Main characteristics of circulation pumps

The main characteristics by which the choice of circulation pump is made:

- pressure

, showing the ability of the device to raise water to a certain height; - performance and flow

, showing how much fluid the supercharger delivers per unit time.

These parameters are key in calculating the heating system. The pressure will allow you to understand whether the blower is capable of serving a pipeline network with a certain height difference. And the flow rate is calculated according to the requirements of the heating boiler for the planned volume of coolant.

All the data the user needs is contained in the markings on the front panel

. The numbers on the circulation pump mean:

- type of device (most often it is UP - circulation);

- speed control type (not specified - single-speed, S - step switching, E - smooth frequency control);

- diameter of the pipes (indicated in millimeters, means the internal dimension of the pipe);

- pressure in decimeters or meters (may differ among different manufacturers);

- installation dimensions.

The pump marking also contains information about the types of connections of the inlet and outlet pipes. The complete coding scheme and word order looks like this:

Responsible manufacturers always follow standard labeling rules. However, individual companies may not indicate some of the data, for example, installation dimensions. You need to find it out directly from the documentation for the device.

The choice of a circulation pump is always made after a careful calculation, which takes into account the type of heating equipment, the volume of coolant, elevation differences, and the minimum required blower performance.

Advice! You cannot buy products from unknown companies that copy products from reliable and popular brands. Such a pump is an ineffective investment. The use of low-quality materials, impellers, and turbines with limited service life leads to rapid failure of the supercharger. On specialized forums you can find many scary stories in photographs about the kind of technological nihilism that the housings of Chinese “no-name” products contain.

Therefore, you should choose a pump only from trusted brands. Reliable devices are also available in the mid-price category

And if you need the highest quality and have the opportunity to pay one and a half to two times more, you should pay attention to products from the brands GRUNDOFS, WILO

What indicators need to be taken into account when choosing

We begin the selection of a circulation pump for hot water supply with indicators of its performance and pressure.

- Productivity is the volume of water (or other liquid) that the pump pumps in a certain unit of time (cubic meters per hour or liters per minute);

- Pressure is the pressure created by the pump (measured in Bars, Pascals or lift height in meters).

In addition, we also take into account the technical characteristics:

- Power of the installed electric motor in W;

- Type of control (temperature sensor or timer).

Capacity depends on the length of the pipe system. If the total length of the pipeline is 40-50 meters (an average house), then a pump with a capacity of 0.2 to 0.6 cubic meters per hour will be sufficient.

The motor power should also be low so as not to waste electricity. On average, the figure for a small private house, cottage, cottage is from 5 to 10 W. For large houses with several floors, 20 W of power is sufficient.

The choice of a circulation pump for hot water supply according to the characteristics of its pressure (lift height) will be correct if one is guided by the following rules:

- For a one-story house, where the pipeline is single-level, we take a pressure with a height of water rising from half a meter to 0.8 meters;

- For a building with several floors, add the height of the water supply pipes;

- Plus - we create a certain pressure reserve, 10-20 percent.

Installation of the pump: stages and nuances during installation

The first thing to do is drain all the liquid from the heating system. Then, if necessary, the pipeline must be cleaned. In accordance with the connection diagram, work on installing equipment and fittings must be carried out. When the installation of the heating system is completed, fill the water. after which excess air is removed from the pump. This is done by opening the central screw

Please note that before each time the unit is turned on, it is necessary to carry out air removal work

When a circulation pump for heating is purchased, you need to decide on the place where it will be installed. Experts recommend installing this equipment on the return line in front of the boiler. The thing is that air can collect at the top of the boiler during operation if the pump is installed on the supply side. This may cause it to be drawn out of the boiler, causing a vacuum to form, causing that part of the boiler to boil.

If the pump is installed in front of the boiler, then water will be pushed into the heating installation. The consequence of this will be the creation of air space and the installation will be completely full. In addition, with this installation option, the pump will operate at lower temperatures, which will have a positive effect on its service life.

