Heating a house or apartment is not such a simple engineering system as it might seem at first glance. When drawing up a project, it is necessary to carry out many calculations , in particular, the required pipeline diameter.

Choosing the right diameter is the key to a reliable, comfortable and efficient room heating system.

For example, heating without a pump, where the coolant circulates by gravity, may not work at all if the pipes are too narrow, and a circuit with forced circulation if the diameter is underestimated will make noise or not warm the rooms to the required temperature. Therefore, you should use calculation rules that will allow you to reduce heat loss to a minimum.

The influence of pipe diameter on efficiency for a heating system in a private house

It is a mistake to rely on the “bigger is better” principle when choosing a pipeline cross-section. Too large a pipe cross-section leads to a decrease in pressure in it, and hence the speed of the coolant and heat flow.

Moreover, if the diameter is too large, the pump simply may not have enough performance to move such a large volume of coolant.

Important! A larger volume of coolant in the system implies a high total heat capacity, which means more time and energy will be spent on heating it, which also affects the efficiency in a negative way.

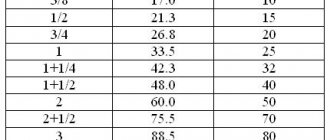

Selection of pipe section: table

The optimal pipe cross-section should be the smallest possible for a given configuration (see table) for the following reasons:

- a small volume of coolant heats up faster;

- smaller clearance creates greater resistance to the movement of the coolant , it slows down, which leads to a decrease in noise;

- a small diameter pipeline will fit better into the interior and will cause fewer difficulties during installation;

- Its cost depends on the size of the pipe , so thin pipes are more affordable.

However, you should not overdo it: in addition to the fact that the small diameter creates an increased load on the connecting and shut-off valves , it is also not able to transfer enough thermal energy.

To determine the optimal pipe cross-section, use the following table.

Photo 1. Table showing the values for a standard two-pipe heating system.

Standard solutions

- usual pipeline diameter is 10 and 15 mm;

- the riser will require a little more - 25.

You need to know: the purchased products are not created by jewelers, and “10 mm” pipes will easily turn out to be a couple of millimeters larger. Be sure to be guided by such a parameter as the thickness of the walls: you need to choose the diameter exactly inside (for this you need to subtract the wall thickness from the total) so that all the fittings fit!

The higher the level of complexity of future plumbing work in a household, the larger the diameter of all pipes, both long and short, should be. When a “complex” pipeline with many turning points, joints and expected pressure surges is expected, it is worth insuring yourself by increasing the diameter. You should also definitely take into account the maximum values of both pressure and temperature in your water supply so that it does not burst from the first water hammer.

The savings here are unjustified. Additional advice: in order for the plumbing system to perform flawlessly and be reliable in operation, you need to select high-quality products. This applies to pipes and small elements (fittings and couplings). It would be a shame to “ruin” a proven system with cheap fittings.

What parameters are needed?

In the description of the characteristics of a specific pipe, the following parameters may appear:

- The internal diameter is the main factor affecting system performance and is taken into account in the calculation.

- External - measured along the outer circumference of the pipeline, affects which holes will need to be drilled in walls and ceilings.

- Nominal, or conditional - approximately coincides with the internal cross-section of the pipe, is selected from a fixed series of numbers according to GOST , designated as DN 100. For common values, it is sometimes also designated as thread diameter in inches, for example: 1/2″, 3/4″.

Calculation procedure to choose the size

Let's consider an example of a typical calculation of the cross-section of a pipeline for heating a room of 40 m 2 .

- Let's calculate the optimal amount of energy to heat the room. For the middle zone, an insulated house and ceilings no higher than 3 meters, 1 kW is required per 10 m 2 of area . Or for 40 m 2 - 4 kW.

- We take a 20% reserve (in case of unexpected heat loss in the form of open windows and other factors): 4 * 1.2 = 4.8 kW, or 4800 W. There should be a heating radiator under each window in the room. there are 3 windows in our room , then these are 3 radiators, each

1.6 kW.

