A cast iron stove or hob is a product that combines the functions of heating a room and a hob.

Due to the properties of cast iron, the stove has inertial heat transfer, i.e., when the surface cools slowly, the room is evenly heated. Cast iron grade SCh 15–20, from which the slabs are cast, is a combination of 2% carbon with iron. Thanks to its composition, it has such qualities as strength and fire resistance. The addition of impurities in the form of phosphorus, sulfur, silicon and manganese further enhances the physical and chemical properties of the material. Therefore, a stove cast from cast iron is not subject to temperature changes and can maintain its integrity throughout the entire period of operation.

Any product made of gray cast iron is initially protected from corrosion, since a layer of rust covers it immediately after pouring.

Important points in the correct operation of stoves:

- Cast iron stoves are designed to work on household stoves that burn solid fuel.

- Before installing the slabs in the furnace surface, it is necessary to leave thermal gaps of 2 mm on each side in advance.

- After installing the stove, gradually warm it up to 640 °C over 8 hours, increasing by 70–80 °C per hour. Having reached the desired temperature, the furnace is cooled until the fuel is completely burned out. This procedure has a beneficial effect on the future operation of the furnace, preventing distortion and cracks.

- During storage of the stove, a layer of rust may appear on it, which quickly disappears when the stove is used.

- It is very important to prevent moisture from getting on the hot surface of the stove.

- Protect the stove from mechanical damage and shock loads during transportation or during operation.

Types of cast iron decking

The hob for a cast iron stove can be produced in two types: prefabricated and solid. The differences between these types are insignificant, because both perform their main functions: heating and cooking.

Prefabricated slabs

These structures consist of a sheet of cast iron and several round parts of different types. Cast iron stove rings fit into each other like a puzzle. Due to the fact that the surfaces have gaps, the metal does not deform under the influence of high temperatures.

And the different diameters of the rings allow you to cook food in different dishes as quickly as possible. After all, to heat a large pan of water, you can use a circle with the largest diameter, and it is more convenient to place an iron mug on the smallest part.

Solid slabs

A cast iron sheet for a stove with a solid surface or burners of standard diameter belongs to the category of solid decks. Due to the integrity of the structure, they do not have any gaps for the narrowing and expansion of the metal.

This feature reduces the practicality and durability of such products. But they also have their advantages. Easy installation and relatively low price due to the simplified design are liked by many buyers.

Which is better - steel or cast iron?

The hob for the stove is made of cast iron or metal. Which product has more advantages: cast iron or steel stove plate?

There are a huge number of manufacturers of these products who insist on the advantages of cast iron over steel.

Advantages of cast iron decking:

- strength and durability. A cast iron stove will reliably serve you for decades.

- heat dissipation Due to the presence of certain chemicals in the cast iron used for casting sheets, it has better physical characteristics compared to steel.

- resistance to deformation and corrosion.

- resistance to temperature changes. Due to this, the cast iron hob for the stove retains its original appearance throughout its entire use.

Some manufacturers focus on some other advantages of cast iron compared to steel: cast iron does not dry out the air as much. You don't have to use humidifiers or other devices to maintain indoor humidity.

The main advantages of steel plates are:

- fast heating. In just a couple of minutes the surface heats up to the desired temperature. But such a stove cools down much faster than a cast iron one.

- light weight. Typically, steel plates weigh ten times less than cast iron. This allows for quick installation without much effort. But due to their low weight, such products are able to withstand a small load. If you will be using fairly heavy cookware, it is better to give preference to a cast iron stove.

- low cost. Prices for cast iron stove stoves are higher than for steel stoves. But their service life is much longer.

Conclusion: If your budget allows, use a cast iron surface, it will last longer. If your budget is limited, buy a steel plate.

Using stones for cast iron stoves

Stove stones are used not only as a decorative element, but also as an important component of the stove. The cast iron product is perfect for use in a bathhouse. Everyone probably knows that the most important component in a steam room is high-quality stones. They must withstand the entire load that falls on them in the steam room. The most important function that stones should have is the ability to quickly heat up and cool down. It is not surprising, but under such conditions the stones often deteriorate and they have to be constantly replaced. Thus, the selection of such an attribute as stones must be approached with full responsibility.

