External insulation of PVC window slopes is an important procedure for maintaining heat inside the building.

It can be used to close joints in window openings or improve the appearance of your home.

Let's consider why and when external insulation of PVC windows is needed, in what ways this can be done, and also we will analyze the materials and tools that may be useful during the work process.

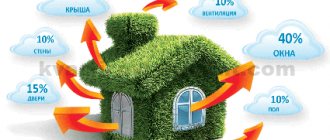

Causes of heat loss

The main places for blowing are: glass unit holders, rubber seal, places under the hinges and handle, around the perimeter of the frame.

There can be several reasons for cold air entering a room. The most common problem arises from improper installation of double-glazed windows, namely ignorance and non-compliance with window installation technology. Negligent attitude of the installation team towards work, poor sealing of cracks, failure to seal installation seams with sealing tape. And if the external slopes of the windows are not finished in a timely manner, then after a period of time, environmental influences will destroy the polyurethane foam.

Saving on construction foam, insulation, not using protective thermal insulation, using low-quality components during the assembly process - all these are the reasons for the necessary insulation work.

The situation of building shrinkage is relevant for those living in new buildings or a wooden house, because... this can lead to distortion of the frame. Another important reason is improper window care. Many people neglect primitive window cleaning. So, about 2 times a year, the window seal needs to be washed and lubricated with glycerin so that over time it does not begin to crack, which will naturally facilitate the transmission of heat.

Cold may enter the room if the clamping flaps are loosened. This can be solved by adjusting the fittings.

When is it necessary?

Most often, insulation of PVC windows may be required when :

- During installation of the frame, uncovered gaps or unclosed mounting foam formed between it and the opening. If it is not insulated, it will begin to absorb moisture or dry out.

- It is necessary to protect the window frame from external influences at the joints with the opening so that water does not get into them, and also to avoid the formation of blow-out spots or cold bridges. Also, temperature changes at fastening points can lead to their destruction and subsidence of the frame.

- After the window shrinks, empty spaces appear through which the cold will pass.

- It is necessary to shift the dew point so that condensation does not form on the window, which causes dampness, mold or mildew to appear.

- It is necessary to improve the appearance of the window opening from the outside.

It is always recommended to do insulation, as this greatly reduces heat loss, but in some cases this procedure is difficult to carry out or it is not necessary :

- In wooden houses, insulation of slopes is most often carried out using wooden panels that cover the seams, since the use of insulation can negatively affect the window opening.

- If the quarter is made of brick (a special protrusion that covers the top and sides of the opening from moisture), then insulating the slope may be difficult or simply not necessary.

- If the joints are plastered and there is no heat loss, then treating the slopes from the outside can lead to the opposite effect, that is, the room will be too hot, and the dew point will also shift, which will cause mold to appear.

Features of insulation of window slopes

Thermal insulation of external window slopes affects the comfort of living in the house, because... maintains an optimal and correct microclimate throughout the year. The procedure does not require the involvement of specialists or professional equipment. You can implement it yourself using available tools.

Since there are seams between the window frame and the wall, they are usually filled with foam to prevent drafts. This substance has good thermal insulation parameters, but can be destroyed by moisture. Boxes that do not have additional lining are not sufficiently protected from negative factors. If there is no insulation, the joints will be exposed to water, so over time the fasteners will begin to wear out and the window will sag.

After the structure shrinks, voids appear between the opening and the frame, which provokes freezing and the formation of cold bridges.

Insulated windows do not accumulate condensation inside the building, and therefore prevent the appearance of mold in residential areas.

How to determine where a draft is coming from a window

Even if there is one defect in the window structure, this will lead to drafts. To find out which direction it is blowing from, you can use the following methods:

- Run your hand around the perimeter of the window and check where there is a draft.

- Using a lighter, evaluate where the intensity of the flame changes.

You can also place a sheet of paper in an open window and then close the sash. Next, you should pull the tip of the sheet: if it comes out easily, the seal is not pressed well enough.

