Many craftsmen make sauna stoves with their own hands. Not only for the bath, however. To make the stove look presentable, it is better to paint it. Paint not only improves the appearance, but also protects the metal from splashes and reduces its contact with oxygen; oxidation occurs more slowly. Brick stoves are painted less often, especially if they are made of good brick. But sometimes the brick starts to crumble - you were unlucky with the batch, or it overheated. Even more often, cracks occur in the masonry. They are covered with a solution, but to give a more attractive appearance, they are painted over. What is much more often needed for a brick stove is to tidy up the doors: stove casting also rusts. Heat-resistant paint is used for all these needs: for a metal or brick oven or for casting.

The painted homemade metal stove looks quite presentable

Rules for painting a stove

Before you start, you need to do the preparatory work correctly - clearing the surface of debris, because this is so important, after which you can only begin to do this work.

Before you begin to carry out the work, be sure to moisten the surface of the product with water; the solution, in turn, is usually applied in a thin and neat layer, not forgetting that each subsequent layer must be applied to a well-dried previous layer, remember this Before you When you start doing the work, you definitely need to moisten the surface of the product with water, the solution, in turn, is usually applied in a thin and neat layer, not forgetting that each subsequent layer must be applied to a well-dried previous layer, remember this.

Which paint to choose

As a rule, when choosing a stove finish, you must adhere to some recommendations and tips. Of course, this work can be done not only with oil paints, but also with enamel paints, but this usually leads to a lot of heat being lost, which cannot be allowed.

So:

When thinking about how to paint a brick stove, you should immediately discard aluminum dyes.

But as for their color range, it is quite scarce; if you could not find this or that shade, then know that you can treat the stove with a special primer, you can always use latex paint. You definitely need to make sure that it is heat-resistant, because this is so important, so using silicon-organic enamel, you can do the right thing, it is distinguished by the fact that it retains its performance qualities, which is so important.

Paint for sauna stove: requirements

Even a person far from stove business understands that it is impossible to simply paint a metal sauna stove with ordinary paint used for interior and exterior work. Conventional enamels and paints and varnishes based on acrylic and polyurethane compounds begin to burn already when heated to 200°C. And even at lower temperatures, regular paint deteriorates, darkens, cracks, and eventually crumbles into powder.

Paints and varnishes that can be used to paint a sauna stove must at least meet four basic requirements:

- When heated for a long time at high temperatures, do not undergo secondary polymerization;

- Do not oxidize, do not interact with water and the humid atmosphere of the bath;

- The paintwork must withstand thermal shock when cold water hits the oven walls;

- The paint composition must ensure normal drying of the paint at home, otherwise there is no point in even trying to paint the stove in a bathhouse if the coating does not dry even in a few weeks.

For your information! One of the important qualities of paint is good coverage, without the formation of cavities or pores, and the main thing is to obtain a minimally thin layer of coating.

It is clear that, if desired, you can paint the sauna stove in several layers. As a result, a thick multi-layer cake of paint is formed on the surface of the stove, which does not adhere well to the metal, while significantly reducing the heat transfer from the firebox to the bathhouse atmosphere. The result will be a situation where the painted stove will look very nice, but the chimney pipe will become red-hot, and the inside of the bathhouse itself will be cold and damp.

In addition, it is necessary to pay close attention to the composition of the paint for metal “hot” structures. Finding a suitable paint for painting a metal stove is not so difficult, fortunately, a huge number of heat-resistant and heat-resistant paints have been developed and produced for the industry

High-quality paint on a metal sauna stove should not be glossy.

High-quality paint on a metal sauna stove should not be glossy.

Another thing is that all of them, or at least the vast majority of the range, are designed for industrial use, so there are no amendments to the environmental friendliness and harmlessness of the material. What is sold on the market today and is offered by many companies for painting sauna stoves is actually a lightweight or improved version of paintwork materials for industrial use. Many companies are trying to modify classic heat-resistant paints by removing the most toxic and harmful substances from their composition, such as toluene, benzene, and volatile compounds based on siloxanes and silicates.

However, there is a real risk of buying industrial paint without any modifications, painting a boiler with it in a bathhouse, and after drying for a couple of months, every time the metal body of the furnace is heated, a small amount of toxic compounds will be released into the atmosphere.

Which part of the stove needs to be painted?

The metal body of a heater or regular stove can reach very high temperatures. The alloy steel firebox easily heats up to 500°C, the stainless steel body heats up even more - up to 600°C, with a screen the temperature can be even higher. Therefore, the paint for an iron sauna stove must at least withstand heating up to 450-500°C.

Most metal sauna stoves are divided into two large groups:

- Double-body construction, inside the metal body there is a stainless steel firebox. The outer shell heats up to a maximum of 300°C, so it can be painted with good heat-resistant paint;

- Single-hull structures made of heat-resistant steel or cast iron. For example, a potbelly stove, the walls of the firebox are simultaneously the lining of a metal stove. It can be painted with a special ceramic powder paint, or not painted at all, but a protective coating applied to the metal surface using a chemical method, for example, bluing.

