When several pumps operate simultaneously in the heating system of a private house for different consumers, it is necessary to ensure uniform distribution of the coolant. For this purpose, a special hydraulic separator is connected to the boiler equipment. Let's look at what a hydraulic arrow for heating is, what is its purpose, design, principle of operation, in what modes it can operate, how to correctly calculate its parameters and what are the features of its connection.

Modern boiler room with hydraulic switch Source san-kras.ru

Hydraulic arrow for heating - device, drawings, compresses

For normal operation of the heating system connected to solid fuel and gas boilers, it is necessary to install equipment that increases its reliability and performance.

A hydraulic arrow for heating makes it possible to simultaneously connect low-temperature and high-temperature circuits. The task of a hydraulic separator is not only to level the difference in temperature and pressure. Additional functions: protection of the heating system from corrosion, removal of debris, etc.

Why do you need a hydraulic arrow in a heating system?

Hydraulic arrow, bottle, hydraulic separator - all these names refer to a simple device necessary for complex heating systems. Professional installers point to four reasons why you should connect the module.

Installation of a hydraulic arrow in the heating system is necessary for:

Is it possible to do without a hydraulic arrow?

Of course, a simple heating system will theoretically work without a hydraulic arrow. Problems will begin if several water heating circuits are connected to one boiler, but this difficulty can also be solved by installing a collector. Also other functions: removing air from the system, filtering solid particles, are easily performed by the safety group installed for solid fuel boilers.

A hydraulic separator in a home heating system is needed to balance the difference in temperature and pressure in the supply and return pipelines. You cannot do without the module when connecting a radiator heating system and heated floors to the boiler.

The difference between a hydraulic arrow and a manifold

The manifold, despite popular misconception, does not replace the hydraulic arrow and has distinctive functions. The main purpose of the collector is to separate and transport the coolant to the final (secondary) heating circuits.

A flow of heated liquid enters the collector from the boiler. Inside the device, the coolant is divided into outlets connected to each individual heating system. Additionally, the collector allows you to disconnect and repair individual circuits without turning off the heating of the house.

The hydraulic arrow should be used in cases where the temperature of the coolant in the supply and return pipelines is expected to be very different. If you do not put a separator, the following happens:

Number of connections on the hydraulic switch

Classic circuit design determines the supply of four pipelines to the hydraulic separator structure. This inevitably raises the question of the possibility of increasing the number of inputs/outputs. In principle, such a constructive approach is not excluded. However, the efficiency of the circuit decreases with increasing number of inputs/outputs.

Let's consider a possible option with a large number of pipes, in contrast to the classics, and analyze the operation of the hydraulic separation system for such installation conditions.

Scheme of a multi-channel heat flow distribution separator. This option allows you to service larger systems, but if the number of pipes increases beyond four, the efficiency of the system as a whole decreases sharply

In this case, heat flow Q1 is completely absorbed by heat flow Q2 for the state of the system when the flow rate for these flows is actually equivalent:

Q1=Q2.

In the same state of the system, heat flow Q3 in temperature value is approximately equal to the average values of Tav. flowing through the return lines (Q6, Q7, Q8). At the same time, there is a slight temperature difference in the lines with Q3 and Q4.

If the heat flow Q1 becomes equal in thermal component Q2 + Q3, the distribution of temperature pressure is noted in the following relationship:

T1=T2, T4=T5,

whereas

T3= T1+T5/2.

If the heat flow Q1 becomes equal to the sum of the heat of all other flows Q2, Q3, Q4, in this state all four temperature pressures are equalized (T1=T2=T3=T4).

Multi-channel separation system with four inputs/four outputs, quite often used in practice. For servicing private heating systems, this solution is quite satisfactory in terms of technological parameters and stabilization of boiler operation

In this state of affairs on multi-channel systems (more than four), the following factors are noted that have a negative impact on the operation of the device as a whole:

- natural convection inside the hydraulic separator is reduced;

- the effect of natural mixing of supply and return is reduced;

- the overall efficiency of the system tends to zero.

It turns out that a departure from the classical scheme with an increase in the number of outlet pipes almost completely eliminates the working properties that a gyro shooter should have.

Operating principle of hydraulic separator

The hydraulic separator is a simple and at the same time effective device. To understand how the system works after installing the module, all processes are divided into several stages:

The above method is used in vertical dividers. In the case of a horizontal heating device or combined use with vertical modules, the operating principle is somewhat different:

How to choose the right hydraulic gun

The correct choice of hydraulic valve ensures smooth operation of the boiler, no overheating of the coolant and comfortable heating of the premises. When choosing a suitable separator, several factors are taken into account:

Traditionally, dividers were made of stainless steel. Metal is distinguished by its light weight and ability to resist oxidation and rust, despite the quality of the coolant used. Modern hydraulic separators are made from polypropylene. The housing is cheaper, has no welds, is easier to install and is neutral to aggressive liquids: antifreeze and antifreeze.