Pressure debugging

Shrinkage of the building and weather conditions can cause slight distortion of the window sashes and slight deformation of the seal. This leads to deterioration of thermal insulation, but in such a situation, the tightness of the structures can be restored in just a few minutes. The only caveat is that you will need skills in working with tools and knowledge of the structure of the window.

You can adjust the pressure using special trunnions, which are located along the entire perimeter of the sashes. To increase the tightness of the fit, you need to turn the element clockwise with a hexagon. You should focus on the serif, which is located on each such detail. If it is directed towards the street, this is the summer mode of the windows, so the pressure is weakened, if towards the room, it is strengthened.

In some situations, you can insulate a window structure by adjusting the hinges responsible for the pressure. All work is carried out using a hex wrench. You should be guided by this simple rule: the sash fits tightly when the tongue is well extended. To pull it out, you need to turn the key counterclockwise if the hinges are on the left side, and if they are on the right, then clockwise.

It is much easier to carry out actions with a glazing bead. The old loose product must be pryed off with a thin spatula, and a new one installed in its place. This part can be purchased from a company that sold and installed windows.

After completing the work, you need to check the tightness of the metal-plastic window again using your palm or a lighter. If the leak is still present, then there is a possibility that the rubber insulation will need to be replaced.

Adjusting the clamping mechanism

During operation, the window is exposed to mechanical and climatic factors. As a result, loss of sealing rubber volume may occur. What causes air to get inside the house. To solve this issue, it is not at all necessary to resort to replacing the gasket, unless, of course, it is completely in unusable condition. You just need to adjust the clamping mechanism.

To begin, find the protruding cylinder - the axle - in the cut places of the metal plug. Then move the hooks to the required position or adjust the trunnions. To change the position of the hooks, loosen the bolts. When moving to the street side, the pressure increases, and in the opposite direction decreases.

How do you determine where it's blowing from?

Even if there is only one defect, there will be blowing from the window. You can determine where this is coming from in one of three ways:

- Run your hand along the perimeter of the window block;

- A lighter. Just like with a hand, in the place of a draft the light will change;

- Place a regular sheet of paper in the open window and close the sash. If, when you pull the tip of the sheet, it easily pulls out, this will indicate poor pressure on the seal.

How to insulate a window for the winter with your own hands

All measures to insulate a double-glazed window must be carried out before the onset of the cold period. Because materials such as dry mix and sealant should be used only at certain temperatures, as they may lose their properties. Air humidity should be optimal, there should be no draft. Insulation must be done simultaneously from the outside and inside.

Materials used Various materials and methods can be used here. Such as :

- Construction foam. It is the best means for window insulation. As it expands, all voids are filled. But the foam must be protected from direct UV rays and temperature fluctuations.

- Using mineral wool. It has good thermal insulation properties.

- Polystyrene foam or polystyrene foam for insulation of slopes.

Note: Rigid insulation is used in cases where the installation seam is no wider than three millimeters. In others it is better to use mineral wool.

Silicone sealant is used when processing plastic parts of windows to eliminate blows. Using dry mixtures, slopes on the street side are insulated. Construction tape is used instead of sealant or on top of it.

External insulation

External insulation work includes insulation of the slope and ebb on the street side. If insulation of the outer slope has not been done previously, then all actions will be useless. After time, the window will still be blown out, in addition, the inner wall may become damp and moldy. Caulking the external cracks will not lead to anything, because the plaster and foam will gradually become unusable.

Tools and consumables

Depending on the type of insulation chosen, the following materials and consumables may be required :

- drill or hammer drill;

- Master OK;

- putty knife;

- chisel;

- hammer;

- self-tapping screws;

- mushroom dowels;

- thermal insulation adhesive;

- silicone sealant;

- construction knife;

- roulette;

- marker;

- building level;

- vapor barrier film;

- sandpaper;

- concrete solution;

- plaster;

- antiseptics;

- individual protection means;

- construction tape;

- fiberglass reinforcing mesh;

- plastic (PVC) corners and plugs.

Why is it necessary to insulate slopes?

Often, after replacing windows, they are limited to only decorative finishing of the slopes, which is wrong and can lead to problems in the near future, because:

- The seams between the wall and the glass unit are filled with polyurethane foam. But this material is not sufficiently resistant to high humidity, ultraviolet radiation and low temperatures. Very quickly, unprotected polyurethane foam will begin to deteriorate under the influence of weather conditions, which will lead to heat loss through voids in the seams.

