Despite their simplicity and simplicity, cast iron grates for a stove or boiler perform several functions, each of which is very important (see Stove heating in a wooden house). Usually the grille lasts no less than the heater itself, but there are force majeure situations when replacement is required. As you know, cast iron is quite fragile and can be cracked even if dropped onto a hard surface from a height of one meter. That is, just accidentally letting go of it while standing at full height. You can find standard grate bars in the retail chain, and if they don’t fit, it’s easy to make them yourself.

What functions do grate bars perform?

The grate is a grate in the firebox of a boiler, stove or fireplace, which is built into the lower part. It performs three functions:

- solid fuel retention;

- air supply;

- ash removal.

Firewood, briquettes or coal are placed on the grates. Depending on the type of fuel, it is necessary to select the gaps between parallel elements. The grate must be strong enough to support the weight of the wood. In addition, the grate for the boiler allows air to be supplied for combustion. In this case, you can regulate the amount of air, thereby controlling the traction force. There is a special compartment under the grate where ash falls. It is closed by a door or flap. Through the door you can not only remove ash, but also regulate the air supply.

Manufacturing process

If you build iron sauna stoves with your own hands, the price of the finished structure is greatly reduced, since inexpensive metal elements are used in the work process. The aesthetic characteristics of home-made structures, of course, cannot be compared with market products, but in some situations the monetary issue comes first, and more attention is paid to quality.

Location of the firebox and ash hole.

- The rolled pipe is cut so that two parts are obtained, one of which should be 90 cm long and the other 60 cm. The first will be used as a base. As for the second piece, it will be useful for the tank.

- Two holes are made in the base pipe, which will correspond to the dimensions of the firebox and blower. Doors are made from the cut parts. Hooks, loops and other accessories are attached to them.

- Next, the grate necessary to maintain solid fuel is fixed. To do this, holes are cut in the side walls. Ears are welded to the grill itself.

- A round hole is made on the back side of the firebox for the chimney. It should be located just above the metal mesh, which serves as a hold for firewood.

- A container for stones is made on top. As for the hot water tank, it is located closer to the combustion chamber. One part is placed on the firebox, and the other part is installed on racks.

- The finished stove is installed on special legs made of metal. There should also be a sheet of iron underneath it to avoid unpleasant moments associated with the floor catching fire.

The diagram shows the location of the stones.

Grate materials and configurations

To make grates for a furnace or boiler, cast iron or heat-resistant steel is used. The first option is preferable and is used most often, since cast iron lasts almost forever. Steel, even strong steel, can burn out over time, especially if heated with coal. As is known, the combustion temperature of coal is the highest among all types of solid fuel.

The lattice can have the form:

- flat plate;

- interconnected round or profile beams;

- metal basket.

In addition, grates can be monolithic or stacked. Monolithic is a solid product of a certain size. Sometimes standard dimensions are not suitable and then they use stacked grates for a fireplace or stove, in which the main thing is to choose the length of the elements.

If you are going to install a heated floor under linoleum on a wooden floor, then only an electric one.

While it is better to make a warm floor under tiles from plastic pipes (water TP).

The grate can be movable. Such products consist of several parts that are driven manually using a special lever. There are two options for movements: translational and rotational. Thanks to the movable grate, it is possible to supply air to the stale layers of fuel, which allows you to completely burn it out. This increases the efficiency of heating equipment by several percent.

How to make grate bars with your own hands

When you buy a thick cast iron grate, you can be sure that it will last as long as your oven. But sometimes it happens that the standard dimensions of the grate are not suitable. And then you need to make it yourself. It is impossible to work with cast iron at home, so only steel can be used as a material. It would be better, of course, if it were heat-resistant, but not necessary. When using regular iron, you need to make sure that the grate is thick enough.

According to reviews, it is not worth laying heated floors under laminate, as this can damage the floor covering.

The following can be used as starting material:

- fittings;

- corner;

- thick-walled pipes of small diameter;

- steel strips.

Before making grate bars with your own hands, you need to take measurements. After this, a frame is made, onto which parallel elements will then be welded. The main thing is to choose the right distance between them. On the one hand, the ash should not clog the grate, and air could flow in sufficient quantities. On the other hand, the coals must remain in the firebox until they burn out completely. The slots occupy no more than 40% of the entire grating area.