Having selected the installation site for pumping equipment, then create a bypass or outlet. The need for it is due to the fact that in the event of a breakdown or when the electricity is turned off, thanks to it, the operation of the entire heating system will not stop and there will be an opportunity for the coolant to pass through the main pipeline thanks to an open tap. When installing a bypass, it is necessary to remember that the diameter of the pipe should be smaller than the diameter of the main pipeline. When the bypass is ready, proceed to the main stage of work on installing the unit.

The heating pump shaft must be completely submerged in water. If it is only partially immersed in the coolant, this will lead to a reduction in equipment performance by 30%. In the worst case scenario, the work area becomes faulty.

In addition, the installation also includes the installation of a terminal box with a top location.

In addition, ball valves are installed on both sides of the pump. During the operation of the equipment, they will be required to perform maintenance on the pump and dismantle it if necessary.

The system must also include a filter. It will protect the unit from mechanical particles. Once inside its structure, they can adversely affect the operation of the pump.

A manual or automatic valve must be installed on top of the bypass pipe line. It is necessary to release air pockets at certain intervals.

Installation

Installing a circulation pump in a heating system will not take much time if you have the necessary tools and the necessary skills:

- keys in a set with sizes from 17 to 36;

- bypass, filter, check valve;

- "American" carvings.

To connect the pump to the heating system, follow the following guidelines:

Installation options

- Technical parameters of the pump, which are calculated as shown above;

- Connecting the mechanism to the return pipelines will ensure the operation of devices with chilled water. This will extend the service life of the products. also connect to the return pipeline;

- When the heating boiler is turned off, the inlet and outlet valves on the pump pipe are closed. Then the product should be installed in a horizontal position, tightened using “American” nuts. Vertical equipment will create excess noise during operation.

Important advice: when installing a gasket, it is better to choose one made of paranite, because rubber ones will become unusable when the temperature rises.

- Installing a circulation pump will be an addition if the circulation is natural. Here you should also purchase a filter and “American” nuts with a diameter suitable for the device. For closed wiring, a check valve will be needed, but for open ones it is not needed at all;

- When installing, do not forget to install taps, which will be useful when repairing the system. The bypass line, when installed, will allow circulation to continue when the device is removed and even in the absence of electricity.

Purpose of circulation pumps

The operating principle of a standard closed-type heating system is quite simple. The boiler heats the water, which passes through the radiators, releasing the accumulated heat

In the case of natural circulation, it is very important to maintain accuracy in design, maintaining a certain angle of inclination of the pipeline. However, due to the low speed of movement of the coolant, it quickly cools down, and cold liquid returns to the boiler, forcing it to constantly operate at full load.

To eliminate this drawback, different types of circulation pumps are used. Their purpose is to create the coolant pressure necessary to ensure uniform heat distribution between all elements of the system. First of all, this helps to reduce the requirements for compliance with slopes and pipeline cross-sections. At the same time, the difference in temperature of the liquid at the outlet and inlet of the boiler is only a few degrees, which significantly reduces the load on the heating equipment and reduces energy costs.

Purpose and scope

Hot water recirculation pumps have a very important function. With the help of such devices, closed pipelines through which hot water is transported operate in the required mode. By pumping liquid into the pipeline due to the rotation of special elements, recirculation electric pumps increase the pressure of the liquid medium they pump and, accordingly, the speed of its movement.

Most often, heating systems are equipped with recirculation pumps, which increases not only the efficiency, but also the cost-effectiveness of the latter. Most of these systems, as is known, operate using a coolant, which, moving through a pipeline, releases heat into the room. Heating of the coolant (in this case, before it is supplied to the pipeline) is provided by a boiler, boiler or water heater. After passing through the entire heating circuit, the water must return to the heating equipment, where it is again given the required temperature.

DHW recirculation scheme

Without the use of special pumping equipment, water circulation in the heating system will flow slowly, and in some cases may not flow at all, since the pressure of the coolant flow, which is not further increased in any way, will be dampened by the pipeline elements. The result of this is unevenly heated heating pipes and, accordingly, an uncomfortable temperature in the premises of the house.

