The range of heating systems for creating a favorable microclimate in the house is currently huge.

Previously, radiators were mainly used to heat rooms - find out how to install them yourself. But now, most owners of private buildings prefer warm floors. However, using only TP does not always allow creating comfortable conditions in the apartment. Therefore, for private homes, professionals increasingly began to recommend a combined heating scheme - with radiators and heated floors.

Our article will be useful to those who are building their own home and planning to install a combined heating model.

You will learn how to combine radiator heating and heated floors, what advantages this scheme has in comparison with conventional radiators, how to make a project taking into account the calculations made and carry out the installation yourself.

We suggest you read the article - which heating radiators are best to install in an apartment, selection criteria and TOP manufacturing companies.

Norms and restrictions

Warm water floor is a low-temperature heating system. According to existing standards, the maximum temperature level of the coolant should be +55 degrees. During operation, standard heating usually ranges from +35 to +45, with the floor heating up to +26 - +31. The standards for different premises differ:

- for bedroom, kitchen, living room - +26;

- for bath, toilet, hallway—+31.

Liquid circulates through the floor lines using a pump. In addition, it allows you to regulate the heating level in the room. You need to select it based on the speed of water movement. The maximum permissible for hydrofloors is 0.6 m/s.

The difference between the heating of water at the supply and outlet should not be within 10 degrees.

What tools will you need?

The tying process is highly complex, so special tools are required, which include:

- Special keys.

- Seal for each threaded connection.

- Tow and thread pastes.

- Threaded threads.

This list is not exhaustive, because each system requires an individual approach.

Features of the combined system

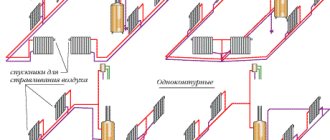

The combined heating system includes radiators, which are high-temperature sources, and low-temperature sources - heated floors.

There are two ways to connect a water floor in a mixed scheme:

- To an existing heating boiler - this method reduces the cost of equipment and installation time. The disadvantage of this design is the inability to work autonomously. This increases energy consumption and reduces floor efficiency.

- By installing separate boiler equipment for the floor, this significantly increases installation costs. However, such a system has the advantage of being autonomous, its operation does not depend on batteries. This is convenient when radiator heating no longer functions.

There are several recommendations that should be taken into account when deciding to create shared heating in a private house:

- Set temperature conditions separately for radiators and heated floors. Since in batteries the heating of water at the supply and outlet is about 70 and 55 degrees, respectively, and for heating floors 40 and 30 are required, the boilers are not able to cope with this task on their own.

- Use special components to adjust heating. Pumping and mixing units, shut-off valves - they will reduce costs and allow you to correctly connect the system with the container in which the water is heated.

- Configure the combined system using special and correctly installed technical means. For example, a mixing unit with a thermostatic head, its function is to regulate the heating level of the liquid; the thermostat is responsible for controlling the degree of heating of each room individually.

When laying a water floor, there is no point in limiting yourself to only the bathroom and toilet. It is better to place such a system wherever possible, since increasing its area does not significantly affect installation and operating costs.

Indeed, in any case, you will need to install a mixing unit and a device that will ensure liquid circulation. It doesn’t matter what the collector group will be - one-pipe, two-pipe or more.

The cost of screeding also does not change, even if the floor is installed in only one part of the room, the concrete solution will have to be poured over the entire area.

We manufacture a distribution manifold

We calculate the material required for the manufacture of the collector. The easiest way to do this is in Excel spreadsheets. At the same time, in this program you can calculate the cost of materials required for the manufacture of the device. We purchase the necessary starting material and prepare tools for self-production.

preparing tools

The starting materials for the main parts of the collector will be regular or square pipes. We make the necessary markings on them using calipers, a ruler and a core.

We make the necessary markings

Using a gas cutter, we make holes for the pipes.

make holes for pipes

We insert the pipes (pipe sections with threads) into the seats.

