Everything is fine in gas boilers, but they just require a careful approach to installation. The requirements for the room where the gas installation will be located are also important. After all, gas is always a potential danger. And in the event of any incident, it is advisable to get by with as little blood as possible. Therefore, in this material we will discuss basic recommendations for installing gas heating equipment in your home.

General information and where is the best place to install a gas boiler

Man is inherently a very warm-blooded creature and living in the cold is contraindicated for him. Therefore, the living space should always be equipped with a heating device. Nowadays, private houses are gaining more and more popularity, no neighbors above or below, you can buy the house that the whole family has long dreamed of or design and build something of your own. But a private house obliges the owner to think through many nuances to make life cozy and comfortable. Prepare your sleigh in the summer, as popular wisdom says, so you need to think about how the house will be heated in advance.

Quite a few heating systems have been developed: stoves, electric, gas. It all depends on the family budget, since installation and consumption tariffs are very expensive. As practice shows, in most cases gas boilers are installed in a private house. The efficiency of this unit is very high, and the ability to regulate the heat temperature in a residential building without additional devices makes it very economical among the heaters in this line. Of course, buying and installing a gas boiler is not a cheap pleasure. But given that the price of gas is much lower than other energy sources, all initial investments will pay off very quickly.

You can't just pick it up and put it in the house. You should familiarize yourself with the requirements for this type of heating in the cold season. The choice of room for a gas boiler is described in detail in documents in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000. The main requirements for this installation are that when building a house, you need to allocate a room that fully complies with fire and explosion hazardous classifications.

Primary requirements

The boiler unit (depending on the size and type) can be installed in a separate room on the ground floor, in the basement of the house or in the attic (but this must be provided for by the layout of the house, determined at the design stage).

It is also possible to use an autonomous module (container with a mini-boiler room), erect a special extension or a separate building. As a separate structure, a ready-made mobile boiler room can be used, mounted from sandwich panels and finished with non-combustible materials.

The heating unit can be solid fuel, liquid fuel or gas. Depending on the type of heating unit, the requirements for a boiler room in a private house have some differences.

The design standards for a boiler room in a private house provide

:

- compliance with requirements regarding room size;

- installation of no more than two boiler units in one room;

- absence of flammable materials in the finishing of surfaces and roofing;

- the presence of doors to the street and to the house (for an extension);

- competent selection and installation of doors: they must be included in the fire category and open outward, like the door of an adjacent room in the house;

- unobstructed access to all heating equipment;

- installing a window with a window for natural light and emergency ventilation, the window sashes should swing outward, and the glass area should correspond to the volume of the room (0.03 m2 per 1 cubic meter);

- the presence of natural or forced ventilation, which is calculated as follows: (room width x ceiling height x room length) x 3. As a result, we get the volume of air that needs to be replaced in one hour;

- the presence of a chimney, if required by the type of boiler (for units with a power of less than 30 kW, the chimney pipe is allowed to exit through the wall);

- connecting the water supply (for filling and recharging the heating circuit) and sewerage (for draining water from the system);

- installation of a separate foundation for boilers weighing more than 200 kg (installation of lighter models on a reinforced concrete floor is allowed).

For wooden walls of built-in and attached boiler rooms (which are common with the rest of the house) a non-combustible finish is needed that can increase the fire resistance limit of structures to 0.75 hours. To build an extension, it is recommended to use bricks, blocks and other non-combustible materials.

Boiler room plan in a private house

Basic standards regarding room dimensions

:

- ceiling height: should be from 2.5 m with a heating unit power over 30 kW, for less powerful boilers the figure is at least 2.2 m;

- boiler room volume: from 15 m3 (if the heating unit is planned to be installed in the basement, then when calculating the volume of the room you need to add 0.2 m2 for each kW of boiler power);

- The boiler room area must be at least 6 m2.

The minimum area makes it possible to ensure the safe operation of the equipment, but for ease of installation and maintenance of the heating system, it is still recommended to equip more spacious boiler rooms.

In the boiler room of a private house, the layout of which is developed taking into account the characteristics of the selected unit, it is necessary to provide free access to the boiler piping elements, control valves, and electrical equipment.

General standards for the room where the heating boiler will be installed

A gas boiler requires a separate room in the house. Typically, this room is located on the ground floor or basement, but this is only suitable for a one-story mansion. If the house has more floors, it is better to build a separate extension, especially since the boiler itself will heat it. Requirements for installing gas boilers are as follows:

- In one room no more than 4 square meters, only one gas boiler can be installed.

- The ceiling height must be at least 2200 millimeters.