How to calculate a hydraulic arrow

It is better to leave the calculation of the hydraulic arrow for heating to a specialist. As practice shows, independent calculations without the appropriate engineering skills are often performed with errors that affect the performance of the system.

There are several formulas for calculating the hydraulic arrow:

The formula for calculating the hydraulic needle requires knowledge of the following indicators:

The calculation method using special formulas gives an accurate result, but requires certain qualifications of the person doing the calculations. The selection of a hydraulic arrow for a heating system takes into account one more factor: the number of outlets.

There is a rule of three diameters: the distance between the pipes is made greater or less than their triple diameter. With a pipe with a cross-section of 50 mm, adjacent branches are made no closer than 150 mm. The hydraulic arrow has 3 circuits, so it will be at least 500 mm. Separator for 4 circuits from 700 mm long. Such proportions ensure the highest quality mixing of the coolant.

Which hydraulic gun to choose

When making a hydraulic gun yourself, it is extremely difficult to achieve the same performance as factory products. If possible, it is better to choose a separator from one of the following brands:

The proposed hydraulic arrows are optimized for the operation and configuration of most European and domestic boilers. Manufacturers in the technical documentation indicate criteria that facilitate the selection of suitable equipment.

Hydraulic flow separation

The hydraulic arrow for heating is more often called a hydraulic separator. From this it becomes clear that this system is intended for implementation in heating circuits.

In heating, it is assumed that several circuits are used, for example, such as:

- lines with groups of radiators;

- underfloor heating system;

- hot water supply through a boiler.

In the absence of a hydraulic arrow for such a heating system, you will either have to make a carefully calculated design for each circuit, or equip each circuit with an individual circulation pump.

But even in these cases there is no complete certainty of achieving the optimal balance.

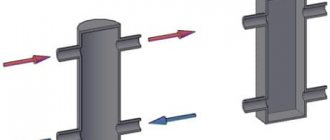

The classic design of hydraulic separators made on the basis of round or rectangular pipes can be considered approximately this way. A simple but effective solution that radically changes the state of the heating system involving the boiler

Meanwhile, the problem is solved simply. You just need to use a hydraulic separator in the circuit - a hydraulic arrow. Thus, all circuits included in the system will be optimally separated without the risk of hydraulic losses in each of them.

Hydroarrow – the name is “everyday”. The correct name corresponds to the definition – “hydraulic separator”. From a constructive point of view, the device looks like a piece of an ordinary hollow pipe (round, rectangular cross-section).

Both end sections of the pipe are plugged with metal plates, and on different sides of the body there are inlet/outlet pipes (a pair on each side).

The natural appearance of the products is hydraulic switches made from rectangular and round pipes. Both options show high efficiency. However, hydraulic guns based on round pipes are still considered a more preferable option

Traditionally, the completion of installation work on the heating system is the beginning of the next process - testing. The created plumbing design is filled with water (T = 5 – 15°C), after which the heating boiler is started.

Until the coolant is heated to the required temperature (set by the boiler program), the water flow is “spinned” by the primary circuit circulation pump. Circulation pumps of secondary circuits are not connected. The coolant is directed along the hydraulic arrow from the hot side to the cold side (Q1 > Q2).

If the coolant reaches the set temperature, the secondary circuits of the heating system are activated. The coolant flows of the main and secondary circuits are equalized. In such conditions, the hydraulic arrow functions only as a filter and air vent (Q1 = Q2).

Functional diagram of the operation of a classic hydraulic switch for three different boiler operating modes. The diagram clearly indicates the distribution of heat flows for each individual operating mode of boiler equipment

If any part (for example, a heated floor circuit) of the heating system reaches a predetermined heating point, the selection of coolant by the secondary circuit temporarily stops. The circulation pump is turned off automatically, and the water flow is directed through the hydraulic arrow from the cold side to the hot side (Q1 < Q2).

How to properly connect a hydraulic separator

The simplest diagram for connecting a water gun in a heating system is as follows:

What are the pros and cons of using a hydraulic separator?

Despite popular opinion, a hydraulic separator is an essential condition for long-term and uninterrupted operation of a heating system with several circuits. One of the main features and functions of the device is leveling pressure between circuits.

The operation of a hydraulic separator in a system with natural circulation is theoretically possible, but loses its meaning. The main application is for closed-type wiring with forced movement of coolant.

Advantages of a hydraulic arrow in a heating system

Installing a hydraulic separator solves several heating system problems:

Disadvantages of a hydraulic boom

At the same time, the existing typical separator manufacturing scheme shows that, in essence, it is a simple device that does not have complex functionality with minimal importance in the heating system. It is not surprising that quite a few domestic consumers refuse to purchase branded devices in favor of making homemade analogues.

