The circulation pump is an important component of the heating system. This element helps improve its performance, so it itself must have reliability, durability and the ability to work in constant mode.

The Wilo heating pump, which is very popular among consumers, meets all these requirements.

The circulation pump is one of the main components of the heating and hot water supply system

Qualified Installation

Having your pump system installed professionally by a certified technician or professional facility can help avoid many problems, protect your drinking water, and prevent contamination. When carrying out work, the installation company must use only products that have a mark of conformity with standards received from an accredited certification organization. And you can't go wrong if you choose products from Wilo.

Our advice

- Have work on your drinking water pipeline done only by specialized companies.

- Careful and rational handling of warm water saves time and energy.

- To protect and conserve our drinking water supplies, never pour toxic substances or waste down the drain.

- Repairing a dripping faucet will not only save you a lot of hassle, but it will also reduce your costs and be a positive contribution to sustainable use of resources. Over a year, more than 1,000 liters of drinking water can flow through a dripping faucet.

- If you have not used the pipes for a long time and the water in them has stagnated, you can use it to water flowers without any problems.

Common labeling

When choosing a Wilo brand pump, you should pay attention to the letter and number designations that come after the main part of the name. Each of the letter designations indicates the type of product, and the numbers in the product labeling indicate its most important characteristics

Using one speed switch, the pump is controlled

For example:

- if the name of the device contains the word “Drain”, it means that it is intended for use in a drainage system;

- devices whose markings contain the words “TWU” or “Sub TWU” are designed for use in wells;

- if the name contains the word “Drainlift” or two capital letters “KH”, then the equipment is suitable for use in sewerage;

- devices with the letter combinations “RS” and “RSD” are circulation devices, and they are used in heating systems.

Let’s say the circulation pump you just purchased says “Star-RS 25/7”. From this designation you can immediately understand that this is a device that is designed for connection to pipes with a width of 25 mm, and its pressure height is 7 m.

The most popular devices today are Wilo Star RS and Wilo TOP-S. Wilo TOP-S pumps can have a threaded or flanged connection. Each of them has several rotation speed options. They can be used not only in heating systems, but also in air conditioning systems.

The motor is resistant to blocking currents and ensures reliable and safe operation of the pump.

For example, if the pump is labeled “Wilo TOP-S 40 10”, you can immediately understand from just one number that the technical characteristics of this Wilo heating circulation pump are:

- the width of the pipes for connection to the system is 40 mm;

- the lowest head height at zero flow is 10 m.

In the production of Wilo pumps, only materials that are particularly durable and can withstand corrosion and other negative influences are used. Most often, such materials are cast iron, metal graphite, steel with anti-corrosion properties, as well as modern polymers. Therefore, when purchasing one of these devices, you can rest assured that it will last a long time if used correctly.

Recommendations for operation and maintenance

Various problems may arise during operation of the circulation pump. The design of WILO products is so simple that you can service them yourself, without the help of professionals.

Frequently encountered problems and ways to solve them:

- The shaft stopped rotating. These pumps operate so quietly that it is impossible to immediately determine the cause of the breakdown. To identify a malfunction, a special shaft rotation tester is used. If the scale shows no movement, the device must be disconnected from the power supply. This situation sometimes occurs during long periods of inactivity or when a foreign object gets inside the camera. In any case, you will have to disassemble the pump and unscrew the shaft, and then remove foreign particles from it.

- A creak appeared. Most often this happens when the system heats up. A squeaking sound is heard when the engine pulley begins to come into contact with the starter plug. To eliminate this problem, it is enough to install a gasket on the plug. If this does not help, then the part of the pulley that rubs against the bushing can be sawed off, but not more than 3 mm.

- The pump stalls. Usually the reason lies in the formation of scale, which needs to be cleaned with a brush. If the system has a coarse filter, this problem practically does not arise.

- Pump vibration. This indicates that the bearings need to be replaced. The appearance of vibration may also indicate a drop in pressure, which should be increased. Sometimes reducing the viscosity of the coolant helps.

- Low water pressure. The problem indicates that the device is not connected correctly. This can happen if the filter is dirty, the water pipes are faulty, or there is a large amount of glycol in the coolant.

These emergency situations occur extremely rarely and are most often due to improper connection of equipment. In any case, they can be fixed simply and without the use of special tools.