Operating principle of the furnace

We keep the house warm according to the weather; it is convenient to heat the stove in the evening for 2-3 hours. Each stack of firewood - 3-5 logs 33 cm long is limited by the dimensions of the firebox in plan - 38x38 cm. With each firebox we burn 12-17 logs, per season 4 cubic meters, taking into account the bathhouse and waste incinerator.

The main part of the heat is accumulated in the hood, which allows you to dry wet towels and wet clothes around the clock. The reversible sleeve allows you to warm your back and quickly relieve fatigue. The stove works as follows: combustion products (smoke) make 4 turns:

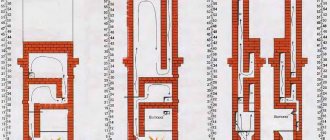

The pattern of movement (turns) of smoke is marked with numbers in circles.

1st turn - at an angle of 90 degrees from the firebox to the hood; 2nd turn - in the hood the smoke is divided into two streams and each goes around an angle of 180 degrees along the arc of the hood; 3rd - at an angle of 90 degrees - the right flow of smoke from the hood enters the reversible sleeve (short path), and the left flow, having passed under the hood (long path), also ends up in the reversible sleeve; 4th - at an angle of 90 degrees from the transfer sleeve into the pipe.

The movement of smoke in each element of the stove is different, and this is especially evident in the reversible sleeve, in its chimney, which in area (25x25 cm) is twice the size of the previous chimney of the hood. Once in the transfer hose, the smoke “rests” there - its pressure, speed, temperature drop and it is in no hurry to enter the pipe - to make the last turn.

Therefore, there is a springboard in the reversible sleeve, but that’s not all. The stable draft of the pipe is created by its heated base and the walls of the chimney. When finishing heating the pipe, leave hot coals at its base and close the door of the mini-fireplace. Now (after a long period of inactivity) you can light the stove.

The high efficiency of the stove is due to the chimney system located in the hood. The chimneys of the hood are heated on both sides, so they heat up more than the outer masonry of the hood. When the oven cools down, the hood retains heat longer than other elements, because heated from the inside by brickwork of internal chimneys. For such a benefit, as for a bed, payment is due in the form of the space occupied on the floor.

The bell-type stove occupies 16% of the room area (18 sq.m.).

The ash pan of the stove, thanks to its large height (25 cm), allows you to remove ash 1-2 times during the month; its volume (8 liters) is convenient to accumulate or immediately fertilize trees and shrubs.

When the stove returns to normal operation, the smoke from the chimney is not visible at all or is barely noticeable. Sometimes, to warm up the room a little, we only use a micro-fireplace.

During the period of operation (14 seasons), the following points in the kindling were identified:

- the most reliable thing is to split a dry aspen log a year or more old into twigs;

- If there is no dry firewood, we do the same with wet firewood and in the morning we put it in a well into a heated oven. During the day the firebox will dry out the contents, in the evening there will be kindling from one match;

- Birch bark is better suited than newspaper for burning wood - the top thin layer of wood, even wet birch;

- Chips of dry aspen are ideal for quick kindling, because it’s not for nothing that matches are made from it.

How to choose grates for the stove and install them yourself

The designs of modern furnaces are constantly being improved and modified, some elements are replaced by others. But there are functional parts that are still impossible to do without. Among them is a grate. This is a firebox element that serves to maintain firewood, coal, and fuel briquettes. Through the holes in it, the ash is poured down, and thus frees up space for a new portion of fuel. Grate bars for furnaces come in various designs and are made from different materials. How to choose and install them correctly?

Initial information

Self-made structures made of steel, when compared with their brick counterparts, are distinguished by the speed of construction and increased heat transfer. To carry out the work, it is enough to find a pipe whose diameter will be approximately 50 centimeters. Such products are especially relevant for small objects.

Requirements

Approximately the following pipe needs to be prepared.

- The heating structure must be located in a place where reliable fire protection is provided for materials subject to easy ignition.

- The area occupied by this object should not exceed 0.15 percent of the useful square footage of the heated room, since it is not very comfortable to carry out water procedures in a cramped environment.

- The side surfaces of the structure must be covered with heat-insulating materials so that the risk of burns is minimized.

