Dismantling old plumbing and communications during a move or renovation is common. However, such a component of the house as cast iron batteries is not always replaced in such cases. The reason is the established opinion that old cast iron batteries are good and nothing can be better than them. But is this really so? What are their advantages and disadvantages, and is it worth replacing cast iron batteries with modern ones? For those who are puzzled by this issue, the Santekhbomb store has prepared useful material that will help you make the best decision.

Who should change the batteries is the responsibility of the parties, heating repair

As a result, the homeowner independently buys and replaces the battery, ensuring warmth in the house.

ATTENTION! If the apartment owner independently repairs the heating system, he may demand compensation in the amount of the cost of the radiator. Unfortunately, even through the court it is difficult to achieve this compensation; the management company finds arguments in its defense. Therefore, it is better to first consult with an experienced lawyer about when you can present an invoice to the Criminal Code before starting a controversial case

Main features of the process During operation, the batteries wear out and require replacement for better operation of the heating system. But radiators, as common property, are to be replaced in the apartment at whose expense.

The management company may not consider such work necessary, and by law, the ability to independently repair common property is limited.

Why radiators fail prematurely

Sometimes devices last less than the stated period. Why does this happen?

There are many reasons:

- the radiator was initially incorrectly selected, which is why it cannot function correctly in the heating system;

- mistakes were made when connecting the device to the pipes;

- operating conditions of the central heating system are harsh;

- the quality of the coolant is low, which causes plaque to form at the joints of sections and clogs the internal space;

- degradation of the intersection gaskets occurred.

Conclusion: you need to choose suitable radiators taking into account heating features, and install them correctly. Regular maintenance of devices is also important. With this approach, they will last the stated period and even more.

The topic is why they don’t change the batteries in a non-privatized apartment at the expense of housing and communal services

When the topic of the urgent need to replace existing radiators with new ones is being intensively discussed, then someone is interested in selling radiators or in providing paid services that amount to a round sum on the scale of apartment buildings. The management company has the right to make a decision on a total change of heating devices at a general meeting of premises owners. Before bringing such a question to the attention of the owners, it is necessary to carry out a series of calculations with an economic justification in favor of one or another option.

Replacing batteries is an issue that cannot be resolved without the intervention of management officials. Even if apartment radiators can be disconnected from the riser and considered the property of the apartment owner, these devices are still involved in the overall heat supply system. Read about the procedure for notifying about power outages in an apartment for non-payment here.

Service life and repair of heating batteries in an apartment, causes of failure

She must monitor the condition of the risers of the apartment building, heating pipes, and carry out repair work if necessary. Battery replacement is free of charge. If there are shut-off valves in front of the apartment, the owner of the property usually pays for the replacement of radiators. If the management company repairs the risers unconditionally, then the management company often refuses to change the equipment in the apartment for free.

ATTENTION! In this case, you should write an application for a replacement officially and register it. It is recommended that you consult with a lawyer experienced in the field of utility law on this issue.

If the management company ignores consumers and does not deal with its direct business, a written appeal will become the basis for going to court.

APPENDIX A

(required)

TERMS AND DEFINITIONS

Nominal heat flux

, kW, is the heat flow determined under standardized conditions: temperature difference 70 °C, coolant flow rate 0.1 kg/s when it moves in the device according to the “top-down” pattern, atmospheric pressure 1013.3 hPa.

Representative size

- standard size, characterized by a weighted average nominal heat flow, determined taking into account the frequency of use of various standard sizes in mass construction.

Section

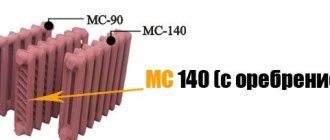

- a radiator element having one column along its front in one casting.

Block

- a radiator element having several columns along its front in one casting.

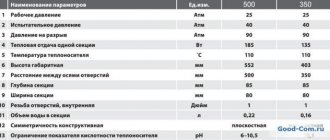

Specifications

There are tables in which manufacturers indicate the technical characteristics of all their products. As for aluminum radiators, the first thing you should pay attention to is what operating pressure the selected model can withstand. As a rule, the indicator can range from 6 to 25 atmospheres

The next parameter is the height of aluminum heating radiators and the volume of each section, on which the level of their heat transfer depends. By calculating how much power the battery needs and knowing what it is for each individual section, you can determine exactly how many cells will be needed.