There are several reasons in favor of purchasing a hydraulic separator: this is a requirement for warranty service for some boiler models; a multi-circuit heating system of a complex type will not work without a separator.

Source

Briefly about the main thing

A hydraulic separator for heating is a metal closed container with pipes mounted in front of the boiler. Designed for optimal distribution of coolant between consumers, as well as regulation of the heating level between forward and reverse flows in heating systems with forced circulation and at least 2 pumps. The need to install the device arises when the following consumers are simultaneously present:

- Separate radiator lines.

- Water heated floor system.

- Boiler operating on a heating boiler.

- Warm water ventilation.

The device is also needed to smooth out the effects of temperature changes on the cast iron heat exchanger. In this case, the hydraulic arrow can operate in three modes - in equilibrium, with insufficient power of the heating circuit and its superiority over the consumer. The last option is the most optimal. Before installation, the device must be calculated in terms of throughput, diameter and length, depending on the diameter and location of the connected pipes.

What is a hydraulic arrow (hydraulic separator) in a heating system

Designing your own heating system is far from easy. Even if the installers “plan” it, you need to be aware of many nuances. Firstly, to monitor their work, and secondly, to assess the need and feasibility of their proposals. For example, in recent years, hydraulic arrows for heating have been intensively promoted. This is a small addition, the installation of which costs a considerable amount. In some cases it is very useful, in others you can easily do without it.

What is a hydraulic arrow and where is it installed?

The correct name for this device is a hydraulic arrow or hydraulic separator. It is a piece of round or square pipe with welded pipes. There is usually nothing inside. In some cases there may be two grids. One (above) for better “discharge” of air bubbles, the second (bottom) for screening out contaminants.

Examples of industrial hydraulic arrows

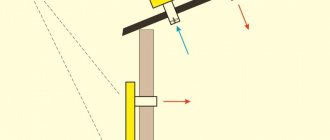

In the heating system, the hydraulic arrow is placed between the boiler and consumers - heating circuits. It can be positioned both horizontally and vertically. Most often they are placed vertically. With this arrangement, an automatic air vent is installed at the top, and a shut-off valve at the bottom. Some of the water with accumulated dirt is periodically drained through the tap.

Where is the hydraulic separator installed in the heating system?

That is, it turns out that a vertically installed hydraulic separator, at the same time as its main functions, removes air and makes it possible to remove sludge.

Purpose and principle of operation

A hydraulic arrow is needed for branched systems in which several pumps are installed. It provides the required coolant flow for all pumps, regardless of their performance. That is, in other words, it serves for hydraulic decoupling of the heating system pumps. That’s why this device is also called a hydraulic separator or hydraulic separator.

Schematic representation of the hydraulic arrow and its place in the heating system

A hydraulic arrow is installed if the system has several pumps: one on the boiler circuit, the rest on the heating circuits (radiators, water floor heating, indirect heating boiler). For correct operation, their performance is selected so that the boiler pump can pump a little more coolant (10-20%) than is required for the rest of the system.

Why do you need a hydraulic arrow for heating? Let's look at an example. In a heating system with several pumps, they often have different capacities. It often turns out that one pump is many times more powerful. All pumps have to be installed nearby - in the manifold unit, where they are hydraulically connected. When the powerful pump turns on at full power, all other circuits are left without coolant. This happens all the time. To avoid such situations, they install a hydraulic arrow in the heating system. The second way is to spread the pumps over a long distance.

Operating modes

Theoretically, three modes of operation of a heating system with a hydraulic arrow are possible. They are shown in the figure below. The first is when the boiler pump pumps exactly the same amount of coolant as required by the entire heating system. This is an ideal situation that occurs very rarely in real life. Let's explain why. Modern heating adjusts its operation according to the temperature of the coolant or the temperature in the room. Let's imagine that everything was calculated perfectly, the valves were tightened, and after adjustment, equality was achieved. But after some time, the operating parameters of the boiler or one of the heating circuits will change. The equipment will adapt to the situation, and the equality of productivity will be violated. So this mode can last a matter of minutes (or even less).

Possible operating modes of a heating system with a hydraulic separator

The second mode of operation of the hydraulic switch is when the flow rate of the heating circuits is greater than the power of the boiler pump (middle picture). This situation is dangerous for the system and should not be allowed to happen. This is possible if the pumps are selected incorrectly. Or rather, the boiler pump has too low a capacity. In this case, to ensure the required flow rate, coolant from the return line will be supplied to the circuits along with the heated coolant from the boiler. That is, at the boiler outlet, for example, 80°C, into the circuit after mixing cold water, for example, 65°C (the actual temperature depends on the flow deficit). After passing through the heating devices, the temperature of the coolant drops by 20-25°C. That is, the temperature of the coolant supplied to the boiler will be, at best, 45°C. If we compare it with the output temperature - 80°C, then the temperature delta is too high for a conventional boiler (not a condensing boiler). This mode of operation is not normal and the boiler will quickly fail.