Heating models

| Wilo model | Connection, inch | Length, mm | Power, W | Price, rub |

| Star-RS 15/2 | 1 | 130 | 20 | 6450 |

| Star-RS 15/4-130 | 1 | 130 | 20 | 6900 |

| Star-RS 15/6 | 1 | 130 | 24 | 8250 |

| Star-RS 25/4-130 | 1 1.2 | 130 | 20 | 7120 |

| Star-RS 25/6-130 | 1 1.2 | 130 | 40 | 8500 |

| Star-RS 25/2 | 1 1.2 | 180 | 20 | 5550 |

| Star-RS 25/4 | 1 1.2 | 180 | 20 | 5550 |

| Star-RS 25/6 | 1 1.2 | 180 | 24 | 7000 |

| Star-RS 25/7 | 1 1.2 | 180 | 40 | 9570 |

| Star-RS 25/8 | 1 1.2 | 180 | 20 | 10290 |

| Stratos PICO 15/1-4 | 1 | 130 | 20 | 15000 |

| Stratos PICO 15/1-6 | 1 | 130 | 20 | 16900 |

| Stratos PICO 25/1-4 | 1 1.2 | 130 | 24 | 11000 |

| Stratos PICO 25/1-4-130 | 1 1.2 | 130 | 20 | 13800 |

| Stratos PICO 25/1-6 | 1 1.2 | 130 | 40 | 12200 |

| Stratos PICO 25/1-6-130 | 1 1.2 | 130 | 20 | 15100 |

Not all models are shown in the table, please contact us with your request.

Features and areas of operation of Wilo pumps

- wear-resistant parts;

- automated assembly and quality control process;

- certification of finished products;

- a developed network of service centers covering the whole of Eurasia;

- energy and resource efficiency;

- possibility of DIY repair;

- environmental friendliness.

Application of Vilo pumps in:

- heating circuits;

- drinking and municipal water supply;

- wastewater disposal;

- drainage of residential and industrial premises;

- construction industry;

- for irrigation purposes.

Classification of Wilo pumps

The entire variety of pumping units from this brand is divided into several groups according to their intended purpose:

- circulation equipment – mounted in heating circuits and air conditioning systems. Serves to increase heat transfer by accelerating the movement of coolant;

- downhole units - Vilo pumps, designed for immersion in underground sources of various depths;

- drainage pumps that work with water of varying degrees of contamination. They drain flooded basements, cesspools, etc.;

- fecal aggregates - unlike the previous class, easily pass through solid and semi-liquid particles, and, depending on the model, are also crushed to a certain fraction. Ideal solution for silted wells, septic tanks, sewer units;

- booster equipment - by increasing the pressure in the water supply circuit (usually for cold water), it increases the water pressure.

Let's look at some well-known modifications of Vilo pumps and their characteristics.

Prices

Downhole equipment can be purchased for an average of 19 (model TWU 4-0207-EM-C) - 27 thousand rubles.

Up to 49 thousand (model TWU 3-0145 3) Prices for drainers: from 6.8 (Wilo Drain TMW 32/7) to 19.8 (Wilo-Drain TC 40/10).

The Vilo sewer installation will cost 20 – 22 thousand rubles.

Pumps that increase cold water pressure are among the most affordable. The Wilo PB-088EA model can be purchased for 4.5 thousand rubles. maximum price - 17.5 thousand rubles. for the Wilo PB-401SEA device.

The price range for circulation equipment is very wide . The device can cost 2 thousand rubles. and 100. For example, the Top line is estimated at 9 – 12 thousand rubles. And Star series units cost from 2 to 4.5 thousand rubles. The most expensive pump from the Stratos line will cost: 48 – 107 thousand rubles.

Conclusion

So, Vilo equipment rightfully takes the place of sales leaders in many countries. The company's engineers develop models for every occasion and budget. The series is replenished with new devices, and German quality allows the units to be used for a long time.

As a rule, heating pumps are needed if the area of the room exceeds 100 square meters. meters. But increasingly, even owners of small houses are purchasing circulation pumps. Circulation pump for heating: how to choose? Let's consider the types of devices and their characteristics.

Instructions for making a heat pump for heating a house are presented in this article.

Positive and negative aspects of choice

Glandless circulation pump

Modern heating systems most often operate on the principle of natural circulation. But sometimes there is a need for forced circulation of the coolant. And then the question arises of choosing a suitable pump. The choice depends on many factors, the most important of which is the power of the device. It should be enough to generate the required feed intensity.

