Efficient home heating is one of the most important tasks for every homeowner. An interesting solution to this problem could be a steam heating system, the operating principles and design of which differ from the usual water circuits.

This is not the easiest option, and has its own strengths and weaknesses. We will talk about the rules of design and organization, the features of the system with a vapor coolant. You will learn how to install steam heating in a private home and how to operate it correctly.

The difference between steam and water heating

The operating principle of a steam heating system is as follows: water brought to a boil in a container is converted into steam, which then enters the heating radiators, heating them. There, the steam condenses, transforming into a liquid state, flows into the expansion tank through specialized outlets, and then goes back to the heat exchanger.

The difference between steam heat supply and water heat supply is considered to be, first of all, the circulation of different types of coolant. Secondly, the heat transfer is higher, and the rate of warming up the room is 3-4 times faster than that of a water heater. With similar costs for solid fuel, the efficiency of steam heating is greater than that of water.

To install steam heating, no large-sized equipment is required, which makes this heating system economical. If the system is inactive, pipes with water coolant may freeze over the winter. In contrast, a steam system can be started without much effort without such difficulties.

There are also certain disadvantages that a heating system with water coolant does not have:

- Heating radiators heat up over 100 degrees, which can be unsafe for those around.

- The heating system is very noisy

- Changing the temperature is difficult

- Inability to install a heated hydraulic floor system.

- Plastic pipes cannot be used for the system.

- An oven with a built-in steam heating system is difficult to use at the same time to cook food.

Galvanized products

In liquid and steam heating, the temperature of the coolant is different. The temperature of the water leaving the boiler can be 90 0C. In the main it gives off heat, the indicator drops to 60-70 0C. The outlet steam can have a temperature of 150 0C. In the system, this parameter is reduced to 120-100 0C.

When installing a heating system, these indicators must be taken into account. For heat supply with steam coolant, only galvanized and copper products are used.

Heating from plastic pipes is used if the coolant is liquid: most often it is water or a mixture with antifreeze. Steel products are not suitable. The material oxidizes quickly; in a short time the highway will become unusable. What are the characteristics of galvanized pipes?

Galvanized steel has increased strength

The main line, with correct diameter calculations, can withstand the force of water hammer, which is very important for steam heating. A cracking sound in pipes should alert household members. The material has sufficient elasticity to be resistant to significant loads: elevated temperature and pressure

Pipes do not deform under constant exposure to steam that enters the main line. Products undergo a galvanizing process on both the internal and external surfaces. The material is resistant to corrosion: does not react with water and salts. Zinc has antiseptic properties, which is an advantage of galvanizing. The products are lightweight and installation is easy. When using thermodiffusion galvanized pipes, welding skills are required.

Galvanized pipes

Water, gas, electric-welded, and profile pipes are made from galvanized steel. Only seamless products are suitable for steam heating. Wall thickness 5.5 mm. Alloy or carbon steel is used for their production, which makes them durable and reliable. There is no risk that the seam may tear under high loads. Operational life more than 50 years.

During installation, the pipes are cut and special devices are used. When connecting parts, welding is not used. The high temperature achieved during welding has a negative effect on galvanizing. She is burned. In addition, zinc vapor causes severe poisoning.

The connection is made with fittings, couplings, and tees are installed. All parts must be galvanized. Otherwise they may rust. FMU is not used as a sealant; tow, a dye with heat-resistant properties, is used.

The vapors evenly distribute the substance over the entire surface of the product. This creates a protective layer of increased strength. It does not burn or deform when exposed to high temperatures during welding: it can withstand temperatures of 470 0C without any changes.

Pipes have high thermal conductivity, quickly give off heat, but they also cool down in a short time. It is necessary to maintain a certain temperature of the coolant in order to create a comfortable temperature in the room. Steel heats up quickly. This means the heating system will warm up in a short time.

Do-it-yourself steam heat supply from a stove

In order not to install a heating boiler for the installation of a steam heating system and spend working capital on this, you can use the stove available in the house. It will act as a heat source with cheap solid fuel, moreover, it does not depend on the central gas and electricity supply. The steam generator is a heat exchanger, which can be made to order or in-house. The disadvantages of a stove-steam boiler are similar to those of a direct combustion stove or fireplace: the inability to accurately regulate the heating temperature, the lack of complete fire safety, and also the possibility of smoke in the room due to incorrect kindling. Similarly, a boiler stove has the same number of disadvantages as an ordinary one, but there are many more positive qualities.

Steam heat supply from the stove

Before steam heat is supplied from the stove, the heat exchanger should be analyzed for leaks. This can be done this way: kerosene is poured inside the device, and the seams are outlined with chalk. Places where the chalk has darkened indicate a leak, which means that this device cannot be used for a steam heating system.

To remove steam heat from the stove, the following components will be required:

- Heating batteries. Their number should be equal to the number of windows in the room.

- Heat exchanger

- Copper or tin pipes for condensate drainage and steam lines.

- Shut-off valves (air bleed valves, valves)

- Connecting fittings: elbows, pipe clamps, fittings.

- Spider fasteners for heating devices

- Hydraulic valve

- A reduction-cooling unit, thanks to which steam is converted into a liquid.

- A reducer to reduce the pressure from inside the system.

- Pump for circulation of forced type liquid.

