Infrared heated floors are an excellent alternative to water and cable systems. They run on electricity, and spending on it is the main disadvantage of these designs. Although it is worth saying that in comparison with cable-type electric floors, the costs are significantly lower.

The level of costs associated with the operation of film floors is affected by the area of the heated room and the power of the device - find out how to select the power of different types of floor heating (water, electric). Therefore, it is important to correctly calculate the performance of an infrared floor for a specific area.

In addition, there are methods that can reduce energy costs - high-quality thermal insulation of the room and installation of the correct thermostat with a special program.

Correct temperature

To achieve maximum comfort levels, we recommend maintaining the following floor surface temperatures:

- Linoleum 26-28 °C

- Ceramic tiles/concrete floor 26-28 °C

- Laminate 23-27 °C

The maximum floor temperature can be limited by a thermostat.

If you do not know the maximum permissible surface temperature for your flooring material, please contact the manufacturer.

Important! Wood is a good thermal insulation material.

What to consider when installing heated floors

- Heating cables are not installed under furniture or stationary objects

- It is necessary to observe the installation interval within the design limits and the minimum bending radius

- Heating cables must not be allowed to cross each other.

- The cable must be in a uniform and homogeneous environment along its entire length

- To avoid overheating, the cable must not be installed inside the thermal insulation layer

- To avoid physical damage, the cable should only be laid on a clean surface.

- The heating cable should not pass through a moving seam, kinks or be installed in areas of possible overheating. Distance to heat sources, such as a fireplace, sauna stove, etc. must be at least 0.5 m

- The possibility of using a heating cable with flooring materials is regulated by their manufacturers

- Resistive heating cable must not be shortened or extended

- A 30 mA residual current device must be used in all zones

- The angle of installation of the corrugated tube under the sensor on the wall should be such that the sensor can be easily removed in the event of its failure. The sensor is installed in the middle between the turns of the cable

- The installation interval may be smaller in areas of maximum heat loss, for example, windows, but not less than 2 bending radii

- Do not turn on the cable until the screed or leveling solution has completely dried. The exact timing is regulated by the manufacturers. For concrete screed this period is about 30 days, for leveling mortar or glue - up to 14 days.

Last stage: finishing coat

Plastic film is spread under tiles, laminate or parquet on top of infrared floors. This will protect the heating elements from possible moisture and mechanical damage when installing the finished floor. When using laminate, you can get by with an underlay.

For tiles, glue and grout intended for heated floors are used.

The solid base under the carpet must be carefully attached to the floor with self-tapping screws. Sometimes dowels are used. It is important to be careful not to snag the electrically conductive strips.

Before laying the finishing floor, you need to make sure that it is compatible with the IR heating film and once again check the functionality of the temperature sensor.

If necessary, IR heat sources can be mounted not only on the floor. They produce models for walls and also ceilings.

Determining the desired temperature in the rooms

The final floor temperature depends on the purpose for which the room is used. For example:

- +29-30 degrees – halls, hallways;

- +27-29 – offices, living rooms;

- +30-35 – floors near windows, on verandas;

- +32 – bathrooms, toilets;

- +17-19 – gyms.

Installation of water heated floor

In this case, the coolant temperature should not be less than +40 degrees or exceed +60. The heating system should be such that the difference between the temperature indicators of the forward and return pipes in the case of water floors does not exceed 15 degrees. Otherwise, the base will be heated completely unevenly.

The balance of thermal/hydraulic loads for a water floor must also be optimal and adjusted. Therefore, the heating circuits must have a certain length in accordance with the diameter. The optimal pipe option is 18 mm, since even with a small amount of water such a pipeline will work correctly and heat the base.

Suitable options for heated floor kits

Code RSNameArea, m2Specific power, W

- Attention!!! The heating cable sets presented in the calculation are required in the amount of 3 pieces!