There are special mathematical formulas that allow you to make the necessary calculations. The finished tables are published on the Internet. They are also in the technical data sheet of the product. When choosing pump power, the area of the heated room and the speed that the circulation pumps are capable of generating are taken into account first of all.

By choosing Wilo products, everyone receives in return a whole package of operational benefits:

- German products eliminate the possibility of heat losses that often occur during evaporation.

- All its working mechanisms are made of corrosion-resistant materials.

- The operation of the system is controlled automatically. There is a built-in thermostat, and all functions are displayed on the LCD display. However, there is a manual switching option that allows you to control the speed of the working shaft.

- Even the most powerful models operate completely silently. Almost all Vilo pumps are small in size, so their installation does not take up much space.

- Connection is quick and convenient thanks to the spring terminals.

- The rotor and motor have a multi-stage protection system, so the unit is not afraid of power surges.

There is only one drawback to such installations. Today, Wilo pumps can only be installed in areas where power supply problems are extremely rare. Without electricity, it is simply impossible to evaluate the advantages and quality of work of German equipment.

Wilo surface pump

Many years of experience allows the German company Wilo to produce high-quality pumping equipment that satisfies the widest consumer demand. Today it is used both in the household sector and in industrial production. High quality and ease of installation, ease of operation and the presence of a large number of technical advantages distinguish the products of the described concern among similar products. But this is not the most important thing.

German pumps can be connected not only to the heating system. They are widely used for air conditioning. The model range is represented by several dozen varieties. All devices are characterized by high performance, compact size, high power and low noise during operation.

Read further:

German Wilo pumps - technical characteristics, types and models

Danish circulation pumps Grundfos - technical characteristics and design features

Modern polypropylene pipes for heating - technical characteristics and operating features

Gas boiler Navien - technical characteristics, design features and model range

What is the difference between wall-mounted gas heating boilers - technical characteristics and operational features of the devices

Types of pumps by number of speeds

The design of each pump provides a certain number of speeds. The performance of the equipment depends on this parameter. WILO products are available in single and multi-speed, allowing you to choose the product for your specific system.

Single speed

Such models are not regulated in terms of operating speed. If you turn them on, they will only work at maximum power. These products are the simplest from a technical point of view and affordable, since the design does not contain additional elements - regulators. This option is convenient in situations where the pump must operate at maximum power - as a rule, these are common cases, which is why such products are very popular.

Multi-speed

Thanks to the presence of several speeds, the user can choose the intensity of operation of the pumping equipment. For example, in some situations it is not necessary for the device to operate at full power, and a reduced speed is set. This leads to energy savings and less wear on the working mechanism.

Modern equipment can have 3 or even 4 speeds, so the user himself decides in which mode the pump will operate. More speeds are not found.

Types of Wilo brand pumps

Wilo pumping equipment can significantly improve the heat supply process not only on an industrial scale, but also in local heating systems, such as private households or apartments.

Now many people know that installing a pump in an individual heating system with natural circulation allows not only to significantly improve the quality of heating, but also to significantly save on the consumption of natural gas or other types of fuel.

Of all the pumps that the manufacturer presents, models designed for use in heating systems are especially in demand. Let's take a closer look at their types and applications.

Pumps are available in two types:

- with dry rotor;

- with wet.

What is the fundamental difference?

Dry rotor pumps

The first type of pump means that the rotor of the electric motor is not in contact with water. The connection between the motor and the working part (housing) is made through special sealing rings that do not allow the pumped liquid to enter the electric drive.

We can say that such a pumping unit consists of two parts: the first part is an electric motor, the second part is a housing equipped with two pipes - one discharge, the other suction, and it also contains an impeller, which carries out pumping.

These pumps are usually used in systems with long pipeline lengths and large connecting diameters. They are widely used in industrial and heating boiler houses. The warranty period is from 3 to 5 years. It depends primarily on the brand and performance.

Equipment indicators:

- High level of efficiency - more than 80%;

- High requirements for the presence of suspended particles in the pumped medium. It is necessary to install filters to prevent foreign objects from entering the unit;

- The room where this equipment is installed should not be dusty. If there is dust, the O-rings quickly become unusable. Replacing rings is a labor-intensive process that requires special skills;

- The type of connection to pipelines is usually flanged.