Attention! The thermal power is indicated in the data sheet for the heating battery. You can use a more powerful radiator, but not vice versa, otherwise the room will not warm up effectively enough.

- Now we turn to the table and find in the cells the closest power value to the calculated one , rounding up.

According to the table, this is 5518 W and you need to use a pipeline with a cross-section equal to 12 mm , and the speed of the coolant will be 0.6 m/s.

Despite the presence of other close values in the cells, the values from the zone limited by blue color are used, which contains acceptable values of the fluid velocity in the pipeline.

A suitable coolant flow rate through the pipes is from 0.3 to 0.7 m/s . A smaller one will lead to slow heating of the room and uneven heating of the radiators, and with a larger one, the liquid simply will not have time to warm up to the set temperature in the boiler heat exchanger and create noticeable noise.

Features of choice in a private house

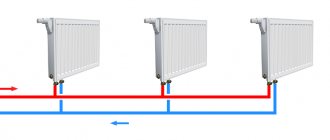

If there is a central heating main, the selection of diameter is carried out similarly to apartment heating systems . However, if you are designing autonomous heating in a private house, then you need to take into account the type of coolant circulation: natural or forced.

Forced circulation of liquid is not so picky about the choice of pipeline cross-section, but the operation of a gravity-flow system with natural circulation very much depends on the diameter of the pipes in various sections.

Generalized data

The construction of water supply systems in both private and multi-storey houses is carried out using metal options, which have different pipe diameter designations. They come in steel and copper, depending on the person’s wishes. The radius is also selected separately, the same applies to plastic or combined options.

It is worth understanding that the diameters of water pipes and other parameters depend on the source material. It turns out that the pipe capacity is calculated based on the following parameters:

- Internal plumbing radius;

- Transitional size;

- Nominal size;

- Outer radius;

- Thickness.

Previously, it was easy to calculate the diameter of a pipe - 15 years ago, identical cast iron pipes were common.

Pipeline as the key to efficient operation

The cross-section of the pipes from which the heating system is installed is of great importance in the efficiency of its operation.

An incorrect calculation of diameters may not manifest itself for the time being.

For example, until you change the coolant temperature or try to start the system in a cold house.

If the heating was already working “on the edge,” then a change in temperature conditions can lower the pressure to such levels that the system simply will not work .

GOSTs and SNiPs

Regarding the calculation of the diameter of pipelines, it is useful to use:

- SP 40-102-2000 - describes the general requirements for all types of installed pipelines made of polymer material;

- SNiP 41-01-2003 - contains building codes and regulations for heating, heat supply, and ventilation systems;

- SNiP 2.04.02-84 and its updated version SP 31.13330.2012 - addresses issues of standardization and design of water supply systems;

- GOST 34059-2017 - contains rules for performing work during the installation of heating, cold water and hot water, testing communications;

- GOST R 52134-2003 – standards for pressure pipes made of thermoplastics, the main regulatory document;

- SNiP 2.04.01-85 - rules for organizing internal water supply;

- SP 40-101-96 – rules for the design and installation of polypropylene pipes.

The influence of diameter on heating performance

The heating system installation instructions are unlikely to address the issues of pipeline calculation (also find out how to calculate the diameter of a heating pipe).

Meanwhile, when moving through a pipe, the coolant encounters several types of resistance and this must be taken into account when selecting the standard size:

- friction against the walls . Due to this, part of the speed is lost;

- loss of speed when turning . It is impossible to route around the apartment without turning (in addition, there are turns at an angle of 90ᵒ);

- change in diameters . If you try to use different standard sizes when wiring around the apartment, then resistance to flow will also be observed at the junctions of different standard sizes.

Note! Narrowing the diameter of the heating pipe is undesirable. When wiring around the house you need to use the same standard size. An exception is allowed in the case of a large length of the circulation circuit; in this case, it is possible to increase the speed of the coolant by reducing D.

As for the pipeline itself, its main characteristic that affects the movement of the coolant can be called the internal diameter (ID). The smaller it is, the greater the pressure and vice versa - with increasing pressure, the pressure in the system drops. This must be taken into account when selecting the diameter of the heating pipe.

