Here you will learn:

- Features of the MS-140-500 radiator

- Technical characteristics of cast iron radiator

Despite the fact that steel, aluminum, copper and bimetallic radiators have appeared on the market, the cast iron batteries familiar to many people have not gone away. They are still sold in plumbing stores and are in some demand. In this article we will talk about the cast iron radiator MS-140-500 and its characteristics, and also tell about its features, advantages and disadvantages.

Purpose, advantages and disadvantages of MS 140 radiators

The technical parameters of cast iron radiators of the MC 140 brand allow them to be used in steam heating systems of any buildings with virtually no restrictions: in private houses, country cottages, apartments in apartment buildings, administrative offices, public buildings, industrial, warehouse, and retail premises. The equipment is intended for operation in temperate and cold climates (MCC).

Advantages of heating radiators MS 140

- Long service life. This is one of the most durable types of radiators, with a service life of 50 years.

- Reliability. The hundred-year history of this type of radiator in the heating equipment market has confirmed in practice its high reliability.

- Anti-corrosion resistance. Cast iron does not deteriorate over time under the influence of water.

- Undemanding to the quality of the coolant. Cast iron radiators are not sensitive to the quality of the water used inside them. The presence of sand, dirt, high content of salts, acids, alkalis in water does not have a strong effect on the life of cast iron radiators.

- Simplicity of steam heating systems. Cast iron radiators can be used in networks with natural water circulation, without the use of a pump. They are compatible with all types of boilers - solid fuel, gas, pellet, liquid fuel.

- Thermal inertia. Cast iron takes a long time to heat up, accumulates heat well, and cools slowly. In a heating system, this is considered a great advantage, since after the burner is turned off, the cast iron radiator remains warm for a long time, releasing heat into the room.

Disadvantages of heating radiators MS 140

- Sensitivity to water hammer.

- Tendency to slagging of internal surfaces, which over time leads to a decrease in heat transfer.

- Radiators are assembled from separate sections, the joints of which are sealed with rubber gaskets. The lifespan of gaskets is significantly less than cast iron. To avoid leaks, after several years of operation, failed intersection gaskets must be replaced.

- The appearance of such radiators is not sophisticated enough; the surface requires painting.

Advantages of cast iron batteries

Let us list the positive qualities of such devices:

- Cast iron is a metal with high anti-corrosion properties. This feature allows the use of such heat exchange equipment for 50 years, without making any special efforts to maintain. No analog device can even come close to such high performance indicators.

- The design of the cast iron radiator is such that it creates minimal resistance to the coolant. These devices can be installed even where there is minimal hydraulic pressure.

- Cast iron can retain heat for a long time even when the hot water supply stops. Due to its high thermal inertness, the material completely releases its thermal energy.

- The temperature of the coolant is also “radiated” into the space in full, so we can safely say that a cast iron radiator is very effective.

What explains the popularity of cast iron models?

Height, length and width of the radiator

It is too early to say that the era of cast iron radiators has already passed. Such devices will be used throughout the post-Soviet space for a long time. And that's why.

It is this heat exchange equipment that is ideal for operating a central heating system. Aluminum and steel radiators cannot be installed in apartment buildings. They fail very quickly, not even fulfilling the warranty period stated by the manufacturer. The reason is the low quality of the coolant.

Water in most of Russia has an alkaline environment, which is detrimental to “pure” aluminum. Often in central systems, salts and acids are added to the coolant to reduce its heat losses. Alkali, when reacting with aluminum, produces a substance that destroys the brittle metal. Over time, an aluminum radiator becomes like a porous sponge, which can easily break from the first water hammer.

With steel batteries the situation is slightly different. They are able to withstand any quality of coolant, but steel does not tolerate oxygen. As soon as it appears in the system, corrosion processes begin to develop sharply. To avoid this, a steel radiator should always be completely filled with water. If connected to a central heating system, this is difficult to achieve. Usually in summer the water from the systems is completely drained.

The choice remains - either use expensive bimetallic analogues (but due to the high price, not everyone can afford these products), or install time-tested cast iron radiators. And even though they look bulky, and their appearance is difficult to fit into modern interiors, such heat exchange equipment is reliable, efficient and durable.