Glandless Rotor Pumps

This type is most common for domestic needs. The design of pumps of this type is fundamentally different from those previously discussed. The electric motor and impeller are located directly in the housing, which has an inlet and an outlet. The liquid is pumped as if by the rotor itself, which, in turn, is equipped with an impeller (impeller).

Cooling and smearing of bearings is carried out directly by the pumped liquid. This type of equipment is used in heating systems with a short length and small diameter pipelines. Most often they are connected using a threaded connection.

Equipment indicators:

- Almost silent operation;

- Has a compact design;

- The ability to change operating parameters, which allows you to save on energy consumption;

- Long working life;

- Virtually no maintenance required.

Wilo products have proven themselves primarily for their energy savings, as well as a high level of quality and durability. The housings are made of gray cast iron or stainless steel, depending on the purpose of the pump. Working shafts are made of stainless steel only. Bearings are made of graphite.

Models of pumps with a wet rotor for heating systems are equipped with three-mode units for adjusting the speed of rotation of the impeller. These blocks are controlled manually. The temperature range in which such units can be operated is from -20 to +130 degrees Celsius.

This type of equipment is used in heating systems with a short length and small diameter pipelines

Equipment marking

To understand what is encrypted on the plates attached to the equipment, let’s look at:

- The first thing that is indicated is the manufacturer’s corporate logo;

- Product number, date and year of manufacture;

- Star-RS 30/6 – pump type or brand;

- Class F – class of resistance to temperature heating;

- IP – equipment protection;

- PN – maximum working pressure;

- Tmax – maximum temperature at which the equipment can operate;

- SV0 – software for this brand of equipment (this parameter is very important when connecting additional functionality);

- P1max, P1min – upper and lower operating temperature ranges;

- Imax, Imin – current limits for normal operation;

- 1~230 V – current voltage. It can be indicated in the range for three-phase connection.

Above are the most common designations that are needed to select a unit. All other technical data, as a rule, are indicated in the product passport.

Glanded rotor pumps are usually used in systems with long pipeline lengths and large connecting diameters.

General and basic characteristics of circulation devices of heating systems

Basically, all heating systems use circulation pumps; they help supply fluid and are installed inside the housing. The general and main parameters of such products are:

- Performance - it shows how much liquid the circulation pump can pass through itself in one hour of operation in the heating system. It all depends on the hydraulic resistance of the line.

- Pressure is another word for hydraulic resistance. It is used to determine the maximum height to which the pump will raise the entire column of water.

- Connecting dimensions are usually selected as follows: selection should be made taking into account the diameter of the connected heating pipes, as well as the length of the housing.

- Maximum temperature. The main task of such pumps is to pump heated coolant. It is better to choose a device that can withstand a maximum temperature of up to 110 degrees.

- Manufacturer - this parameter is also important in work. It is best to buy products from reputable suppliers.

Choosing a circulation pump - rules?

When you have received the required parameters of the desired product, you can begin choosing a model. It may seem that, purely theoretically, absolutely any pump is suitable, which is in no way inferior to the technical characteristics of those already calculated. When choosing, it is necessary to take into account the following recommendations from experts:

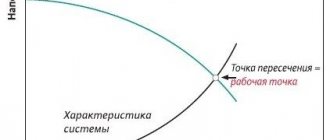

- You should try to study the model you like as best as possible. It is best to choose a pump whose operating point is usually closest to the graph.

- It is necessary to choose a pump that does not have very high performance, as it will consume unnecessary unnecessary electricity and also create unnecessary noise.

- Performance should be calculated based on the maximum load at the lowest outside temperature. If you think that the pump consumes too much energy, then choose a less powerful one.

- Nowadays, all modern devices have three speeds. By switching them, the operation of the entire heating system can be optimized.

Blitz tips

- Do not purchase equipment significantly more powerful than necessary. A unit with greater productivity will not be energy saving;

- The selection must be made according to a previously made calculation. If this does not work, consult the equipment sales points;

- Installation is best done via bypass;

- If the installed equipment will remain inoperative for a long time , periodically put it into operation by short-term start-up;

- Remember that all electrical equipment must be grounded.

Connecting the device

Heating efficiency and uniform distribution of heat throughout the rooms is ensured by a properly selected circulation pump

It is important to install it correctly, a lot also depends on this

Self-installation does not require professional knowledge, but there are several important points.

