Although manufacturers of radiators made of steel, aluminum and bimetal say that cast iron analogues have already outlived their usefulness, this is not so. Indeed, 160 years have passed since the first time heaters made of this metal were installed, and at one time they made a real breakthrough in supplying homes with heat.

At the present time, old Soviet batteries are hardly attractive to anyone, but their modern analogues have become completely different. Starting from appearance to how much water is in one section of a cast iron battery, everything has changed in these “old-timers” of heating systems.

Advantages and disadvantages

Modern design solutions

The advantages of the product are determined more by the material than by the design. Main advantages:

- Cast iron conducts heat well and accumulates it. The radiator takes longer to heat up than a steel or bimetallic one, but gives off heat for a long time after the boiler is turned off. An hour after heating stops, the residual heat transfer for cast iron models is 30%, while for steel models it is only 15%.

- The water used in central heating is not clean. Salts, mechanical impurities, sand destroy the pipeline material. Debris is deposited on the walls: the working diameter decreases over time, and the efficiency of heat transfer decreases. Cast iron is not afraid of salts and abrasive particles. After 30 years, the batteries work as efficiently as on the first day after release.

- Cast iron batteries cannot withstand constant high water pressure, but they are not afraid of water hammer. This option is used when arranging heating with natural circulation.

- Radiators last at least 50 years. If you change the gaskets on time, it will take even longer. Usually they are replaced not because of leaks or low efficiency, but to make the interior more modern.

- The price is the lowest among heaters.

Disadvantages of radiators:

- The main disadvantage is its considerable dimensions and heavy weight. The 8-section model weighs more than 60 kg. They are difficult to transport, lift to the top floor, and install.

- If when the heating is turned off, high thermal inertia acts as an advantage, then when turned on it turns into a disadvantage. The room warms up for at least 12 hours.

- To service the batteries, you need a large volume of coolant and a more powerful boiler. This is not a hindrance for central heating, since the system was originally designed to transfer a large amount of coolant. For an autonomous one, this is a significant drawback.

- There is no need to talk about design. Rough, heavy radiators hardly fit into the interior.

The advantages of a cast iron battery are well demonstrated in central heating systems. The disadvantages are visible when autonomous heating is installed.

How much water is in one section of a bimetallic radiator

As with aluminum, there are many options for manufacturers and brands of bimetallic radiators. Their structure, appearance, and channel diameters differ in the same way.

The volume of water in a bimetallic radiator depends on its height and is (in liters):

- 35 cm – 0.1-0.15;

- 50 cm – 0.2-0.3;

- 60 cm – 0.25-0.35;

- 90 cm – 0.3-0.5;

- 120 cm – 0.4-0.6.

To calculate the volume of a section of a bimetallic radiator of non-standard height, use the formula (V – volume in liters, h – height in meters):

V = hx 0.35

This will give you an approximate value, which may vary within 20%.

Water volume in the heating radiator table

| Radiator type | Height (mm) / model | Minimum section volume (l) | Maximum section volume (l) |

| Aluminum | 350 | 0,2 | 0,3 |

| 500 | 0,35 | 0,45 | |

| 600 | 0,4 | 0,5 | |

| 900 | 0,6 | 0,8 | |

| 1200 | 0,8 | 1 | |

| Bimetallic | 350 | 0,1 | 0,15 |

| 500 | 0,2 | 0,3 | |

| 600 | 0,25 | 0,35 | |

| 900 | 0,3 | 0,5 | |

| 1200 | 0,4 | 0,6 | |

| Cast iron | MS 140-300 | 0,8 | 1,3 |

| MS 140-500 | 1,3 | 1,8 | |

| MS-140 | 1,1 | 1,4 | |

| MS 90-500 | 0,9 | 1,2 | |

| MS 100-500 | 0,9 | 0,2 | |

| MS 110-500 | 1 | 1,4 |

We hope that we were able to help you determine the volume of water in one section of the battery. Let us remind you: if you are going to make any manipulations with the heating system, it is better not to take risks.