Technical characteristics of radiators MS-140 - 500

Radiators of the MC group belong to the category of sectional ones - they are assembled into a single whole from separate sections.

MS 140 cast iron radiator section.

The sections are connected into a radiator using intersection gaskets.

Intersectional gasket for cast iron radiator MS 140.

One section is pressed against another using a nipple.

Cast iron radiator nipple ms 140.

The ends of the radiator are closed with plugs, which can be shut-off or pass-through.

Radiator shut-off plug ms 140.

Radiator passage plug ms 140.

Sections are cast from gray cast iron with graphite additives. Individual parameters of MC 140 radiators may vary slightly in models from different manufacturers.

Main characteristics of the cast iron radiator model MC 140:

| Radiator type | sectional |

| Number of coolant channels, pcs. | 2 |

| Number of sections, pcs | from 2 to 10 |

| Nominal heat flow of one section, W | 160 |

| External casing coating | primer GF-021/0119 |

| Section material | gray cast iron in accordance with GOST 1412-85 |

| Intersectional gasket material | rubber according to GOST 1412, capable of withstanding temperatures up to +150ºC |

| Nipple material | cast iron or steel. GOST 1412 or 1050 |

| Heating area of one section, m2 | 0.195 |

| Center distance, mm | 500 |

| Nipple hole thread size | G11/4 |

| Type of coolant | water |

| Maximum coolant temperature, 0C | + 1300С |

| Operating excess coolant pressure, MPa (kgf/cm2) | 0.9 |

Other technical data:

| Number of sections, pcs. | Weight, kg | Length, mm | Nominal heat flow, kW | Capacity, dm3 (l) |

| 2 | 12.8 | 227 | 0.32 | 2.50 |

| 3 | 18.8 | 331 | 0.48 | 3.75 |

| 4 | 24.8 | 435 | 0.64 | 5.00 |

| 5 | 30.8 | 539 | 0.80 | 6.25 |

| 6 | 36.8 | 643 | 0.96 | 7.50 |

| 7 | 42.8 | 747 | 1.12 | 8.75 |

The basic characteristics of the radiator can be determined by the model name and markings.

For example , model MC-140-500-0.9-7 designates a radiator with the name MC, depth 140 mm, center distance 500 mm, maximum pressure in the system 0.9 MPa, with the number of individual blocks in the radiator equal to 7.

Calculation of the number of sections

Accurately determining the number of sections in a heating battery is a long process.

You need to take into account the region, the material of the walls, what kind of windows and doors there are, how many windows are in the room, what their area is, whether the room below is warm or cold, etc. If you need an exact calculation method, look here, but you can roughly calculate based on the area of the room. It is believed that on average 100 W of heat is required to heat 1 m2 of area. Knowing the area of your room, determine how much heat will be needed: multiply the area by 100 W. Then divide by the thermal power of the selected radiator model. For example, in a room of 12 m2 we will install MS-140M-500-0.9 from the Bryansk plant. Thermal power of the section is 160 W. Calculation:

- Total heat required is 12m2 * 100 W = 1200 W

- How many sections are needed 1200 W / 160 W = 7.5 pcs. We round (always up - it’s better if it’s warmer) and we get 8 pieces.

Technical instructions

1. Installation of heating equipment should be entrusted to organizations specializing in the field of construction and installation work that have the appropriate license.

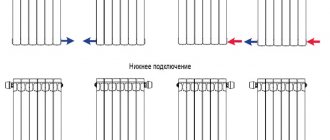

2. Radiators with a number of sections less than 10 can be connected in any way - bottom, top, diagonal. If there are more than 10 sections, then it is recommended to connect in a diagonal way: the coolant inlet is at the top, the outlet is at the bottom.

Diagonal connection of the radiator ms 140.

3. Before installing the radiator, you should conduct a hydraulic test of the integrity of the device, the tightness of the gaskets, and the strength of the nipple connections. To do this, hydraulic testing is carried out under a pressure of 1.5 MPa. If a leak is detected due to loose nipple connections, they need to be tightened and the test performed again.

4. When changing (increasing or decreasing) the number of blocks in the radiator, it is necessary to use only gaskets that are established by the requirements of GOST 1412. After assembling the radiator, the strength of the intersectional connections is checked.