Connection point

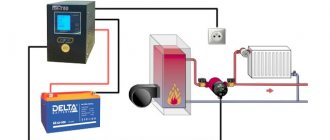

It can be installed on any section of the circuit, but professionals recommend choosing a return pipe.

Photo 4. Diagram of the heating system. The circulation pump is installed on the return circuit.

Installation in a heating system

The water is shut off, the pipes are cut according to the installation length of the product. Before installation, check in which position, horizontal or vertical, the pump should operate. The joints are then sealed and tightened. They think about connecting to the power grid in advance.

Filters

It is recommended to install additional coarse filters; this will protect the device from accidental ingress of particles and significantly reduce the likelihood of failure.

Separate pocket

Sometimes, for ease of maintenance and repair of the pump, installation is carried out in a separate pocket. For this, an additional branch of half a meter in length is created. Valves are installed at the ends, which allow you to disconnect the device from the general circuit at the right time. In this case, there is no need to shut down the system - the valves are closed, the pump is removed from its place and sent for repair, and the structure continues to operate.

Photo 5. Special pocket for the circulation pump. There are valves at the edges of the structure.

Pressure equipment for water supply

Self-priming pumping station "Wilo" PW-175EA

Like other pumping stations from this manufacturer, it consists of a self-priming centrifugal pump, a pressure switch, a pressure gauge, and a hydraulic accumulator. It has a reliable electronic module that allows operation without user intervention. Designed for clean drinking water, but also allows for the distillation of rainwater. Without immersion in a water tank, it pumps liquid from a depth of up to 8 m.

Peculiarities:

- shutdown in the absence of water consumption;

- heat-protected motor;

- capacious hydraulic receiver;

- small size and light weight, simplifying installation and transportation;

- equipped with a high-pressure pump pumping water from a depth of 8 m.

Specifications:

- Throughput – 2.2 m3/h;

- Head height – 40 m;

- Power – 350 W;

- Pressure – 4 bar;

- Receiver – 2 l;

- The diameter of the inlet/outlet pipes is 1 inch.

Pumping stations "Vilo" series Jet FWJ (left) and Jet HWJ

Their functional purpose is similar to the previous modification.

Used for irrigation and drinking water supply. They operate automatically. They differ from each other by the presence of a membrane receiver (only HWJ has it), which can be supplied in volumes of 20 and 50 liters. Advantages:

- anti-corrosion material design (steel, noril);

- overheat fuse;

- the ability to adjust the pressure level at which it will turn on/off. water pump;

- two-way connection - from the suction and pressure sides;

- ease of installation;

- do not require regular maintenance.

Operating parameters "Vilo" FWJ/HWJ (average for the series):

- Self-priming – 8 m;

- Jet height – 50 m;

- Productivity – 5 m3/h;

- Weight – 11.7/18 kg.

Water pump "Wilo" DRAIN TMW-32/8

The model is an automatic submersible pump with a stirring device. Can be used in both stationary and mobile conditions. Structurally, it is designed in such a way that a turbulence is continuously formed in the suction zone, which promotes the drainage of sewer pits, abandoned mines, pits in the most hygienic way today: without odor and sediment formation.

Peculiarities:

- electric motor with a dry rotor and a cooling circuit that prevents overheating;

- end and lip seals of the impeller and motor;

- vertical installation;

- resistance to short-term (3 min) increase in temperature 0C of the working environment up to +90;

- integrated float switch and check valve;

- Built-in Twister function that creates swirls.

Working properties:

- Traction – 450 W;

- Immersion – up to 3 m;

- The cross-section of the pressure pipe is ¼ inch;

- Network cable – 10 m;

- Pump D – 16.5 cm;

- Weight – 4.7 kg.

Drain TMW 32/11

This Wilo pump model is a vortex drainer made from various materials. The device is capable of pumping slightly polluted water (meaning those in which the diameter of the pollution particles does not exceed 1 cm).

Brief technical characteristics of the circulation pump Vilo Drain TMW 32/11:

- The maximum depth at which it can be used is 3 m.

- This device has overheat protection. In 60 minutes of operation it will be able to pump 15 cubic meters. meters of water.

- As the name implies, the head height of this device is 11 m, cross-section is 165 mm.

Its average cost is 10,500 rubles.

Features of the models

The manufacturer Wilo has several popular models of circulation pumps.

Wilo-RS 25 6

Manufacturer's model, which creates a pressure column of 6 meters.

