Designing your own heating system is far from easy. Even if the installers “plan” it, you need to be aware of many nuances. Firstly, to monitor their work, and secondly, to assess the need and feasibility of their proposals. For example, in recent years, hydraulic arrows for heating have been intensively promoted. This is a small addition, the installation of which costs a considerable amount. In some cases it is very useful, in others you can easily do without it.

Hydraulic separator - purpose

A hydraulic separator also known as anuloid , also known as a hydraulic arrow , or a thermostatic separator, is designed for hydraulic separation of two circuits of coolant movement in heating systems.

Just an example. The house has a heating boiler with a flow rate of 30 l/min. The heating system flow rate is calculated as 100 l/min. In order not to “strain” the boiler up to 100 liters, create two loops for the boiler and for heating, which are separated by an anuloid (separator).

What it is

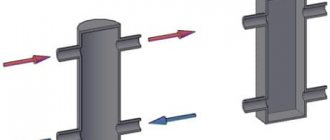

For those who are faced with the need to properly distribute coolant throughout the system when there are several pumps for different consumers, a natural question arises about what a hydraulic pump is. Externally, this device is a metal vertical container in the form of a large pipe with several side pipes of smaller diameter. There are also two tubes at the base and top. The top one is designed to bleed off accumulated air, the bottom one is to remove sediment.

In addition to proper distribution of the coolant, the device ensures equalization of its heating parameters on the forward and return paths in the heating main. Such a mechanism can work optimally only if it fully complies with the characteristics of the heating system. Therefore, ideally, the hydraulic arrow should be designed and selected according to the parameters of volume, number and location of insertion of pipes in each specific case individually.

Hydraulic gun action diagram Source ytimg.com

However, in practice this requirement is rarely met. Often, universal models are installed into the system, which are widely available today - which, naturally, cannot but negatively affect the subsequent operation of the equipment.

The hydraulic arrow inside may contain a number of additional devices:

- Flow dividers.

- Filters for cleaning mechanical impurities.

- Dissolved air compartments.

In practice, not all of them are beneficial. For example, screens for cleaning solid particles quickly become clogged and first reduce the flow rate, and then completely make the system impassable.

Note! The hydraulic separator tank is made of pipes of both round and rectangular cross-section. However, round models are more effective, natural and in demand.

Design of a classic heating circuit separator

There is nothing complicated about the design of a hydraulic separator. Essentially, it is a cylindrical or rectangular chamber with four pipes leading to it.

The hot coolant moves through the upper pipes, the cooled coolant through the lower pipes.

Operating principle of hydraulic separator

Two physical processes from two branches of physics take place in a hydraulic separator. Hydraulics helps to understand how water moves in the separator, and thermal engineering helps to understand how cold and hot flows mix in the separator.

Let's start with hydraulics. We have two coolant flow circuits. Circuit K1 (heating boiler circuit) and circuit K2 (heating system circuit) to ensure the movement of coolant, a circulation pump is installed in each circuit. It is customary to install pumps on cold branches of circuits. Although installing pumps on hot branches increases the speed of movement of the coolant due to the low viscosity of the hot liquid.

So, two dynamically independent flows of circuits K1 and K2 move in the hydraulic arrow. The speed of movement of these flows should not exceed 0.1 m/sec. Let me explain why.

A low coolant flow rate in the hydraulic separator is needed for four reasons:

- At low fluid speeds, sand, sludge and other water debris settle in the separator.

- At low speed, the cold coolant moves down and the hot coolant rises. This natural circulation allows the creation of temperature gradients in heating loops. It is possible to obtain a heating circuit with an increased or decreased temperature. Typically, a lower temperature is created by a separator in a heated floor system, and an increased temperature in an indirect heating circuit with a boiler.

- You can make a mixing unit from a hydraulic arrow. This is useful if the house has one heating circuit. By reducing the diameter of the separator, you will increase the speed of water movement and the temperatures of both loops (boiler and heating) will be equalized. This significantly saves material and reduces costs.

- The low speed of water in the separator removes air from the water, which is not needed in the heating system. The air is discharged through an automatic vent.

Subtotal

A hydraulic separator allows you to separate two coolant circuits of different flow rates. The circulation pumps in both circuits and the diameter of the separator are selected such that the speed of the coolant in the separator does not exceed 0.1 m/sec.

Buy or make it yourself?

As they said, a ready-made hydraulic arrow for heating costs a lot - $200-300 depending on the manufacturer. To reduce costs, there is a natural desire to do it yourself. If you know how to cook, no problem - we bought the materials and did it. But the following points must be taken into account:

- The thread on the bends should be well cut and symmetrical.

- The walls of the outlets are of the same thickness.

The quality of a homemade product may not be “very good.”

It seems like obvious things. But you will be surprised how difficult it is to find four normal fittings with normally made threads. Further, all welds must be of high quality - the system will work under pressure. The bends are welded strictly perpendicular to the surface, at the required distance. In general, this is not such an easy task.

If you don’t know how to use a welding machine yourself, you’ll have to look for a contractor. It’s not at all easy to find: either they charge a lot for the services, or the quality of the work is, to put it mildly, “not very good.” In general, many people decide to buy a hydraulic gun, despite the considerable cost. Moreover, recently, domestic manufacturers are making no worse, but much cheaper.

Hydraulic separator - how it works

The separator divides the heating system into at least two parts. One loop relates to the heating boiler, the second loop connects the heating wiring of the house. A circulation pump is installed in each loop.

How the separator works

We have two heating loops (circuits). Loop K1 with pump N1 and loop K2 with pump N2. The flow rate in loop K1 is equal to W1, and the flow rate in loop K2 is equal to W2.

