressure to an area of low pressure. In winter, such a transfer is carried out from a warm heated room towards the cold outside, where low partial pressure is observed. In the summer, the direction of flow changes, and steam from the warmer and more humid outdoor air is directed into the drier and cooler space of the attic. In the path of the diffusion flow there are attic roof structures (waterproofing, insulation, vapor barrier, finishing). It is the diffusion permeability of these materials that determines the amount of vapor that can penetrate due to diffusion. Since the layers of waterproofing and insulation practically do not resist the passage of steam, they can be ignored. In such a design, only the qualities of the vapor barrier material are important. This is why it is so important to choose a high-quality vapor barrier for your attic.

Important! The greater the difference in temperature and humidity between indoors and outdoors, the greater the diffusion flow.

- Convective is the movement of air and steam flows through loose layers of coatings and thermal insulation materials. The intensity of this transfer is directly related to the strength of the wind and the dimensions of the cracks. In modern roof systems, the function of air protection is performed by layers of hydro- and vapor barrier. They can completely eliminate the possibility of convective moisture transfer.

Under real roof operating conditions, both mechanisms of moisture penetration are present. In this case, the intensity of the diffusion process is directly related to the choice of good vapor barrier and pressure drop. In turn, the convective process completely depends on the quality of insulation work and the use of sealing tapes and mastics.

Attention! When comparing the degree of humidification of roof structures during the diffuse and convective processes, we can say that the latter is much more dangerous, since a larger amount of water vapor penetrates into the structure.

Options for vapor barrier films from the best manufacturers

When it is necessary to install a vapor barrier for the walls of a frame house, you do not need to choose the simplest and most budget-friendly models of protective layers, because it may have a manufacturing defect. We bring to your attention the following list of manufacturers who offer truly high-quality material.

"Izospan"

Vapor barrier film of this brand has existed on the Russian market for more than ten years. The range consists of three types of fabrics: two-layer for roofing, two-component for wall insulation, universal with an antioxidant coating.

Vapor barrier material “Izospan” for frame structures Source eco-kotly.ru

Pros:

- high degree of strength;

- protection from any type of moisture;

- simplicity of installation;

- low cost.

Any of the listed options for vapor barrier layers can even be used as a temporary roof during periods of precipitation.

"TechnoNIKOL"

Another large manufacturer that produces insulating materials for various purposes. These products are renowned for their high quality workmanship. The manufacturer provides a ten-year warranty on its vapor barrier materials. Just like the first brand, it offers three types of materials.

Pros:

- long service life;

- low cost;

- simple installation;

- high efficiency of steam removal;

- There are materials for roofing, walls and flooring.

Among the disadvantages, it is worth noting that products from such a brand may turn out to be cheap fakes. Similar cases have already been repeatedly identified in the building materials market.

Vapor barrier fabric Source gdematerial.ru

"Ondutis"

This brand offers high-quality and fairly inexpensive vapor barriers for roofs and walls. The product line includes several separate types of vapor barriers that are specifically designed for roofs, walls, and ceilings. Such canvases can be with adhesive tape, can be three-layer foil and special exclusively for cold roofs.

Pros:

- long warranty period;

- basic installation;

- there is always something to choose from;

- high degree of strength.

The disadvantage of materials from this brand is that the adhesive tape is present only on one edge. The rest will have to be secured with tape and the seams joined tightly.

"Yutafol"

One of the largest manufacturers of film products. This brand supplies its materials all over the world and to Russia inclusive. The most popular is two-layer polypropylene film. Most often, this is used for vapor barrier of roofing pies in frame structures for residential purposes.

Vapor barrier membrane "Yutafol" for filling the walls of a frame house Source fasadsibiri.ru

HOW TO PROPERLY INSULATE AN ATTIC?

Attics in suburban housing construction today are very widespread. And modern high-rise buildings are increasingly topped not with the usual flat roof, but with a pitched roof, under which there is an attic. And this is not surprising, because the attic allows you to increase the living space, and the proximity to the sky gives a special feeling of comfort.

But it should be understood that for reliable operation of such a roof, its proper implementation is required. In the case of an attic, the roof is much more complex than in the case of a cold attic. To ensure reliability and durability, comfort and warmth, it is necessary, first of all, to have proper insulation. Experts, taking into account many years of experience, share advice on the correct installation of thermal insulation in the attic.

from direct exposure to precipitation by an external covering, which can be made of metal, flexible tiles, natural tiles, etc. Under the covering there is a “roofing pie” - a multilayer structure consisting of a ventilation circuit, a layer of hydro-wind protection on the outside, a layer of thermal insulation, and a layer of vapor barrier on the inside. The main “filling” of such a “pie” is insulation.

The objectives of thermal insulation in the attic are clear : to protect the house from winter cold and summer heat. Due to insufficient or poor-quality roof insulation in winter, heat loss through this house structure can reach 25%, which will significantly increase heating costs.