Single-body metal stoves made of ordinary carbon steel cannot be used in a bathhouse. Even if hot water accidentally gets on the metal, the wall quickly corrodes and burns out. No amount of painting can stop this process.

It is better not to paint a metal sauna stove made of heat-resistant stainless steel at all.

DIY painting materials

If there are any reasons why you cannot or do not want to buy special materials for painting the stove, you can start making them yourself.

- Chalk or lime solution. To prepare it, you only need water and lime, which can be purchased in large quantities at any hardware store. The difference between these solutions lies only in the duration of their drying: when applying the first layer of chalk, you must wait for it to dry completely, and layers of lime mortar can be applied immediately. To prepare the solution you will need 1 kg of lime or chalk and 1.5 liters of water. To achieve strength in the final result, table salt must be added to the solution - 300 g of salt per 2 kg of coloring solution. If there is no salt, you can use wood glue - 100 ml of glue per 10 liters of solution, but this paint will be yellowish. To avoid this, you can pour 20 ml of blue into the coloring mixture.

- You can also paint a brick stove using natural varnish. To prepare it, you will need chicken egg whites and milk in a one-to-one ratio, as well as dust from bricks that remains after laying the stove. To process one square meter of stove you need about a quarter liter of milk and 8 egg whites. To prepare this varnish, beaten egg whites and cow's milk are added to brick dust until a thick consistency is formed. The well-mixed solution is applied with a brush to the preheated oven surface. The result is a smooth red coating with increased temperature resistance and durability. To achieve a matte surface structure, you can cover it with drying oil on top. Natural varnish has its drawbacks: when it comes into contact with a painted surface, marks may remain. To prevent this from happening, you can apply an egg white solution on top. Also, during the heating process of the stove, the coating emits the smell of baked milk, which is a disadvantage for most people.

Offers from manufacturers

| Brand KM | Manufacturer country | Technical specifications | Price, rubles |

| Tikkurila Luja | Finland | Interacts with any base. The coating is matte. Tolerance of detergents containing alcohol. | 1700 |

| Lacra Super resistant | Russia | Wood, plaster, brick are painted. Drying speed for 1 coating layer is 60 minutes, 2 layers – 120 minutes. The coating is water-resistant and wear-resistant. | 1100 |

| Parade F20 | Russia | The paint layer is wear-resistant, tolerates water, and maintains color brightness well. The first coat dries in 1 hour. Polymerization occurs after 2 hours. CM cannot be applied if the humidity is high and the temperature is below 10°C. | 1900 |

| DUFA D1A WANDFARBE | Ukraine | The coating is matte. Complete polymerization after 4 hours. Operating temperature during application is 20°C. | 1200 |

| DULUX BINDO 20 | Russia | Increased wear resistance. Tolerance to water exposure. It is enough to paint 2 times. Drying speed – 60 minutes. A month after decoration, the surface is washed with detergents. | 3900 for 10 liters of containers |

| Tex Universal | Russia | The coating is deep matte. Drying speed 3 hours. The covering layer is wear-resistant, moisture-resistant, and can be washed with non-abrasive agents. | 1100 |

| Tikkutila Remontti Jassia | Finland | The coating is semi-matte, washable and moisture resistant. Drying speed of one layer is 120 minutes. | 1600 for 2.7 liters |

| VGT VDAK 1180 | Russia | A matte layer is formed that is water-resistant and wear-resistant. The surface “breathes”. Color brightness is maintained when exposed to UV rays of the sun. The time interval between applying layers is 60 minutes. Polymerization occurs within a day. | 360 for 7 kg |

| Marshall | Homeland - Türkiye. | The material is easy to work with. Drying speed – 4 hours. Stable layer with high wear resistance. | 580 for 2.5 liters |

| Dali | Denmark | The coating repels water and dirt. Resists direct rays of the sun. Each layer dries in 60 minutes, the structure is ready for use in 120 minutes. Work takes place at temperatures above 10°C. | 1200 for 5 liters |

Mortar

Lime is an accessible material in all respects. Lime solutions have bactericidal properties, and after drying they are absolutely harmless and do not cause irritation of the mucous membranes. Properly prepared lime mortar adheres well to plaster, stone and brick, is not afraid of temperature changes and can be used outdoors and in wet rooms, including baths.

Slaked lime is less dangerous to work with

To prepare the solution, it is better to buy slaked lime in the form of a dry powder. To whitewash oven equipment, it is recommended to use a ten percent salt solution instead of water. Salt makes the coating strong and prevents the formation of cracks.

Lime powder should be diluted in one third of salt water, thoroughly stirring the mass until smooth. If the solution is prepared from lime dough, then it is also diluted with salt water to the consistency of liquid sour cream. To neutralize possible yellowness, it is recommended to add diluted blue.

One liter of lime mortar is enough for about two square meters of area. Accidentally stained floors can be easily washed with clean water, but this must be done immediately, before the lime has time to dry.

Furnace painting

Before staining, the selected composition must be prepared in accordance with the manufacturers' recommendations, which are indicated on the packaging. Some paints must be diluted with solvents, others can be applied at certain temperatures - individually for each substance.