The third operating mode is when the boiler pump supplies more heated coolant than the heating circuits require (right figure). In this case, part of the heated coolant is returned back to the boiler. As a result, the temperature of the incoming coolant rises, and it operates in a gentle mode. This is the normal operating mode of a heating system with a hydraulic arrow.

When is a hydraulic arrow needed?

A hydraulic arrow for heating is 100% needed if the system will have several boilers operating in a cascade. Moreover, they must work simultaneously (at least most of the time). Here, for correct operation, a hydraulic separator is the best solution.

If there are two simultaneously operating boilers (in cascade), a hydraulic arrow is the best option

Another hydraulic arrow for heating can be useful for boilers with a cast iron heat exchanger. Warm and cold water are constantly mixed in the hydraulic separator tank. This reduces the temperature delta at the boiler outlet and inlet. This is a blessing for a cast iron heat exchanger. But a bypass with a three-way adjustable valve will cope with the same task and will cost much less. So even for cast iron boilers located in small heating systems, with approximately the same flow rate, it is quite possible to do without connecting a hydraulic arrow.

When can I deliver

If the heating system has only one pump - on the boiler, a hydraulic arrow is not needed at all. You can get by if one or two pumps are installed per circuit. Such a system can be balanced using control valves. When is the installation of a hydraulic arrow justified? When the following conditions exist:

In the first case, a hydraulic decoupling is most likely needed, in the second, it is worth thinking about installing it. Why just think? Because these are significant expenses. And it’s not just the cost of the hydraulic gun. It costs about $300. You will have to install additional equipment. At a minimum, you need manifolds at the inlet and outlet, pumps for each circuit (with a small system, you can do without them), as well as a pump speed control unit, since they can no longer be controlled through the boiler. Combined with the installation fee for the equipment, this “add-on” amounts to approximately two thousand dollars. Quite a lot indeed.

Why then install this equipment? Because with a hydraulic arrow, heating works more stable and does not require constant adjustment of the coolant flow in the circuits. If you ask the owners of cottages whose heating is made without a hydraulic separator, they will tell you that they often have to reconfigure the system - turn the valves, adjusting the flow of coolant in the circuits. This is typical if different heating elements are used. For example, there is a heated floor on the ground floor, radiators on two floors, heated utility rooms in which it is necessary to maintain a minimum temperature (garage, for example). If you expect to have approximately the same system, but the prospect of “adjustment” does not suit you, you can install a hydraulic arrow for heating. If it is available, each circuit receives as much coolant as it requires at the moment and does not in any way depend on the operating parameters of nearby pumps in other circuits.

Device, principle of operation, purpose

A complete understanding of what a hydraulic arrow for heating is, why it is needed, what its varieties are, can be obtained by considering its detailed structure, principles of operation and purpose. Let's look at these aspects in more detail.

An example of a heating scheme for a private house with a hydraulic arrow Source project-home.ru

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Device

Structurally, the hydraulic separator is a hollow container of round or square cross-section closed at the ends. Its dimensions depend primarily on the power of the boiler, as well as the number and capacity of the circuits. Depending on the weight, the structure is either installed on the floor using support legs, or mounted on the wall surface using a special bracket.

Working pipes, the number of which, as a rule, is at least 4, are connected to the heat pipe via threads or using flanges. The material used to make the device is very different - ordinary steel with low carbon content, stainless alloy, copper, and polypropylene. At the same time, systems operating on a solid fuel unit are equipped only with metal models.

Although the vertical position of the device is considered traditional, it is not mandatory. For example, when eliminating air pockets and filtering sediment from the coolant is not a necessary condition, a horizontal arrangement of the device is possible. In this case, the need for convection mixing of flows is eliminated.

Hydraulic separator device Source vodoteplo.ru

Principle of operation

Uniform distribution of the coolant in the presence of several consumers at the same time is ensured by a hydraulic arrow for heating - the operating principle of such a mechanism is based on dividing the total flow into independent directions for each individual circuit. If the circulation pump of boiler equipment accelerates water to 1 m/s, then in the hydraulic separator it slows down to a minimum of 0.1 m/s. In this case, several conditions are simultaneously met:

- The volume and direction of flow changes.

- Loss of thermal energy is eliminated.

- Hydraulic resistance is eliminated.

- The contours of the unit and the chain of consumers are separated - the hydraulic arrow acts as a buffer area.

- The pumping equipment for each circuit operates independently without affecting the overall hydraulic balance.