Only high-quality materials, such as ROCLITE thermal insulation boards produced by TechnoNIKOL Corporation, can solve the assigned problems

These are stone wool slabs based on basalt rocks, designed specifically for thermal insulation of non-load-bearing structures, which include attics.

Slabs have many advantages . First of all, it is a non-flammable material (flammability group NG), therefore, it is safe and reliable both for humans and for the roof structure. This fundamentally distinguishes stone wool slabs from expanded polystyrene slabs (flammability group G2-G4). In addition, when burned, polystyrene foam releases substances harmful to health and poisonous gases. Glass wool, like stone wool, does not burn, but has a very low melting point of the fibers - 550−600ºС. During a fire, this temperature is reached 7 minutes after it starts, so the glass wool quickly melts and cannot prevent the spread of fire.

Another important advantage of the ROCKLITE material is its low thermal conductivity (λB = 0.041 W/m2 K), guaranteeing low heat loss through the roof. Considering the inclined location of the insulation under the slope, an important characteristic when choosing thermal insulation is compressibility. This value is measured under the load established by GOST and is determined by how much the material will compress in thickness (in %). Since the insulation on a pitched roof is constantly in an inclined position, it is important that it does not “slip” and cold bridges do not appear. In addition, it is necessary that it does not become thinner over time: this will reduce its effectiveness and durability.

Stone wool-based slabs are also distinguished by their high vapor permeability (0.3 mg/mh.Pa). This is very important, since water vapor is constantly generated in a residential building, which, according to the laws of convection, rises upward, under the roof. To prevent steam from “reaching” the insulation, a vapor barrier layer is provided in the attic roof - usually a film based on polyethylene or polypropylene, mounted on the inside. But, given the high penetrating ability of steam, the film is not able to completely “cut off” it. When water vapor gets from a warm zone to a cold one, it can condense, and the dew point often ends up in the insulation. And when it gets wet, it loses its thermal insulation properties. If insulation with a fibrous structure has good vapor permeability, then water vapor does not linger in it. Coming out through a vapor-permeable windproof film located outside the thermal insulation layer, it is ventilated outside the roof through the under-roof ventilation system.

The thickness of the insulation for central Russia should be about 200 mm according to thermal engineering calculations. In practice, insulation is often installed in the space between the rafters. Consequently, it has a thickness equal to the thickness of the rafters, and the maximum cross-section of standard boards offered on our market is 150 mm. To solve this problem, experts recommend installing two-layer thermal insulation.

1. Flexible tiles SHINGLAS. 2. Superdiffusion membrane "TechnoNIKOL". 3. Stone wool slabs “ROCKLIGHT”. 4. Vapor barrier "TechnoNIKOL". 5. Rafter leg. 6. Step lathing. 7. Attic filing.

What is the basis for choosing a vapor barrier layer?

The choice of vapor barrier film for the walls of a frame house is necessarily based on several main rules. Let's look at them below:

- Vapor permeability. This is directly one of the main requirements. It is this ability that will influence the level of ventilation of walls or under-roof gaps. All indicators can be found on the packaging of the material. The higher its value, the better.

- Life time. In this case, the rule “the longer the better” applies. The warranty period usually reaches several decades. Ideally, the roof or wall should last exactly as long as the insulating membrane layer.

- Strength. When choosing, be sure to focus on strength. That is, the canvas should not be damaged when strong gusts of wind occur, because one way or another it will move inside the cake, no matter how tightly you try to seal all the cracks.

- Flame resistant. Another important factor. For example, if there is dry air in the ventilation gap, the risk of ignition increases sharply. Therefore, the higher the safety level of the vapor barrier layer, the more intact the structure will be.

Rolled film-type vapor barrier Source pechiexpert.ru

As for the optimal cost of the material, each owner chooses independently depending on the size of his wallet.

FAQ

The desire to turn an uninhabited attic into a cozy, comfortable living space also gives rise to questions about how to achieve a better result and solve emerging problems. Let's look at the most frequently asked questions:

If the roof is covered?

For this case, the option of insulation from the inside is provided. It is more complex and time-consuming, but if you follow the recommendations of specialists, it allows you to achieve the expected result. It would be good if the construction included such measures as laying a waterproofing membrane and counter-lattice. In this case, work can be carried out using the usual technology.

If the roof is not waterproofed

But it is possible that the house was built and the roofs were not waterproofed. In such cases, the insulation layer will not be protected from moisture, and the entire room will not be protected from mold. But even in this case, you can find a way out. There are three options for insulating such an attic:

- The waterproofing membrane is secured using additional bars. Two bars are attached to the rafter legs on each side, and one is installed between the rafters. The purpose of the bars is to provide an air gap for ventilation, so its width is chosen to be at least 4 cm. After the installation of the bars is completed, the membrane is laid. Laying is done from bottom to top with a margin of 5 to 10 cm on each side and a slight sagging. The membrane is attached to the rafters initially with a stapler, and then fixed with additional bars. In the future, the technology of the thermal insulation system is similar to insulation from the inside.