- Numerous cracks on untreated surfaces of slopes are a common cause of heat leakage from a room.

- Moisture can accumulate in the voids between the wall and decorative panels, which means condensation may form.

New insulation technologies

In order to retain heat indoors in winter, many people wonder how to insulate plastic windows in a more effective way. Today, there are relatively new developments designed to improve the heat situation not only at home.

Insulation using a “smart” ventilation system

Recuperative ventilation can not only ventilate a room, but also retain heat in it. The essence of such a system is as follows. It can simultaneously perform two functions - hoods, where air is forcibly removed from the room, and air conditioning, where air is taken from the street and moved into the room. In a common system, two streams flowing through separate channels in opposite directions, but side by side, partially transfer their temperature regime to each other. That is, cold fresh air from the street will be heated by warm exhaust air leaving the room, thereby maintaining a comfortable temperature in the space.

The disadvantage of such a system is its high cost and payback in 5-8 years. And the advantages are obvious.

Insulation of window slopes from the street

The entire process of insulating windows from the outside consists of the following steps:

- Preparatory work;

- Cleaning slopes from dirt and foam residues;

- Applying a primer to the surface;

- Installing insulation with glue;

- Sealing cracks with glue;

- Arrangement of corners;

- Installation of polymer mesh;

- Plastering.

Important: When installing insulation, it must be laid so that it partially covers the window frame, and the installation seam is completely closed.

First you need to cut off all the remaining foam. The slopes are treated with an antibacterial primer mixture. Tiles equal to the size of the slope are cut from penoplex. They are smeared with assembly adhesive and pressed to the surface. Here you can use dowels. The corner is installed. A fiberglass mesh is placed on the tile over the applied adhesive. You need to give it time and apply glue on top again. Upon completion of the insulation work, water-based paint must be applied to the surface.

Important: Paint is applied only after the glue has completely dried.

Thanks to external insulation of windows, condensation does not form.

Insulation of ebbs To insulate ebbs of plastic windows, you need to fill all the cracks with heat-insulating material and foam them. To prevent water from getting on the insulating material, a metal strip should be installed on top of the flashing. The angle of its installation should be more than five degrees, and the horizontal edge should extend twenty to thirty millimeters beyond the facade, while the side edges should be turned up. The places where the plank is adjacent to the surface must be covered with a hermetic mixture.

Insulating windows from the inside Work on insulating a window unit from the inside of a house may include: replacing a worn rubber seal, adjusting fittings, sealing joints, replacing a double-glazed window with an energy-saving one, insulating it with film. The role of the rubber seal is quite significant, it ensures the tightness of the window. So it is extremely important to regularly inspect the seal and properly care for it. Sealing of joints is carried out by applying sealant to the blow-out areas. Today on the building materials market there is a huge selection of sealing compounds of different types - for different wall materials, for different temperature conditions, etc.

Additional methods of window insulation These methods include primitive window washing. After all, if the glass is dirty, then it does not fully transmit the sun's rays. You can use thick fabric for curtains, which will also help retain heat inside the building.

For insulation, it is possible to use available materials - foam rubber, soaked paper, window tape, etc. Energy heating of a window or double-glazed window can also be arranged. To do this, a heating cable is placed around the perimeter of the window, and a special conductive film is placed on the glass.

Using heat-saving film Insulating film for windows helps keep the house warm. To create the desired effect, you first need to properly prepare the surface. The tools we need are a hair dryer, scissors, and a knife. The surface is cleaned of dirt, the glass is well rubbed. Double-sided tape is glued around the perimeter of the glass box. The film is separated using a stationery knife, cut to the required size and pasted onto tape. The film is blasted with warm air from a hair dryer. If small swellings form, they will need to be burst with the tip of a knife. This is perhaps the most economical method of insulating plastic windows. In any case, for a high-quality result you need the right integrated approach.

What materials are suitable for thermal insulation?

