From the author: Hello, dear readers! If you need a table showing the volume of water in a heating radiator, then most likely you live in a private house. Residents of apartment buildings rarely need this information, since they cannot in any way influence the level of battery filling - and this, in fact, is of no use, since the relevant organization is in charge of everything. The only knowledge you need in this case is the level of pressure that a particular radiator can withstand. You can get this information from the corresponding article on our portal.

As for private houses, the picture is different. An autonomous heating system, its creation, maintenance - all this depends solely on the owners of the home. In this matter, every detail is important: the material of the pipes, the power of the heating boiler, the type of radiator and much more. All this must be taken into account when arranging the heating system.

And not the least factor is how much coolant you need to fill it. A lot depends on this:

- weight of a filled radiator. For example, this point is very relevant for cast iron batteries. They themselves are not distinguished by low mass, and when filled with coolant they become even heavier. Considering that the batteries are hung on the wall, you can understand that their weight should be treated with some care,

- calculation of the power of the heating boiler and circulation pump. Naturally, these indicators depend on how much coolant the equipment will have to work with. Roughly speaking, if the boiler is designed for 50 liters, and you put a hundred liters into the system, then to heat such a volume the device will have to work hard, which will lead to its rapid failure and poor heating of all elements of the heating system,

- selection of radiator size. To do this, you need to take into account what type of circulation will be used in your heating system. In the case of a natural radiator, it must be large and, accordingly, contain a considerable amount of liquid. In the case of forced circulation, you can not pay much attention to the size of the batteries, since the pump will successfully deliver the coolant to all final targets, maintaining the required heating level,

- working with antifreeze. This composition is often used to fill the heating system. There is a lot of information on our portal about the advantages of this approach, and if necessary, you can easily find it. Let us remind you of this: to fill the system, antifreeze must be diluted with water. Naturally, for this you will need to know exactly how much of the finished coolant will go into the system. Firstly, this way you can purchase exactly the right amount of antifreeze. Secondly, you can properly dilute it with water so that the concentration is at the proper level,

- selection of expansion tank. It is clear that its volume also depends on the total amount of liquid in the heating system.

Naturally, for all this you need to take into account how much coolant is needed to fill each element of the heating system: the heating boiler, pipes and radiators. In principle, you can take any necessary technical indicators from the documentation that comes with all these elements.

Methods for calculating volume

The size of the internal space of batteries manufactured in accordance with GOST can be determined in two ways:

- Look at the technical documentation and find the desired number among the specified characteristics. Next, you need to carry out simple mathematical operations.

- Pour in water and measure its volume or weight.

Determining the volume using documentation

Initial numbers can be taken both from documentation with technical characteristics and from special tables compiled by manufacturers. In both cases, a certain indicator is indicated, which corresponds to the volume of water that can fit in a linear meter of radiator.

This specific indicator is the center distance. It refers to the distance that separates the upper and lower collectors. Many manufacturers produce batteries observing standard center distance values. Most often it is 30 and 50 cm.

Calculating the volume of water that can fit in a heating device manufactured in accordance with GOST involves the following steps:

- Determining the length of panel radiators or the number of sections of aluminum or bimetallic batteries with smooth internal walls (such walls can reduce hydraulic resistance).

- Determination of the volume of water per linear meter. To do this, in the table they look at such a characteristic as the interaxle distance. Opposite its value, they look for the volume of water. If the heating device is sectional, then find out how much water can fit inside one section.

- Multiplying the obtained values.

This method is quite difficult to use for tubular radiators and batteries made according to individual needs. This is because for the first devices, manufacturers use various GOST-tested pipes. They have different diameters, wall thicknesses, and lengths. Therefore, there are no tables with average values of volume and distance between collectors. They are impossible to compose. Of course, documentation with technical characteristics, as well as a table compiled by the manufacturer, can come to the rescue. In addition to the center distance, it can also indicate the resistance of the heated liquid and the weight of the device with this liquid.