- Using materials that are not exposed to moisture for insulation. As an option, polyurethane foam can be used. The liquid structure of this material creates a continuous, uniform coating. In this case, the roof structure does not play a role. The main difficulty of such insulation is the need for special equipment for applying the insulating layer.

- Using Teplofom panels. They are designed in such a way that the insulating layer is firmly covered with hard surfaces and is not affected by moisture. The panels are attached quite simply and do not require special skills.

Read more: Roof insulation

Installing a vapor barrier indoors: main steps

When we have decided on the type of suitable material, we calculate its quantity and purchase it. After which the installation is carried out. All installation work will be based on several step-by-step actions:

- Prepare the necessary material that will be useful in the work: mastic, tape, a knife, the material itself, you may need a glue gun.

- Next, installation begins. They make it from floor to ceiling, the stripes overlap both horizontally and vertically.

- The joints of the film, if there is no adhesive tape on it, are secured with masking tape, after first releasing the air from the vapor barrier layer.

- The film should not be stretched too much so that it is in a relaxed state, otherwise it may become deformed due to temperature changes.

- The vapor barrier layer is attached to the racks using a construction stapler with staples of sufficient depth.

- If the material is a diffuse film, then it is fixed using a counter-rail.

- First, the first strip is attached, then double-sided tape is glued onto it, and the next strip is mounted on it.

- First of all, fix the material to the first rack, and then to each subsequent one. And so on around the perimeter of the room.

- When they reach the ceiling, all joints are securely closed so that the insulation layer reliably performs its functions.

Location of vapor barrier in the wall and roof frame Source blog-potolok.ru

Principle of operation

Foil materials are a complex product with a layered structure.

The base here is polypropylene fabric, fiberglass, and lavsan. These are components that are resistant to explosive effects, biological and chemical aggression. The use of a durable non-woven or woven polymer base allows you to create a reliable base for metal foil, which itself cannot boast of particular strength. At the same time, flexibility convenient for installation is maintained. This composition eliminates the possibility of fungal colonies settling and rotting.

Vapor barrier materials on the working side are backed with metallized film. The positive qualities of both aluminum foil and the polymer base are preserved. Vapor barrier with foil copes with three tasks at once:

Possible mistakes, what to look out for: 5 useful tips

Do-it-yourself attic insulation is not always carried out “smoothly”. Here are a few mistakes that DIYers commonly make:

- There are no ventilation gaps between the thermal insulation and the roof of the building. Because of this, the material is not ventilated and does not dry out.

- Hydro- or vapor barriers are not installed.

- The use of polyurethane foam for insulating roof windows.

- Construction of a roof with a slope angle of less than 13 degrees. Such a roof retains precipitation, which causes rust and leaks.

- When installing insulation, leave a gap of 2-3 cm for continuous ventilation. To do this, you can attach additional slats.

- Consider the height of the rafters. If it is less than the thickness of the thermal insulation, bars must be attached to the rafters and screwed onto self-tapping screws. The bars must be treated with an antiseptic.

- Don't forget about installing waterproofing. It will protect the space under the roof from damp air and condensation.

- The vapor barrier must be secured to brackets.

- Carefully seal the junctions of materials with rafters or other structures with tape.

vote

Article rating

Finishing

It will be correct to finish the attic only after all procedures related to the thermal insulation of the slopes have been completed. The inside of the attic floor can be finished with plasterboard, plywood, clapboard or boards.

The finishing material is attached to bars or metal profiles. If the insulation is not equipped with a vapor barrier film, but with vapor barrier foil, the finishing material is fixed at a distance of 5 cm from the foil. This allows you to reduce heat loss.

Dew point problem

Ideally, the roof in the attic should be insulated from the outside at the stage of forming the roofing pie. However, often this is done the other way around from the inside, when the house is already covered with a roof. And here certain problems arise.

The correct and ideal roofing pie is several layers of different materials laid on top of the rafters tightly on top of each other without gaps. Such a sandwich ensures that the dew point will be located on its outer side. As a result, all condensate formed outside will quickly evaporate into the atmosphere.

By doing insulation from the inside, after installing the roof, it is impossible to form the exemplary roofing pie described above. It will not be possible to press the insulation onto the roof so that there are no voids left between them.

For a cold roof

A cold roof means there is no insulation in it.

When waterproofing it, both a diffusion membrane and a waterproofing film with low vapor permeability - polyethylene or polypropylene - can be used. * Strength - maximum tensile force in the longitudinal and transverse directions.

The film is laid directly on the rafters with a slight (about 20 mm) sagging. Laying is done in strips starting from the eaves upwards with the bottom layer overlapping the top layer by 50-100 mm. The joint between the sheets is sealed with adhesive tape.

If a “breathable” film is used, you need to pay attention to which side it is laid up, its correct operation depends on this. This information can be found in the instructions for the material, usually the side with the logo should face up

There should be a ventilation gap above the waterproofing film. To install it, counter batten strips 50 mm thick are nailed onto the rafters on top of the film, and the sheathing is already attached to them.