When several pumps are installed in the system, then a hydraulic separator for heating is connected, the operating principle of which is to ensure the correct operation of each circuit separately:

- Separate branches with radiators.

- Water heated floor.

- Indirectly heated boiler.

- Warm ventilation, etc.

Diagram of a hydraulic separator Source teplo.guru

As an example, we can consider a situation where several pumps are used that differ greatly in power. As a rule, all equipment is located in one room, the collector module. Turning on the most powerful pump will cause the pumping of all the coolant and deprivation of the remaining circuits. A simplified way to solve this problem is to install a hydraulic separator. Without it, all the pumps would have to be placed at a great distance from each other.

How to select parameters

The hydraulic separator is selected taking into account the maximum possible coolant flow rate. The fact is that at high speeds of liquid movement through the pipes, it begins to make noise. To avoid this effect, the maximum speed is assumed to be 0.2 m/s.

Parameters required for the hydraulic separator

By maximum coolant flow

To calculate the diameter of the hydraulic arrow using this method, the only thing you need to know is the maximum coolant flow that is possible in the system and the diameter of the pipes. With pipes everything is simple - you know which pipe you will use for wiring. We know the maximum flow that the boiler can provide (it is in the technical specifications), and the flow rate through the circuits depends on their size/volume and is determined when selecting circuit pumps. The flow rate for all circuits is added up and compared with the power of the boiler pump. A large value is substituted into the formula to calculate the volume of the hydraulic needle.

Formula for calculating the diameter of a hydraulic separator for a heating system depending on the maximum coolant flow

Let's give an example. Let the maximum flow rate in the system be 7.6 cubic meters/hour. The permissible maximum speed is taken as standard - 0.2 m/s, the diameter of the pipes is 6.3 cm (2.5 inch pipes). In this case we get: 18.9 * √ 7.6/0.2 = 18.9 * √38 = 18.9 * 6.16 = 116.424 mm. If we round, we find that the diameter of the hydraulic needle should be 116 mm.

According to the maximum boiler power

The second method is to select a hydraulic needle according to the boiler power. The estimate will be approximate, but it can be trusted. The boiler power and the difference in coolant temperatures in the supply and return pipelines will be needed.

Calculation of hydraulic arrow according to boiler power

The calculation is also simple. Let the maximum boiler power be 50 kW, the temperature delta be 10°C, the diameters of the pipes be the same - 6.3 cm. Substituting the numbers, we get - 18.9 * √ 50 / 0.2 * 10 = 18.9 * √ 25 = 18.9*5 = 94.5 mm. Rounding, we get the diameter of the hydraulic needle 95 mm.

How to find the length of the hydraulic arrow

We have decided on the diameter of the hydraulic separator for heating, but we also need to know the length. It is selected depending on the diameter of the connected pipes. There are two types of hydraulic arrows for heating - with taps located one opposite the other and with alternating pipes (located offset from one another).

Determining the length of the hydraulic arrow from a round pipe

It is easy to calculate the length in this case - in the first case it is 12d, in the second - 13d. For medium-sized systems, you can select the diameter depending on the pipes - 3*d. As you can see, nothing complicated. You can calculate it yourself.

Hydraulic arrows

The correct name for this device is a hydraulic separator; in modern heating systems it is mounted between the boiler and heating circuits both horizontally and vertically. When installed vertically, there is usually an automatic air vent at the top and a shut-off valve at the bottom to remove accumulated dirt and sludge.

Benefits of use

Do you need a hydraulic gun?

The principle of operation of the hydraulic arrow

Calculation of hydraulic arrow

How to make a hydraulic arrow?

Hydraulic manifolds

Simply put, the main purpose of this device is hydraulic flow separation. It makes the heating circuits dynamically independent when transferring the movement of the coolant, but at the same time transfers heat well from one circuit to another. Hence another name for the hydraulic arrow - hydraulic separator.

First, let's define it - why do we need a hydraulic gun?

- In order to obtain, with a low coolant flow rate in the boiler circuit, a high flow rate in the second circuit , for example, in the radiator circuit. Let’s say there is a boiler with a flow rate of 50 liters per minute, and the heating system turns out to have twice the flow rate - 100 liters per minute. In this case, it is not economically feasible to accelerate the boiler circuit to a flow rate greater than that provided by the manufacturer, because the hydraulic resistance will increase, which will either not provide the required flow rate, or will increase the load on the circulation pump and, accordingly, additional energy costs.

- A hydraulic arrow is needed to eliminate the hydrodynamic influence of the circuits on each other and on the overall hydrodynamic balance of the entire heating system. For example, if you have heated floors, radiator heating and a hot water supply circuit (indirect heating boiler), then it makes sense to divide these flows into separate circuits so that they do not influence each other.