Code RSNamePower, WLength, mMinimum laying step, cmStep of laying, cmSpecific power per m2 Code RSNamePower, WArea, m2Specific power per m2 List of suitable options

(PDF) download

- 1. Base

- 2. Thermal insulation

- 3. Foil

- 4. Basic screed

- 5. Mounting tape

- 6. Heating cable

- 7. Temperature sensor in corrugated tube

- 8. Leveling screed

- 9. Waterproofing (if necessary)

- 10. Tile adhesive

- 11. Sound insulation

- 12. Flooring

- 13. Thermostat

Effect of IR heat source on the body

Not many people know about such an advantage as a beneficial effect on the body. The secret is that human heat is emitted in the same range as infrared. This means that an infrared heated floor is perceived by a person as a natural source of heat and therefore more pleasant. For example, if with water heating a person needs 22-25 degrees of heat for comfort in a room, then when using IR heating the same feeling will be already at 18 degrees.

IR radiation ionizes the air, destroys harmful bacteria and viruses, and removes unpleasant odors.

IR rays treat many diseases. Under their influence, nervous tension goes away. In our age of constant stress, this is a great opportunity to strengthen the nervous system without leaving home.

Many people find it difficult to tolerate dry air in their apartments, which is caused by central heating radiators. You have to use humidifiers. IR heated floors do not dry out the air, so it is easy to breathe in such a room.

IR radiation does not heat the air itself, but objects. Therefore, walking on such a floor is a pleasure and a state close to relaxation arises.

Laying film to save energy

It is good to lay a layer of reflective film on top. There is a special foil film with convenient metric markings that allows you to correctly lay the heating cord. You should not lay the cord without markings, and applying markings manually is quite tedious.

Laying foil film

Cunning marking devices made from ropes quickly break and get tangled. For normal installation of the cord, you need to use the factory markings.

Heating a house only with underfloor heating is unprofitable, since this results in pure electric heating.

Warm floors must be wisely combined with the installation of heating radiators.

Features of different types of infrared floors

The production of infrared floors is constantly being improved. Manufacturers are trying to take into account consumer preferences. According to the type of construction, IR floors are:

- film;

- rod-shaped.

Film, in turn, are divided into solid and striped, according to the type of carbon fiber applied, which is the source of infrared radiation. The film with continuous carbon fiber coating is easy to install and easy to cut. It transfers heat from the entire area, the heating dynamics are higher than when applying carbon in strips.

The carbon strips are arranged in groups, between which cuts can be made. Since the connection to the power source is parallel, if any unit fails, the remaining area of the “stripe IR film” will remain operational.

In this case, a film with a continuous coating is more advanced, since only the places where there is a tear or a cut fail. The service life and price of solid carbon film are higher than that of striped film.

The IR rod floor looks like a rope ladder. Many rods, which are filled with carbon, copper and silver, are connected to each other by wires. The rod mat has the ability to self-regulate. Its installation differs from the film type in that installation requires a “wet” cement screed. However, the service life is even higher than that of solid film, and it is not afraid of heavy mechanical loads.

Calculation of the power of infrared heated floors per 1m2

In addition, when starting calculations, it is necessary to take into account the specific operating conditions of the infrared warm floor:

- The type of floor covering, more precisely, the degree of its thermal conductivity and thermal sensitivity.

- What is the IR floor placed on? Below there can be a cement screed or dry, insulating materials.

- The presence of heated floors above and below or a foundation and a cold basement.

- The total area of the room and the area free of furniture.

It is extremely important to consider the permissible temperature thresholds for different floor coverings. Manufacturers should indicate this. For example, when installing an infrared floor under linoleum and laminate, the surface cannot heat up above 28 degrees. Therefore, the power will be limited to 130 W per square. For porcelain stoneware and floor tiles, power up to 250 W is allowed.

Calculation example

Infrared heating elements are mainly installed in areas of the premises that are free from heavy furniture. If you ignore this rule or rearrange beds, refrigerators and cabinets after installing heated floors, the system will overheat under the furniture.

