Many people believe that Chinese products cannot be reliable and of high quality, but this statement does not apply to the equipment in question. If you carefully study the reviews of Chinese bimetallic heating radiators, you will find only positive information related to the operation of the equipment. Chinese bimetallic radiators have many advantages, but the most important thing is the ability to combine high quality and low cost.

During the production of this equipment, all the requirements and features of the systems in which the devices will be operated were taken into account. This allows you to safely install Chinese bimetallic radiators, reviews of which, as already noted, can be found on the Internet; they can be used in autonomous and central heating systems, regardless of their quality, as well as the quality of the coolant used.

What to consider when choosing bimetallic radiators

selection of bimetallic radiators

So, first of all, it is important to decide on the number of sections that the bimetallic radiator will consist of. You can make calculations using the formula: multiply the area of the room by one hundred and divide by the heat transfer that one section has, as a result, we get the exact number of required sections for the radiator

.

When choosing, it is important to clarify the following points:

- what is the thickness of the internal walls of the radiator housing;

- what is the maximum pressure the radiator option under consideration can withstand;

- what is the price of a bimetallic radiator?

If all the requirements and nuances when choosing and purchasing bimetallic heating radiators made in China are taken into account exactly, you are guaranteed to be able to purchase reliable and high-quality equipment at an affordable price, which will serve properly and efficiently for many years.

The main types of Conner brand radiators: cast iron batteries

“Conner” is a radiator that is sold in cast iron products. They are intended for systems with natural or forced water circulation. This heating equipment breaks past stereotypes, as it has high quality workmanship.

These devices meet aesthetic and technical requirements, so they could become a highly efficient addition to heating systems. It is impossible not to note the affordable cost, as well as durability, corrosion resistance and immunity to any type of coolant. This also applies to water quality. “Conner” is a cast iron radiator that is ready to last up to 50 years. It can be used in high-rise buildings, or more precisely in heating systems that operate under high pressure. Due to the fact that the devices have low hydraulic resistance, they can be used in systems with natural circulation. Such products become even more versatile due to the different diameters of the inlet pipes. The components are supplied with the device, which is certified and fully complies with state standards.

Reasons for choosing Conner equipment

You need to buy products from one series, since another may differ slightly in color.

The main reason for purchasing Conner products is that the radiators have an interaxial distance of 200 mm. Buyers note other advantages:

- Italian cast iron has a heat transfer characteristic similar to classic Soviet batteries;

- reducing heating costs due to a smaller volume of coolant;

- availability of all auxiliary parts from the manufacturer - from shut-off valves to repair kits;

- availability of complete information about the thermal power and parameters of each section in the manufacturer’s documentation;

- ease of installation - retro-style products are placed on legs, the rest are fixed to the wall using fasteners.

Knowing the parameters of one section, you can independently calculate the thermal power of the entire system.

A few more advantages of Conner heating equipment:

- inexpensive cost with reliability, stylish design and resistance to damage;

- long warranty period;

- ease of self-service;

- compatibility with powerful double-circuit boilers.

Among the disadvantages:

- differences in the color of sections when purchasing products from different batches;

- the difficulty of self-repairing bimetal batteries;

- low heat transfer of cast iron appliances.

The main problems when using radiators are related to incorrect installation technology.

Characteristics of aluminum radiators of the Conner brand

If Conner cast iron radiators are not suitable for you, you can consider aluminum ones, which, according to users, are durable, lightweight and have an incomparable design. The devices have a high elegance of execution, and work quite efficiently, with increased heat transfer. Consumers also note the high reliability of these batteries.

Conner cast iron radiators may seem quite expensive to some consumers. But aluminum models have an acceptable cost, and they can be made using casting technology or the extrusion method. The depth of these devices can be 70 and 100 mm. The circular cross-section of the collector, the use of composite glue, and the installation of connections by laser welding allow the radiators to withstand high pressure. If we are talking about cast aluminum radiators, then their depth can vary from 80 to 100 mm. The average value is 85 mm. The center distance is 500 mm.

Who produces Conner heating systems

Cast iron and aluminum radiator models Conner (Italy)

The country where the central office of Conner is located is Italy. The design, calculation and construction departments are located here. The equipment is assembled in China at the brand’s own factory.

During manufacturing, individual parts and radiators in the assembly are tested for quality, compliance with the European standard ISO 9001, 14001 and 185, as well as Russian GOST 3111-2005. The manufacturer provides a factory warranty for operation for 15 years.

Konner provides battery service in official centers in the Russian Federation.

Reviews of aluminum models

“Conner” is a radiator that is also offered by the manufacturer in the form of aluminum devices. Consumers especially emphasize that when purchasing these devices, it is necessary to pay special attention to ensure that the product is not defective. This is because some buyers face such problems. It would be good if there was an opportunity to exchange the device. After only 3 years, these units leak in some apartments, but you can still use service support under warranty.