Please note: low-quality stones not only become unusable, they can also harm the structure of the stove itself and human health. Firstly, if the stone is of poor quality, it will become unusable and ruin the stove. Secondly, some stones, with a sharp temperature change, can release radioactive substances, which in turn will cause irreparable harm to human health. Thirdly, during heating, stones can crack to such an extent that fragments are scattered in different directions. This will also harm human health.

Based on the above, we can conclude that in order to always have a favorable temperature in the steam room, so that nothing threatens a person and so that the stove space does not become clogged, you need to use stones with a homogeneous structure, durable and without chemical compounds. Remember that heating stones is a chemical process that is accompanied by complex chemical reactions.

For an example of a high-quality stone, let's take basalt. This natural stone is highly durable and retains heat in its structure. Temperature changes are absolutely not dangerous for basalt. In most cases, this stone is used. An important point is that stones for stoves must be certified. The certificate is a guarantee of the quality of this material. This stone is also often used in construction for additional thermal insulation of a room. When heated, it does not emit any dangerous gases or other substances, but is only capable of emitting infrared radiation. This is due to the volcanic origin of the stone.

Basalt practically does not absorb liquid and steam, which is why its use in steam rooms is so popular. It repels liquid, turning it into vapor. As for the price of this stone, it can be noted that of all the types of stone used for baths, this type is the cheapest.

How to choose?

Choosing a cast iron deck for your stove is not difficult. To buy a quality product, the installation of which will not require much effort, it is enough to take into account several nuances.

What are the sizes of cast iron sheets?

Cast iron sheets can be square or rectangular. The most popular are rectangular slabs. The surface dimensions directly depend on the size of the oven.

The standard dimensions of a cast iron stove for a stove are:

- 34 by 41 cm,

- 71 by 41 cm,

- 66 by 41 cm,

- 51 by 34 cm.

For a non-standard stove, you can order the service of manufacturing a cast iron sheet with individual parameters in a specialized store. But it will cost significantly more than standard products.

Number of burners in different models

Typically ovens have two burners. But their number can vary from one to six (it all depends on the surface area). Solid cast iron sheets may have no holes at all. But the cooking time on this type of stove can be long due to the slow heating of the cookware.

Other criteria for choosing a quality product

You should pay attention to the quality and composition of the material from which the stove is made. If you find chips, scratches and other various defects on the surface, then it is better to refuse the purchase. A high-quality product has a smooth surface and its weight is quite large. There are no lightweight cast iron stoves.

It is worth taking the time to study the composition of cast iron. Cast iron, which is used for smelting, is a combination of 2% carbon with iron. But if it contains any components unknown to you, be sure to ask the seller about them. After all, some chemical elements are not environmentally friendly and can harm your health.

Advantages of cast iron

Cast iron provides the product with inertial heat transfer, which means that slow cooling of the surface contributes to uniform heating of the room. Cooking decks are cast from SCh 15-20 cast iron (carbon combined with iron), which is famous for its strength and fire resistance.

Phosphorus, sulfur, silicon and manganese added to the composition enhance the chemical and physical properties. That is why cast iron structures are not subject to temperature changes and remain intact for quite a long time of operation. In addition, any cast iron structures will not be subject to corrosion due to the rusty layer covering them.

Installing a stove on a stove with your own hands

The installation process should begin by studying this issue on specialized sites, and only then start working.

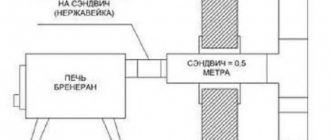

For a brick oven

Installing a cooktop on a brick oven requires some effort. How to properly install a stove on a brick oven?

The following recommendations should be followed:

- There is no need to embed the slab end-to-end. You need to leave a gap of 5 millimeters around the perimeter of the panel. After all, when heated, cast iron tends to expand, and thanks to this installation, the brick oven will not collapse.

1 - During installation, you can use a solution of clay and asbestos.

2

3

4 - A level should be used to lay the slab. This way the cast iron flooring will lie perfectly flat.

- The largest burner in diameter should be installed above the firebox.

