What do we want to learn today? How much does 1 cube of ursa weigh, the weight of 1 m3 of ursa insulation such as mineral wool?

No problem, you can find out the number of kilograms or the number of tons at once, the mass (the weight of one cubic meter of URSA insulation, the weight of one cube of URSA thermal insulation, the weight of one cubic meter of thermal insulation material, the weight of 1 m3) is indicated in Table 1. If anyone is interested, you can run eyes a small text below, read some explanations.

How is the amount of substance, material, liquid or gas we need measured? Except for those cases when it is possible to reduce the calculation of the required quantity to the counting of goods, products, elements in pieces (piece counting), it is easiest for us to determine the required quantity based on volume and weight (mass). In everyday life, the most common unit of volume measurement for us is 1 liter. However, the number of liters suitable for household calculations is not always an applicable way to determine the volume for business activities. In addition, liters in our country have not become a generally accepted “production” and trade unit for measuring volume. One cubic meter, or in its abbreviated version - one cube, turned out to be a fairly convenient and popular unit of volume for practical use. We are used to measuring almost all substances, liquids, materials and even gases in cubic meters (mc). It's really convenient. After all, their costs, prices, rates, consumption rates, tariffs, supply contracts are almost always tied to cubic meters (cubes), and much less often to liters. No less important for practical activities is knowledge of not only the volume, but also the weight (mass) of the substance occupying this volume: in this case we are talking about how much 1 cubic meter of URSA thermal insulation weighs (1 cubic meter of ursa, 1 cubic meter of insulating material, 1 m3 of insulation ). Knowing the mass of mineral wool and the volume of heat-insulating material gives us a fairly complete idea of the quantity. Site visitors, when asking how much 1 cube of Ursa mineral wool weighs, often indicate specific units of mass in which they would like to know the answer to the question. As we noticed, most often they want to know the weight of 1 cube of ursa (1 cubic meter of insulation, 1 cubic meter of thermal insulation, 1 m3 of mineral wool) in kilograms (kg) or tons (t). Essentially, you need kg/m3 or t/m3. These are closely related units that define quantity. In principle, a fairly simple independent conversion of the mass of insulation from tons to kilograms and vice versa is possible: from kilograms to tons. However, as practice has shown, for most site visitors a more convenient option would be to immediately find out how many kilograms 1 cubic (1 m3) of ursa insulation weighs or how many tons 1 cube (1 m3) of ursa of mineral wool for thermal insulation weighs

, without converting kilograms into tons or back - the number of tons in kilograms per cubic meter (one cubic meter, one cubic meter, one m3).

Therefore, in Table 1 we indicated how much 1 cubic meter of thermal insulation weighs (1 cubic meter of mineral wool, 1 cubic meter of insulation) in kilograms (kg) and tons (t). Choose the table column that you need yourself. By the way, when we ask how much 1 cubic meter (1 m3) of URSA thermal insulation weighs, we mean the number of kilograms or the number of tons. However, from a physical point of view, we are interested in bulk density or specific gravity. The mass of a unit volume or the amount of substance placed in a unit volume is the bulk density of insulation or the specific gravity of thermal insulation. In this case, the volumetric density of URSA thermal insulation and the specific gravity of URSA.

The bulk density of mineral wool for thermal insulation and the specific gravity of Ursa insulation in physics are usually measured not in kg/m3 or in tons/m3, but in grams per cubic centimeter: g/cm3. Therefore, in Table 1, the specific gravity of URSA insulation and the density (synonyms) of mineral wool are indicated in grams per cubic centimeter (g/cm3)

Table 1. How much does 1 cube of ursa weigh, the weight of 1 m3 of ursa (mineral wool). Bulk density of URSA thermal insulation and specific gravity in g/cm3. How many kilograms are there in a cube of URSA insulation material, tons in 1 cubic meter of URSA insulation, kg in 1 cubic meter of mineral wool, tons in 1 m3.