If Konner radiators will be installed within the same room, then you should consider whether their shades and appearance match. In some cases, the models differ from each other, despite the fact that the boxes are exactly the same.

Results

In cases with cast iron during normal casting, the reliability of the operation of heating radiators is determined by the quality of the gaskets and nipples. Cast iron from the Conner company has defects, its quantity is 1% of the total mass. The quality of the gaskets and nipples is fine. When installing, you must follow the manufacturer's recommendations and check that the connections have not become loose during transportation. In general, there was an opinion that in recent years the quality of Konner’s products has become worse: there are more defects in painting and there are even burrs on aluminum radiators, which should not happen at all.

Reviews of Konner brand bimetallic radiators

Konner bimetallic radiators are the most innovative development in this area. They are manufactured taking into account operating conditions in Russia. The design is very durable, which is ensured by the presence of an internal collector. According to buyers, it is made of high-alloy steel, which makes the components resistant to corrosion. This feature eliminates contact between the coolant and water, which is why bimetallic devices are able to work together with any coolant. As buyers emphasize, it does not matter at all what the acid-base balance is.

During the manufacturing process, these devices are tested, and at the final stage they are coated with epoxy enamel. Users really like this, since this approach allows it to maintain its original properties and the surface does not compromise its integrity throughout its entire service life, while it remains resistant to ultraviolet radiation.

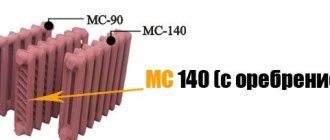

Features of sectional heating devices

Sectional batteries from Konner are individual elements in a molded, ribbed or other design. The elements are equipped with one channel vertically, two channels horizontally, and are tightened with steel nipples. They are made of bimetal, cast iron and aluminum. To ensure coolant circulation, they have special seals.

The standard set has 10 sections, but the manufacturer mainly produces modifications for 4, 6, 8 and 12 battery sections. Conner sectional structures have several advantages:

- the possibility of increasing thermal power by adding one or several elements;

- replacing only the damaged section in case of leakage or damage;

- good maintainability;

- dividing one radiator into heating devices for several rooms;

- high heat transfer, providing savings on utilities.

To install the products yourself, you will need brackets, locknuts, a special seal and various connectors.

Negative reviews of Konner brand cast iron radiators

Heating radiators "Conner", as mentioned above, can be bimetallic, aluminum or cast iron. The latter will be discussed in this section. Some consumers argue that this purchase cannot be called profitable, since the quality makes itself felt during operation. Externally, such batteries look aesthetically attractive, look stylish, the heat dissipation, according to the supplier, is excellent and reaches 150 W from each section.

Consumers claim that the installation is successful in any case, without difficulty and quite quickly. But after starting the heating, the most unpleasant things begin. The rooms are cold, the stated figures turn out to be just a publicity stunt. The temperature does not rise above 23 °C. Some, choosing cast iron heating radiators, the price of which will be mentioned below, then change them to traditional aluminum ones. From this we can conclude that it is necessary to become more familiar with the qualitative characteristics of these devices before purchasing, as well as correctly calculate the heat capacity.

Installation and Operation Requirements

Once every 5 years, it is necessary to clean the inside of radiators with special solutions.

The manufacturer indicates that only specialists should carry out installation. Installation is carried out according to the following rules:

- Tightening nipple nuts that have become loose after transportation.

- Maintain distances from the window sill or niche in the wall of 10 cm, from the floor - 10-12 cm, from the wall or panel at the back - 3-5 cm.

- Installation of shut-off ball valves at the outlet and inlet.

- Installation of a manual or automatic air vent and fittings for adjustment.

When operating radiators, it is necessary to carry out preventive cleaning once every 4-5 years. After removing slag deposits and dirt, coolant circulation improves and heat transfer increases. Before work, the supply is shut off and the batteries are removed. The system must be flushed with water or special products.

From the range of heating radiators from the Conner company, you can choose products for your home and apartment. The presence of separate sections allows you to plan communications and take into account the required amount of heat. The brand produces several modifications of batteries and provides a guarantee on them.

Price

If you decide to purchase Konner cast iron radiators, then you should pay attention to the cost of one section, which is limited to 430 rubles. In this case, we are talking about the Modern 500 device, the heat capacity of which is 150 W per section. If you prefer 4 sections, the power will be 600 W, and the cost will increase to 1,720 rubles. Cast iron heating radiators, the price of which reaches 6,450 rubles, can have a heat capacity of 2,250 W. In this case, the number of sections will be 15. It is worth noting that this equipment is manufactured by injection molding, which is most often preferred by modern consumers.

If you do not need such heat capacity, then you can choose a device whose one section produces 120 W. Thus, for the “Modern 300” model you will have to pay 420 rubles, whereas if the heat capacity increases to 1800 W, and the number of sections increases to 15, the cost is already 6300 rubles.