- When installing, you should take care of the correct location of the stove, because the heat emanating from it should spread in different directions, thereby ensuring high-quality heating.

Basic elements

When making an iron stove for a bathhouse with your own hands, every novice craftsman must familiarize himself with the main components that make up the structure.

Any of the fragments listed below performs some function, so it is important to study all the details in full.

The structure of a sauna stove with water supply.

- The firebox is the main chamber where organic fuel is usually burned to heat the walls and then the surrounding air.

- The ash pit is located below the previous chamber, ensuring the collection of ash, which is formed as a result of the combustion of organic substances.

- The stone container allows you to lay cobblestones of jadeite, gabbro-diabase, crimson quartzite or other high-temperature resistant analogues.

- The pipe is a hollow product that is necessary to remove combustion products from the main chamber.

- The grate is an element inside the firebox that makes it possible to hold a layer of solid substance intended to produce thermal energy.

- Blower and firebox doors allow you to control the flame by covering it, which leads to a decrease or increase in oxygen inside.

- A pipe valve is usually made in the form of a control element that moves perpendicular to the working medium.

Shown is a homemade grate made from rebar.

Attention! If the building combines a washing compartment and a steam room, then the hot water tank is installed directly on the stove. However, in such a bathhouse it is also possible to have stands above the stones.

What functions do grates for furnaces perform?

This element of stove fittings allows you to achieve high-quality combustion of fuel and maintain it while the stove is burning. When one portion of firewood or coal burns out, the ash is poured out, and the top layer of fuel is shifted to the grate, where it is better blown by the air coming from the ash pit and burns more intensely. Thanks to the presence of grates, the task of drying wet fuel is simplified. The efficiency of the furnace depends on the design of the elements, and the durability depends on the material from which they are made. It is also important to install the grille correctly so that it fully performs its functions.

The quality of home heating largely depends on furnace casting

Types of grate bars: materials and most common designs

For the manufacture of stove fittings, cast iron and heat-resistant steel are most often used. The grate bars are constantly exposed to flame, so it is better to give preference to cast iron, because it is more durable.

Solid and stacked grates

Furnace fireboxes vary in size and come in different shapes, so manufacturers produce furnace castings of all possible configurations. For non-standard fireboxes, you can also find a suitable model. Grate bars can be:

- Solid. Monolithic models that cannot be disassembled. There are different standard sizes; when choosing, you should focus on the area of the firebox.

- Typesetting. Consist of separate elements. This is a kind of “constructor” that you can assemble yourself and get a grill of the desired size.

Details of typesetting structures

Types of designs

Steel grates are made of chain type (reminiscent of conveyor belts) or pipe type (cooled models made of pipes).

There are several types of cast iron:

- Tiled. These are rectangular models that are installed in solid fuel boilers, heating stoves, and fireplaces. They are universal, the main thing is to choose the right size.

- Baskets. A good option for open hearths intended for cooking, but since they are practically not used, the design is obsolete.

- Beam. They got their name because of their external resemblance to construction beams. These are stacked structures consisting of single or double elements. Well suited for assembling grates of non-standard sizes.

- Movable gratings. They are called movable because of the design features that allow you to change the size of the gaps. Grates of this type are most often chosen for long-burning stoves.

Types of grate devices

The grates separating the combustion chamber from the ash pan are classified according to the following criteria:

- material of manufacture;

- designs.

Material of manufacture. These perforated plates are made of cast iron or steel; cast iron plates are made by industrial casting; steel plates can be made independently.

For reference. Products made of cast iron (grade SCh-15 or SCh-20) are heavier, but the cast iron grate is more heat-resistant, resistant to aggressive combustion products and is therefore preferable for the stove.

Design.

The movable devices consist of several lattice fragments and an adjusting rod, with which you can change the angle of the lattice ribs relative to the vertical and thereby adjust the size of its gaps. Models of such units differ in the angle of rotation of the adjusting rod, but they are all used in long-burning heating units (not all modifications) and are difficult to manufacture in domestic conditions.

Fixed grate partitions are grates of various sizes and configurations, collapsible or solid, designed for a specific heater design. They are motionless after installation, and their parameters are unchanged.