The exception is self-regulating rod mats, which are able to adapt to the desired heating mode and reduce or increase energy consumption. But popular film infrared floors do not have this ability. Therefore, to calculate, the part occupied by furniture is subtracted from the total area.

For example , there is a children's room with 12 square meters. 5 of them are under furniture. Therefore, 12 – 5 = 7, that is, 7 m2 of infrared heating film can be installed in a room.

Connection of power wires

The connection of the cut supply wires into a single system is carried out using a VVGng installation wire, connecting sleeves in a heat-shrinkable tube and insulating material (heat-shrinkable tubes or bitumen strips), which come complete with the core floor.

The wires are fastened together using sleeves in a heat-shrinkable tube and heat-shrinkable tubes as follows:

- remove the insulation from the cut wire by about 1 cm;

- put a sleeve in a heat-shrinkable tube onto the wire;

- crimp the sleeve with pliers;

- put a heat-shrinkable casing on the installation wire;

- insert the bare end of the mounting wire into the sleeve on the other side and crimp it with pliers;

- use a construction hairdryer to heat the sleeve until it shrinks completely;

- check the strength of the connection by tugging lightly;

- slide the heat-shrinkable casing onto the sleeve;

- shrink the cambric using a hair dryer.

Sometimes, instead of heat-shrinkable casing, bitumen strips are used, and instead of sleeves in a heat-shrinkable tube, metal clips/contacts are used.

After assembling all the contacts, the IR rod floor is connected to the thermostat. A temperature sensor is also connected to it, which manufacturers recommend installing inside the corrugated hose, hidden in the grooved recess of the screed. This is done to access the sensor if it needs to be replaced.

After a positive test, construction of the flooring begins.

Thermoreg TI 200 thermostat

| Manufacturer: | Thermo |

| Model: | TI 200 |

| View: | electronic thermostat |

| Power: | 3600 W |

| Installation type: | recessed |

to compare old price RUR 3,528 RUR 2,990

Photo Name Price per piece. Quantity Cost

| Thermoreg TI 200 thermostat | 2,990 rub. | <1> | RUB 2,9902,990 |

There are 0 items in the cart worth 0 rub.

Continue shopping

Thermostat Caleo UTH-130

| Manufacturer: | Caleo |

| View: | mechanical thermostat |

| Power: | 4000 W |

| Installation type: | overhead |

to compare RUB 3,173

Photo Name Price per piece. Quantity Cost

| Thermostat Caleo UTH-130 | RUB 3,173 | <1> | RUB 3,1733,173 |

Continue shopping Availability

Energy consumption of heated floors

The energy consumption of infrared film heated floors is calculated using simple formulas. Before installation, it is necessary to decide how the film will be used - as the main source of heating or as an auxiliary heat source in addition to radiators, radiators and other devices.

If the film heated floor will act as an addition, you will need a film with a power of 150 W/sq. m. To operate in independent mode, its power should be 200-220 W/sq. m. If the room is cold, and even damp, we increase the power to 300 sq. m. As a basis for our calculations, we will choose two samples - with a power of 150 and 220 W/sq. m. Let's see how much electricity a warm floor consumes per month, in kilowatts.

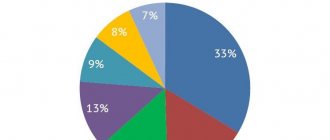

Classification of heating types

There are several types of electric floor depending on the heating elements from which it is made.

The energy consumption of such floors varies quantitatively. The owner of the premises must understand the exact calculation for each project, because if the heaters are installed or selected incorrectly, a large waste of electricity is possible. Classification of heated floors:

- heating film located under the laminate or linoleum;

- an electrical cable that must be pulled in a tie;

- thermomat is a special heating device.

Each type of electric floor has its own characteristics that affect energy consumption. These include, first of all, power.