Heat-resistant varnish for oven coating

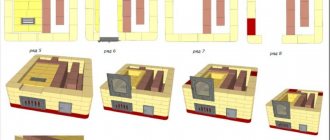

To paint the stove, the following instructions apply:

- Applying a thin layer of paint to the surface of the oven;

- Repeat the first step 2-3 times and dry the layer after each application;

- Heating the oven and cooling to room temperature;

- Applying the final finishing coat of paint.

A symbolic ornament will add a special charm and beauty to the Russian stove.

There is no need to apply fastening compounds, such as primers after plaster or clay, since almost all fastening compounds cannot withstand high temperatures.

To apply paint, you can use any tool - brushes, rollers, spray guns. Compositions with high thermal performance are also available in bottles with a spray nozzle, but the consumption with this method of application is enormous. You need to buy bottles with a reserve, taking into account the need for several layers of paint.

Painting a metal stove

A metal stove is often installed in a bathhouse; it can also be found in old private houses with a classic design, where the stove was used for cooking, and the metal stove was used to heat the room.

Painted sauna boiler

Painting a metal stove can be done in two ways:

- Cold painting - the coloring composition is applied to cold metal. The metal must first be cleaned of dirt and rust - it is better to use a grinding machine with an attachment for cleaning metal products.

- Burnishing - paint is applied to metal heated to a temperature of 100-150 degrees. This method is the best - the paint “tightly adheres” to the iron.

It is much easier to paint metal using a cold method - the modern market offers an abundance of thermal paints, for example, fire-retardant paints for metal Polistil - they protect the metal even from open fire.

Coloring elements

Metal stove elements

Metal elements - doors, dampers, adjacent elements - are painted with protective substances.

Furnace parts must be coated with paints that can withstand high temperatures. Parts that are only adjacent to the stove can be coated with a refractory compound or galvanized - for this, Zinga electrically conductive paint is used, which protects the metal from corrosion and other external influences.

The chimney heats up to a greater extent at the junction with the flame part, gradually cooling down in the upward direction. Also, the chimney is exposed to the influence of natural phenomena in the area where it faces the street.

Before painting the chimney, it must be thoroughly cleaned with a grinding machine. Then it can be coated with compounds - silicon-organic or water-based paint.

Why don't we use regular paints?

Paints for barbecues and other heated surfaces must have certain properties that conventional paint compositions simply do not have. That is why heat-resistant paint is necessary for painting stoves, radiators, barbecues and other surfaces.

Grill paint

Painting with conventional paints is not allowed for a number of reasons, which we will consider further:

- The color of the coloring pigment will definitely change due to the increase in temperature. Any coating may simply turn yellow or blacken

- The coating will crack, and its complete or partial peeling is also possible.

- The binder base will be lost, and the paint layer will be charred and completely destroyed

Preparation and painting of the product

Before painting the inside of the barrel, its surface must be properly prepared. This rule especially applies to old containers that have already been in use. The tank or barrel must be cleaned using abrasive equipment.

The surface must be degreased to ensure adhesion of the metal to the soil or enamel. Used containers always contain residual dirt and corrosion. If there is rust in the barrel, it must be removed using a metal brush or an electric drill with an attachment. Next, treat the inside of the barrel with a rust converter, which will help stop the corrosion process.

If anti-corrosion work is performed incorrectly, the adhesion of paint materials to the metal surface will not occur. You can paint the inside of containers provided that you have provided adequate ventilation.

To prevent water from penetrating into the pores contained in the paint, painting should be done in two or even three layers. The container ready for painting must be completely dry. Priming is also carried out in two layers. For protection, you must have rubber gloves, goggles and a respirator. Each successive layer is applied only when the previous one is completely dry.

You only need to paint on a flat surface. If the container contains non-potable water, then you can use the simplest method of corrosion protection.

On video: how to protect a barrel from rust.

Do I need to paint or is there an alternative?

It is recommended to paint the metal before laying the heat-resistant brick screen and cover the inside of the tank. Instead of painting, bluing is used (details below) or other methods are used:

- Eco-friendly surface treatment with silver is quite effective;

- A budget option is red lead, used in metallurgy;

- A heat-resistant mixture of lime and cement provides good protection against oxidation.

It is recommended to paint the metal before laying the heat-resistant brick screen and cover the inside of the tank.

Painting an iron stove

High temperature, excess humidity, cycles of alternating heating and cooling, all this affects the metal structure - actively destroying its surface. It is clear that paint and varnish materials must withstand all this without losing their physical properties, maintaining an aesthetic appearance and protecting the metal from corrosion.

What kind of paint

Heat resistant paint

Heat-resistant silicone enamel is well suited. Its abbreviation begins with the letters “KU”. Next come the numbers. There are brands that remain resistant to temperatures of six hundred to seven hundred degrees. In addition, heat-resistant silicone enamel reliably tolerates moisture, steam and cycles of sudden heating and cooling. In addition, the influence of high temperatures improves the adhesion index to the substrate.