- The room should be very well lit, with a natural glow. There must be at least 0.03 m2 of window area per 1m3, and a hood must be installed.

- Doorways must be at least 80 centimeters for ease of entry and exit.

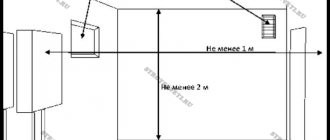

- The distance from the boiler to the front door is calculated from 1 meter to 1.5 meters.

- During operation, any repair and maintenance work is possible, so that they are carried out in accordance with the requirements, you must leave a free space of at least 1.5 meters in advance.

- To avoid vibrations during heating, the gas boiler is installed strictly horizontally, ensuring maximum stability.

- Walls and floors must be smooth and free of flammable mixtures. They are usually additionally covered with heat-resistant material.

- The ignition and pump on the heating boiler are connected using an electrical supply, so the presence of a grounded socket in the room where the device will operate is strictly necessary.

- Like any stove heating there is a chimney, so access for cleaning and maintenance should be as convenient and spacious as possible

Installation conditions, location

The SNP document displays the general requirements for the room where it is planned to install a gas boiler with a closed chamber:

- boiler room dimensions =/+4 m2;

- the mandatory presence of a door whose width is 80 cm;

- the presence of a natural light source (window dimensions 0.3 m² for every 10 m³);

- ceiling height from two and a half to 2.5 meters;

- presence of a grounding circuit;

- close location of cold water supply system pipes;

- chimney, ventilation system based on the requirements set out in the accompanying documents;

- It is prohibited to install a gas boiler in a bathroom or bathroom;

- place on a flat surface of the floor or wall.

Location

Gas boilers for heating and hot water supply are divided into two types:

- floor;

- wall-mounted

Floor-standing devices are mostly used for heating large and medium-sized private houses. Basically, the design uses a chimney with natural draft, and installation is carried out in a separate boiler room (boiler room). Such devices have a more reliable heat exchanger made of several interchangeable sections of cast iron.

Wall-mounted boilers are installed both in a separate boiler room and in the kitchen or other non-residential premises. They are used not only in individual houses, but also in apartments.

Chimney: requirements for its design

Requirements depend on the models of devices used. It is strictly forbidden to discharge combustion products into ventilation shafts. The smooth operation of the boiler depends on the quality of the design. For example, it can stop working automatically if there are windows in the room that cannot be opened, then the boiler can stop working due to the lack of fresh air flow. The quality of the system is monitored by the relevant authorities at least twice during the entire heating season.

Also read with this article: Why does a gas boiler go out?

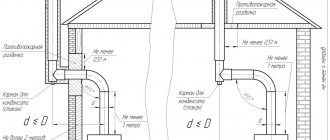

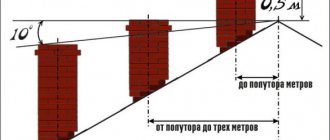

SNiP standards precisely highlight the requirements. They must meet the following parameters:

- mandatory presence of a condensate drainage system;

- vertical shape, absence of any ledges;

- a slight slope is allowed (up to 30 degrees);

- a segment connecting to the boiler of at least 50 cm;

- total height above the building;

- contact with the outer wall is excluded, maintain a distance of at least 20 cm;

- located in the wall, insulated with non-flammable materials (glass wool, asbestos);

- facing the roof, rises to a height of one meter;

- It is prohibited to conduct any part through residential premises.

It is best to carry out installation based on the requirements set by the boiler manufacturer. They are set out in the accompanying documents.

Ventilation

Having an effective ventilation system is a prerequisite for stable operation of a gas boiler. There are two types of ventilation - natural and forced. Sometimes this may be a combined system, classified as a separate category.

The arrangement of natural ventilation is primitive. For its operation, it is enough to have a slot under the door and a window, which guarantees normal traction. There must be an opening with an air duct in the boiler area.

Forced ventilation requires various aids. Most often these are special types of fans that provide air exchange.

Features of energy supply

Modern heating equipment is energy dependent. This requires compliance with certain standards:

- mandatory grounding of the heating boiler;

- taking into account voltage instability, it is better to connect boilers to uninterruptible power supplies or stabilizers;

- The socket must be located in close proximity to the boiler; the use of extension cords is prohibited.

These are all requirements stipulated by the rules.

Requirements for installing a boiler in the kitchen

Very often it is not possible to find a place to install and build a separate room. Then you can place the gas boiler in the kitchen. However, if it does not comply with all SNiP indicators, then its installation and further use should be under the control of the gas service. To install a gas boiler in the kitchen, the following requirements must be taken into account:

- The kitchen should have a door of the required size with the desired isolation from other rooms in the house or apartment.