- The absence of hydrodynamic influence in the hydraulic arrow between circuits is when the movement (speed and flow) of the coolant in the hydraulic arrow is not transmitted from one circuit to another. Hydraulic arrows (they are also often called hydraulic separators, hydraulic separators) are usually used in heating systems consisting of several consumers with their own special circulation and temperature conditions. For example: the system consists of an indirect heating boiler, a main heating circuit, heated floors, there are two or more boilers in the system, etc.

- Their main purpose: removing unnecessary loads from circulation pumps, preventing heat strokes, and ultimately saving money.

Advantages of using hydraulic arrows

The selection of circulation pumps is

greatly . Correct selection of pumps for a complex heating system is not an easy task: primary (boiler circuit) pumps may not provide the required performance, for example: a primary circuit circulation pump has a lower performance than secondary (heating) circuit pumps. Hydroarrow will provide you with cost savings . In systems without a hydraulic separator, low-power pumps will expend a lot of energy to overcome the influence of larger pumps, the influence of additional circuits can cause the pumps to operate in suboptimal or abnormal conditions. As a result, the pumps may fail. Due to the elimination of mutual influence of pumps, the operating mode and durability of boiler equipment are improved . The heating system operates most of the time under conditions far from the design ones that were used in the design. For example, the use of flow control devices in zone heating systems leads to imbalance. The use of hydraulic arrows ensures the hydraulic system stability and balance . Water arrows help avoid parasitic flows created by other operating pumps, due to which heating radiators can heat up even when the pumps are stopped. Protect the heat exchanger from thermal shock : when any circuits from the heating system are disconnected, a small coolant flow occurs in the boiler, which leads to a sharp increase in temperature in the boiler and the subsequent arrival of very cooled coolant. The hydraulic arrow helps maintain a constant boiler flow rate, which reduces the temperature difference between the supply and return pipelines. Commercially available hydraulic separators can be used as effective sludge and air removers from the system .

Is a hydraulic arrow necessary or not in a particular case?

System without hydraulic separator

To decide whether a hydraulic arrow is needed for your heating system, you will have to answer several questions.

- If your heating system is built on several boilers, for example a floor-standing gas boiler and a wall-mounted one, connected to a common heating system, then yes, a hydraulic separator is needed.

- Another example: You decided to install two boilers, gas and electric (or solid fuel and electric), so that they work in pairs for one heating system. The electric boiler was chosen as an “insurance” boiler in case of lack of power of the main one. Answer: necessary. Each boiler has its own pump, and so that they do not conflict with each other, they must be hydraulically separated.

- If you have a complex heating system, for example, an indirect heating boiler, a heated floor, a circuit of heating radiators with its own circulation pumps are used simultaneously, then yes, a hydraulic arrow is needed.

- It can be said more simply: if you have one boiler, and more than one consumer (radiators, heated floors and also, say, an indirect heating boiler), a hydraulic arrow will have to be installed: it will ensure minimal resistance to circulation through the boiler with different or minimal heat dissipation at the collector.

- Is a hydraulic arrow (hydraulic separator) needed for a wall-mounted double-circuit boiler if it simply heats some radiators, and hot water is taken from the second circuit? Answer: not needed.

- Is a hydraulic arrow necessary when using a solid fuel boiler? Answer: yes, it is necessary. And the larger the volume, the better. And for what? To equalize temperature fluctuations for the heating system! A solid fuel boiler can produce very unpleasant temperature surges for the system.

Hydraulic separator system

Operating principle of the hydraulic switch (hydraulic separator)

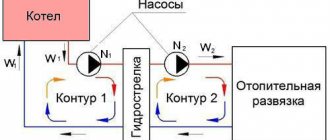

Figure 1

Circulation pump H1 creates coolant circulation through the hydraulic arrow along the first circuit, and pump H2 circulates through the second circuit. Those. The coolant is mixed in the hydraulic arrow. But if the flow rate Q1 = Q2, then mutual penetration of the coolant from circuit to circuit occurs, thereby creating one common circuit. In this case, vertical movement in the hydraulic arrow does not occur. In cases where Q1>Q2, the coolant movement in the hydraulic arrow occurs from top to bottom and vice versa, in cases where Q1 < Q2, the coolant movement in the hydraulic arrow occurs from bottom to top.

In general, if your system operates at high temperatures (over 70 degrees Celsius), then circulation pumps should be installed in the return pipeline. If you have low-temperature heating of 40-50 °C, then it is better to put them on supply, since the hot coolant has less hydraulic resistance and the pump will consume less energy.

Calculation of hydraulic arrow

To calculate the diameter of the hydraulic needle, you need to know:

- Flow of the primary circuit (boiler circuit, indicated in Fig. 1 as Circuit 1)

- Flow of the second circuit (heating decoupling circuit, designated as Circuit 2 in Fig. 1)

- The maximum vertical speed of the coolant in the hydraulic arrow.