There are also special fire-resistant paints. However, their purpose is to protect or maximize the time before the surface ignites. Therefore, such paints are not designed to create a particularly aesthetic appearance. They are certainly effective, but the price...

The “favorite” color covering most stoves is black or close to it. This is due (and not without reason) to the fact that such a color scheme provides better heat transfer. Well, maybe someone remembers the term “absolutely dark body” (this does not apply to people from the African continent). Therefore, most heat-resistant paints are dark in color. By the way, there are enamels that can be applied at negative temperatures. This expands the usability.

“For information: the temperature inside the firebox of an average sauna stove does not exceed 800°

Thermal spray paint

Preparatory stage: If there are traces of dust or dirt on the surface, remove. Wash off with soapy water, scrub, etc. After that, degrease the surface. Acetone and white spirit are suitable for this. If there is rust or scale, carefully brush it with an iron brush, sand it and treat it with a solvent. Wait until completely dry. When using organosilicon enamel (KO), use “classic” solvent, such as P-646 and similar analogues, or turpentine as a solvent.

“If the stove is new, “freshly cooked” - heat it. This will allow you to “burn out” the remaining fats, grease and other debris accumulated in the pores and microshells, from where it is problematic to get them out with an ordinary rag.”

How to paint

The paint is applied in 2-3 approaches. Try to make a thin layer, this will prevent the formation of smudges. Before proceeding to the next layer, test for tack. Complete drying of the paint occurs during the first firing of the furnace, and at 150-200° its polymerization begins, or, more simply, sintering. After which, it gains its maximum strength.

How to coat

In order for enamel or paint to stick well and for a long time on the metal surface of the stove, it is not enough to choose the appropriate composition. It is necessary to strictly adhere to the technology when applying it. All the necessary information is on the packaging, but the principle is the same for any product.

Surface cleaning

Dust, dirt, rust, old coating and any other layers will not allow the paint to adhere well to the surface and adhere to it. They need to be removed.

- First, they use a metal brush to remove obvious contaminants and loose rust.

- Then the surface is brought to a shine with a drill with abrasive attachments or sandpaper.

Cleaning metal from rust Source yandex.net

For reference! If the instructions allow, instead of a mechanical cleaning method, you can use a chemical one by applying a rust converter to the surface.

- The next step is to remove dust using a soft broom or vacuum cleaner and damp wiping.

- The dried metal is degreased using a solvent recommended by the manufacturer. If there is no such recommendation, you can use white spirit or solvent P 646.

Solvent 646 does not cause metal corrosion Source artikaluga.ru

What kind of stove

So, some are looking for how to paint a stove in a metal bathhouse, while others are interested in how to paint a brick stove - we have answers to both questions.

Made of metal

steel, cast iron, especially heat-resistant

On sale you can find paints with different temperature limits, which are formally expressed in its definition:

Heat resistance is a word that defines the relationship of paint to temperatures up to 600 degrees. However, you can find a clearer definition on the label - there are paints that can withstand up to 200 degrees (they are useful for painting heating radiators, not your stove).

BY THE WAY! There are heat-resistant varnishes, the limit of which is around 250-300 degrees - also not an option for a stove, but they can be useful in its environment.

Heat resistance is a loose concept, but this is the name given to paints that can withstand the temperature we need above 600 degrees. Their upper limit is somewhere around 1000 degrees. It is this category that comes in handy when you need to paint the outside of a metal stove in a bathhouse(!).

Because inside it is better to use paints that are called “fireproof”, which means the following: they are not afraid of contact with open fire.

IMPORTANT! Don't confuse "fire resistance" with "fire protection". There are paints that protect the surface they cover, inflating like a pillow and preventing fire from reaching this surface, at the same time depriving it of oxygen supply

Do not cover the stove with them))).

You can paint an iron stove in a bathhouse on the outside with heat-resistant paint and on the inside with fire-resistant paint.

All that remains is to choose the application method, taking into account that by choosing a brush, you slightly increase the amount of paint consumed (compared to a spray bottle, for example), but you benefit in price if you compare it with the price of paint in spray cans. Heat-resistant paint can be applied as usual - with a brush, spray gun, roller or spray can.

Heat-resistant paint can be applied as usual - using a brush, spray gun, roller or spray can.

Brick

The question of painting bricks does not arise very often. Previously, stoves were either left as is or painted with lime, but more often they were plastered brick stoves.

In general, stoves were plastered not just to make them more beautiful, but to ensure that the brickwork did not lose its integrity, because over time, all these temperature changes during kindling in the cold, for example, affect the masonry - it cracks, becomes painted, and opens up smoke into the room.

Therefore, the stove was plastered and covered with lime so that the cracks, which were blackened by the smoke, could be immediately seen.

Nowadays, this is more often done with chimneys, and sauna stoves are preferred to be left “in their natural state” - with bare brick. But there are also designers who paint bricks in different colors, using modern paints - this is another way to make the interior more attractive.

