A membrane tank for hot water supply is an extremely important element of the piping of an indirect heating boiler. It is important that it exists at all; it is important to correctly select its volume and initial pressure.

So that you can be convinced of this, I want to tell you a story, then we’ll move on to choosing the parameters of the tank, and after that we’ll look at the main elements of the boiler piping.

The material will be very useful, so download my manual “Membrane expansion tank and main boiler piping elements” for reference.

History of water leak search.

One day I arrived at a customer’s site.

It was necessary to provide heating and water supply for the bathhouse - a guest house with a swimming pool. There are radiators and water heated floors, ventilation and equipment for the pool. In short, if you also involve subcontractors, then the order is monetary. The customer is not stuffy or stingy, excellent. But at the beginning of the conversation, he asks: Sergei Nikolaevich, I have the following problem in my main house: the water consumption has always been 25 - 40 cubic meters, and for some reason the last two months have been more than a hundred. Everywhere in the house is dry. Can you see what the reason is? And I understand: if I find a leak now, I’ll take the order; if I don’t find it, then I’ll lose it in disgrace.

We checked all the taps for consumers - they are closed, the dishwasher and washing machine are turned off, there is no gurgling in the toilets, all the taps in the garden are closed. And the counter is spinning. I went from the meter through the cold water pipe. Cold pipe, already dripping. On the floors there are collectors to water outlets - at room temperature.

Only the pipe to the boiler is cold, up to the safety valve. The valve itself is cold and the rustling of water can be heard in it. From the valve, the discharge tube is carefully directed into the sewer. Also cold and wet. That is, the safety valve does not hold, and cold water flows through it directly into the sewer.

You may ask, what does the membrane tank of the boiler have to do with it? Well, here's the thing: I unscrewed the nipple cap, pressed the rod, and there was silence. There is no air, it has leaked. The tank must compensate for the thermal expansion of hot water in the boiler when heated. When water expands, it goes into the tank, compressing its air part. If the pressure does increase, it will do so slowly and will not exceed the response pressure of the safety valve. But here the air has flowed out, there is nothing to compress. The entire tank is filled with water. When the doyler heats up, the pressure quickly increases beyond 6 bar, and the valve is activated, releasing some of the water. After several dozen such discharges, safety valves often begin to leak. And then the caring installers installed a discharge outlet into the sewer. The user does not understand at all what is happening, some kind of miracles.

In general, the diagnosis took about fifteen minutes. I said that our installer would come tomorrow, replace the valve and pump up the tank. There will be no leaks. We received the order.

The customer asked to install an additional boiler. This 150 liter was not enough to fill the jacuzzi. So there it is! the puzzle is complete. This means that the boiler often had to be heated from minimum to maximum, which means that the water expanded as much as possible when heated. When air leaked out, this inevitably caused an excessive excess of pressure and activation of the relief valve.

Do you understand how important it is that there is enough air in the tank for the system to operate smoothly?

Tying rules

To achieve maximum energy savings and reduce consumption, you need to carefully insulate the pipe from heat loss. If the main branch and return run along the wall, instead of maintaining warm water for analysis, you can get a heating system for a vertical fence.

Tips for improving your binding:

- It is better to carry out installation work together with the installation of the boiler and additional units of the hot water supply system. It is difficult to incorporate a return flow of heating fluid into a finished circuit. Sometimes devices are initially located in such a way that there is no free space for this.

- Installation of an indirect heating boiler requires arranging a base , because depending on its dimensions, its weight can be significant.

- At the outlet of the DHW branch from the boiler, a membrane accumulator . Autonomy of each supply branch is required; ball valves are installed for cutting off. The counterflow of water in the opposite direction is prevented by a check valve.

- Do not attach pipes to thin partitions made of weak materials . The brackets are secured with anchor dowels that can withstand the load without deformation.

Regardless of the adopted scheme, the pipes are installed at the boiler level or slightly higher. The pipes are directed in the direction of travel to the boiler.

The system must be equipped with separate water filters, but it is better to install a comprehensive cleaning system. Safety rules provide for the installation of an expansion tank and an automatic air vent from the pipes.

The recirculation system can be controlled by time, by temperature, or by two indicators simultaneously.

What initial pressure should be created in the tank?

The tanks come from the factory at 2.5 bar.

Some people put it just like that. I have a different approach and I will explain why. Air must be pumped into the tank based on the pressure of cold water. For example, 4 bars come into the house from the central water supply. Create a little more air pressure in the tank, for example 4.2 bar. This is the opinion of at least one more respected author, I agree with him and I will explain why. If the air pressure was 2.5 bar, then after connecting the tank to water, it will compress the air in it to the same four, and the working volume of air will be significantly reduced, by almost half. If the pressure is set to 4.2, then the volume of air for compression will be consumed only with the beginning of the real expansion of water. Look:

Wall mount

Instantaneous water heaters are lighter, so they are easier to mount on the wall in an apartment. But heavy boilers, which are designed for a water volume of 50 to 200 liters, must be very well attached to the wall.

This is where the installation of the boiler with your own hands begins. Installation can only be carried out using anchor hooks or bolts. Such fastening will be reliable on concrete panel walls or solid brick walls.

But if the wall does not inspire confidence in you: wooden or old brick, then you need to drill through the wall and screw it onto steel strips from behind. Or make a metal frame on the wall and attach it to it using hooks welded to the frame. Well, in general, such a boiler cannot be hung on a plasterboard wall in an apartment.

When installing any water heaters, you must hang them strictly vertically, determining the accuracy of the mounting level. If the boiler hangs unevenly, with a slope, then there will be problems with its operation.

Another nuance that must be taken into account when installing it yourself is that the distance from the shelf to the boiler lid must be left about 15 centimeters.

The video shows in detail how to install a boiler with your own hands:

Tank maintenance.

If the safety valve is triggered, it means that air has leaked from the tank, or the membrane has leaked. Unscrew the cap of the tank nipple and press on the stem. If water comes out, then the membrane is torn and the tank needs to be replaced. If nothing comes out, or the air hisses, then you need to pump it up: • release the union nut on the shut-off valve, • open the drain valve (red handle) and drain the water, • pump up the pressure, for example, with a car pump, • close the drain valve. • attach and tighten the union nut.

Choosing the right device

When choosing a model with the necessary functions and volume, take into account the fact that the frequency of pump operation depends on the total volume of the tank.

The leading characteristic for any tank is not its functionality, but its volume.

At the same time, for each water supply system there are criteria that cannot be neglected, namely:

- Number of regular water users. (Daily use).

- Number of points for water intake. (Appliances, taps and other plumbing fixtures).

- Approximate frequency of using water intake points at the same time.

- The “on-off” cycle. You need to know exactly the limit of this cycle per hour for your pump.

Approximate calculation:

When calculating for three regular consumers, install a tank with a total volume of 20-24 liters. However, the pumping equipment should produce approximately 2 cubic meters per hour.

When calculating for four regular users with a reserve, it is better to install equipment of 50 liters or more. The pump productivity in this case is approximately 3.5-3.7 cubic meters per hour.

If there are more than 10 consumers, then a tank of at least 100 liters is required, and pumping equipment with an indicator of more than 5 cubic meters per hour.

To avoid breakdowns and expensive repairs, you need to carefully familiarize yourself with the manufacturer.

In this choice, there is no need to chase a cheaper and dubious brand. Improper savings can lead to breakdowns in the future.

Models with a low retail price inside are made, as a rule, without defects. But consumable parts are always made from the cheapest materials.

It is better to inquire about the material from which the membrane is made. Its environmental friendliness and stability will improve comfort as well as the service life of the system.

How to choose tank volume

You can choose the tank volume arbitrarily. There are no requirements or restrictions. The larger the volume of the tank, the greater the supply of water you will have in case of a shutdown and the less often the pump will turn on.

When choosing a volume, it is worth remembering that the volume that appears in the passport is the size of the entire container. There will be almost half as much water in it. The second thing to keep in mind is the overall dimensions of the container. A 100 liter tank is a decent-sized barrel - about 850 mm high and 450 mm in diameter. You will need to find a place somewhere for it and the harness. Somewhere - this is in the room where the pipe from the pump comes. This is where all the equipment is usually installed.

The volume is selected based on the average flow rate

If you need at least some guidelines to select the volume of a hydraulic accumulator, calculate the average flow rate from each water intake point (there are special tables or you can look at the data sheet for household appliances). Sum up all this data. Get the possible consumption if all consumers work simultaneously. Then figure out how many and which devices can work at the same time, calculate how much water will be consumed in a minute in this case. Most likely by this time you will have already come to some decision.

To make it a little easier, let’s say that the hydraulic tank volume of 25 liters is enough to meet the needs of two people. It will ensure the normal functioning of a very small system: faucet, toilet, sink and small water heater. If you have other household appliances, the capacity must be increased. The good news is that if you decide that the current tank is not enough for you, you can always install an additional one.

What do you know Installation of an indirect heating boiler:

• Design and principle of operation.

• How to choose the boiler volume. • Simplified wiring diagram for floor-mounted and wall-mounted boilers. • Detailed boiler piping diagram. • Detailed equipment. • How to heat a boiler with a wall-mounted single-circuit gas boiler. • Piping of a wall-mounted single-circuit gas boiler with a boiler. • How to heat a boiler with a floor-standing boiler. • Pump manifold piping diagram for multi-circuit boiler houses with a boiler. • Boiler heating control from its own thermostat. • Boiler heating control by a separate immersion thermostat. • Boiler priority scheme over other consumers. • Application of heating elements and night tariff. • Additional materials. Other articles about membrane tanks:

1. Where in the boiler room should the expansion tank for heating be installed?

2. How to choose a membrane battery tank and set up a water supply system.

All the most common fatal mistakes in installing water heated floors. Sergey Volkov.

Connection diagrams

The principle of tying an indirect heating boiler differs little from tying a conventional unit. Complex equipment - coils, the configuration of which affects the principle of heat distribution in the recirculation branch.