According to their profile, fixed grates are also divided into groups:

- tile - a rectangular flat grate, with or without stiffening ribs at the bottom, used for any stoves, fireplaces and solid fuel boilers;

- collapsible beams - a prefabricated structure from individual longitudinal cast iron slats, which allows you to assemble a lattice device of any contour;

- basket is an outdated device used in open-type kitchen hearths.

Types of grates: from left to right - flat, beam (segmental), basket.

There is another type of movable grate - chain, but its design does not ensure complete combustion of solid fuel and is therefore used very rarely.

Practical advice for choosing

When choosing a specific model, consider the type of fuel you will use. For example, a design of 350 or 30x205 mm is suitable for coal, and for firewood and briquettes - from 140x120 mm to 330x252 mm. The grate must be taken in such a way that the rods can withstand the maximum possible weight of one portion of fuel. You can check with the seller how much a particular model can withstand. If in doubt, consult a specialist.

In order for the grate to be well cleaned of ash, the gaps must occupy at least 40% of the area of the entire structure. If there are fewer of them, the firebox will work less efficiently, because the amount of incoming air is not enough for intense combustion. If there is insufficient ventilation, gases may accumulate. If the area of the gaps is larger, then unburnt fuel will be poured into the gaps along with the ash.

Round grates

How to install grates for a stove with your own hands

Metals expand when heated, so grates must be installed with a minimum gap of 5 mm on all sides. In the firebox you need to cut off a ledge on which the grate is laid with its edges. In a brick oven, the location is usually chosen one brick below the firebox door. This is necessary to prevent burning coals from falling onto the floor.

During installation, it is not advisable to tightly bury the grates. Different materials expand to different degrees when heated, so too strong a fixed fixation of a metal element can result in deformation of the metal or cracks in the masonry. Having laid the grate, the grooves are tightly filled with sand without cement.

Note! If the cross-section of the grille bars is triangular, then you need to lay it with the triangles down.

This is what a properly installed grate looks like

Let's sum it up

- The best material for grates is cast iron. It is reliable and durable, it can be installed in brick and even steel ovens.

- When choosing a grate, you need to take into account the weight of the fuel and the area of the gaps. Monolithic models are easier to install, while modular models are well suited for assembling gratings of non-standard sizes.

- When installing, be sure to leave gaps for metal expansion and do not fill the grooves with cement.

If you take into account all these nuances, the new grate will last for decades, and you will not need to think about replacing it.

What is a grate?

The cast iron grate for the stove ensures the most complete combustion of fuel. The element is placed between the ash compartment and the firebox and looks like a grate. During combustion, air enters through the grate from below. The movement of the air flow - from bottom to top, allows the fuel to burn completely. And after combustion, the ash does not accumulate in the firebox, but spills through the same grate into the ash pan. At the same time, it also serves as a kind of protective layer for the grate itself, since it does not allow it to become hot. The photo shows grates.

The products perform several important functions at once:

- separate the firebox from the ash pan - the temperature in these two compartments is different;

- ensures the passage of air flows from bottom to top - draft;

- the same rising air flow dries firewood and coal;

- the entire system of the ash pan, grate and stove door allows you to regulate the fire.

Ready-made devices - Harvia, Bavaria, products from Castor, of course, are equipped with this element. And, even when it comes to a do-it-yourself design - for a bathhouse, for example, it is recommended to purchase this part. All well-known manufacturers of furnace units - Termofor, Castor - offer grates of any size for sale. It’s also quite possible to make a grate yourself, but getting the material for it – cast iron – is much more difficult to work with.

The design and principle of operation of a potbelly stove

The efficiency of a potbelly stove is largely determined by an accurate calculation of the ratio of the volume of the firebox to the diameter of the chimney. The pipe is made slightly narrower (in moderation, otherwise smoke will pour into the room), because of this, a significant part of the gases is not drawn out immediately, but first makes several revolutions inside the firebox. This promotes more complete combustion of fuel. When calculating, the following proportion is used: the diameter of the chimney in mm should be 2.7 times the volume of the firebox, measured in liters. Today, the term “potbelly stove” is used by everyone. Often this is what all steel furnaces are called. But we believe that only those stoves that have inherited the main design features and properties of the prototype are worthy of bearing the proud name “potbelly stove”. In the modern version, the potbelly stove often has a horizontal design, this is more convenient for laying full-size firewood about 40 cm long, and is also equipped with a blower and grate, which makes it easier and more accurate to regulate the air flow and fuel burning rate.