The third important indicator is the temperature of the carrier.

On average it is +110 degrees. When choosing such a device for operation in a centralized heating system, you should inquire in advance about its parameters. The managing farm is required to provide all the necessary indicators. By checking them with the product data sheet, you can understand how compatible they are.

According to the method of connection to the heating network, aluminum batteries are divided into side and bottom connection types. Again, if you expect to replace old radiators with new ones, then you should purchase models with the same connection method as the one that is being dismantled.

What aluminum radiators are painted with and in what way often depends on their “longevity”.

You should definitely check this with the seller. If the first paint is applied by anaphoresis with pre-treatment of the product with an oxide film, then the device will last a long time. The second layer must be applied by electrostatic spraying, which gives the product a beautiful presentation and protects it from mechanical damage.

In the technical documents supplied with aluminum radiators, the weight is indicated for each section separately. When deciding how many of them are needed for a certain area of the room, you can immediately calculate how much the solid structure will weigh and what components are needed for it.

How to choose the right heating radiator for your home

Before choosing a heating radiator, you should pay attention to the thermal conductivity of the material from which it is made. The thermal conductivity coefficient shows the intensity of heat transfer through the material. The higher the indicator, the smaller the heating devices can be, and the less space under the window they will take up.

The higher the indicator, the smaller the heating devices can be, and the less space under the window they will take up.

Another point that should not be forgotten when describing heating radiators is the smooth start of the system with a gradual increase in pressure. Failure to comply with this requirement leads to water hammer, which can cause the radiator to fail.

The principle of heating a room with a radiator is convection and radiation. Warm air rises where it mixes with cold air. Traditionally, radiators are located under the window - the main source of cold air in winter. It is worth considering that the battery also heats the outer wall, so some of the heat is lost. Heat loss can be reduced by using a heat-insulating layer with aluminum foil on top. Foil reflects thermal radiation, and thermal insulation does not let heat out.

Currently, there are models on the market equipped with a room temperature controller. In order for air to circulate normally, the distance between the battery and the surface of the wall or thermal insulation must be 3-4 cm. A window sill located above the radiator creates an obstacle to the upward movement of warm air. Therefore, it is necessary to leave a gap of at least 8 cm, and the radiator must be raised from the floor by at least 10 cm. Decorative screens reduce the heat emitted by the radiator. If you still decide to install them, you should raise the screen to a distance of 10 cm from the floor and make holes in the window sill for more active air circulation.

In country houses, the pressure in heating devices is lower than in city apartments. In a country house, the pressure should be no more than 3 atm, so most of the radiators presented can be installed in them.

When talking about which heating radiator to choose, in addition to the operating pressure, you should also take into account the factor of gas formation in radiators.

At whose expense is it possible to replace the heating battery in the apartment through the housing office?

Whose property are the heating radiators within the apartment, who is responsible for their operation - the homeowners or the housing and communal services? Content

- 1 Legislative solution to the issue of property

- 2 Replacing a radiator in a council house

- 3 Who carries out the replacement?

- 4 Main features of the process

- 5 How to get permission?

- 6 The management company refuses to change radiators - what should residents do?

- 7 Basic recommendations

- 8 Useful video

Legislative solution to the issue of property Are batteries a common property of the house or is it private property for which the owner is responsible? The government approved Resolution No. 491 of 08/13/06, which provides a list of property common to residents of an apartment building.

The procedure for calculating the number of sections

There are different methods for performing technical calculations of radiators. Accurate algorithms allow calculations to be made taking into account many factors, including the size and location of the room in the building. You can also use a simplified formula that will allow you to find out the desired value with sufficient accuracy. So, you can calculate the number of sections by multiplying the area of the room by 100 and dividing the resulting result by the power of the cast iron radiator section in watts.

In this case, experts recommend:

- in the case where the result is a fractional number, round it up. A supply of heat is better than a lack of it;

- when the room has not one, but several windows, install two batteries, dividing the required number of sections between them. As a result, not only the service life of radiators increases, but also their maintainability. The batteries will be a good barrier to cold air coming from the windows;

- If the ceiling height in the room is more than 3 meters and there are two external walls, in order to compensate for heat loss, it is advisable to add a couple of sections and thereby increase the power of the cast iron heating radiator.

