Comparison of pressure indicators for different types of radiators:

| Radiator type | Average working pressure, bar | Average test pressure, bar |

| Steel radiators | 6-8 | 10-13 |

| Cast iron radiators | 9-12 | 15-18 |

| Aluminum radiators | 6-16 | 9-24 |

| Bimetallic radiators | 25 | 35 |

When choosing heating devices to equip centralized and autonomous heating systems, a number of points must be taken into account. One of the key indicators is pressure. When choosing radiators, you must take into account the pressure they are designed for. This indicator must correspond to that of the heating system. Violation of this requirement is one of the common reasons why radiator sections become depressurized and fail.

It is important to distinguish between two indicators: working and test pressure. Working pressure is the pressure for which heating devices are designed to be constantly exposed during operation. It depends on the operating pressure of the heating system.

Autonomous heating systems in private houses and apartments, as a rule, operate with a coolant pressure of 3-5 atmospheres. In heating systems of apartment buildings, a pressure of 8-16 or more atmospheres can operate. In this case, this indicator depends on the number of floors: the more floors in the house, the higher the pressure in the heating system will be. Radiators must be selected in such a way that their operating pressure is at least 2 atmospheres higher than the maximum operating pressure of the coolant in the system.

The test pressure is the maximum pressure that the radiator can withstand under short-term exposure. This indicator is determined during factory hydraulic tests of heating devices. For the consumer, it is important, first of all, because it characterizes the batteries’ resistance to water hammer, which can often occur in centralized heating systems, especially when they are started at the beginning of the heating season.

Pressure indicators are determined, first of all, by the characteristics of the material from which the radiators are made, as well as by the features of their design.

Technical characteristics of cast iron radiators

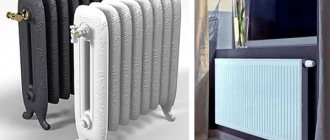

Almost every home has cast iron radiators. Manufacturers improve them over time and improve their technical characteristics. There are steel, aluminum and other radiators on the market. But the most popular radiators are still cast iron. This is due to the many advantages and performance indicators of such heating devices.

Content

1. Features of cast iron radiators 2. Advantages and disadvantages 3. Types of pressure 4. Which coolants are suitable for cast iron radiators 5. Main characteristics 6. Service life 7. Heat transfer and power 8. Calculation of the power of cast iron radiators

Positive and negative sides

Cast iron radiators have a huge number of positive aspects. Among them, the most significant are:

- Low hydraulic resistance, thanks to which the coolant passes through the radiator without significant interference

- Scale and salt deposits do not harm the heating system

- Resistance to chemical reactions

Among the negative aspects are:

- Not the most beautiful and presentable appearance

- It is very difficult to regulate the temperature in the room

- Complex connections between fins make cleaning difficult

- Weight and impressive dimensions make you think about reliable fastening

Inertia is an advantage and disadvantage of cast iron radiators at the same time. Batteries are very difficult to warm up. However, after turning off the heating system, they will retain and release heat for a long time.

Features of cast iron radiators

Cast iron radiators appeared in our country only in the last century. The first city in which such a heating device was seen was St. Petersburg.

Such radiators are made from a fairly strong cast iron alloy. This material is very durable. Cast iron radiators are used both in residential buildings, industrial buildings, and in centralized heating systems. The battery can consist of any number of sections. This allows you to install the appropriate device for each room. For a small area, the power of a small radiator is enough, so it would be inappropriate to use a multi-section heating device. To avoid leakage, sealing gaskets made of rubber or other materials are used at the junctions of sections.

Cast iron radiators do not differ in the nature of their operation from steel or aluminum ones. The coolant is heated in the boiler and transfers its heat using a heating radiator. There are several models of cast iron radiators: with one, two or three channels.

Connection

Fitting

How to properly connect a cast iron battery with your own hands? Traditionally, to connect heating appliances, pipe connections are used; the connection is ensured by a radiator plug and locknut. The connection is sealed by wrapping it with plumbing flax (preferably with paint or silicone sealant).

Connection on the lines.

The radiator installation instructions are as follows:

- A lock nut and plug are screwed sequentially onto the long threads of the connections;

- The radiator is hung in such a way that the hoses are aligned with its collectors and extend into them by 2 - 3 centimeters.

- The plugs are wound up and driven along the connections, screwed into the threads of the outer section.

- Then they are tightened with locknuts - also, of course, with winding.

Recently, however, American ones have begun to be used much more often for installation - detachable fittings with union nuts.

Connection on American.

In this case, the installation looks different:

- The tap with the American connection is mounted on the supply line coaxially with the battery collector.

- The American counterpart is screwed into the radiator plug.

- The union nut is tightened and tightened with an adjustable wrench with moderate force.

Useful little things

It's helpful to remember a few things when installing.