- Welding inverter

Before starting work, a connection diagram and pipe installation are developed in advance. The drawing determines the location of the furnace-boiler, from which the wiring diagram with all the required connection elements is laid down. For heating an area of no more than 80 sq.m. A single-pipe connection diagram for heating devices is suitable. With this connection method, convector heaters heat up gradually, the first of them being stronger than the others. The two-pipe scheme is suitable for heating rooms larger than 80 sq.m. and two-story houses. The pipes are connected to the design radiators in parallel. If it is intended to install a system based on the principle of gravity circulation, the heat exchanger must be placed below all radiators and pipes at an inclined angle. In this case, it is necessary to install a pump for trouble-free circulation of the heating system.

After the scheme has been developed and all the structural details that are needed to assemble the heating system have been taken into account, you can make an estimate for the purchase of materials and begin to work.

After the scheme has been developed and all the structural details that are needed to assemble the heating system have been taken into account, you can make an estimate for the purchase of materials and begin to work.

Work methodology

It is worth considering that installing a steam heating system without dismantling the old stove is unrealistic. In order to build in a heat exchanger, you need to install it inside the combustion chamber at the furnace lining step.

Heating devices are installed under each window, to which inlet and outlet pipes are connected at a slight slope of 3mm. Each heating device is equipped with an air bleed valve.

Steam heat supply from the stove

To protect the system, shut-off valves are installed in front of each convector heater and in front of the entire system in general. A cooling reducer and pressure reducing valve are also installed at the beginning of the system. At the end of the system, a container is placed to collect condensate with a similar small slope as the pipes. From it, water flows into the heat exchanger. A pump is installed in front of the stove in a forced-type circulation system.

Assessing advantages and disadvantages

What are the benefits of a steam heating system? It is relatively easy to make even on the basis of a conventional wood stove. This is especially true in areas where there is no centralized gas supply, but firewood or other solid fuel is quite accessible.

Steam is significantly ahead of water as a coolant. Its heating rate is three times higher. In addition, a steam heating system is unlikely to fail during winter cold due to lack of heating.

If the firebox burns out, water from the system will collect in the storage tank or heat exchanger, and the pipes and radiators will remain empty. With water heating, freezing of the coolant, which fills the entire circuit, is known to lead to pipe rupture.

Finally, the dimensions of steam heating radiators should be significantly smaller than for water systems, since the amount of thermal energy obtained as a result increases several times. This will slightly reduce the cost of installing a heating system at home.

Decorative grilles for steam heating radiators are not only an element of interior design, but also a means of protection against burns

This concludes the list of advantages of the steam system, and we can move on to its disadvantages, which are quite significant:

- high risk of burns;

- increased noise level during operation;

- difficulties in adjusting the operation of the system;

- the need to purchase expensive pipes, etc.

Safety standards do not recommend steam heating for residential premises, as it poses a high risk to the health and life of people living in the house.

Thus, the operating temperature of the radiators will be very high, and if you touch them you can get a serious burn. Therefore, all radiators will have to be covered with reliable decorative grilles.

Ordinary PVC pipes are not suitable for such a system, since they must withstand high pressure and temperatures of more than 100 degrees. The same requirements apply to other elements of the system. Steam heating pipes must be copper or galvanized steel.

Copper pipes are an ideal, but not at all cheap, communication option for steam heating systems. To connect these pipes you will need a welding machine

In any case, this moment cannot be called budgetary. Security issues must be given the utmost attention. All installation work, for example, welding copper pipes, will require the highest quality performance. If the connection ruptures and a stream of steam escapes through the hole, one of the occupants of the house risks serious burns.

Stainless steel pipes are able to withstand the loads typical of steam heating systems, such as high temperature and increased pressure in the system

Another disadvantage of steam heating is the increased noise level. To fix this problem, you must install the radiators correctly. They are suspended on special anti-noise brackets. It is best to place the boiler or stove in a separate room. In addition, copper pipes can be placed in the thickness of the walls, which will also reduce the noise level.

Finally, it is a little difficult to regulate the heating temperature in rooms with steam heating. You cannot install a thermostat and simply reduce the amount of steam. You will have to reduce the amount of fuel, which is not always easy, or ventilate the premises. Before starting work on installing a steam heating system, all these points should be taken into account.

Adviсe

The chimney of a stove with an installed steam generator needs to be cleaned of soot more often. In order to ensure free flow of condensate to the lowest point, it is better to install the stove in the basement. Installing valves will help prevent dangerous situations from occurring, so it should not be neglected.

When installing a heating system in a wooden house, it is necessary to ensure fire safety measures by protecting wooden surfaces from overheating. To do this, the adjacent wall with the stove and the floor surface must be covered with heat-resistant material. A shutter valve for the combustion chamber and a blower must be installed at the stove. It is better to plan the placement of the stove-boiler not near the load-bearing wall for the convenience of the process of installing the smoke exhaust duct system.

The height of the smoke exhaust should not be less than 4 meters, otherwise the accumulated condensate will enter the combustion chamber. If the stove is located in a neighboring building (for example, a separate heat-generating unit), there is no need to dismantle and move it inside the house. In this case, it is necessary to properly insulate the pipe wire that connects this building with the stove and the house

In order to prevent the coolant from overheating more than 100 degrees, you can change the temperature if you completely close the vent and slightly open the furnace combustion chamber.