In order for all the activities carried out to have a positive result, it is necessary to select the right materials. The following is used as a heat insulator for slopes:

- Mineral wool (basalt, slag or glass wool).

- Styrofoam.

- Extruded polystyrene foam.

- Polyurethane foam.

- Sandwich panels.

- Fiberglass, one side of which is covered with a layer of foil.

In the process of selecting the required material, the dimensions of the window opening and the places where the insulation will be installed are taken into account. Mineral wool, for example, performs its functions with a thickness of at least 10 cm, which is not always convenient for insulating a window from the outside.

In addition, cotton insulation requires the use of a water barrier on both sides. This is due to the fact that after getting wet the material loses its insulating properties.

An affordable and popular option is to use polystyrene foam and extruded polystyrene foam (penoplex). Moreover, the latter material is preferable because it has a higher density with a smaller thickness. It is important to protect the polymer insulation from the sun in a timely manner. When exposed to ultraviolet light, foam becomes brittle.

If polyurethane foam was used during the installation process, then there is no hope for complete thermal insulation. Of course, if the voids are densely filled, some of the heat will still be retained in the room, but if the house is located in a region with low winter temperatures, then you will have to take care of additional insulation.

A good option that solves two problems at once would be sandwich panels. The top layer is a decorative material, the bottom layer is insulation. At the same time, it is possible to choose an option for your home if the facade is already lined, but the slopes had to be insulated later. In addition, some creators of such panels offer options with different insulation materials.

A new option for insulating slopes is fiberglass with a foil base. It is difficult to install such material with your own hands, so you need to take the help of professionals. But you will be 100% sure of the result. The insulator perfectly protects against moisture and penetration of cold air currents.

TOP list of the best materials: manufacturers

Having made a conclusion, you can make a small list of materials and give examples of manufacturers:

Heat-saving film. A good option from the manufacturer Termok: the film is sold both in cut pieces and by the meter.

In popular construction stores you can also find already cut film measuring 150x170 cm.- Application of construction foam. It is better to take foam intended for a special gun - it’s easier to work with it. A good manufacturer is Soudal, which offers foams for both summer and winter use.

- Using polystyrene foam. Select a material as thick as the gap in which the seal has broken. A good manufacturer is Knauf.

- Sealant. Universal colorless silicone sealant is suitable. For example, the company Tytan.

- Foam rubber and tape. In this case, materials from any manufacturer will be suitable. Instead of regular tape, you can use masking tape.

All of the materials listed are common and can be purchased at hardware stores in the city.

Sequence of work on internal thermal insulation

Those who want to get a positive result from insulating slopes need to be prepared for the fact that the process is carried out both outside and inside. Both options for carrying out work have features and a certain sequence of execution. Therefore, we will consider each of them separately.

The internal slope is insulated according to the following plan:

- Leave the new window for several days so that it is well fixed in one place.

- Inspect the foamed space. If there are gaps, add foam and leave until completely hardened.

- Trim off excess areas.

- Treat the surface of the slope with an antibacterial primer composition. The solution will help resist the growth of mold and mildew, and will also increase adhesion for subsequent stages.

- Level the slope using plaster. A flat surface will make a good base for tightly fixing the insulation.

- The plastered and dried base is again covered with antibacterial primer, for the same reasons.

- Glue the insulation. To do this, use liquid nails or glue suitable for the selected material.

- The corner is covered with a plastic or metal corner and plastered together with the total area of the slope; a reinforcing mesh must be used. Fiberglass will make the plaster layer strong and reliable.

After this, they begin decorating. Painting, tiling, or another option chosen by the home owner will do.

Sequence of work on external thermal insulation

The outer slope also needs to be insulated, and this process should be taken seriously. Material that is laid outdoors is constantly exposed to destructive factors such as:

- Atmospheric moisture.

- Negative air temperature.

- Ultraviolet radiation.

- Exposure to wind.

- Insects, rodents and birds love to make their nests out of insulation materials.

Therefore, unprotected material quickly becomes unusable. Insulation of external slopes is carried out according to the following points:

- Remove excess polyurethane foam.

- Cover the slope with soil with an antibacterial composition.