A common mistake made by amateur plumbers is associated with this phenomenon. They are confident that if they take a larger size, then more coolant will pass through the radiators and the room will warm up faster.

In fact, the effect will be the opposite - due to the drop in pressure, the batteries will remain cool. In this case, installing a more powerful circulation pump can help out, but the price of such a solution is high; it is much easier to choose the right diameter.

Standard solutions

To supply water from the well to the house, pipes made of HDPE - low-density polyethylene, metal-plastic, polypropylene and copper - are used.

Pipes made of HDPE - low pressure polyethylene

The material is easy to assemble; no tools are required. Only special inexpensive fittings are used, which are tightened by hand, ensuring tight connections.

HDPE pipes will not burst, even if the water in them freezes. Suitable only for cold water, therefore optimal for introducing water into the house.

Pipes made of low pressure polyethylene.

It is possible to make a complete water supply system from HDPE. This solution is suitable in the case of creating only a cold water supply system for cold water supply to premises.

In this case, electric water heaters are used to obtain hot water.

This water supply scheme is used in houses for seasonal residence or in non-residential buildings, such as a bathhouse, summer kitchen, etc. Other types of materials are used inside the house.

Metal-plastic pipes

One of the most popular is metal-plastic. It combines the lightness of plastic pipes and the strength of metal, does not rust, the outer surface does not conduct electricity, and the inner surface does not allow sediment to form. The price of such pipes is less than copper or stainless steel.

The flexibility of this material makes its installation simple; it is possible to ensure the minimum possible number of joints and connections; press fittings and an ordinary adjustable wrench are sufficient for it. Suitable for use in hot water systems

The disadvantages of metal-plastic include the need to periodically tighten threaded connections. Aesthetically, metal-plastic also cannot compete with pipes made of copper or stainless steel. Such pipes are additionally covered with decorative panels.

Polypropylene pipes

Another typical solution could be the use of polypropylene pipes. The durability of this material reaches 50 years. Available reinforced and non-reinforced.

Example of heating system calculation

As a rule, a simplified calculation is performed based on such parameters as the volume of the room, the level of its insulation, the flow rate of the coolant and the temperature difference in the inlet and outlet pipelines.

The diameter of the heating pipe with forced circulation is determined in the following sequence:

- the total amount of heat that needs to be supplied to the room is determined (thermal power, kW), you can also rely on tabular data;

When it comes to installing a heating system, the pipe is often easily selected based on familiar advice or recommendations from store salespeople. Calculating the diameter of a heating pipe is not always done.

By choosing a size at random, there is a risk that the heating system will not work efficiently.

Find out how to choose the right diameter of a water pipe: 4 secrets of a plumber

Everyone inevitably has to understand how a water supply works, what throughput is and how these concepts are interconnected - breakdowns are not uncommon here. It also happens when a person has to quickly understand these matters - when building a house - an option is selected, the diameter of the pipe for the water supply is calculated, and a bunch of similar criteria. So we will pay attention to these kinds of nuances, understand the intricacies and understand what diameter of pipe should be used for water supply and what should not be used.

The influence of diameter on heating performance

The installation instructions for the heating system are unlikely to address the issues of pipeline calculation (also determine how to calculate the diameter of the heating pipe).

At the same time, when moving through a pipe, the coolant encounters several types of resistance and this must be taken into account when selecting the standard size:

- friction against walls . Due to this, part of the speed is lost;

- loss of speed when turning . It is impossible to carry out wiring around the apartment without turns (besides, there are turns at an angle of 90?);

- change in diameters . If you try to use different standard sizes when wiring around the apartment, then resistance to flow movement will also be observed at the junction points of different standard sizes.

Note! Narrowing the diameter of the heating pipe is undesirable. When wiring around the house, it is necessary to use the same standard size. An exception is allowed when the length of the circulation circuit is enormous; under such conditions it is possible to expand the speed of movement of the coolant by reducing D.

As for the pipeline itself, its main feature affecting the movement of coolant can be called the internal diameter (ID). The smaller it is, the greater the pressure and, on the contrary, with increasing pressure, the pressure in the system drops. This must be taken into account when selecting the diameter of the heating pipe.