Weight of cast iron battery section

A cast iron battery is considered one of the most profitable devices for heating a home, because in addition to excellent heat transfer, it is highly resistant to corrosion, has a long service life (50 years and older) and is undemanding in terms of the quality of the heat carrier. These factors encourage many people to include it in their individual heating system. At the same time, when creating a heating system, they are forced to take into account its features. One of them is the weight of the cast iron battery.

This indicator is very important because it allows:

- choose the optimal mount;

- choose the right type of battery depending on the design features of the house.

Classic batteries

one section of the most used option weighs 7.12 kg. The total weight of one battery sector is 8.62 kg.

To heat a room of 20 m², you need to install a battery with 12 sections. This means that the weight of an empty heating device will be 85.4 kg, and a radiator with water will be 103.4 kg.

Such a battery must be installed on a mount fixed in the wall. That is, it turns out that the wall must withstand an additional load of almost 104 kilograms. If the wall is built of brick or concrete, then such a cast iron radiator can be safely hung on the wall.

However, if the owner decided to save on building a house and built it from foam concrete, aerated concrete or SIP panels filled with foam, then the classic hanging of a 100-kilogram structure on such walls is a very bad idea.

The classic installation method involves fixing horizontal brackets with hooks at the end to the wall. The latter are equipped with a battery. Walls made of porous materials or SIP panels simply will not withstand high pressure, and the radiator will fall to the floor.

Of course, there is a way out in such a situation. There are even three of them:

- You need to use a special mount, which should be fixed at many points. This is an extra waste of your time and effort. This option is definitely not to the liking of every owner.

- It is necessary to install cast iron batteries of modern modifications. They are lighter and more efficient in terms of heat exchange.

- Choose models that can be installed on the floor.

Modern options for cast iron radiators

consist of lighter sectors. The total mass of the sector is 4.6 kg.

To heat the above room you need to take a radiator with 14 sections. It will weigh 64.4 kg. This figure includes the mass of cast iron and water.

Such a radiator will still be heavy for walls made of porous material, but if you split it into two parts and place them on different walls, then you can forget about the need for additional fastenings.

Domestic manufacturers offer radiators with a lighter sector. Its characteristics are:

- Weight - 3.3 kg

- Volume - 0.6 l.

- Total weight with water - 3.9 kg.

However, they have worse heat transfer. As a result, to heat a room of 20 m² you need to take 22 sections. This means that the mass of the radiator will be 85.8 kg. This weight is not entirely suitable for modern houses made of foam blocks. Radiators with legs can save the situation. The legs have only the first and last sections.

Algorithm for calculating radiator weight

you need to do the following:

- Find out the weight of the section itself.

- Add the weight of water that can fit in the section.

- Analyze the heat transfer and, based on it, determine the required number of sections.

- Multiply the number of sections by the total mass of one sector.

Types of aluminum radiators

The combination of aluminum and silicon is called silumin, and it is from this that cast sectional radiator models are made. Although the alloy contains only 12% silicon, it provides the necessary strength to the future structure, which is produced by high-pressure casting. The result is separate sections of the required height and width. These elements are then assembled into a single structure using nipples.

The service life of aluminum radiators made by casting is significantly longer than their counterparts produced by extrusion.

In this case, the metal is softened and simply pressed under pressure through a certain profile. The resulting elements are fastened by soldering into a single monolithic device. It is impossible to add the required number of sections to such a radiator, or, conversely, remove them. They are not able to withstand high pressure, therefore they are suitable exclusively for autonomous heating systems.

The anodized type of batteries is the most expensive and the most durable and high quality.

Made from purified aluminum, they are incredibly durable and can withstand pressures of up to 50 atmospheres. In addition, special treatment in the form of anodic oxidation protects the finished structure from corrosion.

Whatever method they are manufactured, the characteristics of aluminum heating radiators indicated in the product data sheet will tell you where they can be used and their service life.

Service life of bimetallic batteries

Bimetallic models are less durable than their cast iron counterparts: their service life averages from 25 to 30 years, and manufacturers usually provide warranties for 10 years. This service life is achieved due to the following factors:

- good strength indicators, which are obtained due to the design features, which include the presence of a steel core;

- ability to withstand at least 20 atmospheres;

- high level of resistance to hydraulic shocks.

Bimetallic radiators are characterized by good heat dissipation, aesthetic appeal and low weight. The availability of products with different axial distances provides wide installation options. They are resistant to corrosion and are not sensitive to the composition of the coolant.