- If there are large differences, the surface is plastered. Select plaster for external use.

- Once again they resort to priming. The composition will protect against fungus and mold, and will also increase adhesion with the following materials. Don't skip this step.

- Start with insulation. For external treatment of slopes, a denser material is chosen, for example, penoplex. It is glued to an exterior adhesive suitable for polymer materials.

- For greater reliability, the heat insulator is fixed to the slope with dowels with a wide head. It is not necessary to do this indoors, since there is no exposure to gusts of wind.

- The corners of the slopes are covered with corner elements. They will make the edging more neat and attractive. In addition, making a beautiful corner will be much easier.

- The insulation is covered with plaster with mandatory reinforcement. If you do not use a mesh, during the first year of operation the layer may crack and crumble.

After the layer has dried, decorative finishing is performed. Sheathing materials are used only those that can withstand external load.

Rules and safety precautions

When insulating external slopes, you should adhere to the following rules :

If insulation of windows on the second or higher floor is required, it is recommended to involve specialists in high-rise work, since there is a high probability of doing the insulation incorrectly due to limited mobility.

Also, working at height can cause physical injury or property damage, and in the worst case scenario, you can die if you fall from a window.- When working with insulation based on mineral wool, as well as when drilling walls, you need to wear protective equipment for the eyes, hands and respiratory tract, since the dust suspension can lead to negative effects on the body.

- During work, care should be taken not to damage the window frame, insulating layer or fastenings. You also need to make sure that the insulation layer does not extend beyond the window boundary too much, as this will shift the dew point or cause deformation of the PVC layer.

Thermal insulation of slopes on doors

The area around the entrance doors also allows heat to escape to the outside, and if you do not create a barrier, cold air will enter the house without restriction. The process of insulating door slopes is not at all different from the same work around the window. Therefore, everything is done according to the same plan:

- Cleaning the surface of excess polyurethane foam or old decorative coating.

- Application of deep penetration primer.

- Plastering if necessary.

- Primer treatment.

- Installation of insulation - fixation with an adhesive solution and several dowels with a wide head.

- Application of primer to improve adhesion.

- Installation of corner elements.

- Fastening the reinforcing mesh with the same glue.

- Plastering insulation.

- Rubbing the dried layer.

- Decorative facing of the slope.

Conclusion

I told you what I knew about insulating windows in the house. Do you know any effective ways besides those listed? Tell us about it in the comments to what you read. In addition, I recommend watching the video in this article, I think it will be interesting.

Did you like the article? Subscribe to our Yandex.Zen channel

September 2, 2016

Windows, Thermal insulation

If you want to express gratitude, add a clarification or objection, or ask the author something, add a comment or say thank you!

Exterior works

To more reliably protect the room from heat loss, it is necessary to insulate the window slopes from the outside as well. The best material for these purposes is penoplex. You will also need a special sealant for exterior use. In a private house, you can do the work yourself, but in a multi-story house it is better to use the services of professionals.

The technological sequence of operations is as follows:

- Clean the surfaces of external slopes from dust, dirt, paint residues, finishing and building materials.

- Level with cement mortar and allow the layer to dry.

- Cut the insulation into pieces of the required size.

- Coat the sheets with glue and install them on the slopes. Additionally secure in several places with dowels.

- Mount the corners. Do not neglect this stage. As a result, you will receive not only insulated, but also smooth slopes.

- Treat the front surface of the penoplex with special glue and secure the reinforcing mesh.

- Level with putty.

- After drying, apply water-based paint or other finishing materials.

The issue of slope insulation should not be ignored. The microclimate in the house and the size of the electricity bills depend on how well and timely this is done. Moreover, the whole process can be carried out independently.

Do-it-yourself insulation of slopes of plastic windows

If problems arise with the functionality of the existing structure, dismantling is performed. Preparations for work begin with the choice of insulation. After this, you can begin the operation.

The procedure is performed in several ways.

Method No. 1

If the slope has unevenness or is located at an angle, materials with high elasticity are used. Experts recommend mineral wool.