As for a heating device manufactured at the request of the client, there may not be technical documentation for it with very detailed characteristics. After all, it is produced only in a small batch, and there is no point in calculating all the characteristics, including volume and water resistance.

Average volume values

For example, radiators with a center distance of 500 mm are taken. So the volume is:

- 1.7 liters for each section of the ChM-140 cast iron radiator designed for high pressure;

- 1 liter for each section of the same battery, however, a new model;

- 0.25 l for every 10 cm of panel device type 11. For structures with two and three panels designed for low pressure, this figure is 0.5 and 0.75 l per 10 cm;

- 0.45 liters for each lightweight aluminum battery section.

- 0.25 l per section of a bimetallic radiator manufactured in accordance with GOST.

Universal method

It is suitable for any type of heating device with any center distance. To implement it, you need to stock up on a large amount of water and a container, the volume of which is known.

The measurement is carried out as follows:

- Install plugs on the two lower holes. It would be possible to install a third plug on one of the top holes, but it is better to wait. This is because when you pour water into one hole, air must escape through the other.

- Pour water until it begins to flow out of the second free hole.

- Place a plug on this hole and slowly add water until the entire battery is completely filled. During pouring, count the number of containers poured. This can also be done while draining water from the radiator. True, you will have to drain the water into a bucket or something else and then pour it out.

- Multiplying the number of containers poured by their volume. The final figure is the volume released according to GOST rules of the battery.

Selecting a heating battery based on the area of the apartment How to choose heating radiators based on heat transfer indicator How hot the heating batteries should be Soldering holes and cracks in an aluminum radiator

Answers from experts

Chairman:

5 square meters

Verik:

cast iron heats, and aluminum transfers heat to the water in the radiator.. 350 mm is a stretch of 8 squares

Truculentus:

The passport for the radiator indicates the thermal power of one section of the radiator (for sectional batteries) or the same indicator of the entire radiator. This indicator differs for different manufacturers.

In practice, an approximate calculation is usually used, based on the fact that for heating 10 sq.m. a normally insulated room with a ceiling height of up to 3 m requires 1 kW of thermal power (100 W/sq.m). For corner rooms (2 external walls), rooms with large windows (or several windows), the obtained value is increased by 20-25%.

Grandfather Au:

look at how many watts it is according to the instructions, divide by 100, multiply by 0.8 and you will get square meters (the same with any radiator)

Vladimir Petrov:

As I understand it, 350 is the interaxial distance and how many sections there are. Look on the Internet in the section. There are a bunch of batteries there, you can take their power rating data. And then consider about 150 watts per square meter. I have about 14 square meters on the terrace at my dacha. m there are two batteries of 12 sections 350mm. I took it with a reserve. The windows are large, 2400 x 140, two of them; I have a winter garden there. It's even hotter when it's minus 25 outside.

vyachko:

Based on the empirical average ratio of 1 kW per 10 sq. m area, then. For example, for a room of 20 square meters. m you need a battery with a total power of 2 kW. One section of an aluminum radiator with a center distance of 500 mm at a temperature difference of 70 degrees produces 140...200 W (need to be clarified for the specific brand of radiator). For 2 kW we get somewhere around 10…14 sections.

Vyacheslav Koshelev:

and there is nothing more to answer...

BOSS:

Read SNiP heating engineering. The number of radiators depends not so much on the area, but on the heat loss of the room (on the correctness of the chosen enclosing structures: walls, floors, ceilings). Everyone protects a private house from the evil one... (from money in his pocket). If you insulated and built it correctly... then consider it as written above... if not, then refer to the calculator and SNiP.

Farit Gafuanov:

in short, one section, two squares, to be sure, take two more sections

Andrey:

Find out the rated thermal power of the section (all manufacturers indicate it for a supply of 90 degrees) divide 90 by the calculated supply temperature, you will get a reducing coeff. Using the tables, determine the approximate heat loss of one square meter of your walls and multiply by their outer area. , add the heat loss of the Windows (tabular data multiplied by the area), add the heat loss of the ceiling, depending on the type of insulation or the presence of neighbors above, they vary greatly. Add heat loss to supply and exhaust ventilation. Set up a winter regional co-off. air temperature and indoor temperature that is comfortable for you. Based on this temperature difference and the amount of heat loss in the room, you determine how many kilowatts are required to maintain this temperature, divide these kilowatts by the actual power of the section and find out the minimum number of sections. The principle is simple; The more sections and the lower their temperature, the more efficient the heating.