So, you can either whitewash the stove with lime or chalk, or paint it with the same heat-resistant paint. And as an example, we’ll show you a video where a stove was painted red and gray using CERTA:

But this, by the way, is a question: is it worth taking paint with a limit of 750 if such temperatures do not occur close to such temperatures on the surface of the brick? After all, the higher the limit, the more expensive the paint - you could have gotten by with heat-resistant ones...

Painting metal: tools

You won't be able to get by with just one brush. Because you cannot paint an iron stove without cleaning and degreasing its surface.

Therefore, arm yourself with protective equipment, a drill with a metal brush, degreasing compounds (the same acetone, for example), place the stove on plastic film and start the process.

Paint selection

Some time ago, when there was a stove in every private home, there were few options for finishing it. Almost always, stoves were coated with a chalk mixture or lime. In the first method, when using chalk, the masonry stained everything nearby. Therefore, lime was a better option. Both options are currently outdated - the modern construction market offers many products that allow you to finish the stove yourself.

A Russian stove, if it is built correctly, can heat up to a temperature of 80 degrees from the outside - many dyes can withstand such heat, but some can be destroyed under the pressure of temperature.

Blackened stove surface

Only these substances can withstand high temperatures without changing their properties:

- Latex - compositions whose properties include elasticity. Therefore, when heated, they can expand, but after that they return to their original form.

- Silicate paints are based on liquid glass, thanks to which this composition is not only resistant to high temperatures, but also has a beneficial effect on long-term heat retention in the room.

- Silicon-organic – paints that are designed specifically for finishing stoves and fireplaces. The heat resistance declared by the manufacturers is 600 degrees. At the moment, silicon-organic substances are the best option for painting a stove, but the price of such compositions is quite high.

- Water-based paints are also a good option. When heated, the water underlying the substance evaporates - and the surface is covered with a durable, temperature-resistant layer of color filler.

Heat-resistant, heat-resistant, heat-resistant paint for finishing stoves.

Previously, when heat-resistant paints did not exist, stoves were coated with self-prepared substances. Almost all of them were based on chalk or lime.

In the photo – varnish PF238

Today there is also a method for creating paint yourself - if the required substance is not in the store, you need to mix PF-283 varnish and turpentine in equal proportions.

The prepared mixture will be almost transparent. If colored paint is desired, you need to take gouache of the required color, dry it and grind it into powder. A mixture of varnish and turpentine, when adding gouache powder, takes on the color of the powder

General concepts about heat-resistant paints

To ensure that the paint applied to the surface does not lose its original qualities for a long time under the influence of high temperatures, heat-resistant paints and varnishes are produced using special technology. They contain protective components, thanks to which the treated brick walls of stoves or fireplaces, and even outdoor barbecue complexes, are able to withstand aggressive external factors such as moisture, precipitation, dirt and dust. A layer is formed on metal elements that can protect them, among other things, from oxidative corrosion processes.

Heat-resistant paint in aerosol packaging

Almost all compositions for painting stoves and fireplaces are produced in the form of suspensions based on heat-resistant varnishes containing silicone and silicon.

As mentioned above, all parts of the structure can be painted, but for small metal elements and large surfaces, special types of paints are produced that are designed for extremely high temperatures. Such compositions are suitable not only for stoves, but also for barbecues, where the metal experiences maximum impact from contact with open fire.

Cast iron oven door, painted with a heat-resistant compound

Other heat-resistant paints are made specifically for treating brick or stone surfaces.

Compositions for coloring materials exposed to thermal effects must withstand heating of at least 350-400 degrees. So, even when ordinary paper burns on its surface, the temperature is + 380-400 degrees; on an intense flame when burning wood, it reaches + 400-450 degrees. Well, when coal is used as fuel, in the phase of its flameless combustion, a temperature is created on its surface that reaches + 900-1000 degrees.

Of course, the external surfaces of heating devices heat up much less than the firebox, but in any case you need to choose heat-resistant paints that can withstand from 400 to 550 degrees of heat.

Why should you buy heat-resistant paint?

It should be noted that heat-resistant paints always have a fairly high price, and, wanting to save money, some stove owners try to use oil, enamel paints or water-based paints to paint their metal parts. However, you need to know how these compounds behave when heated:

Conventional paints are not suitable for extreme temperature operating conditions.

- For example, oil paint made from drying oil will first soften, and at very high temperatures it will begin to burn. Well, an unpleasant smell will come from it in any case.

- Ordinary enamel will dry out, lose elasticity and, accordingly, crack, while also emitting an unpleasant “aroma”.

- Water-based paint, applied in a thick layer, will quickly crack and crumble when moisture evaporates from it, and a thin layer will be covered with a fine network of cracks.

After two or three firings of the stove or fireplace, ordinary paints will change color and acquire an unpleasant yellowness. In addition, you need to remember that rust will negatively affect them from the inside, “eating” the paint and showing up on the outside. Such paints will not protect heated surfaces, and may even cause harm not only to the walls and parts of the stove, but also to the health of people who will breathe in caustic fumes.

In addition, such a coating will barely be enough even for one heating season, and after that the paint on the metal, and possibly on the bricks, will remain in areas that will be difficult to remove due to the porosity of the material.