Mounting sleeves

Installation of the heating system is impossible without the use of mounting sleeves. When laying a pipeline through walls and ceilings, the walls of the products come into contact with an aggressive environment.

Due to physical laws, pipes during operation will undergo periodic contraction and expansion. This will lead to mechanical stress on the surface, guaranteeing faster wear at the contact points. To avoid this, SNIP building codes provide for the supply of pipelines with additional structural parts called sleeves.

The sleeves are designed to:

- prevent the leakage of liquids from adjacent rooms or the street;

- prevent the passage of unnecessary gaseous substances;

- maintain sound insulation;

- ensure the integrity of the structure when dismantling or replacing the pipeline;

- prevent unwanted insects from entering the premises.

The pipeline can pass through any building in two planes: vertical (floors, floors, ceilings) and horizontal (internal and external walls, ceilings).

The sleeve consists of:

- Covers (standard or cut from steel or polymer pipes).

- Packings (filling the cavity between the pipeline and the cover), which can be a soft, non-combustible material. It is possible to use special cement or clay mixtures.

The size of the sleeve assembly is determined by the outer diameter of the pipeline and the thickness of the wall or ceiling: the size of the sleeve and the length of the product should be 10–20 mm larger.

This video will briefly introduce you to the installation of a heating system in an apartment.

General information about heating pipes

All pipes for heating systems can be divided into two types: metal and polymer.

Metal:

- copper;

- metal-plastic;

- bronze;

- metal corrugated;

- steel.

Copper pipes are superior to all others in the following parameters: long service life, smoothness, which increases the speed of coolant movement, and resistance to ultraviolet radiation.

Polymer:

- polyvinyl chloride (PVC);

- polyethylene terephthalate (PET);

- metal-plastic;

- polyurethane;

- propylene;

- polypropylene.

The cross-sectional diameter in which propylene and polypropylene pipes are offered can be in the range of 16-110 mm. The advantages of this material include: relatively low weight, ease of processing and installation work, low price. Long-burning wood stoves for home heating you will find the answer in the link.

Example of heating system calculation

In most cases, a simplified calculation is performed based on such parameters as the number of rooms, the level of its insulation, the difference in temperature flow and coolant velocity in the inlet and outlet pipelines.

The diameter of the heating pipe with forced circulation is determined in the following sequence:

- the total amount of heat that needs to be supplied to the room is determined (thermal power, kW), it is also possible to rely on tabular data;

- Having set the speed of water movement, the optimal D is determined.

Calculation of thermal power

As an example, a standard room with dimensions of 4.8x5.0x3.0m will be used. The heating circuit is with forced circulation; it is necessary to calculate the diameters of the heating pipes for distribution throughout the apartment. The main calculation formula looks like this:

The following notations are used in the formula:

- V – amount of room. In the example, it is equal to 3.8•4.0•3.0 = 45.6m 3 ;

- ?t is the difference between the temperature outside and inside. In the example, 53?C is assumed;

- K is a special coefficient that determines the degree of insulation of the building. In general, its value ranges from 0.6-0.9 (effective thermal insulation is used, the roof and floor are insulated, at least double-glazed windows are installed) to 3-4 (buildings without thermal insulation, for example, change houses). In the example, an intermediate option is used - the apartment has standard thermal insulation (K = 1.0 - 1.9), K = 1.1 is accepted.

The total thermal power should be equal to 45.6•53•1.1/860 = 3.09 kW.

It is possible to use tabular data.

Diameter determination

The diameter of the heating pipes is determined by the formula

Where notations are used:

- ?t – difference in coolant temperatures in the supply and discharge pipelines . Considering that water is supplied at a temperature of about 90-95?C, and it has time to cool down to 65-70?C, the temperature difference can be taken as equal to 20?C;

- v – speed of water movement . It is undesirable for it to exceed 1.5 m/s, and the minimum acceptable threshold is 0.25 m/s. It is recommended to stay at an intermediate speed value of 0.8 - 1.3 m/s.