Irina Manaeva:

1 section for 2-3 sq. m.

Oleg Khrebtov:

I always put 1 section at 1.5m. sq. Enough even in severe frosts..

MIKA:

BOSS said everything correctly, we calculate the heat loss of the premises

Maria:

Take it with a reserve - you can tighten the valves. It wouldn’t hurt to put it in the corners either - outside corners and at the entrance for a pillow.

Gennady Skvortsov:

It’s nice to read the opinions of experts, I would like to add only about the priority location under windows and entrance doors

Pavel Pavlov:

bet the more the better... be realistic - if you are not an expert, why the hell will you calculate possible heat losses and other bullshit, it is better to proceed from what pressure you have in the pipe - how many sections it can push through. but it will be hot, turn down the heat, and this again saves gas...

Modern models of heating radiators

The weight of 1 section is 3.8 kg. water holds 0.8 liters, so the weight of one radiator section with water will be 4.6 kg. With a heat flux of 140 W, to heat a room of 20 m2, 14 sections will be required, and the weight will be 64.4 kg with water. Thus, this figure differs by 40% less than that of the classic MS 140 sample. If this value is divided into two parts (32 kg each), we can conclude that installation on walls made of modern materials, including porous concrete, It is quite possible to carry out without additional fasteners.

An even lighter design was developed by Russian manufacturers. Their heating devices are offered under the EXEMET brand. The MODERN model has the following weight characteristics:

One section from this manufacturer weighs 3.2 kg, heat output is 93 W. To heat a room of 20 m2 you will need 22 sections, then the total weight will be 70.4 kg. These parameters are not bad, especially considering that the company produces models with possible installation on the floor.

The EXEMET FIDELIA model weighs 12 kg, heat dissipation is 156 W, the total mass of the device for our example is simply monstrous - 154 kg. The complex issue of installation is irrelevant here, since the first and last sections are equipped with legs for placing the device on the floor.

So, in order to ensure uninterrupted service for the heating system, you cannot ignore such important indicators as the weight and volume of the battery section. Thanks to the correct calculation of the load on the fastening elements, you can count on reliable installation and long-term operation of the device.

Answers from experts

Chairman:

5 square meters

Verik:

cast iron heats, and aluminum transfers heat to the water in the radiator.. 350 mm is a stretch of 8 squares

Truculentus:

The passport for the radiator indicates the thermal power of one section of the radiator (for sectional batteries) or the same indicator of the entire radiator. This indicator differs for different manufacturers.

In practice, an approximate calculation is usually used, based on the fact that for heating 10 sq.m. a normally insulated room with a ceiling height of up to 3 m requires 1 kW of thermal power (100 W/sq.m). For corner rooms (2 external walls), rooms with large windows (or several windows), the obtained value is increased by 20-25%.

Grandfather Au:

look at how many watts it is according to the instructions, divide by 100, multiply by 0.8 and you will get square meters (the same with any radiator)

Vladimir Petrov:

As I understand it, 350 is the interaxial distance and how many sections there are. Look on the Internet in the section. There are a bunch of batteries there, you can take their power rating data. And then consider about 150 watts per square meter. I have about 14 square meters on the terrace at my dacha. m there are two batteries of 12 sections 350mm. I took it with a reserve. The windows are large, 2400 x 140, two of them; I have a winter garden there. It's even hotter when it's minus 25 outside.