Insert the pipes

We fix the pipes by welding. First, rough it out, and then scald it around the entire perimeter.

We fix the pipes by welding

We also weld brackets to the body for wall mounting.

We weld the brackets to the body

We clean the welding areas from scale and rust.

Cleaning the weld areas

We treat the entire structure with a degreasing compound and cover it with paint and varnish.

treated with a degreasing compound, coated with paint and varnish

The paint completely sets in two to three days and we have a self-made distribution manifold at our disposal. Now all that remains is to install it in place and connect all the incoming and outgoing circuits to it.

ready-made homemade distribution manifold

A system with a distribution manifold will work much more efficiently than a simple pile of heating pipes

In order to catch all the nuances of making a distribution manifold yourself and the scope of its application, we recommend that you watch the training video.

Pumping and mixing unit

It is possible to construct a heating system according to a combined scheme in a private house using a pumping and mixing unit. The design with it is the most effective, but will be more expensive compared to using a 3-way valve, although the operating principle is the same.

Cooled water from the return pipe dilutes the hot coolant, and the presence of balancing taps allows this to be done in the required proportions.

This unit comes in different configurations. It depends on the purpose and cost of the equipment. The standard device includes:

- thermostatic valve;

- immersion temperature sensor;

- balancing valve with fixing spring valve;

- circulation pump;

- immersion thermometer;

- threaded sleeve;

- bypass and shut-off valve;

- drain and ball valve;

- air vent;

- bypass bypass.

How I installed the collector wiring with my own hands.

1.

I decided to install a gas floor-standing boiler in the basement of my house.

The boiler was installed on a concrete screed five centimeters thick.

2.

For the installation of the main pipelines I used a metal pipe with a diameter of 32 mm.

3.

A closed expansion tank was installed on the supply pipe.

4.

A circulation pump was installed on the return pipe.

Installing taps on both sides of the pump will allow you to change the device without draining the coolant.

Creating forced circulation in the heating system is mandatory. Forced circulation improves the efficiency of heating the coolant, and also simplifies the system and makes it more compact.

5.

We install collectors (distribution “combs”) on the main pipelines.

The combs are positioned so that the lengths to each heating device on the floor are approximately equal.

For example, if the distance from the collector to one radiator is 10 times greater than to the other, then the coolant pressure drop on the extended segment will be much higher than on the short one. The system is doomed to imbalance.

However, a difference of 2 times is not considered unacceptable.

6.

Each collector outlet has its own shut-off valve - a ball valve.

This allows, if necessary, to disconnect any radiator from the entire system without in any way affecting the operation of other heating devices. Each circuit is essentially an independent heating system.

It’s very convenient – I couldn’t be more pleased!

7.

I secured both collectors to a vertically placed metal corner.

8.

The wiring to the rooms was mounted along the basement ceiling using a metal pipe with a diameter of 15 mm.

9.

The rays of the circuits were connected to the collectors with a metal-plastic pipe.

10.

I installed a tap on the return pipe, through which I recharge the entire system.

11.

I punched holes in the floor slabs through which the pipes are connected directly to the heating devices.

12.

He connected the heating radiators to the risers of the circuits with a metal-plastic pipe.

This is my second winter using heating with manifold wiring. The system did not cause any serious failures, but we had to “fight” the formation of air in the system. There will be a separate article about this.

Diagrams and installation instructions for one boiler

The simplest and most economical way to build a combined heating system in a private house is considered to be a scheme with a radiator and heated floor from one boiler. All elements and the circulation pump are already installed from it.

There are wall-mounted boilers that already have a pump built into them. When using a floor-standing model, it will have to be installed separately.

When directly connected to a gas appliance (this is the model that experts recommend installing when installing a combined heating method in private homes), it is recommended to install a container for condensate. Installing a conventional gas boiler will lead to rapid failure of the heat exchanger.

Gas equipment is placed in rooms with ceilings of at least 2 meters. Ventilation is required.