How to do it yourself

If you have plumbing knowledge and skills, as well as confident handling of power tools, you can provide steam heating for your home yourself.

To complete the work you will need:

- pipes for heating mains;

- fittings, adapters, Mayevsky taps;

- heating device;

- steam generator;

- control devices.

Attention! In order for the project to be thoughtful, it is worth writing down ideas for the placement of elements, their types and sizes. This can be done directly on the diagram.

The process consists of several stages. In order to start work correctly, and most importantly, to complete it safely, you should design the structure. This means thinking through every meter of the heating circuit taking into account the high temperatures of the pipes.

Boiler

First, the power of the steam boiler is calculated. For a small house, take a capacity of 25 kW; an area of more than 200 square meters will require 30 .

If the heated area is 300 sq. m and more , then you should choose tanks from 35 kW. The boiler power ratio is on average 1 kW per 10 sq. m , if the ceiling is not higher than 2.7 m.

In addition to power, attention is paid to the possibility of heating water for home use.

Important! The boiler must be tested and have a certificate . This is necessary to reduce the risk of accidents.

Heating scheme

After determining the type of boiler, the design operation schemes are selected:

- two-wire with top wiring (the equipment warms up more evenly, condensate goes into the boiler through a separate pipe installed with a slope);

- single-wire with bottom wiring (the part of the line distant from the tank will be heated with hot water).

The choice of scheme is determined by several factors:

- heated area ;

- boiler installation location;

- number of installed pipes and radiators;

- convenient and safe arrangement of pipes and installation of a heat exchanger.

This is a complex process that will require time and careful analysis of the existing conditions.

Materials for lines and radiators

Conventional pipes that are used to supply water will not work. Consumers are offered the following options:

- steel - can withstand high temperatures, however, they rust over time;

- copper - good thermal conductivity, durability and cost;

- galvanized steel - not subject to corrosion, inexpensive.

The last option is considered optimal.

cast iron are primarily considered . They are durable, resistant to aggressive environments and corrosion. Steel ones with ribs are also suitable - for increased heat transfer.

Photo 1. Cast iron radiator with fins, model Prince 640, heat output - 399 W, .

Control devices

The control block is a necessary element, since hot steam is a poorly controlled element. The reducer regulates the pressure, and when it increases, the valve is activated.

The project should have:

- total length of pipes;

- radiator installation locations;

- pipeline branch points;

- necessary adapters.

This is put on paper, a diagram is drawn taking into account the characteristics of the home. All details and dimensions are written directly on the drawing. With the finished model of the future design, they plan and carry out the purchase of the necessary equipment and tools.

Homemade schemes that are easy to repeat

If we consider in detail the materials on the installation of steam heating, it becomes clear that it is quite possible to make a house warm on your own .

Monotube

The simplest scheme is a series connection of radiators , which are connected to the output and input of the boiler. The steam, gradually cooling, moves from the beginning of the circuit back into the boiler. Part of the mechanism is no longer heated by steam, but by hot water.

Reference! The pipes are placed low , and the temperature in the first and last radiators is equalized by connecting the circulation pump.

Horizontal

This simple design is suitable for a small home . If there are many rooms, you will have to speed up the movement of the coolant with a pump . To turn on radiators variably, they complicate the circuit by integrating bypasses (adapters that exclude some sections).

Vertical version of a single-pipe scheme

Provides heat to a house with two or more floors . For a small home with a heated attic or a warm underground floor, this is a suitable type of circuit. Few materials are required, and the design itself is inexpensive.

For each floor a chain of radiators , the required amount of material is calculated, taking into account jumpers with bypasses (this will help make the temperature in the rooms more even).

Leningradka

This is a complicated previous scheme that provides for maximum equalization of coolant temperature along the entire length of the circuit.

The principle of operation is to distribute the coolant in such a way that part of it moves, bypassing the radiators (using bypasses). To do this, a pipe is laid under them, from which there are branches to the inlet and outlet of the battery. The section between the taps is a jumper that will help control the temperature in the room. The coolant goes directly to the next part of the circuit without cooling down.

Differences between steam and traditional heating

Steam heat supply operates according to the principle:

- First of all, water is heated in a container to a boil and turns into steam;

- steam passes through pipes to heating devices, giving off heat;

- in batteries, steam condenses, turning back into water;

- water flows through the outlets into the expansion tank and goes back to the heat exchanger.

Unlike a water heating system, a steam heating system provides greater heat output, heats the room three times faster, and is ergonomic. It requires small equipment, which, in fact, reduces the price of the system in general. Another plus: in an abandoned house, the pipes don’t freeze when it’s cold outside. Thanks to this, it is easy to start the steam heating supply by arriving at the dacha during winter, and when leaving, make sure that the fuel is completely burned out.

By the way, not only furnaces, but also boilers operating during mining can be used as a generator for steam heat supply. But in most cases, a system of this kind is installed in garages and utility rooms for environmental reasons.

Types of furnace equipment

Furnace equipment refers to the structural elements that are used during the installation and operation of the stove. In cast iron stoves, they are already included in the kit from the manufacturer, but when connecting an additional water circuit to them, you will have to purchase additional elements for the stove:

- Pipes

. These can be plastic or metal pipes. Preference is always given to metal ones, as they are more reliable, but plastic ones are cheaper. The disadvantage of plastic pipes is the possibility of their melting at the joints with metal. Metal ones do not have this drawback.