The efficiency of cast iron radiators (let's call it the ratio of their real thermal power to the rated one) will be maximum with the following connection diagrams:

- When the number of sections is up to 10 - side;

- When the number of sections is over 10 - diagonal.

Diagonal connection.

Silting of the battery can be avoided by connecting it from the bottom down. The continuous movement of the coolant through the lower collector will not allow deposits to linger in it. In other cases, it is advisable to equip the lower blind plug with a flushing tap.

Please note: this applies to cases where cast iron heating devices operate in a central heating system. In an autonomous circuit, all suspended matter quickly collects in a mud pan and does not create problems in the future.

Speaking of the declared power: manufacturers give its values for the temperature delta between the coolant and the air in the heated room at 70 degrees (for example, 90/20C). Reducing the delta by half entails, as you might guess, a twofold drop in heat transfer.

Advantages and disadvantages

Advantages:

1. Cast iron batteries can withstand temperatures up to 150°. Such radiators resist corrosion well. Cast iron is difficult to corrode.

2. The radiator walls are made very thick. Therefore, such batteries have a long service life. Radiators can be used in an open heating system and one that is occasionally emptied. Steel radiators under such conditions would become rusty in a few years or completely unusable.

3. Due to the large cross-section of the battery, they can be cleaned less often, unlike other radiators.

4. If a cast iron radiator is made according to all standards and from high-quality material, then it will last a very long time. It is possible to use a radiator for up to 50 years, and sometimes up to 100 years.

5. Such radiators are difficult to damage or dissolve.

6. When the radiator is turned off, it will continue to heat the room by 30%. Cast iron batteries have heat transfer several times greater than radiators made of other materials. In case of irregular heating of the coolant, a battery made of cast iron will cope with its function perfectly. All these qualities are possible thanks to the good heat-storing properties of the cast iron battery.

Flaws:

1. Heavy radiator weight. When lifting the radiator into the apartment, it will be problematic to bring it.

2. The working pressure is much less than other radiators.

3. Due to the number of sections, the surface area of the radiator is reduced. It is smaller than other radiator models.

Along with all the advantages, the disadvantages are insignificant.

Selecting a heating radiator based on operating pressure

In the climatic conditions of our country, the heating season lasts most of the year.

The required room temperature is provided by heating radiators. In such batteries, water heated to a certain temperature circulates, thereby heating the room.

Diagram of the structure of a heating radiator.

When choosing a heating battery, you need to take into account a number of possible operational difficulties, including corrosion of internal lesions, water hammer, gas formation in aluminum batteries, find out the operating and test pressure in the house, and the temperature of the coolant. To find out the pressure and other important characteristics, you need to contact the house management or housing office. In response to the request, 2 indicators will be provided: working and test pressure. It should be noted that it can be given in different units. For example, atmospheric or in MPa (1 MPa = 10 atm). When choosing a radiator, it is necessary to take into account the pressure in the heating system of your home.

Working pressure is the pressure that is maintained in the house throughout the heating season. The test pressure is supplied higher than the operating pressure. It is given for a few hours once a year in order to check weak areas in the system.

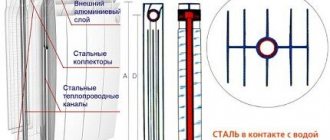

All heating radiators are made in such a way that when heating from the inside, their entire area comes into contact with the air in the heated room. There are 4 main types of modern batteries: steel, aluminum, cast iron and bimetallic radiators.

Types of pressure

The pressure in such radiators is: pressure testing and working. The first is often called maximum.

The pressure test determines how much load the radiator can withstand during severe water hammer. When checking, they try to create a load in the highways that will be close to the maximum. This figure ranges from 12 to 16 atmospheres.

And the working pressure shows the load that the coolant gives in the radiator circulation. Typically the load is 9 atmospheres, but this figure can range from 6 to 9.

Basic elements of the heating system

- Heating fluid boiler;

- a pump that circulates the coolant;

- an expander that eliminates the thermal expansion of the liquid in the system, and therefore the increase in pressure;

- automatic air vent, which is activated when the system becomes airy and releases air;

- shut-off valves that allow you to change batteries without removing coolant from the system.

We recommend: What characteristics are used to choose autonomous heating batteries?

What coolants are suitable for cast iron radiators

In such batteries, it is possible not to monitor the acidity values in the circulating liquids. This is due to the fact that such radiators are insensitive to coolants. Many impurities accumulate inside the central heating system. Due to the width of the channel, impurities can pass freely and not accumulate. This material does not enter into chemical reactions with liquids that contain antifreeze additives. But water treatment must be carried out, since in addition to the radiator, the coolant flows through the boiler, pipelines and other equipment.