Classification of grate

Cast iron grates for stoves were and are still the best option. Steel is less resistant to this mode of operation and is not able to accumulate heat, as cast iron does. Therefore, despite the heaviness of the material, it is cast iron wood-burning stoves - Harvia, for example, and cast iron grates that are considered the best. Moreover, this applies to models both for baths and for heating living quarters.

However, this classification exists:

- steel gratings are lighter. If you know how to handle a welding machine, they can be made with your own hands - for a bath structure, for example. However, the material burns out faster because it is less resistant to chemically aggressive substances.

- Cast iron grates for sauna stoves or other structures are much more stable and, therefore, have a long service life.

Another classification of devices is related to the type of device.

- Fixed - usually a lattice with different sizes for different types of construction. This element does not change its parameters and does not move. There are several types of grating:

- tiled flat - lattice flat rectangle. This is the most popular option and is used for any wood-burning sauna stoves, solid fuel heating boilers, fireplaces, and so on. The photo shows the Harvia model.

- basket - designed for open fireboxes and originally developed for cooking. This device is no longer used, and there are almost no open fires, so the popularity of this model is not great;

- beam - in appearance they resemble a construction beam. The lattice of them is assembled with your own hands, choosing the appropriate size and quantity. This is the best method for fireboxes of non-standard sizes.

- Movable grates are extremely rare in everyday life, as they are designed for long-term heating devices. Such an element consists of several gratings and a shaft. When changing the angle, the size of the clearance also changes, which allows you to effectively regulate the heating. Based on the angle of rotation, devices are divided into swinging and full-rotating.

The chain grate belongs to the same category: its elements are connected by chains. However, in practice it is extremely rare, since it does not ensure complete combustion.

How to install a grate

To select the appropriate device, the most important are the dimensions of the grate for the stove, and not its purpose - for a bathhouse or living room. Moreover, both the dimensions of the furnace structure itself and the type of fuel are important here.

So, for coal, the grate should be more massive, since the weight of stone fuel is higher, while for wood, you can choose a lighter model.

Recommendations

The fuel material must be completely burned, and to achieve this goal, an optimal amount of oxygen must be supplied. Therefore, the total area of the distance between the grates is no more than 60% of the total area of the grate. If the distance is smaller, a small air flow will enter the stove; this will not be enough to maintain the combustion process in the combustion chamber.

If the distance between the grates is large, the fuel material will fall without having time to burn out. This will lead to an increase in combustion consumables.

The cast iron grate for the stove provides good traction and is used for burning wood, coal and fuel briquettes. Cast iron still occupies a leading position in the manufacture of grates. Since it is least susceptible to deformation at high temperatures.

Types of grates for a fireplace or stove

For the manufacture of grate bars, various materials and various designs can be used. In most cases, heat-resistant steel or cast iron is used.

The fact is that the grates are continuously exposed to fire and therefore it is better to choose cast iron . since it has a high strength index. There are two types of grate :

The furnace firebox can have different sizes and shapes, so furnace casting manufacturers make all sorts of configurations . For a firebox with non-standard dimensions, you can also easily select a suitable model . Solid types include monolithic types without the possibility of disassembly. The choice of sizes is quite wide, so the main reference point is the firebox area. The basis of typesetting models is made up of several individual elements. This is something like a constructor . which you can assemble with your own hands and get the desired grille size.

Steel grates for a type-setting stove have the form of a conveyor belt and are called chain grates, and models with the possibility of cooling and made from pipes with your own hands are called pipe grates.

Cast iron grates can be of several types:

basket Ideal for an open hearth . The main purpose is cooking, but today they are used extremely rarely, since the design is morally outdated;

Tools

You only need cutting tools: grinder, jigsaw, knife. All work is carried out manually and does not require special equipment.

Installation diagram

There are several types of chimneys; the most suitable type of design is selected individually.

Installation methods

It is important to take into account the collection of condensate in the system, so it is necessary to have a plug, a condensate drain and a container for collecting condensate. If the potbelly stove is installed through a wall from a pipeline located on the street, then it would be advisable to lead the chimney through a window so that you do not have to prepare a hole for the pipeline in the ceiling

If the potbelly stove is installed through a wall from a pipeline located on the street, then it would be advisable to lead the chimney through a window so that you do not have to prepare a hole for the pipeline in the ceiling.