A circulation pump for hot water supply increases the pressure and pressure of hot liquid moving through a closed pipeline circuit. The use of circulation pumps for hot water is especially important in the pipeline systems of houses with an area of more than 200 m2, in which there are several water intake points, and the boiler is installed in a separate room or in the basement. Water in such pipelines (as a rule, quite long), if they do not have a recirculation system using a special pump, cools down quite quickly. This leads to the fact that when you open the tap you have to wait a long time until liquid heated to the required temperature flows out of it.

In addition, when some taps at water intake points are opened immediately, the water pressure in them drops, because the pressure of the liquid moving through the pipeline by gravity is not additionally supported by anything. To solve precisely these problems faced by owners of private and apartment buildings, a hot water pump is designed to provide forced movement, as well as the creation of stable water pressure and pressure in the hot water supply system.

The recirculation pump should not be installed near tanks or water heaters, the heat from which could affect the thermostat.

Using a circulation pump for heating and hot water supply to a private home, in addition to the above advantages, allows you to save on energy costs. Since in systems with recirculation, water from the boiler is transported through pipes forcibly and reaches all water intake points and heating radiators much faster, its temperature during such transportation decreases slightly. A boiler, if forced water recirculation is provided in the pipeline it serves, requires less time to heat it, and accordingly, the consumption of energy carriers used to operate the heating equipment is reduced.

Pumps for circulating hot water are actively used to equip “warm floor” systems, the design of which assumes the presence of an extended pipeline circuit of a complex configuration, consisting of small-diameter pipes. In such cases, the circulation pump ensures constant movement of the coolant through the pipes.

The circulation pump is a mandatory element of the underfloor heating system

Design of pumps for heating systems

Depending on the design, all pumping units of heating systems are divided into two types:

- dry circulation pumps;

- wet rotor pumps.

Both types of devices are quite effective in heating pipelines and have both advantages and disadvantages.

Dry pumps

In devices with a dry rotor, the electric motor is located outside the pump housing.

In such units, the rotor does not come into contact with the working fluid, since all elements of the electric motor are separated from the working chamber of the device by a special type of sealing system. It consists of polished metal rings carefully fitted to each other. To eliminate friction, there is always a thin film of liquid between the sealing elements, which acts as a lubricant. This is what prevents damage to the seal rings.

Depending on the location of individual structural elements, dry pumps for heating systems can be divided into three types:

- console type pumps;

- vertical centrifugal pumps;

- block pumps.

The suction pipe of cantilever circulation pumps is located on the outer edge of the volute, while the discharge part is placed in the opposite direction. A feature of the second type of units is the location of the electric motor in a vertical plane, which can significantly increase the productivity of the devices.

Design of a circulation pump with a dry rotor

Dry rotor pumps have numerous advantages:

- long service life;

- high performance;

- Efficiency is close to 80%;

- ability to work in case of coolant leak;

- high maintainability;

- relatively low cost;

- reliability;

- Possibility of installation in any position.

At the same time, the increased noise level of units of this type does not allow their installation in residential premises. Disadvantages also include requirements for cleanliness of the coolant and the need for periodic maintenance and lubrication of the moving seal.

Glandless circulation pumps

The advantages of circulation pumps with a wet rotor have opened up broad prospects for their use in autonomous heating systems.

The rotor and impeller of pumps of this type are located in the pumped coolant, which copes well not only with its main function, but also with cooling the electric motor parts. The stator of the pump electric motor is separated from the rotor by a sealed glass made of non-magnetic steel or carbon fiber. “Wet” type units are designed to operate in systems with stable, rarely changing fluid flow. The presence of a control unit allows you to vary the number of connected windings, and accordingly, change the pump performance. The choice of the optimal operating mode has a positive effect on the efficiency of the unit.

The advantages of “wet” type units include:

- low noise level;

- no need for lubrication;

- effective cooling method;

- ease of maintenance and installation;

- relatively low price of the unit and spare parts;

- long service life.

Pumps with a wet rotor are not without disadvantages in the form of low efficiency (a little more than 30%), the inability of the unit to operate without coolant and the requirements for horizontal orientation of the rotor shaft during operation.

Design features by connection method

Flange connections are most often used in high-power pump models.

In utility and industrial pipelines, circulation pumps with a dry rotor are most often used as more efficient and powerful devices. Their connection is carried out mainly by flange connection, and for installation either a common support frame or a specially equipped foundation can be used. At the same time, manufacturers also produce devices designed for integration into autonomous heating systems. As a rule, they all have increased power and performance, and their installation does not require special mounting.