Each type of heated floor has its own power ratings

Approximate power figures:

- for infrared film - from 0.2 to 0.4 kW/m²;

- electric heating cable - 0.01−0.06 kW/m². Approximately 5 turns fit in 1 square meter (here it is worth considering the size of the laying distance);

- thermomat - up to 0.2 kW/m².

Temperature is the main indicator that quantitatively shows the level of heating. The maximum temperature of the IR floor is +60°C, for the cable floor - +65°C. Usually the operating temperature is set lower - +30...+35°C. This is quite enough to create a comfortable environment.

You can take a closer look at the energy consumption of heated floors in this video:

The higher the resistance, the greater the energy consumption. Basically, the power of a warm electric floor is 0.1−0.2 kW/m². This information is usually indicated on the product box or instructions included with it. The average electricity consumption is 120 W/m². It is also necessary to take into account when calculating what function the heated floor will perform: additional or primary.

The main one is when the electric floor takes on the main function of heating the room. For example, a country house that has no central heating at all. An additional function is performed when the building has a centralized heating system.

Thermoregulation and more realistic numbers

Energy consumption of electric heated floors is reduced by installing a thermostat. Without it, the surface temperature of the floor covering would be too high and not the most comfortable. The thermostat monitors the temperature of the finished floors, turning the power on and off as needed. Depending on the level of heat loss, actual consumption drops by 30-40%.

There is another way to save money - it involves turning off the heated floors when no one is home. This technique is relevant if the film is used as auxiliary equipment. If it works as the main heating, then it makes no sense to turn it off - during this time the house will cool down, and reheating it will take approximately the same amount of electricity as will be saved during the shutdown period.

In total, even if film heated floors work 60% of the total time (that’s 14.4 hours a day), the electricity consumption will be about 317 kW (or 216 kW when operating in auxiliary mode).

Let's see what we get in monetary terms. Since electricity tariffs are different in the regions, we will take an average figure of 4.5 rubles/kW. For a month of operation in the main mode, the consumption for film heated floors will be 1426.5 rubles/month, in the auxiliary mode - 972 rubles/month.

Cost reduction

The energy consumption of underfloor heating can be reduced in several different ways.

First of all, this is the use of high quality thermal insulation materials in the premises. Secondly, energy costs are reduced by flooring with good heat conductivity. These measures will reduce energy consumption by a third.

Tiles can be laid on any type of heated floor. This material has high thermal conductivity, which is why the floor can consume much less electrical energy when warming up.

- The surface of the floor and the back side of the tiles are covered with glue, then the material is laid on the floor taking into account the geometric shape.

- When the glue is completely dry, the joints are thoroughly grouted.

Note! In some cases, it is advisable to put a small layer of primer under the tiles. This step is not necessary if you are using a high quality adhesive.

However, the most effective method to reduce costs is to use a thermostat. When installing it, it immediately becomes obvious how much warmer the room becomes with less energy consumption.

Reduced energy consumption

The heat reflective layer allows you to maximize the effectiveness of the IR film by retaining and directing heat in the desired direction.

We were able to calculate very real figures on the consumption of electricity for the operation of film heated floors. The costs are not that terrible, but it will take some work to achieve compliance. First, you need to correctly lay the IR film, placing a heat-reflecting layer under it. Thanks to this, the heat it generates will not escape into the concrete screed or other underground structures.

It is also necessary to reduce heat losses, this will be somewhat more difficult. First, you should work on the walls of your home, since losses here can be up to 15-20%. This figure is reduced by installing thermal insulation and an additional layer of brick. It is best if all this is taken into account at the stage of building a home, otherwise you will face additional costs.

Ceiling insulation will help reduce the energy consumption of a film heated floor, from where another 10-15% of thermal energy can be lost. Ceiling structures should be insulated using basalt wool or any other similar insulation, in two layers. Such insulation will help reduce energy costs and prevent heat loss outside the home.