- If W1=W2, then the circuits are mixed in the circuit separator, forming a single heating system, without separation along circuits;

- If W1

- If W1>W2, then the coolant moves from top to bottom.

Pump N1 creates a flow rate in the first loop equal to W1. Pump N2 creates a flow rate in the second loop equal to W2.

Alternative operating modes of the hydraulic gun

Despite the fact that the correct principle of operation of the hydraulic arrow is only the method described above, it must be taken into account that it is technically possible to use an alternative.

One of them is when the boiler operates in a balanced manner, giving off as much heat as it goes to the return. But this condition is similar to a spherical horse in a vacuum, since complete identity of the values of Q1 (boiler circuit) and Q2 (consumer circuit) is achieved extremely rarely and for a very short period of time. So it is impossible to seriously build work on this regime.

The second operating mode of the hydraulic gun is dangerous and should be avoided at all costs.

It is based on the fact that the boiler gives off less heat than is required by the consumer, and in this case, part of the heat from the return flow through the hydraulic separator goes back into the consumption circuit, which does not benefit either the system or the consumers.

The disadvantages are obvious - the return to the boiler comes with reduced temperature values, that is, the boiler actually cools down when receiving the return coolant, which is prohibited by all standards, GOSTs and even common sense, since the final power supplied to the consumption circuit becomes less and the desired result is not is achieved.

Hydraulic separator dimensions

The height of the hydraulic separator can be any. Depends on the installation location. The minimum diameter of the hydraulic separator is determined by the formula:

According to the formula, everything is very simple:

- Speed of liquid movement in the separator: 0.1 m/s;

- Flow W is the difference between the boiler circuit and the heating system circuit. We calculate costs based on the maximum flow rates of the pumps according to the passport.

Example.

- Boiler circuit flow 30 l/min;

- Heating circuit flow 80 l/min.

- Flow difference W: 80-30=50 l/min.

- Pi = 3.14;

- Speed V=0.1 meter\second.

We count:

50 liters÷60 seconds=0.833 l/sec;

- 1 liter=0.001 m3;

- 0.833 liters/sec=0.000833 cubic meters/sec;

- D=0.102 measures=102 mm.

So, we found that the diameter of the separator should not be less than 102 mm .

Video description

Video about the hydraulic separator and its purpose:

The calculation is carried out in the following several ways:

- Maximum coolant flow rate.

Calculated by the formula:

D = 3*d*√Mp/Vd

D is the diameter of the hydraulic needle, d is the diameter of the nozzle, MP is the maximum flow for the boiler, Vd is the maximum speed (0.2 m/s).

For example:

7*3*√8/02 = 21*√40 = 21*6.32 = 132.8 cm – 133 cm – diameter of the hydraulic needle.

The diameter of the pipe is 7 cm, the boiler flow rate is 8 cubic meters per hour.

- Highest boiler power.

The calculation is carried out using a similar formula:

D = 3*d*√Mk/(Vd * Traz)

However, some replacement parameters appear in it:

Mk – maximum boiler power, for example 60 kW,

Traz – the difference in heating of the coolant in the supply and return flows, for example 15 degrees.

For example:

21*√60/(02 * 15) = 21*4.4 = 94 cm.

- The length of the body of the hydraulic needle itself. The length of the device depends on the diameter and location of the pipes. Below is a diagram for calculating the characteristics. In the first version it will be equal to 12 diameters, in the second - 13.

Scheme for calculating the length of the hydraulic arrow according to the location of the pipes Source stroychik.ru

Advice! When calculating the parameters of a hydraulic arrow, it is important to determine the maximum possible coolant speed. If the flow moves quickly enough, a characteristic noise will arise in the system, significantly reducing the comfort in the house. Therefore, in order to avoid this negative effect, this parameter is limited to a value not exceeding 0.2 m/s.

Calculation of hydraulic separator

There are two types of dividers; they are clearly visible in the photo. But the calculation is the same for them.

As you can see, all calculations are tied to strict compliance of the separator design with the diameter value d .

Additional features and myths

There is an opinion that the design of the hydraulic gun also allows you to perform the following tasks:

- Boiler protection against thermal shock

- Increasing the durability of the heating system

- Increases the efficiency factor (efficiency) of the boiler

However, independent experts claim that these are just fairy tales to increase sales.

At the same time, there are still additional options, such as additional protection from dirt, air removal, and protection of the boiler from return flow with a low temperature.

But these functions can be provided by much cheaper devices.

Rotations in editing

When installing dividers, and indeed the entire heating system in general, there is a golden rule: the fewer turns, the better. In conclusion, I will give an example of how to get rid of unnecessary “elbows” in the installation of a hydraulic separator.

©Obotoplenii.ru

Other articles in the Heating installation section

- Heating system pumps: types and methods of installation of heating circulation pumps

- Home heating: where to choose home heating

- Flushing the heating system: methods for flushing heating

- Marking of circulation pumps for heating systems

- Methods for laying heating pipes

- Heating system with solid fuel boiler for houses over 25 kW

- Methods of heating a private house: choosing how to heat the house

Do you need a hydraulic gun?

In pursuit of additional benefits, many sellers, managers and even production workers are ready to tell anything if it helps sell the product. So various miracle hoses, incredibly reliable boilers and so on appear.

But the real scope for scammers to operate is in goods about which the consumer knows little. I heard something about its benefits, but I don’t know what they are.

One of these devices, surrounded by a lot of legends and rumors, is a hydraulic gun. The device is necessary, but for a very specific task, everything else is marketing and profanity.