The delivery package for pumps with a coupling type of connection necessarily includes fastening elements.

Coupling connections of circulation pumps are typical for low-power wet-type units with direct-flow coolant movement, which can be built directly into the pipeline. Such devices are represented by a wide range of household centrifugal pumps, while powerful industrial units with a flange connection require additional pipeline support using a console and foundation.

Electrical part

- The electrical connection must be carried out by a trained specialist in accordance with the connection diagram, which is in the instructions and installation manuals.

- The terminal box should not be directed downwards, because In the event of a leak, coolant may enter it. In addition, in this position it is inconvenient to maintain.

- The pump must be grounded.

High noise levels during operation of a wet rotor circulation pump can be caused by:

- presence of air;

- low suction pressure;

- too high coolant speed;

- mechanical particles have entered moving parts.

Review of popular models

It is impossible to give a clear name of the model of the best among superchargers without a clear segmentation according to their operating conditions. Therefore, the rating of heating circulation pumps represents the competition between brands and the key features of the equipment they offer.

Grundfos UPS

One of the most popular and high quality

types of pumps. A company with roots in Denmark ensured maximum reliability using stainless liners, ceramic bearings, and turbine wheels made of composite materials. Glandless rotor pumps have the following features:

- low energy consumption, from 45 to 220 W;

- very low noise level (up to 43 dB) and vibrations - you can understand that the pump is working only by placing your hand on it;

- wide temperature range from 2 (-20 for some models) to 110 degrees Celsius;

- simple installation;

- unpretentiousness, lack of maintenance;

- durability, service life is at least 10 years.

Grundfos UPS pumps are very compact and lightweight. Their disadvantages include high price,

up to 2 times higher than competitors. However, the popularity of the products of this brand suggests that their characteristics justify the price tag.

Pump Grundfos UPS 25/40

Products from this brand are considered the most reliable. Only proven and simple solutions are used in their design and electronic circuits. The pumps are characterized by:

- efficiency;

- simple power adjustment;

- reliability, durability - cast iron housing, turbine wheel made of polypropylene, bearings made of metal graphite, stainless shafts;

- operating temperature from -10 to 110 degrees Celsius;

- protection against voltage surges and surges;

- ease of installation.

Wilo Star-RS pumps are compact, lightweight and maintenance-free

. Their price is also higher than that of competitors, but lower than that of the leader in the rating. Users note that at the highest speed the pump begins to make noise over time.

Pump Wilo STAR-RS25/4-130

The Compass series is a reasonable choice, a strong mid-ranger with attractive characteristics and cost. The pumps are distinguished by:

- efficiency;

- simple speed switching circuit;

- small dimensions;

- fairly low noise level up to 65 dB;

- rich equipment and easy installation;

- fault tolerance due to the absence of complex technical solutions and the use of reliable materials;

- low price.

The manufacturing company has an extensive service network, but users note that the pumps of the Gilex “Compass” series break down extremely rarely.

Pump Gilex "Compass" 25/60

DAB VA

A series of pumps from an Italian manufacturer is an optimal balance of characteristics and price.

They are not able to offer record performance, but they are reliable and adapted to the realities of domestic energy networks. The devices are characterized by:

- three-stage speed adjustment;

- simple installation using a quick-release connection;

- two types of mounting dimensions: 130 and 180 mm;

- noise level up to 70 dB;

- affordable price.

Circulation pump DAB VB 55/120

Unit features

The principle of operation of circulation pumping equipment is based on creating continuous circulation of liquid in the system without changing the pressure indicator

A circulation pump is a device that operates in a closed heating system and moves water in a pipeline. The unit maintains a certain temperature of the coolant in the system. The device does not replenish coolant losses and does not refill the system. The system is filled using a special pump or a certain pressure in the pipes.

The principle of operation of circulation pumping equipment is based on creating continuous circulation of liquid in the system without changing the pressure indicator. Since after installation the device operates constantly, the main requirements for such pumps are low noise level during operation, economical energy consumption, reliability, durability and ease of use.