To reduce heat losses and a corresponding reduction in energy consumption for the operation of the film floor, you should work on other elements:

- Doors - you need to either install normal entrance doors in your house or endure the cost of electric heating;

- Floors are another place through which thermal energy can escape. This leakage is prevented with the help of an additional concrete screed, as well as with the help of serious heat-insulating materials. In wooden buildings, only thermal insulation is used, on top of which subfloor boards are laid - then the film is spread, and the finishing coating is placed on top of it;

- A large area of window openings and extra windows - all this contributes to an increase in energy consumption for the operation of film heated floors. Extra windows should be filled in, and openings that are too wide should be made narrower - the minimum ratio between the window area and floor area is the cause of losses.

Reference

K=0.35 is not confirmed by calculations. Let's take the most unfavorable option: on for 60 seconds and off. 120 sec. Total cycle time 60+120=180sec. Hence Kvkl=(60/180)*100%=33%. Please correct the text. Thank you!

What kind of lighting do you prefer?

Built-in Chandelier

Further calculations can be made by taking the average cost of electricity in the region (the price may vary depending on the location of the house). By making a simple calculation of power consumption up to 50 m², you can come to the following results:

Next, we calculate electricity costs. The average cost for 1 kW in Moscow is 4 rubles. 50 kopecks It turns out that for the heating season you will have to pay approximately 6804 rubles, with a long winter and late spring 9072. The result is serious savings on heating.

Of course, these results can only be achieved under all the conditions listed in the previous subtitle.

If you plan to use an infrared heating system as the main source of heating for the building, you will need a film with a power of 240-400 W. Accordingly, the energy consumption of heated floors with infrared radiation will increase by approximately one third, in rare cases by two times.

Is infrared floor heating profitable or not?

As has been shown, the energy consumption of an infrared carbon heated floor is not so large as to categorically refuse to use an IR heating system.

To this it is worth adding several more economic benefits from their use:

- Low operating costs. Laying the floor can be done independently, unlike gas equipment; when connecting, no permits or approvals are required, payment for the production of projects, etc. Repairs do not require large economic costs.

- The operating energy consumption per m² is lower than that of a similar system in which floor heating is carried out using cable heating. To quickly calculate energy costs when using IR film heated floors, there are special tables. With their help you can calculate approximate heating costs.

- Quick installation. Installation work by specialists (floor insulation and heating system installation) will take approximately 1 hour. Provided that linoleum is used as a floor covering.

You can find out how much power the floor consumes in Watts from the technical documentation. If necessary, all calculations and layout diagrams will be performed by consultants of the company selling the film.

Infrared floors are one of the most economical heating systems, which makes them the main competitors of gas and solid fuel heating.

Expert opinion

It-Technology, Electrical power and electronics specialist

Ask questions to the “Specialist for modernization of energy generation systems”

How much electricity does a heated floor consume per hour: power and consumption? This leakage is prevented with the help of an additional concrete screed, as well as with the help of serious heat-insulating materials. Ask, I'm in touch!

How to calculate an electric heated floor

The calculation method is similar to what is written about a water floor. It is necessary to know the heat loss and method of using floor heating, the power of one meter of heating element. In this case, everything is somewhat simpler, because electric materials for floor heating have a specific number, which manufacturers use to indicate maximum heat transfer. They are not able to give out more than the stated figure. Therefore, the calculation of underfloor heating with electric heating is simpler and clearer. However, a fair number of variables remain. This is the thickness of the screed, its thermal conductivity, and the thermal conductivity of the finishing floor covering. They also need to be taken into account.

The calculation depends on the heater power per square meter

Effective heating area

The calculation of a heated floor with electric heating begins with determining the effective heating zone and its area. Most heating elements do not tolerate overheating (resistive cables, resistive cable mats, film heaters and infrared mats). An exception is self-regulating heating cables, but they are expensive, so they are rarely used. Although, there are also cables and mats made from them.