Bulk density of Ursa miwata, specific gravity of URSA thermal insulation in Table 1.

Bulk density of URSA thermal insulation and specific gravity of URSA insulation, mineral wool

are given in Table 1 as additional information.

REVIEWS. How much does 1 cube of ursa weigh, the weight of 1 m3 of insulation. The number of kilograms in 1 cubic meter of URSA thermal insulation, the number of tons in 1 cubic meter of mineral wool, kg in 1 m3. Bulk density of URSA insulation, specific gravity.

What should be the density of insulation in a winter jacket?

Insulation density in winter

clothes

Insulation density

usually indicated on the label

of winter

clothing - these are numbers from 60 to 350 (grams). The higher the number, the lower temperatures the product can withstand.

Interesting materials:

How to find out why it is cold in the apartment? How to find out how long to drill a well? How to find out how many kilowatts are in the engine? How to find out how many amperes it consumes? How to find out how much electricity your computer consumes? How to enable USB debugging if the screen is broken? How to recover contacts from a phone if it won’t turn on? How to restore contacts from a phone if it's broken? How to restore mail to mail ru if you don’t remember anything? How to unscrew a screw if it turns?

What is basalt insulation?

The name speaks for itself - stone wool fibers are made from basalt

groups, and with the help of a synthetic binder they form heat-insulating boards. ...

Interesting materials:

What to cook at work for a sign? What to bring to work for a snack? What runs on alternating current? What counts as a job at altitude in 2022? What does the working drawing of the part contain? What is a diode and how does it work? What is a Camera Trap and how does it work? What is geotechnical engineering work? What is survey work? What is the concentration of the working solution?

How much do Rockwool slabs weigh?

The weight of mineral wool from Rockwool, a popular insulation manufacturer in our country, depends on the density of the thermal insulation material that the buyer chooses to perform a certain type of work:

- Weight of Rockwool Acoustic Butts, density 45 kg/cu.m. meter, dimensions 1000 x 600 x 50 mm is no more than 1.35 kg.

- Weight of Rockwool Acoustic Butts, density 37 kg/cu.m. meter, dimensions 1000 x 600 x 50 mm is no more than 1.1 kg.

- The weight of Rockwool Light Butts Scandic mineral wool, density 37 kg/cubic meter, dimensions 1000 x 600 x 50 mm, is no more than 0.75 kg.

The mass of mineral wool can differ radically when using combined types of insulation - Rockwool Fire Butts foil plate, density 110 kg / cubic meter. meter, dimensions 1000 x 600 x 30 mm, weighs within 2 kilograms. The weight also depends on the thickness of the insulation used - Rockwool Light Butts Scandic, density 37 kg / cubic meter. meter, dimensions 1000 x 600 x 100 mm, weighs about one and a half kilograms.

Types of mineral wool

3. Vertically layered.

4. Horizontally layered.

The main component of the material is basalt. It acts as a binder, which can be urea resins, bitumen, phenolic alcohols, clay and starch.

In the process of making mineral wool based on rocks of molten mineral materials, thin fibers of 1–3 microns with a thickness of 50 mm are obtained. To improve strength, molten charge or limestone can be added to the molten basalt fibers. Mineral wool substances repel moisture, thereby protecting the thermal insulation properties.

Brief description of the material

Cotton wool for wall insulation is the optimal price-quality ratio when creating comfortable living conditions. It consists of a large number of fibers that are obtained by specific processing. They can be made of glass, slag, stone. The density of any mineral wool, measured in kg per m3, also depends on the material of manufacture. Insulation has a number of advantages, including:

- Easy to install. Mineral wool can be presented in the form of a roll or slabs that hold their shape.

- The light weight of the material allows it to be used for floors without weighing them down.

- Convenience of subsequent finishing. This indicator depends, among other things, on the density of the insulation.

- Environmentally friendly - mineral wool is created from natural materials, which allows it to be completely safe.