It will also be difficult to remove oil or enamel paint from brickwork, and you cannot paint over it, as it will still release harmful substances and have a bad effect on the top renewed layer. You will have to clean the surfaces with a wire brush or a grinder with an appropriate attachment.

Therefore, you should not take risks, otherwise you will end up paying much more than the cost of high-quality heat-resistant paint.

Basic requirements for paints for stoves and fireplaces

When choosing heat-resistant paint, you need to consider several factors:

- Resistance of the composition to high temperatures. The maximum heating level is indicated on the packaging.

- Resistance to aggressive environments.

- Material consumption, that is, the amount required to paint 1 m².

- Composition of the dye.

- Ease of paint application.

Heat-resistant paint and varnish compositions are divided according to the base component on which they are made:

- Acrylic base.

- Silicon-containing (potassium or sodium liquid glass).

- Epoxy resins.

- Silicone.

The base of heat-resistant paint directly affects its performance.

The compositions themselves, made on an epoxy or silicone basis, are not very resistant to high temperatures. Therefore, to enhance heat resistance, aluminum or bronze powder is added to the paint, after which the composition can be used at temperatures up to 400-650 degrees.

Heat-resistant paints are also divided according to their purpose, that is, according to the type of surface on which they are applied.

Paint for brick surfaces

Painting the brick surface of the stove

The following requirements apply to heat-resistant paints used for coating brickwork:

- resistance to temperatures reaching up to 300 degrees;

- resistance to steam and moisture, especially for stoves installed in bathhouses;

- crack resistance;

- resistance to fading.

Organosilicon compounds, which include enamels KO-168, KO-8101, KO-813, etc., have all these qualities.

A fireplace or stove can be coated with a transparent heat-resistant varnish, which will preserve the natural appearance of the stone

For brick stoves and fireplaces installed in residential premises, an important factor is the aesthetic appearance, since many heating structures also play a decorative role in interior design.

Transparent varnish for brick surfaces

For example, a fireplace or stove, decorated with artificial or natural stone, which you want to preserve in its original form without painting, is coated with a heat-resistant transparent varnish called “invisible”.

Paint for metal surfaces

In recent years, the installation of steel or cast iron compact stoves and fireplaces has become increasingly popular. They do not take up much space and look aesthetically pleasing and stylish, decorating any interior with their presence.

Metal stoves and fireplaces require special care

This type of appliance, as well as the metal elements of brick heating structures, require a special approach in choosing paint, since metals are quite “capricious” and rust may appear on them during operation. In addition, they expand quite significantly under the influence of high temperatures, and can also be destroyed by stray currents. Therefore, heat-resistant compounds for metal parts must have the following qualities:

- the paint must withstand temperatures up to 750 degrees;

- when heated, the composition should not emit toxic substances or strong unpleasant odors;

- the paint must have sufficient elasticity so that when heated and cooled it is “movable” and does not crack;

- it is desirable that the paint has high anti-corrosion qualities, which will allow it to be applied to a surface that has not been cleaned of rust without prior priming;

Heat-resistant paints filled with metal powder

- resistance to phenomena that affect color changes - fading and yellowing;

- for stoves installed outdoors, paint is selected that is also resistant to negative temperatures;

Particular attention to paints used on stoves located in the open air

resistance to aggressive external environments, since the composition must reliably protect the metal from atmospheric humidity, water and active chemical compounds.

Characteristics of heat-resistant paints

Nowadays, specialized stores stock a wide range of heat-resistant paints and varnishes from various manufacturers, both domestic and foreign, with a large selection of decorative designs. Mentioned above are some of the most popular heat-resistant paints suitable for brick and metal stove surfaces. Now it’s worth considering their characteristics in more detail.

Rating of heat-resistant paints

| Photo | Name | Rating | Price |

| #1 | Paint "NEW TON" | 100 / 100 | |

| #2 | Enamel "Certa" | 98 / 1002 - votes | |

| #3 | "Tikkurila" | 98 / 100 | |

| #4 | Enamel KO-814 | 97 / 100 | |

| #5 | Enamel KO-168 | 95 / 100 | |

| #6 | Enamel KO-811 | 94 / 1001 - voice | |

| #7 | Enamel KO-8101 | 91 / 1001 - voice |

What would you choose or recommend?

Enamel KO-8101

Enamel KO-8101 is a paint that is produced with heat resistance of 400, 600, 800 degrees. It can be called universal, since it is suitable for application to various surfaces - it can be concrete, brick, metal - from stove elements to radiators, structures located both under the roof and in the open air.

Enamel KO-8101

For metal parts, it is recommended to choose the anti-corrosion paint composition KO-8101 - it will allow you to coat surfaces without prior preparation. After drying when heated, the paint does not emit harmful fumes, so it can be called a safe product.

The big advantage of this paint is that you can work with it even at subzero temperatures.

Thanks to its high protective qualities and variety of colors, this enamel is able to satisfy the needs of the most demanding customers. The certified technology of its manufacture allows the manufacturer to provide a guarantee for a period of 15 years.