- Diaphragm (expansion) tank

. It is necessary to maintain constant pressure in the pipes. When heated, the water begins to expand and enter this tank, so the pipes will not collapse from excess pressure. When cooling, excess water from the tank begins to gradually flow back into the pipes.

You can’t do without an expansion tank for any method of heating a house. Source koffkindom.ru

Radiators. They are usually installed directly under the windows. They increase the heat transfer of the water circuit. Water pump. It is required for water circulation in the circuit. Its installation helps to quickly heat the room, since the heated water quickly enters the radiators and heats the room. Without a pump, the movement of water through the pipes is carried out by gravity, but for this it is necessary to make special slopes, calculate the difference in heights and the difference in temperatures of the first circuit with heated water and the second circuit with cooled water - it is also called return. Heat exchanger. It is installed in the furnace firebox, above it, or on the chimney. All options have their advantages and disadvantages. This is a kind of boiler in which water will subsequently be heated

For chimneys, the heating tank is made in the form of a coil; for a firebox, it can have an arbitrary shape, but it is very important that it has a sufficient area of contact with the stove flame.

Scheme of operation of stove heating with a pipelineSource m.yukle.mobi

Disadvantages of steam heating and ways to eliminate them

- heating devices from steam heat up above 100°C, due to which they pose a danger, especially for children and animals;

- the steam heating system does not stop working noisily;

- temperature control is difficult;

- impossibility of installing warm hydraulic floors.

The first disadvantage can be removed by protecting heating appliances and supply pipes with screens. There is a huge range of such decorative interior elements made of wood and plastic.

The noise in the system can be greatly reduced if you use anti-noise spider fasteners for heating devices when installing them, and install the steam generator itself in an individual room.

The 3rd point is hard to remove. But for the 4th, there is a solution - if you wish, warm hydraulic floors can be replaced with infrared film floors.

Attention! It is not advisable to designate a brick stove with a steam generator for heating and cooking at the same time, since it will still be unrealistic to use it in the summer months. Or, you will have to come up with an alternative option for the warm period. For example, perform a summer oven in clean air.

Also, plastic pipes cannot be used in the system; they will not withstand the temperature regime.

Russian stove

A beautifully laid brick stove will be an excellent decoration for your home. If working with brick is not new to you, installing a water-heated stove in your home will not be difficult. Any construction work begins with a project, which indicates all the parameters of the future structure. After a carefully developed project and drawing up an order, you need to purchase building materials. The main materials used in the construction of the furnace are red ceramic bricks.

For masonry, only the highest quality brick is needed. You cannot start work if you have pale pink unburned brick or burnt brick with a glassy surface.

Good quality building material makes a metallic sound when tapped and has a uniform red color over the entire surface.

To make a firebox you will need a refractory refractory brick. If the firebox is needed for coal, it is advisable to use fireclay bricks. For a firebox that runs on wood or peat briquettes, white brick from the Gzhel or Borovichi plant is suitable.

The mortar plays an equally important role in the quality of the masonry. On the construction market you can buy dry special mixtures, which are simply mixed with water before use, but kiln masters prefer to use a solution.

Popular publications:

The basis for heat preservationBefore you properly insulate the floor in a wooden house, you need to study the diagram...

How to make a window sill: materials and methods Before starting work on the manufacture of a window sill, you must carefully take the dimensions...

Plastic or wood? Plastic window with wooden window sill We definitely recommend one or another type of material for manufacturing...

Autonomous heating in an apartment building. Is it possible to install autonomous heating in an apartment with your own hands? Although legislative...

Installation diagram of steam heat supply from the furnace

- Natural and forced circulation system

A system operating on the principle of gravitational circulation requires placing the pipe coil below the level of the heating devices and all pipes at an angle. A forced system requires a pump to ensure uninterrupted circulation of the pipe coil.

Schemes also come in one- and two-pipe.

- Single-pipe steam heat supply scheme for a private house

This scheme operates on the principle of serial connection of heating devices. The coolant moves through the pipe, moving from one battery to another. As a result, the first heating device turns out to be the hottest, and the final one is almost cooled down. Due to this, it is best to use this scheme for rooms with a modest area - from 40 to 80 m2.

- Two-pipe scheme

This system is better suited for houses with large areas and two-story country houses. It is distinguished by the fact that the heating devices in it are connected in parallel, using two pipes: inlet and outlet (condenser). In this scheme, the coolant is supplied to all heating devices at the same temperature, since it does not have time to cool down.

Features of low pressure systems

A common version of such a system is closed, using gravity return of condensate to the boiler, which does not completely fill the pipes, and an upper pipe distribution is used.

First, the system is filled with water to the required level, after which heating begins. The condensate flows down a common riser and, when a predetermined level is reached, is forced into the boiler.

In the same system with bottom distribution, it is recommended to install pipes with a slight slope in the direction of steam movement in order to reduce noise effects. At the point where the condensate is drained, a loop-shaped water seal is installed, which prevents the movement of steam onto the condensation line.

The steam velocity in such systems should be moderate, no more than 0.14 m/s. Otherwise, the steam will also capture particles of moisture accumulated on the walls. As a result, the system operates with more noise and increases the risk of water hammer.