- The material is a good sound insulator.

- Non-flammable - it melts but does not burn.

There are also disadvantages and they should be taken into account when insulating with mineral wool:

- Glass and slag wool are very prickly, this must be taken into account during the installation process. Stone wool is practically free from this drawback.

- The material, together with air, allows moisture to pass through, which leads to its loss of its technical characteristics. To avoid this, it is necessary to isolate the insulation from moisture.

- To purchase high-density mineral wool, you will have to spend a lot of money, but the result will exceed expectations.

Insulation structure with different densities

Mineral wool sizes

Manufacturers present 3 types of mineral wool, each of which has its own type of raw material, namely

3. Basalt mineral wool.

All types are successfully used for hydro and thermal insulation of various residential and industrial buildings. For more comfortable installation, manufacturers produce products of various sizes and shapes.

Mineral wool rolled into rolls is produced in the form of a large piece, pre-cut and completed. The dimensions of the material are indicated on the packaging, since many manufacturers have different sizes. Thickness can vary from 40 to 200 mm, width from 565 to 610 mm, length about 1170 mm. The thickness of rigid slabs for hydro and thermal insulation varies from about 50–170 mm, the width of the product is about 1190 mm, and the length is 1380 mm.

Mineral wool in this format is ideal for thermal insulation of large areas, since the rolls contain a large amount of material. As a rule, the width of the materials varies between 50–200 mm, the length of the sheet is about 7000–14000 mm, and the width is approximately 1200 mm. The material is easy to cut and adjust to the size of the room.

Description and influence

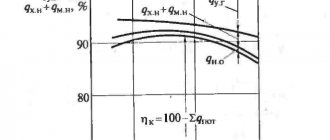

Density is a value that is inversely proportional to the porosity of the insulation. Porous materials retain heat and create a kind of buffer. Therefore, the conclusion arises about how density affects: the higher the specific gravity, the less thermal insulation properties the insulator has.

A good example

For example, birch timber - 500-770 kg/m3, basalt fiber - 50-200 kg/m3. And the thermal conductivity coefficient of birch is 0.15 W with the same fiber index of 0.03-0.05 W. Thus, porous mineral insulation retains heat almost 5 times more efficiently than denser wooden beams.

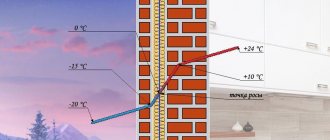

It is precisely because of their specific gravity that even thick, reliable walls do not always provide good thermal protection. But a thin layer of insulation can correct this problem. In addition, low specific gravity gives less load on structures: cellular concrete with a low thermal conductivity coefficient of 0.1 W is not suitable for insulating thin walls and frame buildings since its density is almost 400 kg/m3.

Density provides resistance to mechanical stress, so insulators with low specific gravity require a protective layer. Such materials include penoizol, polystyrene foam and penoplex, as well as mineral wool.

Types of produced mineral wool

According to the indicators of GOST 52953-2008, the technical regulations of which apply to the material - mineral wool, this class includes three types of material:

All of them differ in different thicknesses and fiber lengths, as well as other parameters - different load resistance, resistance to heat and moisture, thermal conductivity. For example, insulation is glass wool, which was very popular in the USSR, and is now cheap

However, working with it requires specialists to be careful - fiberglass mineral wool is too prickly

Let's look at each type of cotton wool separately.

This material, created from slag, has a fiber thickness of 4 – 12 microns and a length of 16 millimeters. Since mineral wool is characterized by residual acidity, when the room is damp, it has an aggressive effect on metal surfaces. In addition, the technical composition that cotton wool has makes it possible to absorb moisture well. This fact does not allow it to be used for cladding facades. Considering the previous reasons, mineral wool made from slag is not used as insulation for plastic and metal pipes.

Technical characteristics of slag wool:

- hygroscopicity – very high;

- thermal conductivity – 0.46-0.48 W/meter/Kelvin;

- maximum heating temperature – 3000C (if the limit is exceeded, the material will sinter).