When working with non-standard models, calculate their volume with a small margin of 10-20%. This will not complicate the task, but will help avoid trouble. Don't forget to share the article with your friends!

Do you want to get help from a master, a specialist in this field? Go to the professional search portal. This is a completely free service where you will find a professional who will solve your problem. You do not pay for posting an ad, views, or choosing a contractor. If you are a master of your craft, then register on Pro and receive a flow of clients. Your profit is just one click away!

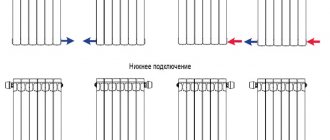

What situations can be avoided if you correctly calculate the volume of coolant

Many people install a heating system, relying on the advice of experts, friends or their own intuition. Choose a more powerful boiler and increase the number of radiator sections “just in case.” But the result is the opposite picture: instead of the expected heat, the batteries do not warm up evenly, the boiler “winds” fuel idle.

You can avoid the following unpleasant situations if you know how to calculate the amount of water in the heating system:

- uneven heating of the water circuit in the rooms;

- increased fuel consumption;

- emergency situations (broken connections, leaks in radiators).

All these “surprises” are quite predictable if the volume of coolant is incorrectly calculated.

Attention! Antifreeze should not be used in a heating system that uses galvanized pipes or other elements.

Modern life of cast iron batteries: new pros, old cons

Like other types of heaters currently on the market, cast iron structures have a set of both positive and negative qualities. The advantages include:

- This type of metal is not susceptible to corrosion even when the water is completely drained from the system. They can be installed in houses where the coolant is not clean and has a uniform Ph level.

- The service life of these devices is 35 years or more.

- The volume of one section of the cast iron battery is only 0.8 liters, which increases the rate of heating of the coolant, and therefore reduces the level of energy consumption. This, in turn, leads to cost savings during their operation.

- Like old-style radiators, they are cheaper than other types of heating devices.

- The heat transfer, taking into account the volume of the cast iron heating radiator, is high enough to effectively heat the apartment.

- This type of heating device does not require special care. Occasionally you should wipe off the dust, otherwise new cast iron heaters are as easy to maintain as, for example, steel or aluminum sectional models.

- If the system is turned off, the cast iron batteries cool down long enough to keep the apartment warm. This is one of the properties of this metal.

If we talk about the disadvantages of these devices, they remain the same:

- Cast iron is still the same brittle metal that does not withstand even minor impacts. During transportation, special attention should be paid to protecting cast iron batteries from falls. As a rule, major damage does not occur with weak external impacts on the body, but microcracks may well appear. During operation, they become larger until the seal is completely broken.

- Even though the volume of a cast iron radiator section is small, their weight remains quite heavy compared to analogues made of other metals.

Currently, new types of cast iron batteries are presented on the market, the stylish appearance of which is suitable for any interior. If the design requires the installation of antique-style radiators, then vintage models can also be found in construction stores.

In what cases is the coolant volume calculated?

The liquid in the water circuit of the heating system performs the most important function - it is a heat carrier. Many elements of the heating system are selected relative to the volume of coolant being distilled. Therefore, preliminary calculations will allow you to complete the heat supply most efficiently. It is easy to calculate the total volume of coolant, given that the amount of liquid in radiators is 10-12 percent of the total amount of liquid being distilled.

Calculation of water in the heating system must be done in the following cases:

- before installing heating, determine the amount of coolant that will be distilled by a boiler of a certain power;

- when non-freezing liquid is poured into the system, it is necessary to maintain a certain proportion in relation to the entire distilled liquid;

- the size of the expansion tank depends on the amount of coolant;

- you need to know the required volume of water in the heating system of country or private houses where the water supply is not centralized.

In addition, in order to properly mount the batteries on the wall, you need to know their weight. For example, just one section of a cast iron radiator, already heavy, holds 1.5 liters of liquid. That is, the seven-section cast-iron battery becomes more than ten kilograms heavier when the system starts.