The technology includes the following actions:

- the remaining foam is cut off and the resulting cut is carefully sealed;

- A guide profile is attached to the edge of the frame. Its task is to fix the installed panels;

- A wooden strip is mounted on the outer edge of the window opening. She secures the panels. If the window opening is smooth, there are no irregularities or protrusions, the rail does not need to be installed;

- the surface is treated with a putty mixture. After drying, you need to go over it with a primer and an antibacterial solution;

- While the surface is drying, it is necessary to prepare the insulation. When using mineral wool, you need to remember to wear protective gloves. This material is hazardous to health;

- a panel is prepared, which fits into the initial profile. Between these elements there is a void into which the insulation is placed. The space is completely filled.

This method is considered the simplest. Users who do not have deep knowledge in the field of construction can cope with it.

Method No. 2

Several materials are used for insulation in a brick house. They will create maximum thermal insulation. Instead of insulation, a combination of mineral wool and foil is used. Finishing is done with three-layer sandwich panels.

The procedure is performed sequentially:

- preparatory work. It is worth eliminating defects and getting rid of cracks. All joints are treated with sealant;

- Profiles for panels are installed around the perimeter of the window. After this, you need to fix the wooden slats. They will serve as a guiding element. Foil with steam and heat insulating properties is applied to the slats;

- The sandwich panel is cut into pieces of the required size. They are superimposed on the main profile;

- free space appears between the slats and the foil. It must be filled with mineral wool.

The final step will be securing the panels. They are pressed tightly against a wooden block and secured with glue or dowels. After performing this operation, the corner is puttied. You need to wait until it dries. Then a plastic corner is mounted on it.

Process

- Clean the surface with a rag;

- We pass with a thin layer of primer;

- We install a profile located closer to the frame and on the outer part of the slope;

- We seal the seams between the frame and the wall with foam;

- We measure and cut foam sheets of the required size;

- Apply glue to polystyrene foam or mounting foam on the wall;

We wrote separately about whether it is worth attaching polystyrene foam to polyurethane foam.

- Carefully apply the foam sheet to the wall;

- We foam the seams on the inside of the profile.

This procedure will make it possible to avoid cold bridges, which will become the self-tapping screws screwed into the profile.

- Apply a layer of primer to cover small seams between the profile and the foam;

- Using self-tapping screws, we attach pre-cut sheets of drywall to the profiles.

The insulation of slopes with foam plastic can be considered complete. We move to the street.

How can you insulate it?

Not all types of seals are used to insulate Euro-windows; the most preferred materials for sealing are:

- Rubber material obtained by vulcanizing carbon black with the addition of sulfur under UV rays.

The advantages include a high service life of more than 30 years, high sealing ability, excellent flexibility and resistance to natural influences. Disadvantage - it comes in one color - black. - Silicone is the most expensive and durable, capable of working without cracks or tears for more than 40 years.

Temperature range from -40 to +50 C, environmentally friendly, exhibits high resistance to ultraviolet radiation. The disadvantage is the high price and low mechanical strength in comparison with a rubber product. - EPDM is the most commonly used chemical material for insulation, can last up to 20 years without visible damage, and is highly resistant to atmospheric influences. Disadvantage: it requires constant maintenance in the form of lubricating external surfaces.

TPE is a modified synthetic polymer; at room temperature it exhibits the characteristics of rubber, and at temperatures above 40 C it becomes soft.

Advantages: reliable protection of window corners, where other types fall short. It exhibits the highest chemical and thermal resistance and can be produced in different colors.Disadvantage: restrictions for working in hot climates.

- Polyethylene with filler has more disadvantages: low strength, elasticity and service life. Its only advantage is high thermal protection.

- Basalt wool. Advantages: low thermal conductivity from 0.032 to 0.048 W*m/K, high vapor permeability 0.3 mg/(uPa), high fire resistance withstands temperatures above 1000 C, high compressive strength up to 80 kPa, high noise insulation, high biological protection and affordable price .

The disadvantages of this material include high hygroscopicity, so during installation an additional layer of hydro and vapor protection will be required. - Polystyrene foam , advantages: lightweight, cheap, heat-resistant.