Important: circulation pumps are compact devices that do not take up much space and do not create noise during operation. The scope of use of circulation units for heating systems is quite extensive.

They are installed:

The scope of use of circulation units for heating systems is quite extensive. They are installed:

- in traditional radiator systems;

- when installing a water heated floor;

- in geothermal systems;

- when organizing hot water supply for cottages and dachas.

Unlike forced circulation systems, this pumping equipment does not require pipes with an increased diameter. In addition, the device has the following advantages:

- speed of heating the room;

- the boiler can be installed in any suitable place;

- coolant losses and air pockets are minimized;

- The thermal relay ensures automatic control of temperature conditions;

- Electricity costs are reduced due to the use of automatic rotor speed control;

- Since liquid is constantly supplied to heating devices, their service life is extended.

How to choose a heating circulation pump

When selecting circulation pumping equipment, you should take into account such a parameter as the power of the unit.

Many owners of private houses, when choosing such equipment for their heating system, try to buy the most powerful model. Such an installation will cost more, and besides, it will make a lot of noise during operation, despite the fact that the owner will not need to use its power to the maximum. In order not to spend extra money and purchase a good pump, it is necessary to calculate the power of the equipment. which will be enough for your home. When performing them, the following parameters are important:

- pipe diameter;

- coolant temperature;

- coolant pressure level;

- boiler performance;

- throughput.

You also need to know about the number of liters of water that can pass through the heating system within one minute. You should also calculate the amount of water required for the radiator and heating system rings to operate normally.

The length of the pipeline is also an important factor on which the power of the circulation pump depends. Typically, 10 meters of pipeline requires half a meter of pumping pressure.

To calculate the coolant flow, it is necessary to equate its parameters to the boiler power. For example, if the installation power is 25 kW, then in this case the coolant flow will be at the level of 25 liters per minute. If the heating system has a battery power of 15 kW, then for its normal operation it will require 15 liters of water per minute. As the diameter of the pipeline decreases, the resistance that occurs when the coolant moves increases.

Calculation of circulation pump flow for heating

Any circulation pumping equipment has a number of indicators by which the performance of the installation is determined. The main parameter is the pressure flow. It is reflected by the equipment manufacturer in the technical passport.

When calculating the flow rate of the heating pump, use the following formula:

where N is the boiler power;

t1,t2 is the temperature leaving the heat source and located in the return pipeline.

The pressure of the heating pump is calculated in a similar way. Based on European standards, 100 watts of equipment power is needed per 1 square meter of private building.

Choice

Which is the best circulation pump for a heating system? When heating, the main attention is paid to such a parameter as the heat generated, which the device will provide to the room. In organizations where they evaluate device parameters, the data is evaluated using special programs, then after the calculation, real calculations are issued

Product design

One of the popular methods for choosing a pump is to estimate the area of the room that the pump can heat. According to European standards, houses with two or fewer apartments require a heating power of 100 watts per square meter. And for houses with many apartments 70 watts per meter. And depending on the quality of thermal insulation, the power parameters depend. If the thermal insulation is good, then 30 - 50 watts per square meter is needed.

For poor quality thermal insulation, high power ratings are taken.

The following data corresponds to our harsh climate:

- for a two-story house at an air temperature of minus 25 degrees - 173 watts per square meter, if minus 30, then 177 watts per square meter;

- for a building with more than two floors, 97 and 101 watts per square meter are suitable, respectively.

Design features of pumps with a wet rotor

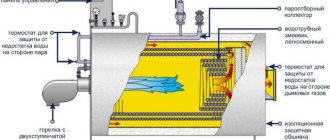

Models with a “wet” rotor are characterized by a low level of noise generated. They are of interest from the point of view of domestic use. They are widely used in the installation of autonomous heating systems in private buildings or in small administrative and industrial premises. The pump rotor is located directly in the liquid. They are attractive because they are easy to repair at home. But in order to eliminate the malfunction, you need to know the design features. Therefore, let’s take a closer look at how a circulation pump with a “wet” rotor works.