The outer part of the chimney is insulated using thermal insulation and covered with protective material. A fungus is installed at the end of the pipe, which will protect the chimney from debris, rain, various small animals and foreign objects.

Floor preparation

The chimney pipe for a potbelly stove is most often installed in such a way that it passes through the ceiling, therefore, before installing and fixing the pipeline structure, it is necessary to make a hole for it in the ceiling: using a jigsaw or other cutting tool, having a diameter suitable for the passage of a glass for elbows of the internal chimney.

Example of a hole for a chimney pipe

Pass-through glass

The passage glass is installed in the hole before the chimney for the potbelly stove is assembled. The diameter of the glass should be selected according to the diameter of the inner pipe, although sometimes the joint is made before the chimney passes through the ceiling

It should be understood that it is important to secure the glass tightly - it serves as a retainer. But in addition to this, the pipeline must also be attached to the wall surface

If installed incorrectly, the following consequences may occur:

If there are easily flammable materials, insulation or wooden parts in the ceiling, then they must be removed so that they do not come into contact with the passage glass.

Once the pipe has been inserted, the whole thing needs to be sealed with a fire-resistant material, such as heat-resistant sealant or special fire-resistant wool.

The following stages of work are shown in the photo:

Sealing

Pipe outlet to the roof

Roof work

At the last stage you need to put a deflector on the pipe

Tips for working

- The pipes used in the structure are located exclusively in a vertical position; to fix them, it is best to use special brackets with dimensions corresponding to the elbows of the system. To save money, you can make the brackets yourself using a metal corner.

- All connections must be treated with sealant so that there are no holes through which smoke can escape into the room air. There is a large selection of sealants on the market that are suitable for sealing pipeline seams for smoke exit:

- High temperature sealants;

- Heat-resistant sealants;

- Heat-resistant sealants;

- Heat-resistant sealants;

High temperature and heat resistant sealants are used to seal areas that reach temperatures of 350 degrees Celsius. Since the chimney for a potbelly stove heats up to higher temperatures, these types of sealants are only suitable for parts outside the piping system.

Heat-resistant and heat-resistant polymers can withstand enormous temperatures, up to 1500 degrees Celsius - they are the most suitable choice for a potbelly stove chimney.

Choosing the right grates

To choose a specific model, you need to consider the type of fuel. which is planned to be used most often . For example, for coal, a design with dimensions of 350-300x205 mm . for briquettes or firewood, it is better to determine the size frame 140x120 - 330x252 mm. The grate must be selected in such a way that it can support the maximum weight of a single load of fuel .

To determine the maximum weight, it is best to seek advice from a qualified dealer. To avoid problems with cleaning ash, the gaps should be at least 40% of the area of the overall structure .

If the specified proportions are not observed, the installation of the furnace will not be as effective, due to the fact that the volume of supplied air will be insufficient for the combustion intensity . In addition, insufficient ventilation can lead to the accumulation of gases, which should not be allowed under any circumstances. If the area of the gaps is made larger, then unburned fuel residues .

Do-it-yourself grate installation

Metals tend to expand when heated. It is for this reason that when installing grates for a fireplace or potbelly stove, it is necessary to make gaps on all sides of at least 5 mm. The ledge on which the grating will be laid must be trimmed .

For brick fireplace models, the cooled grates should be located one brick below the firebox door. This is necessary to prevent coals from falling onto the floor. Different degrees of heating affect all metals differently, precisely for this reason, in the case of monolithic fixation of elements . deformation or cracks in the masonry are possible.

After laying the grating with your own hands, the grooves are filled with sand without cement. If the base of the lattice is made up of triangular-shaped rods, the top should be directed downwards .

Drawing conclusions

The optimal choice of grate for a fireplace or potbelly stove is cast iron, as it is durable and has a large margin of safety. Another advantage is the possibility of installation in metal and brick ovens . The main criterion when choosing a grate type is the area of the gaps and the mass of the fuel to be installed .

Installation of monolithic models is somewhat simpler, while stacked models are the best choice for gratings with non-standard dimensions. When installing, be sure to leave gaps for the possibility of metal expansion .