Note! An incorrect choice of pipe diameter for heating can lead to a drop in speed below the minimum threshold, which in turn will lead to the formation of air locks. As a result, the work efficiency will become zero.

The value of Din in the example will be v354•(0.86•3.09/20)/1.3 = 36.18 mm. If you pay attention to the standard sizes, for example, of a PP pipeline, you will see that there is no Din. Under such conditions, the closest diameter of propylene pipes for heating is easily selected.

In this example, it is possible to select PN25 with a diameter of 33.2 mm; this will lead to a slight increase in the coolant movement speed, but it will still remain within acceptable limits.

Features of heating systems with natural circulation

Their main difference is that they do not use a circulation pump for pressure. The liquid moves by gravity, upon completion of heating it is forced upward, after which it passes through the radiators, cools and returns to the boiler.

Compared to systems with forced circulation, the diameter of pipes for heating with natural circulation must be larger. The basis of calculation in this case is that the circulation pressure exceeds the losses due to local resistance and friction.

In order not to calculate the value of the circulation pressure every time, there are special tables compiled for various temperature differences. For example, if the length of the pipeline from the boiler to the radiator is 4.0 m, and the temperature difference is 20? C (70? C in the outlet and 90? C in the supply), then the circulation pressure will be 488 Pa. Based on this, the coolant speed is selected using the transformation method D.

When performing calculations yourself, a verification calculation is also necessary. In other words, the calculations are carried out in the reverse order, the purpose of the check is to determine whether the losses due to local resistance and friction do not exceed the circulation pressure.

How to install water pipes

It’s worth noting right away that it is most convenient to install both the pump and pipes at once. At the same time, all the necessary calculations should be done in advance, otherwise you may encounter a lot of difficulties. The descent of the pump into the well should be smooth. Moreover, if the preliminary preparation is not carried out correctly, then you can receive an insufficient amount of water that is required to supply the house. The lack of pressure will affect the comfort of residents. As a result, they will have to choose between doing laundry, using the shower, or watering the garden. Carrying out side procedures simultaneously will become impossible.

Modern pumps are most often equipped with a flanged or threaded version for connecting a pipe. Although sometimes a coupling type of connection is used. Experts recommend first connecting the water-lifting element on one side, and only after that proceeding with the installation of the second part of the pipe. Lowering the structure to the ground is strongly discouraged. This may cause damage to important components or displacement of certain parts.

Carrying out installation

Features of installing pipes and pumps largely depend on the type of well. In some cases, installation of conventional devices will be very difficult. In such situations, it is possible to use flexible hoses that can replace water-lifting pipes. The main thing is that these elements are strong enough and safe for humans. Under no circumstances should they release harmful chemical compounds into the water. In addition, you should make sure that the pipes are reliable enough and that all fasteners are of high quality. Otherwise, the water supply will have to be repaired immediately after its first use.

Experts strongly recommend using only those options that have been developed and manufactured for these purposes as water-lifting pipes. You should not take nylon hoses or fire pipes, as they will quickly fail and may even damage the pump. As a result, you will have to spend money on purchasing a new set of expensive equipment.

Pump types

The requirements for the pipes depend on which pump will be used to lift the liquid and move it through the water supply system. Therefore, before choosing one or another option, it is necessary to clarify which pump is being used or will only be installed on the site. There are 2 main types of well pumps. This can be manual or mechanical. Each type can be further divided into subclasses.

Hand pumps can have a piston or hose system. The latter option, as a rule, is used when it is necessary to lift water from a depth of more than 7 m. Piston ones are more convenient to use in shallow wells.

The hose pump contains a pump cylinder, which must be secured to the very bottom of the water supply system. The kit includes hoses equipped with a piston and a manually operated mechanism. It must be placed on the top of the well.

Piston pumps differ slightly from hose pumps. But there are still installation features. Such a device must be secured to the end of the water-lifting pipe. It is for this reason that piston pumps are not recommended for use where the well depth exceeds 7 m.

Mechanical devices are more complex, but easy to use. This group is also divided into several types. Mechanical pumps can be gear, centrifugal and electromagnetic.