For the manufacture of the body of models for heating, cast iron is usually used, although products are produced in which the body is made of stainless steel (non-ferrous metals, aluminum, bronze, brass). They are used for hot water supply and cold water supply systems. The rotor is placed in a special glass and is rigidly connected to the impeller (impeller). This achieves its isolation from the stator. The peculiarity of the technology is that the shaft can be either metal or ceramic. It is secured in plain bearings (graphite or ceramic). The volute, on which the inlet and outlet pipes are located, is attached to the body using bolts, which are unscrewed with a special key (hexagon) supplied with the product. There is a plug on the front (end) part of the pump; by unscrewing it, excess air can be released. Although it is also possible to automatically remove it during operation. For this purpose, an air vent is located in the upper part. There is a box for electrical connection with an operating mode regulator. When the plug is completely unscrewed, access to the shaft opens, on the end of which there is a slot for a screwdriver. Thus, you can manually scroll if the pump does not start after a long “idle period” (for example, due to salt deposits). Perhaps the only drawback of such pumps is their low efficiency. If for “dry” models it is within 70–80%, then for “wet” models it does not exceed 55%. But at the same time, such a circulation pump design has a number of undeniable advantages:

- the liquid it pumps simultaneously cools and lubricates the parts;

- upon startup, the products automatically remove trapped air;

- The pumps are assembled using a modular principle. Therefore, when repairing, it is enough to replace the faulty part;

- due to low power, they consume little electricity;

- switching of operating modes is provided, which allows you to choose the most optimal one;

- the ability to automatically regulate the start and stop process when using a temperature sensor, which also reduces energy consumption;

- absolute silence in operation;

- does not require maintenance.

The latest models of “wet” pumps are produced shaftless. The impeller (also known as the rotor) rotates on ceramic bearings under the influence of the electromagnetic field created by the stator winding. This significantly simplified the design (no shaft and seals) and increased reliability and durability. Even if small fractions get inside along with the liquid, it will not affect the operation of the pump.

Brief installation instructions

A common option is to install the pump on a bypass. This is due to two good reasons: it becomes possible to quickly dismantle or temporarily disconnect the device from the network, for example, if problems arise with electricity.

Various modifications of ready-made pumping units are available for sale: for welding or flange connection, with places for installing taps or valves, with a special area reserved for the pump.

But if you cannot purchase a ready-made unit or there is not enough space for its installation, you can independently organize the bypass piping and fix all the parts in the places allocated for them.

The following tools and materials are required for work:

- a set of open-end or adjustable wrenches for assembly;

- pliers:

- linen thread or tow;

- Unipak sealant.

American nuts are usually supplied with the pump, but taps, adapters or fittings will also have to be prepared. Attention should be paid to more reliable materials for making fittings and the diameter of the products.

- Assembling units with taps . Two will be located on the edges of the pump, the third will become part of a straight pipe. It is important to measure the “return” section in order to accurately weld the fragment with the tap.

- Assembling the pump loop. Tightening the nuts must be postponed until the final stage of installation, but for now they just need to be screwed on.

- Trying on the bypass loop . Mark the places where the units are welded into the pipe.

- Welding should be left to a qualified welder.

- Assembly of the lower unit is on the “return” side.

- Connecting the pump to the power supply.

As an example, install the GRUNDFOS .

Maintenance of the installed pump is carried out in operating mode. It is necessary to clean the filter more often and check the pressure gauge readings.

If the values do not correspond to the norm, the device must be removed and adjusted. It is better to do this in a specialized workshop.

How to choose a circulation pump

Each circulation pump has a set of technical characteristics. They are selected individually for the parameters of each system.

Selecting technical specifications

Let's start with the selection of technical characteristics. There are a lot of formulas for professional calculations, but to select a pump for the heating system of a private house or apartment, you can get by with average standards:

Selecting a circulation pump for heating following these rules is not difficult. Elementary calculations. But it must be said that these figures are statistical averages. If your house at some point differs greatly from the “average” indicators, you need to make adjustments either towards increasing or decreasing technical characteristics. For example, you have insulated your house well, but the power of the previously purchased boiler turned out to be excessive. In this case, it makes sense to choose a pump with a lower capacity. In the opposite situation - the house is chilly in extreme cold - you can install a more efficient circulator. It will temporarily solve the problem (in the future you will need to either insulate or change the boiler).

Model selection

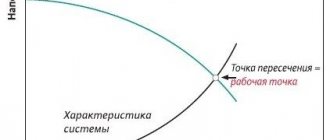

When choosing a specific model, pay attention to the graph with the pressure characteristics of the pump. On the graph you need to find the point at which the pressure and productivity values intersect

It should be located in the middle third of the curve. If it does not fall on one of the curves (there are usually several of them, characterizing different models), take the model whose graph is closer. If the point is in the middle, take the less productive one (the one located below).

What else to pay attention to

In the technical characteristics of circulation pumps there are several more items that are worth paying attention to. The first is the permissible temperature of the pumped medium

That is, the temperature of the coolant. In high-quality products this indicator ranges from +110°C to +130°C. In cheap ones it can be lower - up to 90°C (but in fact 70-80°C). If your system is designed as a low-temperature system, this is not a big deal, but if you have a solid fuel boiler, the temperature to which the coolant can be heated is very important.

It is also worth paying attention to the maximum pressure at which the pump can operate. In the heating system of a private house it is rarely higher than 3-4 atm (this is for a two-story house), but normally it is 1.5-2 atm

But still, pay attention to this indicator.

Something else to pay attention to is the material from which the case is made. The optimal one is cast iron, the cheaper one is made of special heat-resistant plastic

Connection type and size. The circulation pump can have threaded or flanged connections. The thread can be external or internal - appropriate adapters are selected for it. Connection sizes can be: G1, G2, G3/4.

It is also worth paying attention to the presence of protection. May have dry running protection

In circulation pumps with a wet rotor, it is very desirable, since the cooling of the motor occurs due to the moving medium. If there is no water, the motor overheats and fails.

Another type of protection is overheating protection. If the motor heats up to a critical value, the thermal relay turns off the power and the pump stops. These two features will extend the life of the equipment.

For what purpose and where are recirculation pumps used?

The hot water supply system (DHW) is a closed loop of pipes. The water is heated using a boiler or boiler, or an electric heating element, and then, at the desired temperature, it circulates through the pipeline. To increase its pressure and thus increase the speed of water movement, install a circulation pump for hot water. The purpose of this device is to ensure smooth and fast circulation of water in a closed pipeline system. For this purpose, special elements of the pumping part are used.

The widest area of application of recirculation pumps is heating systems. Since they increase the speed of water movement, the heating itself becomes more economical. Water (or other liquid) acts as a heat carrier. It moves through pipes to all rooms of the house, while giving off heat and providing space heating. Then it returns to the starting point, already cooled, where it heats up again.

If you do not create pressure using a pump, then there will be no forced circulation. The water will move at low speed or stop altogether and not reach the highest points. The result will be uneven heating: some rooms are warm, while in others the pipes and radiators are cold.

DHW recirculation scheme

It is very important to create pressure in the hot water passing system, especially in large houses (over 200 sq.m.), in which water must be supplied at several points (showers, bathrooms), and there is only one heater (boiler or boiler). And it is usually located in the basement of the house or in another room on the ground floor. This results in a large length of pipes, and the water immediately begins to cool before reaching the water intake point, if its pressure is not sufficient. That is, the situation is like this - you opened the tap and are waiting for a long time for hot water to come out. In addition, if several water intake points are open, then the pressure gradually decreases, and at the very end point there may be no pressure at all. The situation is familiar to those who have a large private house, as well as residents of apartment buildings.

A DHW recirculation pump eliminates such discomfort very quickly. It creates pressure and water flows to all faucets, no matter how far they are located from the water heater.

In addition to pressure and uniform distribution, we get another important factor - saving money. After all, hot water, pushed by the pump, moves very quickly and does not have time to cool down much. That is, it is not cold water that returns to the starting point (to the heater), but rather warm water. The thermostat of a boiler or other heater analyzes its temperature and heats it up only a little, using little energy - electricity or gas. That is, the consumption of gas and electricity is reduced, so you save money.