Combined wiring, i.e. a combination of upper and lower wiring is used if pipes are laid under the floor of the upper or middle floor of the house. The lumen of the pipes through which water returns to the boiler will in this case be closed by condensate.

If the pressure in the system exceeds 0.02 MPa, it should be made open. The air is removed through a condensate storage tank, and to prevent steam from leaving the system, a condensate drain or water seal is installed. Water from the storage tank is pumped into the heat exchanger, which allows the storage tank to be installed below the level at which the heat exchanger is located.

The coolant for heating a private house with a boiler room is heated in a heat exchanger located in the boiler room. Upon reaching the operating temperature, the steam moves to a manifold that divides the flow into two circuits: for the main rooms and for the boiler room (+)

How to arrange steam heat supply from a furnace with your own hands

Equipment and materials

For a steam heat supply device you will need:

- heating devices (under each window);

- heat exchanger - essentially a water tube boiler or steam generator;

- pipes for steam and condensate drainage - give preference to materials resistant to high temperatures: galvanized steel or copper;

- elbows, connectors, pipe clamps, spider fasteners for heating devices, shut-off valves: valves, air release valves;

- a hydraulic valve used to allow drying of the steam pipeline;

- pressure reducing valve to reduce pressure in the system;

- reduction-cooling unit;

- inverter device;

- container for collecting condensate;

- pump.

It is better to rent expensive equipment.

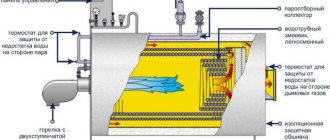

Heat exchanger

You will have to make a heat exchanger for a brick stove yourself or choose one. For this you will need metal pipes, a wall thickness of 2.5 mm and an inverter apparatus. You can combine them as in the picture or make them in the form of a coil. The main thing is to monitor the quality of the weld seams. The calculation is performed approximately like this: 1 m 2 of the coil surface delivers up to 9 kW.

After the design is made, you need to check it. To do this, you need to pour water into it and make sure there are no leaks. However, this method is not very informative, because welds may have slag inclusions, which will not be detected in the absence of excess pressure.

The best way to control the quality of seams is using the “kerosene on chalk” method. To do this, you need to chalk all the welds and pour kerosene inside the structure. If there is a tiny pore, the chalk will fade because kerosene will seep into it.

Sequence of work

The heat exchanger is built into the furnace at the stage of its laying directly into the combustion chamber

Next, according to the diagram, heating devices are installed under the windows. Inlet and outlet pipes are connected to them. For gravitational circulation - with a smaller slope of 3 mm per meter. Each convector heater should be equipped with an air release valve.

For safety, it would be a good idea to install shut-off valves in front of each heating device and one in front of the entire system. At the beginning it is also necessary to install a pressure reducing valve and a cooling unit.

At the end of the system, a tank is placed to collect condensate, from which water also flows downhill back into the heat exchanger. It would not be a good idea to use a membrane expander for this purpose, since it is designed for temperatures up to 85 ° C.

In a forced-type circulation system, a pump is installed in the return pipeline in front of the furnace.

Wood-burning brick oven

If stove heating is used to heat the home, then the main question that needs to be resolved is where to install the heat exchanger or steam generator.

There are several options. The generator can be a coil or a boiler. To ensure that the water in the generator heats up quickly, it can be installed directly into the firebox. The water will boil quickly, but the equipment will soon become unusable. It will be under constant exposure to fire.

The coil is built into the brick walls of the furnace, filled with mortar. This design will last a long time. The water will absorb the heat that is transferred through the brick walls. It will boil quickly. This design option has some disadvantages. If a breakdown occurs in the coil, it will be impossible to eliminate it. You will have to disassemble the furnace wall and install a new heat exchanger.

It is not recommended to install the steam generator close to the wall. Soot and dirt can get into the niche. It should be possible to clean the surface of the coil and the niche itself. The steam line can be connected to the boiler or directly discharge steam to radiators or to the “warm floor” system.

The system must be equipped with control devices to regulate the temperature and steam pressure. The optimal outlet temperature is 150 0C. The pressure at the outlet to the steam line is 170 kg/m2. When installing the main line, it is not recommended to use fittings. The pipes are connected by welding seams.

Invisible moments when operating steam heat supply from a furnace

Brick stoves with a heat exchanger produce more soot in the chimney than in most cases, and it must be cleaned more often.

With a gravity system, the furnace will have to be built in the basement so that the condensate flows freely to the lowest point.

Do not neglect the installation of valves - they are needed for safety and elimination of accidents. Since the pump requires electricity, it is necessary to take into account that if the power is turned off, it will be impossible to stop the operation of the furnace.

Steam heat supply in a wooden house is installed according to a similar principle as in a brick one. You just need to follow fire safety measures - protect wooden surfaces from overheating.

Two-pipe system

The steam heating system can be two-pipe. In this case, steam and condensate pass through different pipes. More consumables will be required, but the risk of water hammer in the line is minimal.

With a single-pipe system, the condensate level may exceed the steam level. The coolant outlet is blocked. This leads to a sharp increase in pressure in the device or pipes. A water hammer occurs, which may be accompanied by a rupture of the main line. With a two-pipe system, condensate is removed and does not interfere with the flow of coolant to the devices in the room. Steam heating at the dacha is done with their own rivers according to a certain scheme.