When calculating the hydraulic arrow, it is important to obtain a slow vertical movement in the hydraulic arrow: no more than 0.1 - 0.2 meters per second. A low coolant velocity in the hydraulic separator is needed in order to:

- allow suspended particles of sand, sludge, etc. to settle.

- to allow the cold coolant to go down and the hot coolant to rush up to obtain the required temperature pressure. For example, for a heated floor you can get a secondary heating circuit with a lower coolant temperature, and for an indirect heating boiler you can get a higher coolant temperature that can intercept the maximum temperature drop.

- reduce hydraulic resistance in the hydraulic arrow.

- separate air bubbles from the coolant and remove them through an automatic air remover.

To calculate the parameters of the hydraulic arrow yourself, you need to calculate its diameter and assemble it according to one of the methods in the figure.

The diameter of the hydraulic needle is calculated using one of the formulas (observe the dimensions!)

| Formula for calculating the diameter of the hydraulic arrow (option 1) D - internal diameter of the hydraulic arrow (in meters) Q - water flow (m3/sec) V - coolant flow rate (m/sec) |

| Formula for calculating the diameter of the hydraulic arrow (option 2) D - internal diameter of the hydraulic arrow (in millimeters) Q - water flow (m3/hour) V - coolant flow rate (m/sec) |

For example, let's calculate the diameter of the hydraulic needle using the first formula: In Fig. 1, the flow rate of the primary circuit will be the maximum flow rate of pump H1. Let's take 40 liters per minute. The flow rate of the secondary circuit will be the maximum flow rate of pump H2. Let's take 120 liters per minute. Then the flow rate in the hydraulic arrow is equal to: Q = Q2 - Q1 = 120 - 40 = 80 liters/min (or 80: 1000: 60 = 0.001333 m3/sec) n - constant. n = 3.14 The maximum vertical velocity of the coolant in a hydraulic arrow is usually taken equal to 0.1 - 0.2 m/sec. Let's take V = 0.1 m/sec. Substituting the values into the formula we get: D = √(4x0.001333):3.14:0.1 = 0.130 meters If we use the second formula, then the flow rate must be recalculated in m3/hour: 80: 1000: 60 = 0.001333 m3/sec = 0.00133 x 3600 m3/hour = 4.7988 m3/hour D = 18.811 x √(4.7988:0.1) = 130 mm.

How to make a hydraulic arrow yourself?

And you think - is it worth doing? After all, if you have found funds for a complex heating system, the installation and equipment of which cost quite a lot of money, is it worth bothering with it (in terms of manufacturing)? Isn't it easier to buy ready-made? In addition, ready-made hydraulic guns have a high-quality factory anti-corrosion coating, are equipped with such useful devices as sludge separators, have insulation, etc.

Hydraulic manifolds (boiler manifolds)

One of the ways to install a high-quality heating system or hot water supply system is collector wiring . The simplicity, speed and ease of installation of such a system, as well as the comfort of further operation, lead to its increasingly frequent use. The use of CALEFFI collectors, assembled collector cabinets and additional accessories allows you to assemble a system of great reliability and a high degree of comfort.

What is a boiler manifold for?

Boiler manifolds (combs, hydraulic manifolds) are used to uniformly distribute coolant flows along the contours of the heating system or along “threads”, as well as to simplify the installation of boiler room piping systems. To correctly design your comb, the designer makes a hydraulic calculation. For example, your house has 2 floors, there is a bathhouse, heated floors, and a hot water supply system (DHW). Each of these heat consumers needs its own temperature regulation. What to do if the boiler has only one input (return line) and one output (supply). In this case, we install a boiler manifold (the main separator of heating circuits), in our example we install a 4-output manifold + boiler. Depending on the heating system chosen by the designer, one of the main elements in the boiler room is selected - the distribution comb or, in other words, the boiler manifold. Today you can find many options for boiler manifolds in stores and on the market, but often their standard size does not match the specific project of your boiler room. In such cases, you can consider various options with combining several collectors into one large one, trimming or plugging unnecessary threads, etc. The heating system should not be confusing , but logical and easy for anyone to understand, and it is the boiler manifold in an emergency that will help the owner of the house (an inexperienced housewife, an emergency service engineer, etc.) understand what and how to quickly turn off, and not have to figure out diagram of your pipelines for hours.

Our specialists will help you select and install a hydraulic arrow and find an acceptable solution at a price. You will be satisfied by cooperating with us!

Buy or make it yourself?

As they said, a ready-made hydraulic arrow for heating costs a lot - $200-300 depending on the manufacturer. To reduce costs, there is a natural desire to do it yourself. If you know how to cook, no problem - we bought the materials and did it. But the following points must be taken into account:

It seems like obvious things. But you will be surprised how difficult it is to find four normal fittings with normally made threads. Further, all welds must be of high quality - the system will work under pressure. The bends are welded strictly perpendicular to the surface, at the required distance. In general, this is not such an easy task.