Advantages:

- wet rotor, speed adjustable;

- the motor does not respond to blocking currents, there is no need for a relay;

- coolant with a temperature in the range (from -10°C to 110°C);

- a filter is installed in front of the cartridge, which increases the reliability of the pump;

- operates with full functionality at ambient temperatures up to 40°C;

- simple installation;

- takes up little space (installation length - 180 mm).

Wilo Star RS Series

A line of compact, reliable pumps for domestic use.

The letters in the name mean the characteristics of the product:

- RS - type, rotor, fittings;

- Then there are numbers indicating the connection diameter, pressure, and pipe diameter.

The pump is capable of providing constant pressure in the heating system, but it is important to choose the right option, taking into account the following factors:

- head column in meters;

- pump flow (the amount of water that it is capable of pumping per unit of time).

Photo 3. Wilo circulation pump model Star RS. The device is a wet rotor device.

These values are provided by the manufacturer, who tests the device under conditions as close as possible to real ones. The documentation for the pump contains graphs reflecting the pressure and flow capabilities of the pump.

Main characteristics:

- pressure column;

- power (depending on frequency);

- the pressure in the system reaches 10 bar.

Designed for pumping only clean water; glycol can be added in a 1:1 ratio.

Peculiarities:

- The engine does not require additional devices, is resistant to blocking currents, and does not respond to voltage surges.

- The rotation speed is switched; for this purpose, there is a toggle switch on the terminal box with markings of different sizes. This helps achieve the optimal temperature in the house and helps save energy.

- To remove air from the system, which leads to idle operation of the device, a special screw is used.

Using the frequency change function makes it possible to reduce power consumption by up to 50%. If the temperature drops, the frequency will have to be increased. If noise occurs when the frequency is too high, lowering the frequency will help reduce it.

These universal devices are used:

- for pumping cold and hot water;

- in cooling and air conditioning circuits;

- in homes and businesses.

The pump is easy to install:

- installation on any segment of the circuit is allowed;

- horizontal or vertical installation (restrictions are indicated in the data sheet);

- the terminal box can be installed in 4 positions;

- possibility of two-way cable connection;

- For ease of installation, spring terminals are provided.

The product is made of quality materials:

- high-strength gray cast iron alloy (some models are made of bronze);

- polypropylene (for the impeller);

- stainless steel (for shaft);

- metalgraphite (bearings).

Among the advantages, the first positions are occupied by the inspiring price and low energy consumption.

Installation features

Installation can be done using different methods.

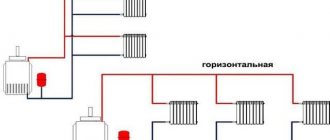

There are 2 schemes:

- Single-pipe. The coolant is constantly consumed, while temperature differences are insignificant.

- Two-pipe. With high drops and variable flow rates.

Before starting installation work, study the instructions for the product in detail. It is also important to choose the installation location, namely, there must be access to the device for maintenance. Most often, equipment of this type is installed in front of the boiler. Installation on the supply is not relevant, since there is a possibility of creating a vacuum.

Installation steps:

- The remaining liquid is drained from the system.

- The pipeline is being cleaned.

- The pump itself and auxiliary fittings are being installed.

- Liquid is poured into the system, from which excess air is removed.

For proper installation, circuit preparation is required. Thanks to it, the device will be able to continue working even if the power is turned off. The diameter of the main pipe and the bypass must be different.

By following these recommendations, even a novice master can handle the installation:

- To achieve maximum performance, the shaft of the device must be in a horizontal plane.

- The terminal box is installed on top.

- There should be a ball valve on each side of the pump, which is necessary for subsequent maintenance.

- The system must have a filter that removes small particles from the coolant.

- There should be a valve on top of the bypass line to remove air.

- The presence of shut-off valves is necessary to prevent water from leaking.

- An expansion tank is provided for an open heating system.

- To improve performance, the connection points of the device must be properly sealed.

Proper installation in compliance with all rules and recommendations is the key to efficient operation of pumping equipment.

Factory VILO RUS

Construction in the Moscow region began in 2013 with the purchase of a land plot. In the fall of 2014, the foundation stone of the plant was laid. The volume of investments in the new production of VILO RUS amounted to 35 million euros. It is planned to create about 400 jobs at the plant.

The project and the plant building were awarded the highest rating of the GREEN ZOOM professional energy efficiency system - “Platinum Certificate”. In May 2022, the production and warehouse complex "VILO RUS" was awarded the "Gold Certificate of the international certification system LEED-NC (New Construction)". The facility scored the maximum number of points in the following sections: “Water Efficiency”, “Innovation”, “Regional Features”. Based on the certification results, the facility scored 64 points. According to the results of energy modeling, the energy efficiency of the facility was 25.09%.

The plant is located at 50 km of the Gorky Highway (M7 Moscow - Nizhny Novgorod highway). On an area of 5.5 hectares there is a production (8500 sq.m.), a logistics center (7000 sq.m.) and an administrative and office building (6110 sq.m.). The plant has 21 assembly lines, 10 test pipelines for submersible pumps and the largest test bench in Europe with a pool depth of 12 m and a capacity of about 1000 cubic meters. m.

BAC family

This line represents pumps operating with a dry rotor. This is a single-stage centrifugal unit that can be used as a circulation unit. Such models, in particular, are used in equipping residential buildings, as well as industrial infrastructure and agriculture. The working medium can be both cold and hot water. Since the Wilo BAC heating circulation pump does not provide for passive lubrication with a working medium, you should initially prepare for regular maintenance. True, if we are talking about pumping clean water, then the list of such measures may be limited to checking connections and technical and operational parameters.

Advantages of devices

Thanks to the special properties of the Wilo pump, the efficiency of the heating system increases significantly. In this case, thin pipes can be used, which, in turn, helps reduce material and fuel costs. Also, when using a pump, the volume of carbon dioxide that is released into the atmosphere is reduced, and the daily consumption of electrical energy is no more than 250 W.

Vilo pumps have many positive properties.

During operation, the working part of the pump is constantly washed by the pumped liquid, so there is no need for regular maintenance of the unit

The most important of them are the following:

- After water evaporates, there is no heat loss.

- The operation of the system can be controlled automatically. The device has a liquid crystal screen, a built-in thermostat and other elements that allow control. You can also manually switch the speed of rotation of the working shaft.

- Compared to many circulation pumps from other brands, Wilo devices are quite compact and therefore do not take up much space.

- The motor and rotor have a multi-stage protection system that helps prevent failure due to sudden surges in voltage in the electrical network.

- The motor operates silently, making it possible to install the device in residential buildings.

Wilo pumps are used in small rooms of several hundred square meters. The selection is carried out according to such parameters as power, volume of circulated water, room area and pressure height. The last parameter is the most important.

You can see how to distinguish an original pump from a fake in the following video:

How to choose a pump for heating a private house

Wilo, as a pump for heating a private house, is used by owners everywhere. Selecting a pump is actually quite a delicate matter and of course it is necessary to take into account all the little things. You need to calculate the length of the line, take into account the number of radiators, do not forget about heat loss and much more. In general, as a rule, the design of a heating system is calculated at the stage of building a house and it is better to entrust such a calculation to a competent specialist. In addition, on the official website of the manufacturer Wilo, the online pump selection program - Wilo Select - can help you.

Wilo pump calculation

However, we can certainly give some indicative recommendations. For initial calculations, it is necessary to calculate the heated area and decide on the purchase of a boiler of sufficient power. Roughly enough, “by eye,” the required boiler power is calculated based on 1 kW per 100 square meters.

Having calculated the boiler power, it will not be difficult to find out the flow rate of our pump using the formula: Q=N/(t2-t1), where Q is the flow rate we need to select a pump in m3/h; N is the power of our selected boiler in watts; t2 – water temperature at the boiler outlet; t1 – water temperature at the boiler inlet.

Next, we need to determine from the hydraulic curve (which is attached to all pumps) the pressure we need. If you did everything correctly, then with a high degree of confidence we can say that your system will work properly. Do not forget that Vilo pumps are supplied with three speeds, so you can slightly adjust its operation locally. With frequency regulation, this will be even easier.

Areas of application

The Wilo brand produces pumps designed for different purposes and therefore having different characteristics.

With the help of such a pump, you can water the beds directly from a well, borehole or the nearest body of water.

The scope of their application is wide and varied:

- Wilo devices are used in heating systems in closed circuits.

- They are used in the water supply of private houses and in wells for water extraction.

- Such pumps are also suitable for pumping out groundwater when creating basements and cellars.

- They are also used on construction sites when working with contaminated water.

- Owners of private suburban areas have found good use for them, in particular those who grow plants on their plots.

You can connect the device yourself without any problems. For this purpose, it is equipped with special spring terminals. It does not have a fan, so there is virtually no noise during operation.

Which pump is best for heating a private house?

The modern market offers us to buy a pump for heating a private home at a variety of prices, in the most unusual colors, with the best characteristics, and simply in a huge assortment. We will remain conservative on this issue and traditionally arrange the products in order: Grundfos, Wilo, DAB. All three manufacturers offer excellent quality, and the model range and characteristics allow you to accurately select equipment for any designed heating system. Which one is better?, let's leave this debate for those who like to endlessly find out what is better: samsung or iphone, mercedes or bmw, or finally blondes or brunettes...

Characteristics of Wilo circulation pumps

Since much in the use of pumps depends on the connection parameters, first of all you should calculate the voltage and frequency of the network. Models of this brand are characterized by a voltage support of 230 V and a frequency range of 50-60 Hz. Next, the working pressure indicator is taken into account, on which, in principle, the ability to maintain circulation at the proper level will depend. The manufacturer produces models with pressure levels from 6 to 10 Bar. However, there are other indicators for Wilo equipment. The circulation pump in the special version of the Top line, for example, provides 16 bar

You should also take into account the throughput and pressure indicators. As for the flow volume, it leaves an average of 3-5 m3/h

The power (in terms of pressure) varies on average from 4 to 7 m

In each case, it is important not to forget the parameters of the circuit through which the coolant will circulate, but these data are selected individually, depending on the needs of the house

Specifications

First of all, the main technical characteristics of any pumps are:

- Volume of pumped medium per hour;

- Head or amount by which pressure can be raised;

- Purpose of the pump - for what purpose it is intended;

- At what voltage can the unit operate with a single or three-phase electric motor connection;

- According to the type of connection - they can be with a flange or threaded connection.

The most common Wilo brand pumps designed for heating systems in small industrial premises, residential buildings and apartments are:

Wilo Star-RS - available in three modifications, designed for heating systems and available with a unit for adjusting the flow rate of the pumped liquid. Depending on the series, they can pump a volume from 2 to 5 m3/hour, while the pressure can be from 0.2 to 0.6 atmospheres, type of design - with a wet rotor, threaded connection;

Wilo-TOP-RL - almost identical to the previous pump, differs in higher performance indicators. The volume of pumped liquid is from 6 to 9 m3/hour, the pressure is from 0.4 to 0.77 atmospheres. Type of execution – with a wet rotor, threaded connection;

Wilo-BL - differs from previous pumps with higher productivity from 5 to 60 m3/hour, pressure from 0.6 to 1.6 atmospheres. Type of execution - with a wet rotor, threaded or flanged connection.

Two main characteristics of a circulation pump

With a long list of technical characteristics of heat pumps, there are two main ones. This is the diameter of the connection pipes and the power of the “accelerator”. These two numbers are considered decisive and are indicated in the name.

Connection pipe diameter

The most important parameter for pump installation, especially with already installed heating systems. This is a numerical value indicated in millimeters and indicating the diameter of the heating pipes that can be connected to the inlet/outlet pipes.

Please note that for connection to the body pipes, taps are made with threaded threads

Booster pumps "Wilo" series PB: PB-088EA and PB-201 EA

Thanks to booster technology, the problem of low pressure in the water main has long since become obsolete. By increasing the pressure in the water supply network, they ensure uninterrupted operation of water heating devices and the functioning of bathrooms. The pumps in question are externally and functionally identical. The main difference is the diameter of the impellers. Designed exclusively for domestic use. Distillation of heavily contaminated water with large inclusions is not permissible. The maximum t 0C mark, depending on the model, is 60-80 0.

Advantages:

- corrosion-resistant cast iron and plastic parts;

- withstand minor (up to 10%) voltage surges;

- operation in manual and automatic modes;

- thermally protected engine with a production life of 10 years;

- built-in flow sensor, instantly triggered when the tap is unscrewed;

- quick installation - each pump comes with union nuts and gaskets for installation.

Technical characteristics of "Vilo" PB-088 EA/ PB-201 EA:

- Torque – 2.9 thousand rpm;

- Engine power – 70/200 W;

- The cross-section of the pressure/outlet pipe is 15/25 mm;

- Outlet pipe diameter -

- Pressure – 8/15 m;

- Productivity – 2.1/3.3 m3/h;

- Self-priming – 8 m.