If a solid fuel model is used, then to connect the heated floor to it, you need to install a buffer tank. Its function is to limit the temperature regime, since it is difficult to directly regulate the temperature.

The principle of operation of heating according to a combined scheme - warm floor and battery from one boiler is as follows. The heated water is directed to the mixing unit, where it rests against the safety head. The thermal head determines its temperature, and if it exceeds the required level, the valve opens and the hot and cold coolant is mixed to the required degree.

Then the water is distributed along the contour lines of the floor and radiators. After passing through the entire pipeline, it returns to the heat generator for heating.

The connection diagram for underfloor heating and radiators from one boiler includes the following elements:

- boiler with expansion tank - heats the coolant;

- hydroarrow - wiring, in the form of a pipe with four branches, through which water moves;

- radiator and sex pump - they supply fluid to the collector unit;

- collector - floor loops are connected to its outputs, and hot water is supplied;

- mixing unit - in it the coolant for the TP is diluted;

- thermostat - a head that opens or closes the flow of water into the circuits.

System installation

After constructing the floor “pie” - leveling the base, hydro and thermal insulation and laying the heating elements, you can proceed to installation work and connecting a combined heating system from one boiler (warm floor and radiators). Let's look at the process step by step:

- The boiler is installed and its piping is made (in a private house it is often installed in a separate building). The room must have a chimney and air flow.

- The pipes from the radiators are connected to the water heater, and a pump is mounted between them.

- The floor circuits are connected through a device in which the water is diluted to the required temperature. For this purpose, the following are used: a mixing unit, a 2- or 3-way valve, they are attached to the supply pipe.

- A circulation pump is installed.

- The floor contours are connected through a comb to a source of hot water; it is the coolant that will heat the room.

Installation of heating with forced circulation in a one-story house

Do-it-yourself heating of a one-story house is done using a technology that includes the following operations:

- First of all, the heating boiler is installed;

- The boiler is connected to a chimney that is led outside the building;

- When using a gas boiler, you must connect to the main line (this operation must be performed by specialists from the gas service);

- Heating batteries are installed along the walls in pre-selected places;

- All structural elements are connected by pipelines;

- The circulation pump and expansion tank cut into the return pipe;

- The pipelines are connected to the corresponding boiler nozzles;

- The assembled system must be launched in test mode, after which it can be put into operation.

This technology is common to all types of heating systems - there are minor differences only in the laying of pipes and installation of radiators.

Mixing valve circuits

In private homes, experts advise giving preference to a combined type heating scheme, using a mixing valve; it can be 2 or 3 way.

Heated floor collectors. Pumping and mixing units.

With 3-way mixing valve

In this combined scheme, the liquid is heated to 80 degrees for the radiator, and 40 degrees is required for heated floors.

The main task is to reduce the temperature of the water that comes from the radiators to the required degree for heated floors. This is exactly the problem that the 3-way thermostatic head solves.

The principle of operation of the system is that heated water is supplied from the heat source through this device to the collector, where it is diluted to the required degree with cooled coolant from the return pipe of the TP. In this state, the liquid is supplied to the floor circuits.

This combined scheme has a drawback - there is no way to make adjustments and limit the flow of cooled water from the return. In this regard, both excessively cooled water and hot water will flow into the main, and this can lead to overheating of the floor, or insufficient heating.

But these temperature changes can go unnoticed, since they are compensated by the concrete screed.

The circuit with a three-way valve is easy to install and has low cost. It is especially suitable for a one-story private house, or rooms with a small area.

If a three-way valve with bypass is used, mixing of heated and cooled coolant is carried out inside the device.

Installation is simple:

- a tee is installed on the supply;

- after that, the circulation pump is connected.

With 2-way mixing valve

Two-way valve - its thermostatic head controls the temperature level at the entrance to the floor pipe.

It is recommended to use the scheme in rooms with a large area, but not more than 200 sq. m. The presence of a balancing valve makes it possible to regulate the degree of mixing of liquid for underfloor heating circuits. It is capable of blocking or opening the flow of hot water.