This insulation consists of fibers 15–50 mm long and 5–15 microns thick, which make glass wool a durable and elastic material. Glass mineral wool suggests. You should work with it very carefully so that the glass threads do not get into your eyes or skin. Inhaling glass dust can damage your lungs, so you must use a respirator and special goggles when working with it.

- thermal conductivity – 0.03-0.052 W/meter/Kelvin;

- heating temperature – 5000C;

- cooling temperature – minus 600C.

Mineral fiber made from such fiber is characterized by fibers with dimensions close to slag wool. A significant advantage of the material is that it does not prick. By the way, professionals who talk about mineral wool most often mean stone wool.

- thermal conductivity – 0.077-0.12 W/meter/Kelvin;

- heating temperature – 6000C.

Of the many varieties, basalt mineral wool has the best parameters, since it is created from diabase or gabbro. However, the insulation - stone mineral wool - contains impurities in the form of dolomite, clay and limestone, which contribute to an increase in the fluidity of the mass. Mineral wool contains less than 10% of the resin-based binder component. When this indicator decreases, the material allows more moisture to pass through, however, the evaporation of phenol decreases, and thus the negative impact on human health is reduced.

Basalt mineral wool is characterized by the absence of additional components. That is why it can withstand heating up to 10000C and cooling down to -1900C, and this does not harm the thermal insulation material in any way. Basalt fiber is easily formed into sheets or rolls. Just like standard mineral wool, basalt mineral wool will not burn when heated above normal.

What determines the weight of the mineral wool used?

In the process of producing insulation, offered to customers under the general name of mineral wool, both basalt rocks can be used, which makes it possible to call the final product basalt wool, and waste from the metallurgical industry - slag, the weight of which is significantly less than basalt, which affects the weight of the insulation.

The weight of mineral wool depends on its density, which influences the choice of material depending on the area of application - loaded or unloaded surfaces. For the most part, this figure can range from 35 to 100 kg/cubic meter. Considering that the size of the insulation boards used is on average 0.6 square meters, the weight during installation is also insignificant. The term “density” in some cases can be replaced by the name “volumetric weight of the minislab”, which fully corresponds to the definition of density and represents the weight of 1 cubic meter of insulation.

weight 1 m2, wall, roof, 150 mm, 100 mm

To quickly and inexpensively carry out construction work, sandwich panels are often used, the weight of 1 m2 of which is lower than the weight of a brick or concrete wall of the same area. Depending on the thermal insulation parameters, the optimal type of panel and its thickness are selected and the tabulated weight value required for calculating the load-bearing structures is found.

Types of Sandwich Panels

All varieties consist of outer and inner layers, between which a heat insulator is laid. The composition of the layers determines the technical characteristics and properties of the building material.

OSB sandwiches

The inside and outside of the structure are covered with oriented strand boards, and the filling is most often polystyrene foam. Ready-made “sandwiches” are 4 times stronger than wooden-frame structures, so they are suitable for capital construction. With a small thickness (from 120 to 150 mm), OSB sandwiches have a thermal conductivity that is 8 times less than a brick or concrete wall. Sandwich panels made from OSB boards have dimensions of 1.25 (2.5) m x 2.5 - 7.3 m, the weight of 1 m2 of puff material ranges from 18 to 20 kg.

Sandwich panels of element-by-element assembly

The design consists of a cassette profile into which any insulation is inserted, covered with a windproof film. Corrugated sheeting and metal siding are most often chosen as cladding. The advantage of this type of sandwich is their maintainability, the possibility of selecting insulation with a lower specific weight - if it is 40 kg/m3 (mineral wool), then the weight of a square meter of a prefabricated structure with a thickness of 200 mm does not exceed 25 kg.