- For structural strength, the top row of bricks must be equipped with a piece or angle of steel.

- To increase the strength of cast iron, the first lighting should be done as follows: heat the stove for a long time (7-8 hours). Every hour the temperature should rise by about 70 degrees. Use small logs for the fire, then you can throw in larger ones. After this, the oven should be allowed to cool naturally. This procedure is the key to successful and long-term operation of the entire furnace.

5

Metal

Installing a cast iron surface on a metal stove has the same steps. But it should be taken into account that the cast iron stove has quite a lot of weight.

The steel structure may not withstand it. It is necessary to strengthen the stove additionally: with a corner made of cast iron or other stable metal.

DIY stove installation kit

Start by preparing all the necessary masonry equipment.

- brick. Buy simple and fire-resistant masonry material. To accurately determine the required amount of brick, first prepare the order of the future furnace;

- clay. Based on it, you will prepare a mortar for laying the stove;

- metal doors and other fittings;

- sheet metal;

- corners;

- mesh or reinforcement bars to strengthen the structure;

- tires;

- lime;

- container for preparing the solution;

- metal sieve with cells 1-2 mm;

- plumb line;

- building level;

- hammer;

- Master OK;

- shovel;

- cast iron stove with burners.

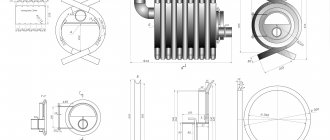

Overview of cast iron decking

The most popular are Finnish models. But domestic production also produces decent and high-quality goods.

- Pilsa (HTT) Plate 3A. Material: cast iron. Black color. Size: 985 x 650. Diameter of burners: Ø 32, 393 mm. Weight: 51 kg. Price – from 49 thousand rubles.

- 2-burner stove “Russian casting”. Cast iron stove 710x410. Weight: 25.08 kg. Price – from 3000 rub.

- 2-burner stove "R". "Furnace casting Russia". Cast iron stove for oven 700 cm by 400 cm. Weight: 25 kg. Price from 3 thousand rubles.

- Cast iron stove for cauldron H2521 “HALMAT stove casting”. Dimensions: 505×455. Weight: 21 kg. Price from 15,000 rub.

- PLATE 5A SVT 301. Manufacturer: SVT. Dimensions: 460 x 700. Price 0t 17,000 rub.

Instructions for use and care

Careful handling of the product will increase its service life.

- The correct first firebox is the key to the durability of the flooring. It is necessary to gradually light the firebox (shavings and small logs first) and allow it to cool for several hours.

- Mechanical damage should be excluded: chips, scratches.

- Rust may appear during storage of the stove. You should not rip it off or try to remove it in other ways. It will disappear during use.

- Do not overload the device.

- It is necessary to ensure that moisture does not fall on the heated flooring.

With proper use and proper care, your stove will last for many years.

Conclusion

A cast iron stove stove is an excellent option for cooking and heating the room. A large selection of these products will satisfy even the most fastidious buyer.

Cast iron material is characterized by heat resistance, durability, and ease of use. A high-quality cast iron stove will serve you reliably for several decades.

But its purchase should be made in a specialized store. Experienced consultants will help you choose between a prefabricated or solid slab, and will also select the right size at an affordable price.

Attention must be paid to the quality, absence of defects and weight of the product. You can even install this flooring yourself. To do this, it is worth considering only a few nuances.

When melted and used, cast iron decking will remain in its original condition throughout its entire use. It will become not only a functional item, but also a decoration for your interior.

Masonry mortar

A high-quality and correctly prepared mixture is a guarantee of reliable service for the future solid fuel stove. Earlier in the article it was discussed that it is customary to use sand and clay as materials for mortar. The components must be mixed to the desired consistency.

The kneading method is not particularly complicated. The clay is soaked in water and then ground through a sieve to achieve uniformity. Sand is added to this composition in the required quantity. To ensure that the stove heats the room effectively, only high-quality materials are used. If you do not follow this and do not follow the cooking technology, you can get low heat transfer and a number of other problems. In particular, the stove may be extremely short-lived and collapse after some time.

After preparing the mortar, we proceed to masonry work. At this stage we will need to arrange the oven.