If you don’t know how to use a welding machine yourself, you’ll have to look for a contractor. It’s not at all easy to find: either they charge a lot for the services, or the quality of the work is, to put it mildly, “not very good.” In general, many people decide to buy a hydraulic gun, despite the considerable cost. Moreover, recently, domestic manufacturers are making no worse, but much cheaper.

Source

Heating comb, distribution manifold.

If we present this wiring in its simplest form, then:

This is a pipeline closed at one end and with several outgoing pipes connected to heating devices.

The number of outgoing pipes depends on the conditions of use and the number of radiators. Thanks to the comb, the fluid flow in the pipes is optimized. It also smoothes out pressure drops in the system. The manifold distributor is used in radial distribution due to the presence of separate coolant outlet and supply pipes for each battery. It is this device that ensures uniform heating of the radiators and the possibility of their separate adjustment. In addition to the above advantages, the collector allows you to include additional equipment into the overall system. designs. (for example: pool heating).

Heating distribution manifold

Summarizing the above, we can highlight the following positive aspects of the distribution manifold:

1. Thanks to the design features, uniform heating of the radiators is ensured. It is also possible to adjust the temperature in each individual room. 2. The entire heating network will be protected from water hammer, which will affect its service life. 3. Possibility of installing additional devices to increase its functionality.

There are also two types of collectors based on their operating principle. There are combs for boiler rooms and local ones.

Heating distribution manifold with circulation pump

The hydraulic arrow serves to completely replace the cooled coolant with a hot one.

Specifications

After a comprehensive calculation of the heat loss of buildings has been made and the required power for heating the hot water supply and other consumers who do not take part in the process of heating the room has been determined, it is necessary to determine the required power of the heating boiler. This power corresponds to certain values of the input characteristics of the difference and temperatures in the base coolant circuit.

Domestic distribution manifolds and hydraulic separators do not generate thermal energy, but only transfer coolants. Consequently, the total power of the hydraulic separator and the distribution manifold of domestic production is a relative temperature value for individual heating systems. The use of the Proxytherm distribution manifold makes it possible to comprehensively reduce the total financial costs when creating a local heating circuit in a single organization.

Heating manifold with hydraulic arrow.

There are two types of collector circuits:

The second option has much greater functionality and serves to create different temperature conditions in each individual circuit (for example: radiators - from 45 to 65 degrees; warm water floor - from 30 to 45 degrees; tap water about 80 degrees). In such a scheme, an important element is used - a hydraulic arrow.

Hydraulic gun in the “comb”

The hydraulic arrow is a piece of pipe closed on both sides and 2 pairs of pipes connected to it. The first two pipes connect this element to the boiler. A couple of other pipes are connected to the combs.

The main function of the hydraulic arrow is to create a hydraulic obstacle.

Mixing units with 3-way valves that regulate temperature are installed on the distribution manifold. A separate outlet pipe has its own pump, which ensures the required temperature conditions for this circuit.

If you install a network without additional pumps and hydraulic arrows, the temperature of all radiators will be equal and its adjustment will be impossible. There is only one circulation pump in the system. Due to differences in the length of individual circuits, it is better to install balancing valves in the manifold to approximately regulate the amount of coolant entering the individual batteries.

Calculation of hydraulic arrow

The hydraulic distributor is calculated using formula D to take into account the maximum mode according to the factory parameters of the boiler:

D = 3*d=1000* √ (4*Q)/(π *3600*ω)=18.8*√G/ ω,mm

Calculation of the diameter of the hydraulic valve taking into account the design thermal power of the boiler unit and the temperature difference between the forward and return lines:.

D = 3*d=1000* √ (4*P)/(π *C* ∆T*ω)=17.4*√G/(ω* ∆T), mm

Diameter of the hydraulic arrow pipe for incoming coolant:

d = √ (4*Q)/(π*V), mm

Where:

- D — D of the distributor body, mm;

- D — D of the inlet pipe, mm;

- P is the design heat output of the floor-standing boiler, kW;

- G is the highest coolant flow through the distributor, m3/hour;

- C—heat capacity of water, W/(kg*C);

- V is the speed of water through the CP, m/s;

- Q is the estimated hourly water consumption in KO, m3/h.

Heating manifold in the apartment.

In old apartments with already equipped heating lines, installing a collector system is very problematic. This is due to the fact that rooms usually have 2 or more risers, whereas for a collector circuit it is necessary to connect all radiators to a single riser. This type of wiring can be arranged in a new type of apartment building, if special additional provisions were provided during construction. taps for connecting other circuits.

Heating distribution manifold

When installing, you should be aware of the following points:

Source