KO-8101 paint is produced by many Russian and foreign companies, Termika, Karst and others. All manufacturers adhere to the same manufacturing technology and recipe. The only difference can be the number of colors of the composition.

This enamel was tested at the Mosstroy Research Institute for heat resistance, adhesion, waterproofing abilities and resistance to aggressive environments.

The solvents used for this paint are xylene and toluene.

The consumption of the composition for a three-layer surface coating is 120-240 g/m².

The drying period of the coating at a temperature of 150±2 °C is no more than half an hour, at 20±2 °C - no more than two hours.

This enamel can be applied by spraying using a spray gun, or manually - with a roller or brush, in 2-3 layers, with each layer drying for 0.5 to 2 hours, depending on the ambient temperature.

Prices for paint enamel KO-8101

Enamel KO-8101

Heat-resistant enamel KO-811 and KO-811K is intended for painting steel, cast iron, and titanium surfaces that can be heated to temperatures of 400 degrees. The paint is a suspension consisting of pigments dissolved in silicone varnish.

Heat-resistant enamel KO-811

This composition is most often applied by pneumatic spraying. To do this, the enamel is diluted with a stabilizer 100:6 for white paint and 100:7 for other colors. The mixing process is carried out immediately before use, and the finished composition must be used within 24 hours.

Enamel is applied to a metal surface that has been cleaned of dirt, fats, water-soluble salts and oils using acetone, solvent or other solvents. Before applying paint, the metal is wiped with a clean and dry cloth.

The solvents used for this enamel are R-5A, toluene and xylene. The paint can be diluted: KO-811 by 30-40%, KO-811K (white) by 70-80%, other colors by 40-50%.

Enamel consumption varies from 100 to 250 g/m², depending on the color.

The drying time of the painted surface at temperatures of 200, 150 and 20 degrees is no more than 2 hours.

This heat-resistant paint is produced by Termika, NPF Emal LLC and other companies.

Prices for paint enamel KO-811

Enamel KO-811

KO-168 enamel is designed for operation at temperatures up to 150 degrees, which means that during the process of painting the stove it can be used for brick surfaces and metal elements located remotely from the combustion chamber. Enamel performs not only protective, but also decorative functions, as it is produced in a variety of colors. In addition to painting the stove, this paint is used for facade work, and therefore is perfect for finishing barbecue stoves located in garden areas.

The heat resistance qualities of enamel KO-168 are not so pronounced

If the operating conditions for painted surfaces are observed, the paint will provide excellent protection for any material from which the stove is built, since the coating has hydrophobic, moisture-resistant and frost-resistant properties. In addition, the paint is highly resistant to ultraviolet rays, which means the enamel will retain its original color for a very long period.

KO-168 enamel is also a suspension consisting of pigments, fillers and targeted additives mixed with silicone varnish.

Paint consumption depends on the chosen color:

- for red and white enamel – 150 g/m²;

- for yellow – 180 g/m²;

- for blue – 140 g/m²;

- for brown, blue, light green, beige – 130 g/m²;

- for green – 120 g/m²;

- for black – 80 g/m².

KO-168 enamel is produced in ready-to-use form. If it is necessary to dilute it, toluene or xylene solvents are used.

Drying time for enamel at a temperature of 20 ± 2 °C is about a day.

If a metal surface is to be painted, it must be cleaned of various contaminants and degreased - also with xylene, solvent or acetone, and then the surface is wiped dry. Painting with this composition can be carried out at air temperatures from -30 to +40 degrees.

Prices for enamel KO-168

Enamel KO-168

Enamel KO-813 and KO-814

Enamels KO-813 and KO-814 are produced on the basis of varnishes KO-85 and KO-815, using aluminum powder PAP-1 and PAP-2. They are intended to protect metal products from various contaminants, aggressive influences and mechanical damage. These heat-resistant enamels can withstand temperatures from -50 to +500 degrees.

Heat-resistant enamel KO-814 is intended for metal elements of stoves and fireplaces

Drying time for an enamel-coated surface at temperatures from 20±5 to 150±5 degrees is about 2 hours.

Before using the enamel, it is necessary to mix the two components in certain proportions, so KO-813 should consist of 94 parts of KO-815 varnish and 6 parts of aluminum powder. KO-814 paint is mixed in proportions of 100 parts KO-85 varnish and 5 parts aluminum powder. The finished paint must be used within 8 hours from the moment of mixing.

To dilute this enamel, the same solvents are used - toluene, xylene and solvent.

Before applying paint, the surface must be prepared by cleaning it from dirt and greasy stains. Surfaces are degreased using solvents used to dilute paint.

The finished paint must be thoroughly mixed until homogeneous without sedimentary formations or lumps.

Today you can find other heat-resistant paints from domestic and foreign manufacturers, which have gained popularity due to the high quality of their products.

Prices for enamel KO-813

KO-813

Prices for enamel KO-814

KO-814

Tikkurila is a well-known Finnish company specializing in the production of a variety of paints and varnishes. The product range also includes heat-resistant varieties - black and silver.