What is the heat output of Soviet cast iron batteries?

Cast iron batteries

| Radiator type | heat output , W | Crimping pressure, bar |

| Bimetallic with a gap between the axes of the sections 500mm | 204,0 | 30,0 |

| Bimetallic with a gap between the axes of the sections 350mm | 136,0 | 30,0 |

| Cast iron with a gap between the axes of sections 500mm | 160,0 | 15,0 |

| Cast iron with a gap between the axes of sections 300mm | 140,0 | 15,0 |

General provisions

First of all, let's look at the pros and cons of cast iron batteries:

Advantages

- Resistance to corrosive processes . You can rest assured that even during summer periods, when the liquid is drained from the system, the cast iron will stand.

- Unpretentiousness to the quality of the coolant , which is very important for apartment heating systems, where you cannot control the composition of the liquid running through the pipes from the central boiler room.

- Durability . The service life is at least 35 years.

An old cast iron radiator with 7 sections has been successfully heating the apartment for decades

- Low price . Especially in comparison with newer aluminum and bimetallic models.

- High heat dissipation . Combined with a large area, you get a powerful heating device for your home.

- Simple operating instructions . After installation and application of paint, you can forget for a long time about the need for any maintenance of the cast iron structure.

- Slight inertia . Even after turning off the heating, cast iron radiators will remain warm for a long time.

Flaws

- Heavy weight. This is one of the biggest problems that arise when installing cast iron radiators with your own hands. The weight of one battery, depending on the number of sections, can vary from 50 kg to 150 kg, which will create incredible difficulties even when simply hanging a cast-iron product on brackets, not to mention carrying it at least from one room to another. In addition, it will also be necessary to take care of strengthening the fastening system.

Cast iron radiators with 12 sections are very difficult to lift even with two people

- Fragility. Despite its visual power and solidity, cast iron is a very fragile material.

Tip: when moving a cast iron battery, be extremely careful and try to avoid accidental impacts on the floor or door frame. The fact is that at the moment of a collision, microcracks may appear on it, which will increase over time and cause many problems.

- The need for periodic painting.

Painting a cast iron radiator

Tip: for painting it is recommended to use acrylic compounds that are non-toxic. Otherwise, a constantly heating battery will be a constant source of unpleasant odors and toxic fumes.

Acrylic enamel for heating radiators

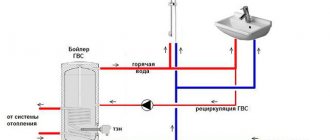

Critical stage: calculating the capacity of the expansion tank

In order to have a clear idea of the displacement of the entire heating system, you need to know how much water is placed in the boiler heat exchanger.

You can take averages. So, on average, a wall-mounted heating boiler contains 3-6 liters of water, while a floor or parapet boiler contains 10-30 liters.

Now you can calculate the capacity of the expansion tank, which performs an important function. It compensates for the excess pressure that occurs when the coolant expands when heated.

Depending on the type of heating system, tanks are:

- closed;

- open.

For small rooms, the open type is suitable, but in large two-story cottages, closed expansion joints (membrane) are increasingly being installed.

If the tank capacity is smaller than required, the valve will release pressure too often. In this case, you have to change it, or install an additional tank in parallel.

For the formula for calculating the capacity of the expansion tank, the following indicators are needed:

- V(c) is the volume of coolant in the system;

- K is the coefficient of water expansion (the value is taken as 1.04, based on the water expansion rate of 4%);

- D is the expansion efficiency of the tank, which is calculated by the formula: (Pmax – Pb)/(Pmax+1)=D, where Pmax is the maximum permissible pressure in the system, and Pb is the pre-pumping pressure of the compensator air chamber (parameters are indicated in the documentation for the tank );

- V(b) - expansion tank capacity.

So, (V(c) x K)/D = V(b)