This is done in a standard way - hydraulic tests are carried out under high pressure of 1.5 MPa, exceeding the maximum permissible loads. During the test, the prefabricated structure must not leak or allow air bubbles to pass through.

5. After completion of the installation work, the entire water heating system is pressure tested, based on the results of which a certificate of commissioning of the facility is drawn up.

Why is cast iron so in demand?

Cast iron radiators have advantages over other heating devices. They differ:

- Highly resistant to corrosion. This property is explained by the fact that during operation the surface of the battery becomes covered with “dry rust”, which is unable to enter the corrosion stage. Cast iron is wear-resistant and will not be affected by various debris from heating pipes.

- Good thermal inertia. While steel radiators retain 15% of their heat after the boiler is turned off, the cast iron analogue of the MC 140 can radiate up to 30% of heat even after an hour.

- Long service life. High-quality models of cast iron radiators can reach a hundred-year operational period. But manufacturers are reducing these periods and promising reliable operation in the interval between 10-30 years.

- Large internal cross-section. Thanks to this technical characteristic, the cast iron radiator MC 140 500 rarely needs cleaning.

- This material cannot cause electrochemical corrosion. That is, cast iron comes into excellent contact with steel or plastic pipes.

terms of Use

The radiator is used in water/steam heating systems with any type of boiler, in which the coolant is ordinary water, without specific requirements for its quality.

Installation should only be carried out in a heating network that is designed, installed and operated in accordance with regulatory documentation adopted by government industry organizations.

For Russia, such a regulatory act is the rules SP 60.13330.2012 or 73.13330.2012.

Peculiarities

All heating radiators, regardless of the materials used in their creation, as well as regardless of shape and size, are equipped with an inlet and outlet. In the bulk of commercially available devices, these holes are duplicated to allow both bottom and top connections.

Not all available technological holes are used during the installation process. To ensure the tightness of the device, special plugs are used that are screwed into unused holes.

The standard package of the heating battery does not include the necessary plugs (plugs) and fittings (connecting elements for joining with the pipeline). As a result, you will need to additionally buy a special kit for installing radiators.

Typically, these kits are universal and suitable for cross or side connections. But there are devices designed for the lower supply of the inlet and outlet pipes. In such a situation, along with the main installation kit, it will be necessary to purchase a special unit for connecting to closely spaced pipes.

Total information

Batteries offered by manufacturers differ in the number of sections.

They are made:

- in 10-section form;

- in 7-section design;

- in 4-section form.

Types of MC batteries

MS-140-500 have a flat surface and are painted in different colors.

To compete with more modern types of devices, manufacturers of cast iron heating batteries had to expand this product line.

The following models are currently available on the Russian market.

- Cast iron heating radiators MS-140-500 are produced by the Republic of Belarus. This device has undergone several improvements. Now its surface, as a rule, has a flat appearance. In addition, the product comes already painted in different colors.

- Battery MS-140-500 with 7 heating elements. This is a frontal variation of the previous model.

- Analogue MS-140-300. This device has a gap between nipples of 300 millimeters.

- The MS-140-108 model does not require significant care and does not require constant maintenance.

Difference between different device models.

- Cast iron heating radiators grade MS-140-180 and 98 have gaps between nipples of 108 and 98 millimeters. The devices, like the previous one, are produced in Russia and Ukraine.

Thanks to such a wide selection of products, property owners can optimally arrange heating in their home.

Selection rules

Radiators with a flat surface have higher efficiency.

The recommendations are simple:

- The most important thing is the correct calculation. The power of the section is assessed and the efficiency of the entire heater is calculated. If there are not enough sections, increasing the temperature of the coolant will not improve the situation; the room will be cold.

- You need to choose the height. If the product is mounted under a window, there should be at least 20–15 cm between the radiator and the window sill, and at least 5 cm between the floor and the bottom edge of the product. For large windows, choose low radiators and compensate for the small height with a large number of sections. Tall radiators are mounted near blank walls.

- Batteries with a flat surface have higher efficiency and are more attractive in appearance. Models with artistic casting and decorative coating fit perfectly into retro, classic, and rustic interiors.

- Radiators are mounted on the wall using special brackets. However, there are floor-standing models. The latter are used if the walls cannot withstand such a heavy load.

The appearance of the battery can be radically changed by covering them with a decorative grille or screen.