The disadvantage is increased flammability, which is why it can be used for outdoor installation. - Penoplex , advantages: high thermal insulation properties, low thermal conductivity, water absorption equal to “0”, high strength characteristics, light weight, ease of installation, wear resistance and environmental safety. The disadvantages include the high price.

Useful tips

Knowledge of some of the subtleties that experts share will allow you to do the insulation of the slopes of plastic windows with your own hands more efficiently. As a result, the windows will not be damaged by the environment and will last a long time.

It is worth considering these recommendations:

- Polystyrene foam tends to expand in heat. When attaching it, it is not recommended to use a large amount of glue. Otherwise, it will quickly crack and lose its thermal insulation capabilities.

- To extend the service life of the insulation, outdoor work should be carried out only in dry times and in warm weather.

- The use of thermal liners will significantly improve heat retention in the room and protect against moisture penetration.

- When installing insulation on slopes, it is recommended to treat all wide cracks and joints with silicone sealant.

How to change the seal

Special rubber bands are used as a seal on plastic double-glazed windows, improving sound and thermal insulation. They are available in different quality on sale. Rubber bands marked EPDM optimally combine affordable price and good quality, which is why they are most often purchased. Products with the VMQ brand are of high quality, but are too expensive. There is no need to buy TPE sealant, as it quickly deteriorates when exposed to weather.

Important!

There is also a seal with an adhesive layer on sale, which is attached to the window using the principle of adhesive tape. It is not a complete replacement for a conventional seal, so it is not advisable to buy it.

Seal replacement procedure:

- The seal that has served its useful life is removed by prying it by the middle. The freed space in the grooves is thoroughly washed with laundry soap or other detergent. Then thoroughly dry and degrease with alcohol.

- To make the fit tighter, the corners of the profile are glued with construction adhesive, PVA or silicone. After applying the composition, wait until it dries completely.

- After this, the rubber seal is prepared for installation. If material marked EPDM is used, it is measured along the length of the perimeter of the opening, since it bends easily. The remaining materials are cut to the length of the side of the opening with a small margin.

- Then the elastic is inserted into the grooves, being careful not to deform the material. It is more convenient to do this operation together using improvised tools.

To extend its service life, the rubber band should be washed and coated with silicone grease several times a year. After five years of operation, the seal is replaced with a new one.

Expert recommendations

The insulation procedure is characterized by its peculiarities. Knowing the subtleties, you can avoid many problems. To ensure the highest quality work, adhere to the following rules:

- If there is no insulation of the required size, you can use separate pieces. They are placed tightly to each other.

- Ideal adhesion can be achieved through a combination of glue and reinforcing mesh.

- Preparatory work includes getting rid of cracks and defects. If the hole is larger than 3 mm, sealant must be used.

- Of all insulation materials, extruded polystyrene foam has the maximum thermal insulation function. This will be a plus when performing outdoor work.

- You need to choose thermal insulation based on the dimensions of the gaps. If the free space exceeds 4 cm, use polystyrene foam or polystyrene foam. If the gap is 2-3 cm - fiberglass, less than 2 cm - polyurethane foam, mineral wool.

You cannot take foam with a density of less than 30 kg/cubic meter. m. If you prefer mineral wool, the density should exceed 75 kg/cu.m. m. Otherwise, the insulation will not withstand the load and will quickly become unusable.

Sources

- https://domsdelat.ru/okna_i_dveri/uteplenie-okon-snaruzhi-svoimi-rukami-prichiny-poteri-tepla-metody-utepleniya-otlivov-i-otkosov-instrukciya.html

- https://ebtim.com/montazh/uteplenie-otkosov-okon-snaruzhi.html

- https://balkon4life.ru/osteklenie/okna/tyoplye-otkosy/.html

- https://1pofasadu.ru/uteplenie/otkosov-snaruzhi-svoimi-rukami.html

- https://uteplix.com/obyekty/okna/uteplenie-otkosov.html

- https://okna-dom.net/utepleniye-otkosov-plastikovykh-okon/

- https://vdome.club/remont/okna-dveri/teplye-otkosy-dlya-plastikovyh-okon-kak-sdelat-svoimi-rukami.html