Pretzel:

For 10 square meters of a house there is approximately 1 watt. at 24, respectively, 2.4 watts. One section is approximately 150-200 watts. Approximately 12-15 sections are needed. I have a house of 120 square meters, sections 5+5+5+10+5 = 30 second floor and 7+5+5+5=22 + warm floor first floor

Truculentus:

To heat a typical room in a 1 m³ panel house, 0.041 kW of thermal energy is required. To heat a room in a brick house with wall insulation (mineral wool, foam plastic) and installed double-glazed windows on 1 m³, 0.034 kW of thermal energy is required. A double-glazed window will reduce heat loss by 15-20%; accordingly, the number of sections can be reduced. If the room is corner, then heat loss will be approximately 20% greater. For premises built in accordance with the latest building regulations, 0.020 kW of thermal energy is required per 1 m³. Any radiator has information about the thermal power on the packaging or in the included insert.

Frosya Burlakova:

You can approximately determine how many radiator sections are needed if you multiply the area of the room by 100 and divide by the heat transfer of the section (according to the passport) in W. It should be remembered that the obtained value is approximate and a number of factors are not taken into account (heat losses of the room, heating network parameters and types of radiator connections). 15 approximately

uncle Ivan:

At least 14, and it is better to install two blocks of 8 sections.

Andrey:

There is not enough data for a correct answer. Please indicate: 1. the difference in temperature between your comfortable temperature and the minimum winter temperature for your region. 2. the amount of heat loss from the surfaces of the heated room 3. the rate of air exchange from the room to the street and adjacent rooms 4. Connection diagram for radiators. 5. how many windows are there in the room? 6. Estimated temperature of the supply and return pipelines. 7. circulation speed and coolant type. 8. Thermal power of the section declared by the manufacturer and at what temperature conditions. 9. You can also add pressure in the system, but this is nitpicking since the effect on heat transfer is insignificant. We are waiting for the data and will immediately issue an accurate answer.

MurYska:

oh wow, what sophisticated answers)))))) we thought so for 2 square meters 1 section, now in the apartment it’s 28-30C in the winter before the renovation it was 20-22

Grandfather Au:

per square meter you need 100 watts, especially in a panel house! DO NOT take aluminum - especially if the high-rise building breaks! and they don’t like our water very much

Smirnov Vladimir:

The required number of sections is determined by the formula: S rooms * H ceilings * window coefficient (35 - if double-glazed windows, 40 - if regular windows) / section heat transfer = number of sections. Aluminum radiators have a heat output of 190 watts

Valentina Bryzgalina:

The locksmith spoke. “What’s the point of installing many sections, if the pressure is small, it will not push through to the end. “This often happens, because (zheki, reu) have big savings on this. I changed batteries and wanted 10-12 pcs. put in a room of 18 sq. m. As a result, they installed 8 pieces, the circulation is good, it’s warm. Aluminum ones last 6 years.

Ivan Krasnoshchok:

I used the table, see the Kermi website. about (only in English letters) is very convenient and sensibly written.

Egor Lvov:

why do you want it?

Why know the volume of coolant in the battery?

Calculation of the volume of coolant in the battery is done in order to:

- choose the correct radiator mount. It must withstand not only the weight of the product, but also the weight of the water that fills the entire internal space. The weight of the liquid is equal to the volume;

- select a boiler of the required power. If it is weak, it will create little pressure and the water will move slowly;

- select an expansion tank of the required volume. Many people refuse this element. However, it is better to use it, since it compensates for the pressure created by the increased volume of the heated coolant. For example, when heated, the volume of a liquid increases by 4%. If it has nowhere to go, then the pressure on the batteries and pipes increases. Sooner or later, thermal expansion will cause a leak;

- determine the total coolant requirement. To do this, you need to take into account the internal volume of pipes with low hydraulic resistance, as well as the volume of the heating boiler capable of creating the required pressure;

- maintain the correct concentration of antifreeze. This applies to cases where water will be mixed with antifreeze. This can be done, and in some cases the resulting liquid for heating radiators freezes at lower temperatures than 100% antifreeze;

- select the type of circulation. The coolant can move naturally (from top to bottom) or move under pressure created by the pump. The natural type of circulation is chosen in the case of batteries with a large internal volume and low resistance to the heated liquid. As for the second type, the size and weight of the batteries does not matter.