Bimetallic heating devices are able to maintain their functions for a long time both in autonomous networks and in centralized systems of high-rise buildings. However, it is more rational to use products when laying communications in multi-apartment buildings, where they show maximum efficiency throughout their entire service life.

Whose property is the battery in the apartment and who should repair it?

If you want to replace outdated equipment with new equipment, you should contact the management company or other authority that is responsible for the heating systems of the apartments.

- If the replacement is carried out with similar structures, it is enough to simply provide information about the upcoming installation work.

- Will radiators of a different model be installed, which could lead to an increase in the heating area? Representatives of the management company will perform an examination to determine the possibility of changes in the heat balance of the building. The technician will inspect the area of the house, new batteries, and study their technical data.

- The examination is also carried out in cases where major renovation of an apartment involves changing the configuration of the pipeline.

IMPORTANT! The work must be carried out taking into account all the requirements of municipal legislation. In this case, they will not be considered a violation

In this situation, it most often turns out that scheduled inspections of the common household facilities were not carried out, the system was not tested, as a result of which a leaky pipe and radiator were inspected. How to calculate ODN for electricity according to the established standard? Read about it here. to contents Replacement procedure If the replacement of radiators does not take place as part of a campaign for planned or major repairs of apartment buildings, but is an initiative of the residents, then both the purchase of materials and the work will be carried out at the expense of the apartment users themselves

It is important to realize that unauthorized actions with the heating system are unacceptable.

The construction market offers users many types of radiators for heating systems.

They differ from each other in material of manufacture, appearance and characteristics

.

Such a variety of products allows ordinary people to choose the appropriate option for their home.

Minuses

- Heavy weight. Cast iron is a very heavy metal; the weight of one section of a cast iron radiator can reach several kilograms. On average, this is 2-3 times more than the weight of a bimetallic battery section, and 4-6 times more than the weight of an aluminum radiator. .

- Price. One section of a cast iron radiator is noticeably more expensive than a section of a bimetallic or aluminum battery that is similar in size and heat transfer.

- Impossibility of installation in a system with automatic adjustment. The design features of the battery and the properties of the metal will prevent the sensors from receiving up-to-date information about the temperature of the coolant and surface. When choosing which heating radiators are best to install in an apartment, be sure to take this nuance into account.

- Low efficiency. Due to thermal inertia, heating a square meter of area will require much more energy and coolant than in the case of other types of batteries. This may be completely unimportant if your heating is centralized and you pay based on the square footage of the house. But if you have a gas boiler, you will have to spend more of your own money, and it will be spent mainly on heating the battery itself, and not on increasing the temperature in the room.

- Unaesthetic appearance. Note that this only applies to old batteries, but if you have just such ones, they are unlikely to fit harmoniously into a modern environment. In this regard, cast iron batteries of the new type are no different from their bimetallic or aluminum “brothers” - they look modern and stylish and will fit perfectly into the interior of any apartment.

Radiator durability

- Types of radiators

- Durability of structures

- Additional attributes

Modern stores offer a wide range of heating systems. The cast iron radiators most commonly used by residents may reach the end of their service life. The question arises about replacing products. A wide variety of aluminum, cast iron, bimetallic structures allows you to choose the right model.

Scheme of a two-pipe heating system using bimetallic radiators.

Batteries made from different materials and different brands can make choosing difficult. Therefore, it is necessary to think in advance which radiator will be used indoors and how long its service life is. In addition, modern heating devices have an attractive design. Which will undoubtedly make a certain addition to the existing style.

Information about cast iron batteries

Radiators made of cast iron are the most popular and most familiar option to every resident of the post-Soviet space. These batteries were installed in almost all standard apartments. Old cast iron batteries can hardly be called beautiful and stylish. The new samples look much better, although they are inferior in their aesthetic qualities to devices made of aluminum and steel.

Cast iron radiators

Cast iron is a fairly heavy material. Batteries made from it also weigh a lot, which causes certain difficulties and inconveniences when installing them. Among the undoubted advantages of cast iron radiators, one should highlight their reliability and durability. High-quality products can last 35-40 years without any problems, without even requiring minor repairs, which is much higher than for batteries made from other materials.

Cast iron heats up relatively slowly and cools just as slowly. It is characterized by low thermal conductivity, but has a high heat capacity. Heating is carried out by convection.