Once again: electric floor heating elements are laid only in an area where there will be no furniture and/or plumbing fixtures, carpets, etc. That is, an electric heated floor is placed where there will be a constant and certain heat flow.

To calculate the cable for a heated floor, you must first determine the area on which it will be laid

Before starting the calculation, we outline the proposed places for furniture/plumbing/carpets and calculate the remaining area. This will be the effective heating area. We will use it further in calculations.

How to calculate the footage of a heating cable for a floor

The calculation method is based on the amount of heat that needs to be replenished (heat loss) and the effective heating area. We divide heat loss by the effective heating area. We obtain the required thermal power, which we must obtain per square meter of area with the installed heating element.

For example, the area of a room is 16 squares; furniture will be located on 4 squares. Heated area - 16 sq. m - 4 sq. m = 12 sq. m. Heat loss of the room - 1100 W. Let's find out how much power is needed from one meter: 1100 W / 12 m² = 92 W/m².

Calculation of heating cable based on room area and meter power

Next, we look at the power of the cables for floor heating. For example, the power of one meter is 30 W. To get 92 W per square meter, you need to lay a little more than three meters of cable. Quite a real task. When developing a diagram, remember that it is better that for a screed with a height of 3-4 cm, the distance between the wires does not exceed 25 cm. Otherwise, the floor will have pronounced “stripes” - alternating zones of heat and cold.

There is another way. Buy a ready-made cable set of a certain power. Look for the right power and laying area. You have everything included.

Calculation of heated floors with cable mats

The essence of the calculation does not change. Heat loss and effective laying area are also needed. This is the same cable, but pre-attached to a polymer mesh. This heating element is easier to install. Most often used under tiles. It is simply rolled out onto a prepared base and the tiles are placed on top using special glue.

Heating mats are usually sold ready for installation.

With this type of floor everything is simple. It is sold in pieces of a certain capacity for a certain area. All you need to do is find the option that suits you.

Let's calculate the film heated floor

The film heating element is sold in sets and by the meter. Select the footage and power so that it provides the required amount of heat. The film panels should be laid close to each other. This is necessary to avoid temperature banding.

Warm floor film. The calculation is very simple: we select the power and width so that they provide the required amount of heat

The width of the film heated floor is 30 cm, 50 cm, 80 cm and 100 cm. It is quite possible to use different widths in one room. It is important that the heating elements do not overheat.

The procedure for performing installation work

The first step is to lay insulating tape made of any suitable material (for example, polystyrene foam) around the perimeter of the room. This measure will prevent heat loss.

Thermal insulation material is laid out on the subfloor, which has been previously cleared of debris, with the foil facing up. This is a very important point: the foil will help the heat move upward and thereby improve the quality of heating.

Thermal insulation - in rolls or plates, attached to the floor with staples of a mounting gun, double-sided tape or glue.

Then roll out the IR thermal film, always with the copper strip down. The matte side of the film should be at the top. In this case, it is necessary to exclude the accumulation of air.

In the necessary places, the roll is cut according to the applied markings. The width of the infrared heated floor can be different; it is enough to cover about 80 percent of the heated area.

It is advisable to turn the heating elements of the film with their contacts in the direction where the thermostat will be. The strips are laid out tightly, at a distance of 10 mm, but in no case overlap.

The next stage is the parallel connection of the strips using a cable. A contact is made on the copper strip, which plays the role of a current-carrying strip, with one part under the core and the other at the top. Then you need to crimp the contact with pliers. Do this for all sections. They should be laid towards the thermostat. The remaining open areas of the copper conductor are covered with special bitumen insulating tape.

When all the contacts are connected, the insulators are installed, the IR film must be attached with tape to the heat insulator. Scotch tape is also used to connect strips together. The contact clamps are hidden in recesses cut to size in the insulating material.