Materials used

The core of the bimetallic radiator section is made of steel pipes. For batteries of normal strength (working pressure 16 - 20 atm), the core is made of carbon steel grade St.3 or its foreign analogues (for example, Tenrad radiators). The core (frame) of high-strength models is welded from stainless steel pipes. High-strength devices with a stainless steel core (for example, Biliner from Royal Thermo) can withstand burst pressures of more than 100 atm.

The outer part of bimetallic radiators is made of aluminum by injection molding. The extrusion method used in the production of some aluminum models cannot be used in this case, since a core must be placed inside the workpiece before forming begins. O-rings are made from heat-resistant silicone rubber.

Profiled fins.

Aluminum radiator section power

Many people note that in the formula for calculating the number of sections, you can substitute the power of the heating radiator section that the manufacturer indicated in the technical documentation. This idea is correct when a coolant with a temperature of 100 °C circulates in the heating system and is cooled to 80 °C. The fact is that manufacturers indicate the heat transfer of the battery under the condition ΔT = 70 °C. They calculated this indicator based on the formula:

- where t1 represents the inlet coolant temperature,

- t2 is the coolant outlet temperature,

- t3 represents the room temperature of the house.

ΔT = 70 °C only when the coolant has the above temperature levels and t3 = 20 °C.

After that, they take a special plate in which the manufacturer indicated the heat transfer of the radiator at different ΔT, and look for the resulting indicator. Next to it is a correction factor. For example, for ΔT = 50 ° C it is 0.65. This figure is multiplied by the power of the radiator section. Next, the obtained result can be substituted into the formula indicated at the very beginning.

How to install

A significant part of aluminum radiators are built on the same principle as all other heating batteries. They can have one-piece or stacked sections, any configuration of ribs, but, adhering to the standards, a standardized distance is established between the collector pipes.

The normal range of values for this distance is: 200, 300, 500, 550, 600, 700, 800 mm.

For generation, a fitting with an external thread, an American fitting or an internal thread of an open inter-sectional connection is used.

Radiator connection options

Connection methods are determined by the wiring diagram:

- one-sided;

- double-sided (top, bottom);

- diagonal.

The greatest heat transfer is ensured by a diagonal connection, when hot water enters the upper collector, and the coolant exits from the lower collector on the side of the battery opposite to the input.

In addition to connecting to the collector, aluminum radiators often have collector outlets formed by internal channels. The connection points are placed compactly at a short distance from each other on the side of the radiator or below. To connect to the pipes, an American fitting is used, attached to the pipe.

It is important to determine the radiator model after choosing the wiring method and before calculating the detailed diagram, so that the number of heat exchangers and the method of connecting them, down to the millimeter, are known.

It is necessary to determine an advantageous position for the radiator. When installed under a window opening, the battery must occupy at least 2/3 of the opening width to form a thermal curtain. The distance from the battery to the windowsill and from the floor to the lower ribs of the battery is at least 10 cm. It is important not to create barriers to active air convection.

Installation and wiring diagram

The radiator is attached to the wall using at least two brackets. It is advisable to use the fastenings provided by the manufacturer of the aluminum radiator. They are fixed to the wall using two to four self-tapping screws with dowels or anchors. The distance from the wall is adjusted by moving the front part of the bracket.

Below you can watch a video with a detailed description of the installation work.

Parameters of aluminum radiators

The technical characteristics of heating batteries are the first thing a consumer pays attention to before purchasing. The most important indicators of a truly high-quality product are:

- The level of heat transfer of one section, since it depends on:

- First, how many elements are needed to heat one room.

- Secondly, how warm the room will be thanks to the radiator.

- Thirdly, what will the microclimate in the room be like?

- Resistance to water hammer and operating pressure of an aluminum radiator.

- Cost of the finished product.

The volume of one section of an aluminum radiator indicates its power and largely depends on how it was manufactured.

If the aluminum battery was made by pressing, then its parts were connected using glue, which makes it vulnerable. Such a radiator is not afraid of corrosion, but increased pressure can damage it.