- Install the boiler and radiators in the areas provided for them in the house.

- The chimney is removed from the boiler at an angle of 300.

- It is necessary to install an expansion boiler in the attic.

- Pipes for steam inlet and condensate outlet are removed from the radiators. For heating to be effective, steam must enter the device from above. For condensate, an outlet is made from below.

- A pipe through which coolant will be supplied is led out of the expansion tank at an angle. It is connected to the hot circuit: all radiators are connected.

- The steam line is connected to the outlet pipe in the boiler.

- The condensate line is removed from the last radiator. It is connected via fittings to the lower pipes in the radiators.

- A container is provided to collect condensate. The condensate pipeline approaches it vertically.

- A pipe for liquid outlet is removed from the tank. Strengthen the pipe at an angle to the boiler. At the outlet of the tank, a water filter and a circulation pump are installed, which will pump liquid into the water circuit located in the boiler. It is recommended to remove the air pipe in front of the pump. Air will pass through it into the atmosphere, which will prevent the pump from airing.

- The highway is being closed. All connections are checked and pressurized.

- Testing the heating system.

To be able to install hot water in the house, it is necessary to provide an additional circuit. Through it, hot water will flow from the boiler to household appliances in the kitchen, bathroom, and toilet. For water heating, the circuit can be removed from the expansion tank. With steam heating, the hot water line leaves the condensate collection tank.

In order not to make corrections to the country heating pipeline, it is recommended to purchase double-circuit boilers or equip the stoves with an additional heat exchanger. There is already an outlet for water supply from the furnace or boiler. If a furnace with heat exchangers is built independently, then a steam line is removed from one coil, and a pipe for hot water is removed from the other.

Installing steam heating in a country house is a profitable undertaking. For a small home, a single-pipe system is well suited. For multi-storey cottages, it is recommended to consider a two-pipe main.

Condensate is used for domestic needs: the water is hot, cools down to a temperature of 60 0C. To install a separate DHW pipeline, boilers with a double water circuit are purchased.

YouTube responded with an error: Daily Limit Exceeded. The quota will be reset at midnight Pacific Time (PT). You may monitor your quota usage and adjust limits in the API Console: https://console.developers.google.com/apis/api/youtube.googleapis.com/quotas?project=268921522881

Steam home heating from a stove

Heating with a stove has been used since the moment people thought of building a stove in their homes. The first furnaces, naturally, were not steam - they used either specialized shafts - rough ones, or only the heat that came from the stove. Immediately after its appearance, steam heat supply began to use the furnace as the main heating element in the system.

Scheme for connecting the stove to the heating system

The principle is very simple: the fire heats the pipe wire passing through the furnace. Water moves throughout the system due to temperature differences.

Features of wood heating

In general, water heating is a method of heating a room using a circulating liquid coolant, the role of which is most often played by water. Accordingly, water heating with wood or water heating from a stove involves heating the water mass using the classic Russian method - by burning wood.

The most reliable and effective scheme can be considered when water cooling radiators (battery) are used. Thus, the heating element is a stove with a wood firebox, and the heat source is a radiator, which provides a certain heated area. The entire circuit is looped through a pipe system (wiring), through which the coolant liquid is transferred from the stove to the radiator and back. The number of radiators depends on the volume of the room and the required air temperature.

Why the actual furnace steam heat supply

No one forces you to build a furnace in order to replace the boiler with it. However, if you already have a stove, then installing a boiler is somewhat impractical. There are several reasons for this at the same time:

- heating with wood or coal will not be very expensive than other types of fuel;

- demolition of the furnace can cause additional expenses for repairs, and in some cases even capital ones;

- steam heat supply control is manual, which means the risk of automation failure is completely eliminated;

- heating with wood is the best option for a private village house or a country house;

- if the gas can be turned off, then the stove stops working only if there is no firewood or coal, and this is on the owner’s conscience.

Water furnace

Water heated stove.

In view of the fact that large houses are currently being built and 2 or even 3 stoves would have to be placed in them for stove heating, the consumption of firewood with this heating method turns out to be very high.

For these reasons, they came up with heating and cooking stoves with water heating with a special water boiler mounted in the firebox of the stove for water heating of the house - this is a water stove.

The advantages of this method of heating rooms are that even in severe frosts, lighting a water stove twice a day is sufficient. These heating and cooking stoves warm up the house in between fireboxes, when the pipes cool down and release heat into the room for 5-6 hours. The efficiency of such boilers together with heating and cooking stoves is noticeably higher and reaches a threshold of 80-85 percent.

Oven with water circuit

The following is a diagram and order of laying a furnace with a water circuit measuring 1020 x 1020 mm with a boiler. The efficiency of this stove, when used correctly, is high and reaches 85 percent.

Dimensions of the iron boiler: length 75 cm, width 48 cm, height 30 cm. The heat transfer of a water furnace with a double firebox is about 7600 W (6,500 kcal/h), the heat transfer of such a boiler with a good firebox is 17,500 W (15,000 kcal/h). The total heat output of a stove with a water boiler is about 25,000 W (21,500 kcal/h), which allows heating rooms up to 300 square meters even in extreme frosts.