Such batteries work normally even with low-quality and dirty coolant. The material is resistant to corrosion damage. The radiators themselves can have a one-, two-, or three-channel structure.

Additional advantages of such heating units include a relatively affordable cost. Only imported designer models are expensive. Here, everyone must decide for themselves what is more important to them: saving a certain amount of money or purchasing a beautiful unit that will become a worthy addition to the interior.

Thus, batteries of any type considered can be used to heat residential premises. But the purchase of bimetallic batteries in most cases turns out to be unjustified. In terms of their properties, such radiators are practically no different from their aluminum counterparts, but are much more expensive. So it’s better to leave them to various public and industrial buildings.

What are the best heating radiators?

Apartment owners are not recommended to choose aluminum appliances, because... Pressure surges have a bad effect on this material. The optimal and proven option for heating city apartments are cast iron appliances. For the rest, focus on personal preferences and available budget. Good luck with your choice!

Replacing heating batteries in an apartment with your own hands or through the housing office

An example of a complaint to the management company about replacing heating radiators. back to contents If the batteries leak after the heating is turned off If the heating radiators leak after the heat supply to the MKD is stopped, the malfunction should still be eliminated, but not in such a strict mode. A battery leak indicates that water has not been drained from the system. The procedure is as follows:

- Residents report the problem to the management company.

- Management company employees fix the leak, if possible, or change the battery at the expense of funds donated by the owners.

Only a specialist servicing an apartment building can quickly shut off the riser or cut off the heating from the entire entrance.

You can learn how to get the heating riser replaced by the housing and communal services from the video: back to content Who is responsible in an emergency? In the event of an emergency, all responsibility lies with the technical service of the management company, homeowners association or housing office.

pros

- Reliability and durability. Cast iron is unpretentious to the coolant; it will not be damaged even by large fractions or aggressive chemical impurities, often contained in water from Russian thermal power plants. The maximum permissible coolant temperature reaches 130-150 degrees. With regular cleaning, the service life of such a battery can be decades.

- High heat capacity and thermal inertia. Such batteries give off heat for a long time, which after switching off can remain in them up to one third of the original volume. However, this same feature of the material is also its disadvantage - more about this in the corresponding section.

Strengths and weaknesses of aluminum radiators

Among the nice features that these heaters have are the following:

In addition to such pleasant qualities, radiators of this type have a number of disadvantages, but they relate exclusively to a centralized heating system. If you use them for autonomous heating, then these disadvantages seem to be absent:

If you take into account all the pros and cons of aluminum radiators, then it is quite possible to choose the optimal model for each specific room.

Although manufacturers give aluminum radiators a guarantee of 10-15 years, this does not mean that they will last that long. If you install them in an autonomous heating system, the service life can be extended to 30-40 years if the owners monitor the quality of the coolant. If they are used for central heating, where the composition of the carrier is questionable, they can fail within 7-8 years, and it will be difficult to prove anything to the manufacturer.

Average service life of radiators of different types

| Battery type | Resistance to water hammer | Corrosion resistance | Duration of use, years. | ||||

| Steel | weak | low | 15-20 | ||||

| Aluminum | average | high (if additional protection is available) | 20-25 | ||||

| Bimetallic | high | high | 25-30 | ||||

| Cast iron | average | high | 25-35 | ||||

In addition to the quality of the raw materials used and compliance with the technological process regulations, other factors also influence the lifespan of radiators. Among them are:

- correct installation;

- regularity of maintenance;

- working pressure value;

- maximum permissible temperature in heating networks;

- composition and quality of coolant transported through pipes.

The operating pressure depends on the heating characteristics. In autonomous networks, which are used to maintain a comfortable temperature in the premises of private houses, it varies from 3 to 5 atm. The pressure in central heating systems of multi-storey buildings is about 8-16 atm. To ensure long-term use of radiators, their operating pressure must exceed the same parameter in the network by at least 2 atm. The composition of the coolant also differs. In autonomous networks, antifreeze solutions can be used, and water for central communications is usually subjected to chemical treatment.

In addition, the duration of use of batteries installed in apartments with central heating is negatively affected by water hammer in the pipeline. They occur due to pressure changes and often occur when utilities are started at the beginning of the heating season. Since different materials are used for the production of radiators, their level of resistance to external influences, reliability and durability differ significantly. Some manufacturers achieve improved technical parameters and increased service life by introducing new technologies and methods of metal processing.