Manufacturing radiator tests with trial pressure

Today, the production of radiators for water heating systems in terms of developments, design features of products, technologies and materials used is not inferior to high-tech fields such as mechanical engineering, and sometimes even surpasses them. Indeed, despite the apparent simplicity of the form and operating principle, radiators must meet the most stringent requirements. And they concern not only the effective transfer of heat from the coolant into the room, but also ensuring a long service life, which is directly or indirectly influenced by various factors - sudden temperature changes, excess pressure, aggressive coolant environment, local power loads due to violation of installation rules and etc.

In addition, taking into account the practice of using heating equipment poses new challenges for developers. In particular, the issues of ensuring a comfortable microclimate in each room by eliminating excess heat, effective redistribution and use of all thermal energy, saving energy resources, and introducing automatic control systems are becoming increasingly relevant. Their solution is possible by supplying radiators with individual means of adjusting heat transfer - thermal valves, thermostatic regulators, smart sensors, etc. Not every radiator is suitable for using such devices. This is due to the fact that the device must quickly change the heat transfer parameters depending on the values set on the control elements. It is advisable to supply these elements only to radiators with low inertia.

Following the requirements of the time, the manufacturer of heating devices takes into account all these particular and general wishes in its products. At the same time, it uses both accumulated production experience and unique new developments, the latest achievements, incl. from other areas - robotics, chemical industry, instrument engineering, etc.

Trends and prospects for the production of heating devices are inextricably linked with the constant increase in their manufacturability

The given pace of improvement of the technical characteristics of radiators means for the manufacturer not only the introduction of design changes while maintaining established standards of appearance, not only the use of advanced technologies, automation systems and the use of high-precision equipment, but also compliance with new requirements for quality control at all stages of manufacturing - from the selection of the original material before shipment of finished products to the customer. Control is established for the chemical composition of raw materials, melting, mechanical properties, threaded and welded connections, thickness and quality of painting, surface roughness, packaging parameters, storage conditions and much more. Controls must also be continually reviewed. Therefore, the production of a modern heating device is impossible without a complex of quality control.

The production of radiators is regulated by GOST 31311-2005 “Heating devices” [1]. In particular, according to clause 5.2, heating devices must be durable and sealed, and withstand a test pressure of water or air that is at least one and a half times the maximum operating pressure, but not less than 0.6 MPa. To monitor compliance with this requirement, the manufacturer uses special test benches. The maximum operating pressure must be indicated in the radiator data sheet [1, 2].

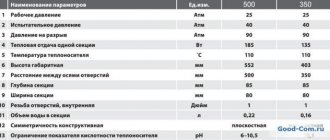

Main characteristics

The main technical characteristics are:

- The depth of the section is usually from 7 to 12 cm, the width is 8-10 cm, and the height ranges from 37 to 57 cm;

- Working pressure reaches no more than 18 atmospheres;

- 200W is the power of each section;

- The radiator weight is quite large. The weight of each section can be from 3 to 7 kg;

- The section volume is 0.7-1.5 l;

- The average service life is 30-50 years.

- Radiators made of cast iron are superior to other batteries in many ways.

High

Radiators of great height are installed in cases where the need for thermal power is high, but the layout of the room does not allow to occupy a large length of the wall. Accordingly, with a large height, these products have a limited width.

Cast iron

If domestic cast iron radiators mostly remain purely utilitarian products and are made of standard dimensions, then among imported products there are very stylish products of unusual height for cast iron.

As an example, take a look at the Demrad Retro line:

- With a standard width of 76 millimeters, the section height varies from 661 to 954 mm. The depth in all cases is 203 mm.

- The operating pressure is 10 atmospheres, but radiators are tested at 13.

- The thermal power of the largest sections reaches 270 watts.

- The size of the heating radiator can reach 2400 millimeters in height.

- Working pressure is often limited to 6 atmospheres, but it is easy to find more durable products.

- Thanks to the high altitude, solid heat transfer is achieved: at a temperature delta of 70C it can reach 433 watts (Oscar 2000 from Global) and even more.

Aluminum

Often the supply for high radiators is connected from below. The goal is to hide the pipes.

Bimetallic

A significant part of tall bimetallic radiators are designer designs, for which there is no need to talk about standard sizes or any kind of unification. In addition, often these are not sectional, but monolithic products.

As an example, however, we will take a serial representative of the family - the Sira RS-800 BIMETALL radiator.

- Section dimensions: height 880 mm, length 80 and depth 95 mm.

- Heat dissipation - 280 watts per section.

- The operating pressure is SUDDENLY 4 kgf/cm2 when tested at 6. The radiator is clearly not intended for central heating and is equipped with cores only in vertical channels.

Heat dissipation and power

When considering the characteristics of radiators, you should learn more about battery power and heat dissipation. Usually the power of only one section is indicated. You will have to independently calculate the power of the radiator before installing it.