The capacity of one section of an aluminum radiator, regardless of the method by which it was produced, is almost the same, but the fact that the cast model is stronger and more durable, heats up faster and can be adjusted in size puts them in first place in sales.

Find out useful information about aluminum batteries on our website:

Which ones are better

Cast iron or aluminum

Cast iron is inferior to aluminum in thermal conductivity, the coefficient is 62.8 W/m*K for cast iron versus 200 W/m*K for aluminum alloys. Exactly the opposite is the case with the heat capacity of metals.

Due to their high thermal conductivity, aluminum batteries can be made with a smaller cross-section of the internal channel; the heat will still have time to transfer from the coolant to the metal and then to the air in the room.

Along with low density, it is possible to build heating radiators that are many times lighter and more efficient in terms of heat transfer. The final touch is that aluminum has a higher formability than cast iron, and the batteries can be given almost any convenient shape.

All that cast iron can offer is resistance to corrosion and complete chemical neutrality to any type of coolant. Aluminum lags far behind in this regard. It is less durable and, without additional protection with an oxide film, ceramic or polymer coatings, enters into a violent chemical reaction with water, releasing gas.

If there is an electrically conductive connection with steel or copper parts, it provokes an electrochemical reaction, also with disastrous results.

Steel and bimetallic or aluminum

Steel is much stronger than aluminum and at the same time more ductile than cast iron. Bimetallic and tubular steel radiators are able to withstand greater pressure and especially water hammer, but at the expense of thermal efficiency. The thermal conductivity of steel is lower than aluminum, as well as the weight of the radiator is greater.

In a private house, where it is possible to control the quality of the coolant and the composition of the equipment in terms of thermal efficiency, aluminum radiators clearly win in all respects, including even cost.

However, in the case of central heating, the risks are too great that aluminum will become a determining factor in failure already in the first season of operation.

Types of coolants

As a rule, the question of what coolant is used in a centralized heating system is not asked, since water always flows through the heating pipe there. Another thing is autonomous heating, where you can choose the best option for a particular house, taking into account the climate of the region where it is built.

- Antifreeze for heating systems has been used for heating country houses for many years and has proven itself to be excellent. Its best qualities (the ability not to freeze at temperatures down to -70 degrees) are especially good in buildings where there is no permanent residence of people. Summer residents can close their house, come several times a month to warm it up, and not worry that something will happen to their heating system.

- Alcohol-containing coolants have properties similar to antifreeze, only they can not freeze at -30 degrees. Their use is not advisable in residential buildings, since such liquids contain ethyl alcohol, which is not only highly flammable, but also dangerous to humans.

- Water in autonomous heating systems is only good where aluminum radiators are under supervision, that is, people permanently live in an apartment or private house. It has one indicator that aluminum does not “like” - the ability to cause corrosion in metals. If the carrier is drained from the system in the summer, then by the beginning of the new season the batteries may leak due to corrosion that has “eaten” the metal. Residents should leave coolant in the system to prevent this from happening.

The viscosity of all three coolants is different, and when manufacturers indicate the volume of an aluminum radiator, they imply that it will contain water. When purchasing such a device for a heating system, for example, one that uses antifreeze, you should compare its characteristics with the capacity of the battery.

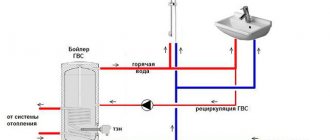

Critical stage: calculating the capacity of the expansion tank

In order to have a clear idea of the displacement of the entire heating system, you need to know how much water is placed in the boiler heat exchanger.

You can take averages. So, on average, a wall-mounted heating boiler contains 3-6 liters of water, while a floor or parapet boiler contains 10-30 liters.

Now you can calculate the capacity of the expansion tank, which performs an important function. It compensates for the excess pressure that occurs when the coolant expands when heated.

Depending on the type of heating system, tanks are:

- closed;

- open.

For small rooms, the open type is suitable, but in large two-story cottages, closed expansion joints (membrane) are increasingly being installed.