Black heat-resistant paint "Tikkurila"

The silver version of the enamel consists of two components - varnish and aluminum powder. This composition is designed to heat up to 900 degrees, so it can be used for painting metal surfaces. The paint can be used for stoves installed inside the house and in the garden, as it withstands any influence of the external environment.

Heat-resistant black paint is designed only for surfaces heated to +400 degrees. It can be applied to the surface by spraying or manually with a brush.

Prices for heat-resistant paints "Tikkurila"

Heat-resistant paints "Tikkurila"

"Certa" is a Russian manufacturer that produces heat-resistant paint designed to protect metal surfaces, as it has pronounced anti-corrosion qualities. However, such enamel can also be used for application to other materials.

“Certa” enamel in various factory packaging

The coloring composition is able to protect both the entire structure and its individual elements from overheating, moisture and aggressive influences. It is designed for temperatures from -60 to +900 degrees. This paint is produced in cans for brush application and in 520 ml aerosol cans.

Prices for Certa enamel

Enamel "Certa"

“NEW TON” is an enamel from a Ukrainian manufacturer, which is popular on the Russian market due to the high quality and relatively inexpensive cost of its products. The paint is available in aerosol cans.

Aerosol cans of paints “NEW TON”

This heat-resistant enamel is used for metal parts of the stove and can withstand temperatures of + 600 degrees. This paint contains anti-corrosion components that will protect metal surfaces from various external influences, from rust formation and from overheating. After drying, the paint retains its elasticity and therefore does not crack or deform due to temperature changes.

Before applying this composition, the surface is degreased and dried, but it is not required to prime it before painting.

Then, the can is shaken well and the enamel is sprayed onto the surface from a distance of 250-300 mm.

The paint reveals all its capabilities after the initial heating of the coated surfaces to +200 degrees for 20-25 minutes.

Prices for paint “NEW TON”

new ton heat resistant paint

In conclusion, it must be said that due to the variety of colors of heat-resistant enamels, several shades can be used to paint the stove, which will make this structure a real decoration of the interior or garden area.

Since heat-resistant enamels are not cheap, before purchasing you should carefully study their performance characteristics and instructions for use so that you do not have to make a repeated purchase.

Rules for painting a stove

Video - Aerosol heat-resistant paints “Bosny Plus”

Paint selection

There is a large selection of dyes on the sales market that can be used to reliably protect metal from corrosion. If the water container is not made of stainless metal, then it must be painted. The recommended paints and varnishes can help solve the problem of preserving the container.

Paint for drinking water tank

Water supplies are especially in demand in settlements where there is no centralized water supply. Even if there is a well on the site, you cannot water vegetables with ice water. Therefore, using a pump, water is pumped into a barrel, where it is heated under the sun during the day, and in the evening it is ready for irrigation. To ensure that such a container does not rust and serves the owner of the site for a long time, it must be painted.

Available products for painting water tanks include the following:

- primer-enamel AntikorKhim;

- enamel EP-5116;

- primer XC-04 V;

- anti-corrosion primer-paint brand PTSV.

No less popular products:

- Alumol paint;

- acrylic urethane enamels;

- Tsinacol paint.

The latter option contains zinc in its composition and provides long-term protection against corrosion. In addition, this material is not flammable, and the product coated with it is weldable. Tsinacol paint is not afraid of exposure to different temperatures and is recommended for contact with drinking water.

Tsinacol primer paint is sold in metal buckets weighing up to twenty kilograms

Precautions must be taken when working with this material. The coating is non-toxic and can be used for painting barrels and water tanks

In any case, the paint for painting a container under water must meet sanitary and hygienic standards. The drying time of the metal directly depends on the material with which it was painted.

There is another simple way to paint the inside of a barrel or tank: the dry container is coated with inexpensive PVC paint made from polystyrene foam. Food paints are also widely used for coloring. Sanitary standards for storing water in metal tanks require coating the inside with anti-corrosion agents. It is also necessary to choose a paint for painting a tank, taking into account that such a container can be used for other household needs.

How to paint a hot water tank

A hot water container is usually used in a bathhouse, so it is necessary to protect the product from rust. If this is not done, then washing with rusty water will not be entirely pleasant. A particularly high level of corrosion is observed in ferrous metal containers. Without special treatment of the inside of the tank, it will not be possible to get rid of rust.

Before two-component enamels and high-quality paints and varnishes were invented, the surface of a barrel or tank inside was painted with the following compositions:

Aluminum powder diluted with liquid glass. As a result of painting with this composition, the tanks could withstand high temperatures of up to 700 degrees.

On the sales market these days there is a large selection of paint and varnish products that reliably protect the metal surface from corrosion:

Anticorrosive TSVES No. 2 based on zinc powder. Before starting coloring, this mixture must be filtered.

The user needs to be careful when choosing a coloring material. If at a summer cottage the quality of painting is checked by pouring water at normal temperature into a barrel, then it is better to fill a container intended for use in a bathhouse with warm, hot water

For each product recommended for treating metal against corrosion, the seller must provide a hygienic certificate.