Similar articles:

Adhesive for stoves and fireplaces Doors for stoves and fireplaces

The use of heat-resistant adhesive for lining fireplaces and stoves Cast iron hobs for stoves

The grate for the stove, like the combustion chamber, chimneys and flue pipes, valves, views and other sections and parts, have changed little since the invention of wood-burning stoves. Stove grates, or grates, are necessary to separate the combustion and ash chambers, but must allow air to pass through to the place where the wood is burned, so the grate is always grated. Grate bars are located at the very epicenter of combustion, work under extreme conditions of thermal loads, and the material of the grate bars for furnaces must match and withstand all external factors. Even for a small homemade stove, craftsmen use factory grates that will not let you down and will work for a long time. The size, shape and price of the grates depend on the stove model and the type of fuel.

Chimney maintenance

First of all, good care of the smoke exhaust pipe from a potbelly stove ensures the safety of people and property in the room.

It also provides an equally important property - good heat transfer from the chimney and draft. And in order for the chimney to faithfully serve the entire period allotted to it, a visual inspection of the chimney pipe must be carried out at least once every six months. There should be no traces of burning or corrosion on the metal, it should not burn out, crack or rust

There should be no traces of burning or corrosion on the metal; it should not burn out, crack or rust.

The presence of one of these defects is a signal of the need to urgently replace the damaged area: smoke will flow into the room through the cracks, which, at a minimum, will negatively affect the health of the people in it. In addition, by burning and cracking in certain places, the metal of the chimney can weaken, and the entire pipe will soon simply collapse.

Traditional cleaning methods will come in handy here - you can use the method of cleaning the chimney with potato skins. An original, but dangerous method of raising the temperature to the maximum so that the soot burns and flies out is strictly prohibited: high temperatures not only contribute to rapid wear of thin metal, but can also easily cause a fire.

A potbelly stove is the best option for those who need a portable and convenient stove

And the only problem - the construction of a chimney - is no longer a problem! It turns out that making a high-quality and efficient chimney for a potbelly stove is quite easy; it is only important to follow the technology. A finished chimney does not require special attention, only regular but rare care, for which it will repay with years of good work! In order for the potbelly stove to always have good draft and to avoid smoke in the room, it is necessary to carry out preventive measures that will help keep the chimney in order

In order for the potbelly stove to always have good draft and to avoid smoke in the room, it is necessary to carry out preventive measures that will help keep the chimney in order.

Any chimney requires periodic preventative maintenance:

In order to keep the pipe clean from soot deposits, it is necessary to periodically add chemicals specifically designed to loosen carbon deposits to the wood being burned. Aspen firewood is also used for the same purposes, which helps clean the internal walls. To clean the pipe with their help, only aspen firewood is used for preventive combustion. It is advisable that they do not burn out quickly, but smolder for as long as possible in the firebox. To create such conditions, the draft is artificially reduced by closing the ash pit after the wood has burned well. The pipes are mechanically cleaned annually to remove carbon deposits and rust. To do this, you can use a special cleaning brush with a weight.

After each cleaning, be sure to inspect the surface, carefully lowering the switched-on light bulb into the chimney. This is necessary to detect burnouts or cracks in time.

Since any chimney must be extremely reliable, and all segments must perfectly match each other when joined to seal them, it is recommended to install parts manufactured exclusively at a professional level. It must be remembered that the entry of carbon monoxide into a room from poorly sealed seams or burnt holes is, without exaggeration, a mortal danger.

Tags: potbelly stove, dacha, chimney

Installing a grate in a furnace

The grate is installed when installing a stove and fireplace, but if it is necessary to repair or replace the grate in the unit, you must first understand the reasons for the damage to the grate, or its displacement, or fall. The seat for the grate must provide not only mechanical retention of the grate, but also thermal clearances to compensate for the linear expansion of the part. The size of 0.5 cm around the entire perimeter of the grate is minimal, but it will protect both the brickwork from damage due to expansion of the metal of the grate, and the grate itself from deformation when heated. Brick and metal have too different coefficients of linear thermal expansion, and compensation clearance is required. The brick frame - a row under the grate - is cut together to form a corner. This simplifies the installation of the grate, and if necessary, disassembly and replacement of the grate. Cleaning the grates is also simplified.