The enormous heat output of the water-circuit furnace and the high efficiency of the modernized water boiler are achieved due to the fact that the heating surface of the water boiler is well developed.

Hot gases intensively wash the iron boiler from all sides, at the same time, the inner walls of the lower heating chamber become very hot, where, with breaks of 7-8 hours between fireboxes, they allow the water boiler to be maintained heated. A 2-time firing of such a stove with a water circuit is sufficient for heating small areas. When using such a furnace with a water circuit, wood savings of two or more times are achieved compared to factory-made continuous water boilers.

What specifics might there be?

Like any other heating system, steam heat supply using a wood-burning stove has certain disadvantages. It would be correct to use even a word that is not given and change it to specifics that may seem inconvenient to some:

- Sometimes the stove is located in a neighboring building. This is not uncommon, but a solution has been found. It is only necessary to pay great attention to the proper thermal insulation of the pipeline, which will connect the house and the building with the stove. Otherwise, a lot of heat will be lost.

- The coolant in the system can heat up above 100 degrees. This is due to the fact that in a closed space the pressure becomes greater when heated and, based on this, the temperature increases. Stopping the supply of wood or coal does not solve the problem; putting out the stove is also not an option. It will be quite simple to slightly open the combustion chamber of the furnace and completely close the vent so that the temperature from inside the system stabilizes. This is inconvenient, but it is quite possible to learn how to determine the required amount of fuel for a one-time use.

- The lack of automation means the impossibility of independent work. To maintain the desired temperature, you will either need to accept that until the morning the pipes and heating devices cool almost completely, or add a new portion of fuel in the middle of the night. This is also uncomfortable, although not critical.

- The risk of smoke in the room where the stove is located is quite high. Low atmospheric pressure, dirty chimney, damp firewood, poor quality coal - these moments can bring their own share of troubles.

Diagram of the wood stove and heating system

Features of heating a private house with steam

Heat delivered by steam has a number of advantages that attract the attention of zealous owners:

- installation of the structure will be relatively inexpensive , repair and maintenance also do not require a lot of money and time;

- the equipment does not take up large spaces;

- the room heats up in a matter of minutes;

- there is practically no heat loss ;

- heat is transferred through pipes and distributed not only by convection, but also by radiation ;

- due to efficiency, a small number of radiators and even only pipes are used.

Due to high heat transfer, the area of radiators and the diameter of pipes are reduced.

When choosing a heating design, you should know not only the advantages.

There are a number of disadvantages :

- the equipment itself is noisy ;

- you will have to be careful as the temperature of the pipes can be more than 100 degrees;

- the surfaces of the heating main must be closed , especially if there are children in the family, to avoid serious burns;

- high air circulation in the room , a low level of humidity will be established, which will require measures to purify and humidify the air;

- In the event of an accident, there is a risk of serious injury - hot steam will erupt.

If you do everything on your own

Furnace steam heat supply can be done independently. Certain knowledge and, very importantly, tools are needed, but acquiring them is not a big problem:

- The stove should be located in a place where it will not be a hindrance to residents. And the point is not that she will ask for free space for herself. Adding firewood or adding coal - sometimes smoke escapes, and then the risk of absorbing a “smoky smell” is very high.

- If you need to choose between a steel and plastic pipe, then it is better to go with the first option. Iron wire pipes for air heating are the most suitable, since the economy in this case cannot be compared if gas or liquid fuel were used. Thanks to this, it is possible to make the pipeline diameter larger, thus increasing the volume of the coolant. But the area of the metal from which heat will emanate also increases. So it makes sense to think about this.

- The stove is made of metal or fireclay brick. Two options worked well. But there are differences, and for some they are fundamental. For example, a metal stove cools down much faster after the last batch of wood or coal has burned out. Brick retains heat longer: even if the stove goes out in the evenings, in the morning you will feel a temperature of about 30-40 degrees on the surface of the brick. For steam heating, this will not play a special role, but if the stove heats a separate room, then it is better to look in the direction of brick.

Water heating system circuits installed in the furnace

Steam heat supply using a furnace is an affordable option, although with characteristic features. However, this option has been tested over time and has proven itself very successfully. So you shouldn’t discard it outright.

Single-pipe scheme

If the country house is small, less than 100 m2, then it is more economical to use single-pipe heating for heating. The coolant and condensate in this case will be in the same pipe. Installation diagram:

- boiler containing the steam generator;

- steam line;

- radiators;

- condensate line;

- the highway is closed.

For an area of 100 m2, a boiler of no more than 10 kW will be required. This power will be enough for normal heating of the house. To ensure that the water in the boiler heats up quickly, gas, electric boilers, and stoves running on diesel fuel or waste oil are used.

A brick wood stove or fireplace looks attractive, but it takes a long time to heat up. The advantage of wood heating is that it is completely autonomous. If the house is connected to a gas main, then they use a gas stove, but choose equipment with piezo ignition, which will make the heating independent, independent of electricity.

To connect individual sections of the system, galvanized fittings are used. Tow is used as a sealant. Radiators are also purchased from galvanized steel. If the rooms in the house are small, then heating devices are not installed. A pipe is laid around the perimeter of the room. It will act as a heater.