If the tank capacity is smaller than required, the valve will release pressure too often. In this case, you have to change it, or install an additional tank in parallel.

For the formula for calculating the capacity of the expansion tank, the following indicators are needed:

- V(c) is the volume of coolant in the system;

- K is the coefficient of water expansion (the value is taken as 1.04, based on the water expansion rate of 4%);

- D is the expansion efficiency of the tank, which is calculated by the formula: (Pmax – Pb)/(Pmax+1)=D, where Pmax is the maximum permissible pressure in the system, and Pb is the pre-pumping pressure of the compensator air chamber (parameters are indicated in the documentation for the tank );

- V(b) - expansion tank capacity.

So, (V(c) x K)/D = V(b)

Section volume and coolant flow

Today, not all autonomous heating systems are filled with water. This is due to two factors.

- A situation arises when the owners need to leave the house without heating for a long time, since due to a long absence there is no need to heat the premises.

- Water tends to freeze even at zero temperatures. When water freezes, it expands and turns into ice, that is, it changes from one physical state to another. During this process, the intermolecular bonds of water are released and changed, resulting in a huge force that breaks radiators and pipes made of any metal.

To prevent such situations from occurring, instead of water, another coolant is used to fill the heating system, which does not have the problem of freezing. These can be household antifreezes such as:

- ethylene glycol;

- saline solution;

- glycerin composition;

- food alcohol;

- petroleum oil.

Thanks to special additives that are introduced into these components, coolant compositions retain their state of aggregation in liquid form even at subzero temperatures.

Poor heating

If the batteries become colder, even though the boiler is operating at full capacity, you will have to look for the problem from the radiators.

However, first of all, you should pay attention to the pressure gauge readings before and after the filter, the operation of the circulation pump, as well as the settings of the thermostats installed along the circuit. If everything is fine with these components, then the only problem that remains is with the heat exchangers.

There are several reasons why aluminum batteries do not heat well:

- Radiator airing;

- The battery is dirty;

- Initially there was a connection error.

The consequences for all reasons are the same - the normal coolant flow is interrupted and, naturally, there is no heat exchange.

The radiator should be blamed if only a few heat exchangers in the house become cold, while the rest continue to function normally.

How to rinse

Deposits on the inner walls of radiators increase resistance to coolant flow and can completely stop heat transfer if the channels in the battery sections become clogged. This is especially dangerous for aluminum radiators, because the cross-section of the channels in it is smaller than in any other heat exchangers.

It is unacceptable to use chemicals for cleaning, especially household cleaning products. Any acid or alkali can destroy the surface protective layer of aluminum and give rise to an active chemical reaction.

The same thing happens when using any hard brushes or abrasives. All that remains is to flush with a stream of plain water or with special compounds designed for flushing aluminum radiators, which can be found in stores selling heating equipment.

It is enough to disconnect the radiator from the heating system and run water into it under pressure, preferably in the opposite direction to normal, in order to squeeze out all the dirt that has accumulated on the walls.

To rinse each collector separately, simply unscrew the plugs on the back side of the inlet one by one and replace them with a valve with a connected hose leading into the sewer or a prepared container. Under pressure, as well as during short-term openings of the valve due to water hammer, the battery will quickly clean itself.

How to deflate

To remove air from radiators, including aluminum ones, a Mayevsky valve or automatic air vents are used. In the first case, if the battery stops heating normally, you should unscrew the valve plug and wait until the air comes out and clean coolant flows out.

In the second case, it is enough to adjust the volume of the air plug at which the valve will operate, and it will independently get rid of the accumulated air as it appears.

Automatic air vents for aluminum radiators are much preferable, especially if they also have thermostats installed. When the coolant current regulator is completely blocked, the risk of gas lock formation increases due to the slight but inevitable contact of aluminum with water.

Quite quickly, the pressure in a hermetically sealed battery will increase significantly and exceed the permissible value. For the same reason, in no case should the valves installed on radiators be completely closed in the summer if coolant remains inside the system.