The heat transfer of cast iron batteries is much less than that of aluminum and other radiators. The heat transfer is approximately 2 times less. But thanks to its low inertia, cast iron remains warm longer and will release useful energy longer.

The power of one section of this radiator reaches a maximum of 160 W, and for example, for an aluminum section it is 200 W. The most profitable option would be to purchase a cast iron battery with natural coolant circulation.

Pressure standards in heating systems of private houses

Water heating of a private house, as a rule, consists of a boiler, distribution pipes, radiators (warm floor pipes) and auxiliary elements (expansion tank, safety group).

In open (gravity) systems with natural circulation, the static pressure does not exceed 1-2 atm.

To move liquid in closed types of heating, a circulation pump creates a dynamic pressure that is 0.5 atm higher than the static pressure, i.e. for a private house with a height of up to 10 m, 1.5-3 atm is considered normal.

All modern boilers and radiators can withstand this parameter with a margin. If the pressure increases for any reason, the emergency valve is activated, releasing a certain amount of coolant or steam formed in the system.

Modern boilers have a built-in emergency valve; when purchasing, it is important to find out the maximum pressure (indicated on the cap) for which it is designed, and when debugging the system, carry out adjustments (if necessary). By turning the adjustment knob, you change the characteristic at which the trigger will occur.

Adjustable spring safety valve. Most often used in individual heating systems.

Pressure testing of heating in private houses is carried out by increasing the pressure to 0.2-0.4 MPa (2-4 atm), which is 1.5 times more than normal working pressure. Boilers and expansion tanks are turned off for the test period, as they are the most susceptible to destruction.

An increase and deviation of the indicator by 15-20% from the norm indicates the appearance of a malfunction. The cause must be identified and eliminated as soon as possible.

Calculation of the power of cast iron radiators

There are several methods for calculating the required number of battery sections. There are several main factors that influence the required amount of power: the area of the heated room, the number and size of windows and doors, the material from which the external walls are built and the technical characteristics of the batteries.

There is a simpler option for calculating power. To do this, you need to multiply the area of the heated room by 100, and then divide the resulting number by the power of the section.

But there are some nuances that need to be changed:

- If more than one wall has borders with the street, then it is necessary to add several radiator sections;

- If the floor height is more than 3 meters, then add 1-2 sections;

- The value increases upward if the number is fractional;

- In a room with two windows, it is necessary to install 2 radiators with an equal number of sections, which was obtained as a result of the calculation.

Battery installation

Installation of heating devices is carried out by specialists. You can also handle the installation yourself. But it is recommended to hire an assistant for the job. It is difficult for one person to hold and secure the weighty structure.

Do It Yourself Battery Preparation for Polypropylene Connection

Preparatory stage

First you need to prepare the surface on which to attach the radiator. It should be clean and even. It is impregnated with liquid glass and covered with a heat-reflecting screen to increase system performance.

Before starting installation, it is important to make sure that all components are available, and that the battery itself is suitable for the type of connection to the circuit diagram.

Installation work

The radiator installation process consists of the following steps.

- Fastening brackets to the wall using dowels. You need at least 4 of them. The places where the hanging elements are fixed are sealed with concrete mortar. Further work is carried out after its complete polymerization.

- Air vent installation. The connection is made through an adapter to the upper manifold. Free openings of the collector are closed with plugs.

- Hanging the radiator on brackets.

- Installation of ball valves at the inlet and outlet of the battery. This will help to maintain and change the heating device without shutting down the entire system. At this stage, control valves are also installed.

- Connecting the inlet pipe and return pipe to the radiator.

- Checking the tightness of connections.

At the final stage of installation, the batteries are filled with hot water under low pressure. This will help avoid water hammer and damage to individual elements of the system.

How to properly wash cast iron batteries

Clogged radiator channels lead to reduced heat transfer. To prevent this, it is recommended to carry out maintenance in a timely manner. If a low temperature of the battery is detected in relation to other heating devices or the riser, flushing is performed.

You can clean the inner surface of the channels from rust and other deposits by dismantling the radiator. It is taken out to the bathroom, which is recommended to be pre-covered with rags. This will prevent damage to the enamel during manipulation of the heavy structure.

A shower hose is inserted into the inlet. The watering can is first removed. Under pressure, all the dirt comes out of the sections. There is no need to rush into washing. Solid particles fill any recesses and gaps, so when performing the procedure you need to turn the structure over and shake it slightly.

When the water from the radiator begins to come out clean, close the outlet hole with a twisted rag. A hot solution of soda ash is poured into the inlet hole. Next, the outer side is tapped with a wooden hammer (moderately!). This promotes the detachment of plaque from the internal walls of the canals. After draining the detergent, repeat rinsing with running water until no more solid particles come out.