Pump installation location

Thus, heating and hot water supply greatly benefit from installing a circulation pump. This device has also proven itself very well in underfloor heating systems using hot water pipelines. Since pipes under the floor are always thin and have very complex bends, forced circulation is simply necessary for them.

This is interesting: Submersible pumps for a well: which one is better to choose, types and features of well pumps

Design

The pump device consists of a cast iron casing in which an electric motor rotates a composite wheel mounted on a shaft. The wheel consists of two disks, between which curved blades are located radially. The coolant enters the wheel through a hole in the lower disk.

In wet running models, all moving parts (including the motor rotor) are in contact with the coolant, which will act as a lubricant/cooler for the ceramic (graphite) end bearings and the rotor itself. In this case, the stator is isolated from the coolant using a metal partition with sealing gaskets.

The design of “wet” pumps is more complex than the design of pumps with a dry rotor, so their cost with equal characteristics will always be higher.

Note! As a rule, circulation pumps have 3 speeds, which are switched by turning the regulator to one of three speeds. At the same time, at minimum speed, the pump consumes approximately 2 times less electricity compared to maximum speed.

Adviсe

Before you start looking for pumping equipment, you need to correctly calculate the device parameters. Only after this can you decide on a purchase and invest wisely. Such data includes the workload of the water supply system, as well as sufficient flow strength. An important point is to take into account the number of taps that can be turned on simultaneously. It is necessary to create the same pressure of the circulation pump so that the pressure remains constant everywhere.

If we talk about the average water consumption at one point, it is about one hundred and eighty liters per hour. If a house or apartment has two bathrooms and a kitchen where taps are located, the best choice would be to install a device with a throughput capacity of at least 0.7 cubic meters per hour. We must not forget about the hydraulic resistance of the overall system. Pressure and pressure are affected by the length and height of the pipeline, so these indicators also need to be clarified. A water column of 0.6 meters uses 10 linear meters of contour. The manufacturer always adds technical documentation to each model and type of pumping equipment, so it is worth studying all the indicators and descriptions.

Thanks to such calculations, it is possible to obtain the average heat consumption of hot liquid through a circulation pump, which will help you quickly make a choice and facilitate the purchase. Of course, an industrial-type device is suitable for pumping water at a large enterprise, but slightly different models are suitable for a home.

Today, calculations can be made online thanks to electronic calculators, where the corresponding indicators are entered, which speeds up the solution of the problem. If a pump is selected for an apartment building or a cottage with a large area, such calculations are carried out only by qualified specialists from design and installation organizations, since they are responsible for the performance of the entire system.

To correctly install the pump in a hot water supply system, you must first study the instructions in detail and strictly follow the manufacturer’s recommendations. In addition, building codes are important and must be heeded.

To complete the installation you will need to complete the following steps:

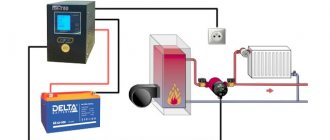

- the installation location of the circulation device is selected. The module must be installed on the return line, which will prevent air from entering, which in turn will lead to a decrease in the functionality of the entire system;

- a check valve must be installed between the pump and the storage tank;

- shut-off valves are installed before and after the station, their number depends on needs;

- A UPS is used for connection. As soon as the power is turned off, it will ensure that the device operates in autonomous mode. The duration of its operation ranges from several hours to a day.

Of course, it is also necessary to choose an uninterruptible power supply according to certain parameters, taking into account the rules. Uniform distribution of pressure is an important task. For this purpose, special manifolds and pressure-reducing valves are used. You cannot run the electric motor idle, which will negatively affect its performance and the device will quickly fail. After installing the pump in the DHW system, it is necessary to fill the water circuit and do a test run to check the functionality of the mechanism.

The device with a wet rotor is a simple design that does not require regular inspection or even repair, which is one of the main advantages of this equipment. The only thing you need to do is clean and replace the filter if necessary. Glanded rotor pumps require maintenance once every two years. It is necessary to replace the lubricant and clean the housing for the device to operate smoothly. If desired, you can consult with qualified specialists to make the right choice.

In the next video you will find a review of the surface circulation pump GRUNDFOS UP 15-14 B.

This is interesting: Circulation pumps for heating: varieties, selection rules, installation