- Presence of a window.

- Installation of a hood is required.

- Separate socket with grounding.

- A smoke exhaust system must be in the kitchen.

It must be remembered that the air around the heating device must constantly circulate, and accordingly there must be enough space to install the gas boiler. The heating installation can be perfectly designed in the same style as the kitchen unit. After all, closing the boiler with a door is not only possible, but even necessary. And when entering the kitchen, it will not immediately be clear where and what is located. When installing a boiler in the kitchen, you need to remember that compliance with all standards and requirements will protect you and your family, and the gas boiler will last a long time and save a lot of money.

Some nuances

Important! There are SNiPs and there are requirements of regional gas companies. SNiPs are uniform throughout the country, but the requirements of regional gas workers sometimes differ quite greatly.

And if the requirements of SNiP will affect the operational characteristics of the boiler room, then the requirements of gas workers will affect approval, specifications and the actual launch.

You can build a gas boiler house in accordance with all the requirements of SNiP, but it is the local gas workers who decide whether to connect you to the main gas or not.

Second point. We are talking, first of all, about connecting to the main gas. Yes, a boiler room using liquefied gas, as well as equipment using it, are sources of increased danger and all mandatory requirements must be observed.

However, when connecting your equipment to a gas tank, all work and acceptance are carried out by specialists from a commercial company that is implementing this project on your site.

But the local branch of RAO Gazprom Distribution works with main gas. This means that the requirements will be more stringent, and acceptance will take place in a completely different way.

Requirements for installing a wall-mounted boiler with a closed combustion chamber

There are several types of wall-mounted heating boilers. Before you give preference to one of them, you need to carefully study the characteristics. The power of these installations usually does not exceed 42 kW. Their device includes a gas burner (gas enters the chamber and burns), a heat exchanger or coolant, an expansion tank (excess water produced during heating flows into it), a circulation pump, a fan and a security system (it is triggered in case of failures in the system, and also notifies about problems). The requirements for the installation of gas heating boilers are also regulated by SNiP, but there are a number of distinctive rules that must be taken into account.

- The wall or supporting structure on which the device will be mounted must match and support the weight of the boiler.

- If the wall is covered with decorative finishing, then a 3-millimeter thick gasket made of refractory material is installed between it and the boiler.

- The distance to the ceiling should be at least half a meter, and to the floor at least a meter.

Whatever choice of installation of gas heating equipment you choose, you need to obtain all the necessary documentation to allow installation. Obtain an agreement for the right to connect to the city gas main. The installation must be provided to the gas organization and its specialists. Of course, this will require financial expenses, but peace of mind is not measured by money. The safety of the residents of the house is paramount. However, if you still decide to take a risk and install the boiler yourself, then first you need to obtain the appropriate permission from the gas service. Installation is not an easy task and requires maximum skill.

- Check the availability of all components to begin work.

- Make sure that the requirements for floor coverings, doorways and window structures are met in accordance with SNiP.

- Install the device in a stable and horizontal manner.

- The gas appliance must be placed away from electrical appliances, and access must be ensured in every way.

Compliance with all of the above requirements is mandatory, and if you miss even one of them, an irreparable disaster may occur. During installation, everything needs to be weighed and the possibilities assessed. After all, the issue of installing a heating system using the gas method should be carried out by specialists. The risk is great.

Safety system

Gas-powered appliances require serious monitoring. It is provided either by a person or an automation system. The latter is capable of providing multi-stage protection that prevents dangerous situations and increases equipment safety. The main task of the protection system is to turn off the device in time by stopping the fuel supply.

Let's look at the stages of protection using the example of the Proterm Wolf KSO floor-standing boiler. These modern devices have multi-stage protection. One of the stages is an ionization sensor that controls the flame. If the fire goes out, a signal will be sent to the control unit, it will shut off the fuel supply and prevent an accident.

The combustion chamber has a temperature sensor that monitors the heating of the coolant and prevents the firebox from quickly burning out. “Wolves” are equipped with a KTD system - chimney draft control. It prevents the accumulation of carbon monoxide. If there is no draft, combustion products begin to accumulate in the chimney, and the thermostat heats up. When the temperature limit is reached, the thermostat contacts open and the flow of fuel stops.

Automatic protection

Modern heater models are equipped with electronic control and measuring instruments that generate signals for the control unit. Automation, receiving signals from sensors, coordinates the work of all nodes. Elements that prevent various types of malfunctions and problems are safety valves, expansion tanks, air valves, smoke detectors and other devices.