Dry sand or a sand-clay mixture is poured into the gap between the grating metal and the brick, but cement and mortars with cement binder are never used for this purpose. Asbestos cords are used for contour laying, sealing the fastening and not interfering with thermal expansion. According to the rules for constructing stoves and fireplaces with open fireboxes, grates must be mounted in a plane under the firebox doors through a row of bricks to prevent burning fuel from falling out when the stove doors are opened. The grate bars are laid on only one side, and it is unacceptable to confuse the sides - many grate models have narrowing cross sections, this is clearly visible: triangular or trapezoidal grate levels should look with their tapering sides down towards the ash chamber.

The dimensions of the grate are standard, and furnace designs are drawn up based on these settings. If the furnace is complex, non-standard and a similar grate is required, then it is assembled from beam elements or small modular grates. The best material for grates is gray cast iron, followed by steel. The choice depends on the type of fuel, and even the range of cast iron grates is divided into wood or coal stove models. It’s easier to mount a monolithic slab grate, but the stacked version not only gives you more options, but according to stove makers, it will last longer. And repairing stacked grates is easier and cheaper, because sometimes you only need to replace one cracked bridge, but in a monolithic version this is impossible without replacing the entire grate.

Self-manufacturing of steel grates is possible, although the service life of such a part is unlikely to be long. But when taking into account the cost of high-quality cast iron grates, there is a point in such work - the master can always make a new steel grate and replace it, this will be much more economical than purchasing a ready-made model.

“>

Specifications

There are many types of stoves, varying in size, type of fuel used, and other characteristics. Therefore, the grate for them will also be different. As for the material of the stove itself, it does not directly affect the choice. Grates are installed in brick, steel, and cast iron devices.

Type of design

There are gratings:

- monolithic;

- typesetting;

- refrigerated.

Monolithic are solid structures. Dimensions are selected depending on the depth and width of the combustion chamber.

Available to fit all standard firebox sizes. This option is the easiest to install.

The typesetting version is made up of individual rod elements. It is used if a standard one cannot be selected, for example, in non-factory-made ovens.

Important! Often the rods are wedge-shaped. When installing, they are positioned with the narrower part down

This increases service life.

Cooled ones are used in systems with heat exchangers. They are made of tubes through which coolant passes. Thus, the grate itself is cooled, and the overall efficiency increases. This option is more often used in solid fuel boilers. The temperature inside the chamber reaches 1000°C. Thanks to cooling, the material can withstand a similar thermal load.

Form

The grate bars differ in the shape of the canvas. Different types are used in different designs. The following types of gratings are available:

- flat;

- basket;

- movable;

- beam

Photo 1. Basket grate made of cast iron. This type of device is usually installed in fireplaces.

Flat (or tiled) - the most common type. They are installed not only in stoves, but also in boilers that burn solid fuel, as well as in fireplaces. They have a rectangular shape. The dimensions are standard, selected depending on the dimensions of the fuel chamber.

Baskets have curved edges, which is why the whole structure resembles a basket. Such structures are placed in open-type ovens intended for cooking. Since such stoves are rare nowadays, and the parts for them are also not very common.

Movable grates are installed in long-burning furnaces, where it is necessary to regulate the air flow. The design allows for the possibility of changing the width of the gaps. They have several sections and a shaft, thanks to which movement occurs. Rotation axes can be horizontal or vertical. An additional advantage is greater ease of cleaning.

Beams consist of individual crossbars (beams), which can be single or double. They are typically used in non-standard sized ovens.

Size

The dimensions of the product depend on two parameters:

- dimensions of the furnace combustion chamber;

- type of fuel used.

In equipment operating on wood, peat and fuel briquettes, a width of 150-350 mm (in increments of 50 mm) is most often used.

The depth is usually 180 or 250 mm. The largest possible dimensions of standard models are 900x800 mm.

When coal burns, more harmful substances are formed. Therefore, the dimensions of the grille should be larger, from 300-350 mm on both sides.

In any case, gaps of at least 5 mm are left at the edges. They serve to compensate for expansion when heated.

Attention! When choosing a size, the weight of one load of fuel is also taken into account. Dimensions, especially thickness, are selected in such a way as to withstand this load