Centrifugal ones are considered the best option for simple cottages or small houses. Small water-lifting pipes are connected to them, but this is quite enough for domestic use. Such devices are considered relatively inexpensive. They are rust resistant as they are made from stainless steel. In addition, centrifugal pumps can be equipped with several useful accessories. For example, they often use a protection system against turning on in the absence of water. This allows you to protect the device from breakdowns and premature wear.

The peculiarity of electromagnetic borehole pumps is that they last a very long time. There are no rubbing parts that can wear out over time. During installation, such a pump can be immersed directly in water.

Hydraulic pumps are quite powerful and can be used to supply large quantities of water. But for its uninterrupted operation, electricity is required. If there is no light in the house, then, accordingly, the water will turn off. This is not always convenient, since in some settlements, and especially rural areas, power outages are not uncommon.

Selecting casing size

Quite often, decisions about laying a different type of well structure occur when drilling a hole. The dredging process may reveal the need to use different pipe widths to create a more reliable and efficient water supply system. This is what leads to the fact that when forming a structure, pipes of various diameters are used, thanks to which the initial width of the deep-hole equipment column expands or narrows.

Some well drilling companies initially offer their customers to make narrow passages, which makes it possible to offer more favorable conditions in a competitive market. And in some cases, the owner of the facility himself decides to reduce the cross-section of the well, since it is cheaper

It is important to understand that the productivity of the well does not depend entirely on the width of the pipe, since to a large extent it is determined by the technical parameters of the filter components and the ability of the rocks to produce water.

In any of the options, it is very important that there is a gap between the casing pipe and the casing of the pumping equipment, allowing you to quickly and easily dismantle the pump along with the pipe and other parts. Most often, specialized documentation indicates that pumping equipment should be no less than 10 millimeters thinner, compared to the internal diameter of the pipe

This allows you to minimize damage from axial displacements, sagging welds, compression of the pipe under soil pressure, as well as other unpleasant factors.

That is why it is recommended to choose so that the gap is more than 10 mm.

About connecting a polypropylene pipe to a pumping station

There are most often two situations when it is necessary to connect a polypropylene pipe to a pumping station:

- When connecting a new station for the first time;

- When replacing old metal pipes with new HDPE pipes.

In any case, to connect to the central water supply, you must perform the following sequence of actions:

The first step is to shut off the water flow at the point of connection to the central water supply.

Next, we prepare the pumping station. The main thing when setting up a pumping unit is to select the correct pressure in the system. To adjust the equipment, a small amount of water (about 2 liters) is poured into a special hole on the pump unit. Now you need to open the valve and measure the pressure in the system at which the pump turns off and on.

If the pressure at which the device operates does not fall within the specified range, the device must be adjusted. It's very easy to do:

- The pressure cap on the pressure switch opens.

- To adjust the shut-off pressure of the device, use a screw marked “DR”. It should be rotated in the direction of decreasing or increasing depending on the results.

- To adjust the switching pressure, turn the screw marked “P”.

- After adjustment, the cover on the relay is put in place.

So the sequence of actions when connecting a polypropylene pipe to the pumping station:

- First we assemble the ejector. As a rule, this is a monolithic cast iron assembly with three outlets.

- At the lower outlet of the ejector we install a coarse filter made of propylene mesh.

- At the top of the cast iron structure there is a plastic bell. It is necessary to put a squeegee with a diameter of 32 mm on it.

- Next, you need to assemble a surge along the diameter of the pipeline. Usually two parts with adapters are enough for this.

- A bronze coupling is installed at the outlet of this flow. It will be used to connect to a polyethylene pipe.

To connect the ejector to the water supply, use couplings.

Before lowering the second end of the polypropylene pipe, it must be passed through the elbow at a right angle. Polyurethane foam is used to seal the space. After this, the pipe can be connected to the adapter, and it in turn must be connected to the external part of the water supply system.

Now you can lower the ejector into the well. The immersion depth must be determined in advance, taking into account the mark on the top of the body. The lid is fixed to the body using reinforced adhesive tape for sanitary purposes.