You must always remember that steam comes out under a pressure of 170 kg/m2. Its temperature is 150 0C, its speed is 30 m/s. If the pipes are connected poorly, the line will rupture, which will be accompanied by a powerful flow of steam. Before starting work, it is necessary to perform a pressure test of the system to identify the places where air passes from the pipes.

Where do you start installing a heating system? First, the entire diagram is transferred to a sheet of paper. The drawing indicates the location of all elements of the system and the length of the pipeline in individual sections.

- Install the boiler. A separate area must be equipped for a wood-burning stove. The walls are protected from high temperatures with asbestos sheets. The stove is located away from interior items. The gas boiler is mounted on the wall. A chimney is installed for heating units. It should exit the oven at an angle to increase draft.

- Install radiators if necessary. They are fixed to the wall on brackets. Distance from the floor 10 cm, from the window sill 10 cm, from the wall 5 cm.

- Pipes of the appropriate diameter are supplied to the radiators. To create a slope, the pipe is raised: 0.5 cm by 1 m towards the boiler. Fittings are used for connection. All heating devices are connected one by one.

- A pipe is removed from the last radiator: a loop is installed. It is necessary to make the condensate pipeline inclined to the boiler 0.5 cm/m.

- The main is closed: the pipes are connected to the boiler.

- If a high-power boiler is used, it is recommended to install an expansion tank to remove excess steam. The tank is installed in the attic. A steam line from the boiler leads to it and a pipe goes down to the radiator.

To be able to remove the radiator without affecting the main line. Bypasses and ball valves are installed on the sides in the lower corners. If there is a need to change or repair the device, the taps shut off the access to steam, the radiator cools down: it is ready for repair work.

Steam boiler structure

The design of a PC can be simplified in the form of a container where water is converted into steam. It is made of pipes of different diameters. In addition to the pipe system, the PC has a combustion chamber in which natural fuel is burned.

The design of a steam boiler and its design features are determined by the type of fuel. For example, coal fireboxes are equipped with grates on which a burning fuel layer is placed, through which oxygen enters the firebox.

A chimney is installed at the top of the firebox, which creates draft in the steam-gas path of the unit, thereby maintaining normal operation. Gas-fired steam boilers have gas or oil burners.

I heat the hot exhaust gases produced during the combustion of fuel to boiling water, after which steam begins to be released from the evaporation surface and supplied to the consumer, and the flue gases escape through the pipe into the atmosphere.

The main structural elements of steam boiler houses are connected into one complete boiler system using fittings, fittings, circulation pumps, instrumentation and control of smoke exhausters and fans.

Conclusion

From the article you found out how to make steam heating, and that its use in a private residential house is cheaper than water heating, despite the fact that it is more dangerous to operate. Based on this, you need to strictly adhere to the guidelines and equip the system with special equipment that will increase its safety.

You have the opportunity to order a heat exchanger from experts or make it yourself. Connecting and installing radiators is not difficult. The video in the article will help you find additional information on this topic.

Additional elements of the unit

The design of a steam boiler may include not only a combustion chamber and pipes (drums) for circulating water and steam. Additionally, devices are used that increase the efficiency of the system (raise the steam temperature, its pressure, quantity):

- Superheater - increases the steam temperature above +100ºC. This in turn increases the efficiency and efficiency of the machine. The temperature of superheated steam can reach 500 ºC (this is how steam boilers work in nuclear power plants). The steam is additionally heated in the pipes into which it enters after evaporation. Moreover, it can have its own combustion chamber or be built into a common steam boiler. Structurally, convection and radiation superheaters are distinguished. Radiation structures heat steam 2-3 times more than convection structures.

- Steam separator - removes moisture from steam and makes it dry. This increases the efficiency of the device and its efficiency.

- A steam accumulator is a device that takes steam from the system when there is a lot of it, and adds it to the system when there is not enough or little of it.

- A device for water preparation - reduces the amount of oxygen dissolved in water (which prevents corrosion), removes minerals dissolved in water (using chemical reagents). These measures prevent pipes from becoming clogged with scale, which impairs heat transfer and creates conditions for pipes to burn out.

In addition, there are valves for draining condensate, air heaters, and, of course, a monitoring and control system. It includes a combustion switch and switch, automatic regulators of water and fuel flow.

Steam generator: powerful steam engine

A steam generator is a steam boiler that is equipped with several additional devices. Its design includes one or more intermediate superheaters, which increase its operating power tens of times. Where are powerful steam engines used?

The main application of steam generators is in nuclear power plants. Here, with the help of steam, the energy of the decay of an atom is converted into electricity. Let us describe two methods of heating water and generating steam in a reactor:

- Water washes the reactor vessel from the outside, while it heats itself and cools the reactor. Thus, steam formation occurs in a separate circuit (water is heated against the walls of the reactor and transfers heat to the evaporation circuit). This design uses a steam generator - it acts as a heat exchanger.

- Pipes for heating water run inside the reactor. When pipes are fed into the reactor, it becomes a combustion chamber, and the steam is transferred directly to the electric generator. This design is called a boiling reactor. A steam generator is not needed here.

Steam generator for a nuclear power plant

Industrial steam units are powerful machines that provide people with electricity. Household units also work in the service of humans. Steam boilers allow you to heat a house and perform various work, and also provide the lion's share of electrical energy for metallurgical plants. Steam boilers are the basis of industry.

What else to read: