They are less often connected to free-standing boilers of similar volume. Among the latest models of water heaters, aluminum tanks have performed well. But it is still better to equip it with a temperature sensor; there is a place in the case for this. The process of connecting and piping an indirect heating boiler occurs in one of the ways described below.

Such equipment operates automatically. How to properly connect an indirect heating boiler

The circulation pump is powered through a thermal relay, so it starts to operate only when the temperature drops below the required one.

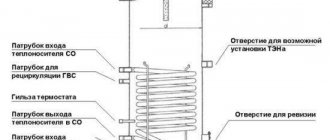

During installation, it is necessary to install a temperature sensor in a certain place (there is a hole in the housing) and connect it to a certain boiler input.

Scheme without priority When connecting an indirect heating boiler, it is better to choose a scheme with priority - it provides hot water in the required quantity. Instead of supplying gas, the heating element is connected to the electrical network. An autonomous control system is much more convenient.

The servo drive in this circuit serves precisely to control the operation of the valve.

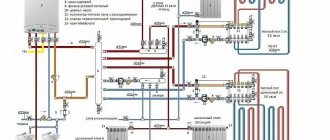

Piping a single-circuit boiler with a hot water boiler.

What is an indirect heating boiler

A water heater is a tank filled with water. It is based on a heat exchanger cylinder. It, in turn, is connected to a hot water supply system or to a heating boiler.

This design is quite simple: hot water moves from the boiler through the heat exchanger, from which its walls heat up and transfer their heat to the water with which the container is filled.

It turns out that heating occurs not directly, but indirectly, hence the other name - indirect exchange broiler. Types of equipment.

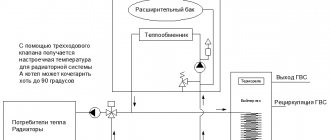

Pipelines for the DHW recirculation system

It is worth keeping in mind that DHW recirculation will require significantly more money to be spent on its installation.

In addition to the cost of the plumbing circuit, it is additionally required to provide thermal insulation of the pipes in order to keep heat leakage within normal limits. The pipeline layout itself is quite simple. One part of it, supplying water to water collection points, is sequentially mounted in a continuous line from the thermal unit to each point. However, the pipeline does not end at the last water withdrawal point, but returns back to the heating unit.

Before installation begins, each pipeline segment is placed in a belt insulation made of foamed polyethylene or rubber. Rubber is more suitable for those sections of pipes that will subsequently be walled up. Not only the pipes themselves are insulated, but also the fittings, and all joints in the heat-insulating material must be sealed with metallized tape.

Indirect heating gas boiler

In this type of device, the tank is heated using a gas burner. Despite the fact that the installation of this equipment is not cheap, this method significantly saves the budget, because the use of natural gas is the most economical solution.

The device should be operated strictly following the attached instructions. This is necessary to maintain your own safety, because all gas appliances pose a potential danger.

Preparing the tank for water heater assembly

To make an indirect type boiler, you can use a new or old gas cylinder. This container is made of thick stainless steel 3-4 mm thick and is perfect for working with hot water.

Before assembling the heating structure, you will need to carefully prepare the cylinder. To do this, the product is cut in half using a grinder. The inner surface of the container is cleaned using an angle grinder with an appropriate attachment.

Before assembling the boiler, the cylinder must be opened and the inner surface cleaned

After this, the inside of the cylinder is washed, dried and coated with nitro primer paint. This work must be carried out without fail, otherwise after putting the boiler into operation, the heated water will smell like gas.

When using a tank from other metal containers, preparation is carried out according to a similar scheme.

Electric indirect heating boiler

An electric water heater is similar in function to a conventional boiler; its operating principle is as follows: when a metal heating element is heated, the water temperature rises.

The main advantage of such a water heater is its accessibility and ease of installation, because for its installation it is not at all necessary to contact a special service. The disadvantage is that it takes a long time to heat up the water.

As a rule, the choice of device depends on the type of energy carrier; for example, if liquefied gas is available, it would be more appropriate to install a gas boiler. An electric model is suitable for multi-storey buildings.

The principle of operation of a magnetic starter and a small-sized contactor + Video explanation

Sometimes the question arises: why use MP or KM at all, why not just use a three-pole machine?

- The machine is designed for up to 10 thousand shutdowns and starts, and for MP and KM this figure is measured in millions

- During power surges, the MP (KM) will turn off the line, playing the role of protection

- The machine cannot be controlled by remotely applying a small voltage

- The machine will not be able to perform additional functions of turning on and off additional circuits (for example, signal circuits) due to the lack of additional contacts

In a word, the machine perfectly copes with its main function of protection against short circuits and overvoltages, and MP and PM do theirs.

That's all, I think that the principle of operation of MP and CM is clear, for a more clear explanation, see the video.

Happy and safe installation!

In addition to the article, I attach technical documentation for KMI series contactors

Differences between boilers by type of installation

- Wall. This device is compact in size and mounted on the wall. Its main advantage is that it is suitable for small spaces. Storage boilers have a small tank volume, no more than 100 liters.

- Floor. This device is quite voluminous, which is why it differs from wall-mounted storage boilers. The tank volume can hold 115 liters or more, which is quite enough for a large family living in an apartment or a country house.

Storage boilers with a large volume are usually placed on the floor. Flow-type devices are often mounted on the wall.

Harness for seasonal use

In apartments, boilers are most often installed as a necessary measure during the period of scheduled repairs of the heating network.

Most of the time the water heater is idle and, although it is recommended to keep it filled, the constant flow of water can cause deposits to deposit in the tank. Therefore, it is necessary to provide a system for disconnecting the tank from the water supply system, which is quite simply implemented with a pair of ball valves or one three-way valve. If you use ball valves, install one of them before the hot outlet inserts into the water supply system. This tap is closed in the summer to prevent water from flowing into the mains. The presence of a tap on the hot outlet is strictly necessary to limit the flow in winter.

1 - shut-off valves at the inlet of the water supply system; 2 - three-way valve; 3 - security group; 4 - storage water heater

One three-way valve installed at the point of insertion into the hot line also solves the problem of switching between modes. It is noteworthy that it is on three-way taps that it is most simple and profitable to implement a system with several water heating devices connected by a parallel pipeline.

Differences in the principle of heating water

- Storage boiler. It has a heating element, and hot water accumulates in an installed tank - a thermos.

- Instantaneous water heater. Models of this type are called columns. They are ready to use and heat water immediately after turning on the tap. A heating element is mounted inside the device; when interacting with it, the water temperature quickly reaches the desired heating level.

DHW recirculation. A simple solution to the problem

This article will describe a fairly simple technology for solving a common problem - hot water recirculation, or rather, the lack of hot water when you need it. If you live in a compact house and the water heater is located near water consumption points, you are not familiar with this inconvenience. If you live in a large house and the boiler is in the basement, 15 or more meters of water supply may stretch to the last consumer. Owners of large homes are familiar with long waits: they turn on the tap and wait two whole minutes for hot water to flow. This wastes energy and water resources.

As a rule, a series water supply connection is used. The main pipe extends from the heater to the farthest point. Consumers are connected from it using tees - a sink, a bathtub. The disadvantages are obvious - pressure drops if several taps are open at the same time, waiting for hot water. Another option is a balanced system using a collector, where each endpoint is served by a dedicated line from the collector. The price is several times higher than in the first case.

Connection features

There are two ways to connect an indirect heating boiler, both with and without priority for heating hot water. When heating water with priority according to demand, all the coolant is pumped through the boiler heat exchanger.

Heating occurs quite quickly. As soon as the temperature reaches a certain point, and this is controlled by a sensor, the entire flow is redirected to the radiators.

- With a method without priority for heating water, only a certain part of the coolant flow is directed. As a rule, with this method the water takes much longer to heat up.

- When connecting an indirect heating boiler, it is preferable to choose the method with priority. This will always provide hot water in the right quantity.

- This does not greatly affect heating, because it takes 20-40 minutes to heat the entire volume of water, and 3-8 minutes to maintain the temperature.

Power calculation and equipment selection

Initially, in order to select a BKNSR scheme and select equipment, it is necessary to calculate the thermal load on the domestic hot water supply for a specific consumer. An incorrectly selected connection method will lead to ineffectiveness of the DHW recirculation system or breakdown of the main and pumping equipment.

How to choose a boiler

For example, to perform the calculation, for a family of 4 people they take hot water standards according to SNiP 2.04.01-85 “Internal water supply and sewerage of buildings.”

Simple calculations show that washing dishes will require 336 l/week, showering - 1280 l/week, and minor activities another 280 l/week, for a total of 2856 l/week or 17 l/hour.

Formula for determining power:

17x0.0375=0.637kW

Heater design parameters:

- The minimum volume of water consumption is 1.5 l/min.

- Capacity volume - more than 100 liters.

- Water heating time is up to 2 hours.

- Thermal insulation material is polyurethane foam or mineral wool.

- Safety elements: valves, temperature and pressure sensors and fuses.

- Service life is from 10 to 12 years.

General rules

According to the rules, the closer the equipment is to the boiler, the more efficient the heat exchange from the heating system.

Installation of the boiler must comply with the recommendations:

- Wall-mounted models are attached to the wall;

- Floor-mounted ones are installed on the floor.

In order for the circulation point to be in the center of the tank, the flow of cold water must be supplied through the lower pipe, and the intake of hot water through the upper. This is a prerequisite for high-quality operation of the device.

The movement of hot water should be carried out along the coil, from top to bottom.

Following these simple recommendations will ensure the correct operation of all elements that perform an important function.

Don’t forget about installing ball valves. Thanks to them, it is possible to turn off elements such as a three-way valve, circulation pump and others for maintenance.

Connection on the water supply side

If the water collection points are located close to the heating tank, the connection is made according to the standard diagram presented below. Let us explain the functions of some elements:

- It is recommended to use a pressure reducer for pressure surges above 6 Bar;

- a check valve on the cold water supply prevents the tank from emptying into the water main;

- the expansion tank compensates for the increase in the volume of heated liquid;

- a safety valve set at 7 bar discharges water into the sewer if the pressure rises to a critical level;

- The drain valve is used to drain water using the method of communicating vessels.

It is important to leave the drain line filled - then when the drain valve is opened, the water will flow out according to the law of communicating vessels

When consumers are away from the boiler, it is worth installing a recirculation line with an additional pump and check valve. If your heater model does not have a separate fitting for connecting this line, simply cut the return line into the cold water inlet line.

Before starting a system with a water heater of the “tank inside the tank” type, you must first fill the internal tank with sanitary water, only then pump in the coolant and perform pressure testing. The master will tell you the details in the video:

Common mistakes

During the installation process of the device, some difficulties and, therefore, errors may arise.

To avoid their occurrence, you need to:

- Install the broiler and boiler as close to each other as possible. Be sure to check the pipes to see if they are aligned correctly.

- Correctly connect the pipeline to the coolant.

- Properly install the circulation pump.

Installation of equipment requires correct and competent work. This guarantees uninterrupted operation of the device and timely supply of water.

Design of rafter fastenings

To do this, it is necessary to correctly calculate the wind and snow loads, i.e. optimal weight of the roofing system as a whole. Based on these calculations, the material and thickness of the load-bearing walls are designed. Errors made in assessing loads and other shortcomings can cause deformation of the entire structure, compromising the integrity of the coating and even collapse of the roof. The following factors should be considered when designing:

Calculation of the load on the rafters.

- roof type and shape;

- the presence of internal supports and their location;

- type and weight of roofing material;

- roof slope and angle of inclination;

- rafter system and its design;

- dimensions (length) of the space to be covered;

- cross-section of timber for rafters.

How to choose an indirect heating boiler

There is not much difference in choosing an indirect heating boiler and a storage boiler.

But you need to pay attention to such points as:

- Volume. This is the main selection criterion. How to calculate? For example, on average, about 40-80 liters of water are spent per person. From this, expenses should be made for a family consisting of several people.

- Today the market offers devices with a volume from 200 to 1500 liters.

- Water flow through the heating circuit. In order to understand this feature of the device, you need to use the data sheet that comes with it. Water consumption should be no more than 40% of the total water volume.

- Tank and thermal insulation material. Of course, it would be better to choose a stainless steel container. Polyurethane foam or mineral wool are suitable as insulation. Their use guarantees high-quality thermal insulation.

Calculation

In order to find out the ratio of the length of the coil to the volume of the tank, you need to apply the following formula:

Here:

d – tube diameter (in meters);

p – coil power (thermal) in kW;

ΔT is the difference between the temperatures of the heated water and the coolant.

Calculation example

As an example of a calculation, you can take the following parameters:

- coil pipe diameter 0.01 m;

- coil power 30 kW;

- coolant temperature 80 degrees Celsius;

- tank volume 200 liters;

- the temperature of the heated water is 15 degrees Celsius.

Next you need to make a calculation:

It is advisable to do the coolant input and output on one side. In this way, the maximum level of convenience will be achieved.