The circulation process of the coolant is designed so that the liquid moves in a circle, and the addition of heated water occurs when the temperature drops. Since the throughput of the device is small, the adjustment is carried out smoothly, without jumps.

It is also mounted on the supply, and requires the installation of a device for forced circulation of liquid.

Specifics of distributor operation

Collector design

The collector is a distribution-type device for a heating system, which promotes uniform heat distribution. The cooled water flows back into the boiler under the influence of circulation. The main branches attached to the distributor function independently.

Device design

The intermediate node consists of two parts. The supply comb supplies the coolant to the communications, and the return comb leads it to the heat generator when it cools. Two combs are a collector group, and each of them can connect one circuit or several connections to heating devices. The pressure inside each circuit is adjustable.

Features of work

The principle of operation of collector heating is to heat the water with a heat generator and send it to the supply comb. Due to the large internal diameter of the unit, the liquid contained in it slows down the speed and is distributed over all outlets.

The coolant moves to the individual circuit through connecting pipes with a smaller diameter than the distributor. Heated water can be directed to radiators and underfloor heating systems, ensuring uniform heating of each element.

After entering the circuit and releasing heat, the water moves through another pipeline to the distributor. The direction will be the opposite. Having reached the return comb, the coolant is sent to the heat generator.

Using the built-in boiler pump

This scheme involves the use of boiler equipment with a built-in pump, the power of which is up to 35 kW. It creates a pressure at the outlet of the tank in the range of 20 - 25 kPa, with a water flow of 1000 - 1500 liters per hour.

The installation process is similar to that of a conventional heating element, but an additional pump for underfloor heating is not required.

To fully utilize the potential of the device and create coolant circulation in the heated floor and radiators, it is necessary to correctly connect the device to the circuits.

This can be achieved in this scheme by ring combination - the boiler with the TP, and with the radiator. These two rings are united by a small common area with low hydraulic resistance, thereby one circuit does not affect the other.

In this scheme, the slant filter acts as a slag catcher, and there are air vents in the boiler, radiator and floor circuit.

The essence of the functioning of the ring circuit is that water flows from the container where it is heated into the pipelines. Pressure surges in the supply and return pipes lead to the movement of liquid through the lines and its return back.

Selecting the power of the heating boiler

A heating boiler piping is a system of pipelines and equipment designed to provide radiators with coolant. Simply put, it's everything except the batteries.

The first step is choosing a heating boiler, the performance of which must be determined in advance.

The calculation of the required power of the heating unit is influenced by many factors, these are:

- volume of the building;

- number of windows and total glazing area;

- number and area of doorways;

- thermal conductivity of materials used in the construction of walls;

- degree of insulation of load-bearing structures;

- average annual temperature in the construction region;

- location of the building, i.e. Which side of the world faces the main, traditionally most glazed, façade?

However, there is an average indicator that, without in-depth calculations, allows you to determine the required performance.

For the middle zone, 1 kW per 10 m² of heated area can be taken as a starting point (but not a guide to action!). It is imperative to add a reserve of at least 20% to the design power of the heating boiler.

Next, you need to decide on the type of heating boiler: autonomous or manual loading.

Heat for heating buildings is obtained by processing fuel in boilers that heat the coolant

When can systems be combined?

It is permissible to install a combined heating system in premises of any purpose. The main thing is to choose the finishing product and the type of heated floor in accordance with the requirements. The combined design is ideal heating for a two-story private house.

When laying a heated water floor on the first floor, warm air masses, rising, will warm up the floors of the second floor, where only radiators can be installed. For the finishing material on the first floor it is better to choose tiles, and for the second floor any material is suitable.

It is not possible to build a combined system in apartment buildings, since it is prohibited to connect hydrofloors to the heat supply source for the entire house. The solution is to install a heat exchanger.

What materials is the harness made of?

At the moment, there are several popular materials that are used for strapping.

This list includes:

- Polypropylene pipes.

- Reinforced polypropylene pipes.