The system necessarily contains the following modules:

- storage tank;

- thermal insulation layer preventing heat loss;

- performance measurement sensors;

- return branch (pipe);

- distribution tee.

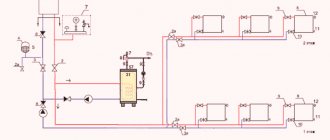

are used :

- with the inclusion of a three-way valve;

- using two circulation pumps;

- with piping via hydraulic arrow.

A system is selected taking into account various conditional factors and individual characteristics of the water main.

Incorporating a three-way valve into the system

Such a module is also called a servo drive. The method is applicable for supplying recirculation to mounted and floor-mounted units.

System Features:

- two pipes are connected to the boiler, one for heating, the other for hot water supply;

- the main source of heat is a water heater;

- water reduces the temperature - the three-way valve turns on and works to heat the tap fluid;

- The heating is closed for this period and turns on after reaching the desired temperature in the water supply system.

The circuit provides a control switch, and a servo-driven valve replaces it, so when the water cools, there is a flow of energy from the water supply branch into the boiler heating system. This connection principle provides for the simultaneous activation of heating water supply and heating energy.

Place the storage tank near the boiler. The scheme is calculated using the method of double-circuit heating of housing. The system is effective for large tanks.

Scheme with two feed pumps

One pump recirculates liquid in the DHW branch, the other drives water through the boiler circuit. This scheme initially provides for maintaining normal tap water temperature, with heating of heating pipes in the background.

The following nodes and modules are installed in the project

- thermostat to start the pump;

- mode switch for temporary redistribution of hot flow between branches;

- two pumps for heating and water supply.

The boiler pump starts working based on a signal from the thermostat, which is located inside the storage tank. Modified system - one extended sensor is installed. In this case, one thermostat is responsible for the operation of the heating and boiler pump.

If cooled liquid from the return flows into the heater, condensation appears on the walls due to the temperature difference. Drops lead to damage to equipment, so attention is paid to the quality of the programmer.

Piping via hydraulic boom

This option is effective for a large residential building, where a tank of 200 liters or more is planned, and the heating and plumbing systems use several circuits (DHW, heated floors, a branch of radiators in individual rooms, and others).

Hydrosterlka is a special type of distributor to make the insertion system simpler:

- no need to install pumps on any of the branches;

- all circuits have the same fluid pressure, so there is no threat of thermal shock;

- facilitates the distribution of flow from boiler units whose power is more than 50 kW;

- regulates the thermal balance of an extensive network of highways;

- provides the required difference between the main line and the return pipe.

If the system already has circulation pumps, the hydraulic arrow balances the functions of several of them at once and reduces the hydraulic resistance.

Installation of an open type hydraulic tank

An open-type device is used less and less often, as it requires constant user intervention in its operation. An open expansion tank is an unsealed container that serves to generate pressure in the water supply system, accumulate water, and also serves as an expansion chamber.

The tank is connected to: a drain tap, pipes for the recirculation and supply pipes, a control and overflow pipe

The tank is installed above the highest plumbing point, for example, in the attic, water enters the system by gravity. Every meter the device rises increases the pressure in the water supply by 0.1 atmospheres.

To automate the process of providing water, the tank is equipped with a float switch and an automatic relay is installed that will turn the pump on and off.

The container is mounted in a frost-free room, covered with a lid to prevent dust and debris, and the walls are wrapped in mineral wool or other insulation.

This method of organizing water supply requires regular monitoring by the user, otherwise the water may freeze at subzero temperatures (if the room is not heated). The liquid will evaporate, so you will have to constantly add it.

In addition, such a container is bulky and not aesthetically pleasing; it requires an attic space in the house. But the main drawback of the device is that the tank is not designed to work under conditions of high water pressure in the system.

Fighting water hammer

Water hammer is a short-term pressure surge that occurs in a closed circuit due to the inertia of a moving water flow when it instantly stops. Water hammer often pushes pressure beyond the strength of pipes and flexible connections; the consequences are very predictable - the owner receives ruptures in the water supply at the seams and fittings.

The combination of high temperature and pressure surge led to the rupture of a polypropylene pipe

If expansion tanks are connected to the water supply, the water supply is made absolutely safe: the air tank in this case also acts as a damper. A small volume tank is mounted at the water supply inlet or (for collector water distribution) on the collector.

Membrane shock absorber on the manifold

Device

How are expansion tanks for water supply arranged?

A membrane tank is a steel container with a pipe for connecting to a water supply or heating system and a spool for pumping. It is divided by an elastic membrane into two compartments - air and water. The air compartment is often filled with nitrogen instead of air, which prevents corrosion from damaging the tank walls.

Construction of a water supply expansion tank: a steel container is divided into two compartments by an elastic membrane

Curious: the expansion tank of a hot water supply or heating system is usually equipped with a membrane with increased heat resistance. There are no other design differences between it and the hydraulic accumulator, so the expansion tank can be safely used as a hydraulic accumulator.