Metal sandwiches

They are faced with a galvanized metal sheet (smooth or profiled) with a thickness of 0.5 mm. A decorative and protective polymer coating is applied on top, and a layer of primer is applied on the inside. Mineral wool, polystyrene foam or polyurethane foam are used as insulation. Multilayer products for walls and roofs are produced; they differ in the type of locking connection and the height of the cladding profile. The applicability of metal sandwiches is the construction of garages, hangars, and outbuildings.

Weight of wall metal sandwich panels

The information given in Table 1 shows how different the weight parameters of structures are, depending on their thickness and the insulation used. Table 1 Dimensional and weight parameters of metal sandwiches for walls

| Options | Meaning of indicators | |||||

| Thickness, mm | 60 | 100 | 120 | 150 | 200 | 250 |

| Weight of 1 m2 with mineral wool, kg | 15,8 | 20,5 | 22,8 | 26,3 | 32,1 | 37,9 |

| Weight 1 m2 with polystyrene foam, kg | 9,6 | 10,2 | 10,5 | 10,9 | 11,7 | 12,5 |

As an example, we find the weight of a 1.2 m x 10 m wall sandwich panel, 150 mm thick, filled with mineral wool. First, calculate the surface area: 1.2 * 10 = 12 m2. The result is multiplied by the weight of a square meter: 12 * 26.3 = 315.6 kg.

Weight of metal roofing sandwich panel

Roof “sandwiches” with anti-corrosion coating and unique locks serve reliably for several decades. Table 2 allows you to compare options with different insulation by weight.

Table 2 Dimensions and weight parameters of metal sandwiches for roofing

| Options | Meaning of indicators | |||||

| Thickness, mm | 60 | 100 | 120 | 150 | 200 | 250 |

| Weight 1 m2 with mineral wool, kg | 15,4 | 19,8 | 22,0 | 25,3 | 30,9 | 38,0 |

| Weight 1 m2 with polystyrene foam, kg | 10 | 10,5 | 11,0 | 11,5 | 12,0 | 12,7 |

| Weight 1 m2 with polyurethane foam, kg | 12,4 | 14,0 | 14,8 | 16,0 | 18,0 | 20,0 |

Calculation of the weight of a roofing sandwich panel 100 mm thick with dimensions 1 m x 2 m with polyurethane foam filling: area = 1 * 2 = 2 m2; weight = 14 * 2 = 28 kg.

Knowing the estimated number of sandwiches for the walls and roof, their total mass is found - the parameters of the floors, foundation and rafter system depend on this. Conclusion: the weight of 1 m2 of sandwich panel is one of its main technical characteristics.

Using wool of different densities for insulation

The choice of insulation according to the indicator under consideration depends on the place of its use. It is not always necessary to overpay in order to get the desired result. Most often, the facade, walls, roof and floor are insulated. These are the options that are worth considering.

Regardless of density, the material must be protected from moisture

Facade

When selecting insulation for a facade, you need to pay attention to the mass and density of mineral wool. For most buildings, weighting is very undesirable. It is also worth paying attention to the possibility of subsequent finishing, because this indicator also affects this. So:

- If the facade is equipped with a ventilated one, then a sufficient density is 45-100 kg m³. Here the cotton wool is laid into the sheathing and there will be virtually no stress. The main tasks for this type are to maintain its shape and not sag under its own weight, and the indicated indicator is enough for this.

- If the facade is to be plastered over insulation, then the density should be above 100 kg m³, optimally from 145 to 165. This will allow the use of any types of plaster mixtures, including bark beetle, barenkom and even mosaics. Since this mineral wool will have to withstand heavy loads during installation, it must be securely fastened; for this, a system with dowels is used in combination with adhesive fastening.

Wall insulation

In this case, the selection is made based on ease of installation, that is, the density should be at least 30-45 kg m³. In this case, you need to insulate from the inside; MDF boards or drywall should be screwed onto the material on top. In order to mount such mineral wool, you need a lathing; rolls or sheets are placed in it.