- Steel pipes.

- Other materials.

It should be understood that in addition to the basic materials, additional ones are also used, which include:

- Ball valves.

- Tees.

- Sgony.

- FUM tape.

- Linen windings.

- Packaging pastes.

Errors and problems

To save money, many simplify the design, excluding important elements. But this should not be done for the following reasons:

- With closed radiators and a functioning heated floor, the boiler and heat pump pumps will interfere with each other’s operation.

- When radiators and floor heating are operating, the floor pump can reduce the pressure, thereby reducing the circulation of water in the radiators.

- Even when the boiler equipment is stopped, the TP pump moves liquid through the boiler and radiators, which is impractical. And if unnecessary movement of the coolant in the batteries can be dealt with by installing a check valve, then it will not be possible to stop the movement of water flows in the boiler.

- The absence of a protective thermostat can cause failure of the mixing unit, excessively hot water will enter the floor pipes, and there is a risk of damage to the screed.

- In the absence of a bypass valve, if the floor loops are closed, the circulation of liquid in them stops. Moreover, if you forget to turn off the pump, then it works on a closed valve and heats up, which leads to rapid failure.

You may not need to install a bypass valve if:

- one floor contour will be constantly open;

- the pump has frequency regulation;

- TP automation can control the circulation and, if necessary, turn off the equipment.

If you decide to heat a private house using a combined heating system - warm floors and radiators, you should familiarize yourself with all the diagrams, their pros and cons. Only then, you need to move on to choosing a model in accordance with your requirements, financial capabilities and characteristics of the room.

Making a solar collector for alternative heating in your home

Recently, the interest of ordinary people in renewable energy sources has increased. Because of this, many homeowners are looking to buy a solar collector for home heating, which converts the sun's energy to heat water. But the decision to buy a solar collector for heating in a store is not always rational. The cost of the finished device is far from budget, so such a purchase can hit the family budget hard.

To avoid expenses, you can make a solar vacuum collector for heating yourself. Various solar collectors for home heating, reviews of which are positive, have the following design details:

- container for storing heated water;

- heat exchanger;

- device for collecting solar energy;

- insulating layer.

The materials from which the collector can be made are very diverse. There are known technologies for the independent production of solar collectors from polypropylene, ordinary garden hoses, window frames, plastic bottles, old refrigeration units and other available materials. The collector assembly diagram directly depends on the type of material chosen, so it is worth studying after the owner has decided on the concept of the collector.

Self-made vacuum solar collectors for home heating, the price of which in the store is $200 or more, can be used as full-fledged heating sources.

Vacuum solar collectors have a number of advantages:

- energy efficiency;

- environmental friendliness;

- autonomy;

- availability.

It is not difficult to make traditional distribution or solar collectors for heating your home with your own hands. This does not require large material costs, complex technological equipment or solid experience. However, these hand-made devices will greatly optimize the home heating system and will help the owner create a reliable, efficient and uniform source of heating for his home.

- How to fill water into an open and closed heating system?

- Popular floor-standing gas boiler made in Russia

- How to properly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes for malfunctions

Recommended reading

Heating thermostat - operating principle of different types How to make an expansion tank for heating with your own hands? Bypass in a heating system - what is it and why is it necessary? Expansion tank for closed heating: device and principle of operation

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement will result in legal liability. Contacts

What to choose

It is believed that the choice of PN25 pipes should correspond to the cost of boiler equipment. For cheap wood burning, you can use Chinese pipes. But not the first ones that come to hand, but those that are produced in China under a license from one of the European Union countries, made from imported raw materials using original equipment. For example, the “BLUE OCEAN” brand.

To piping a double-circuit boiler with polypropylene, you can use German products from Banninger or Italian pipes from Valtec. Among the cheaper ones, we can recommend high-quality polypropylene from. They are not capricious during installation and tolerate low temperatures well. Vesbo is the best Turkish pipe for piping.

Did you choose the pipes for piping the boiler yourself?