Freezing of a well is a very unpleasant event for residents of country houses who use well water for water supply all year round. It’s quite simple to avoid this - insulate the well yourself. And for a positive result, you need to know the specifics of performing thermal insulation and understand the materials. Do you agree?

We will tell you how to choose the right insulation for thermal insulation of a well shaft. Here you will learn everything about the methods and nuances of carrying out work. Taking into account our recommendations, you can ideally protect your water source from low temperatures.

Insulation of a country well from concrete rings

Insulating the topmost ring of a well is actually not that difficult.

The technique of this procedure is quite clear and primitive. To explain briefly and concisely, the top concrete ring needs to be covered with the familiar polystyrene foam. Let us consider in detail the progress of the work to be performed

- The wall ring needs to be dug out twenty centimeters - to the depth of ground freezing. In total you will have to go deeper by about 1.2 meters. Since this is not very comfortable to do, you will have to dig a fairly large pit. If you count the rings from above, then it is enough to get by with a depth of 20 cm below the junction of the first two rings.

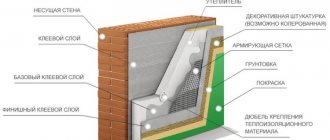

- We take layers of foamed polymer and cut it into strips 20 cm wide. High-density material is more suitable, and the best option would be to purchase extruded or ordinary foam.

- We clean the wall rings from dust and dirt, moisten them with water, and glue the parts of the prepared foam polymer with special glue.

- When the surface of the ring is fully covered, the gaps between the individual strips of foamed polymer are filled with foam for installation. Its remains are cut off after complete drying, the soil around the well is added, and the well itself is put in order.

So that the foam for installation work does not fade in the sun and the foamed polymer does not deteriorate, the structure is reinforced with a mesh and then covered with a layer of plaster. This option is very effective, but it doesn’t really help in all cases: the cold can penetrate through the top.

Thanks to this, it will be better, without delay, to move on to the next insulation method with your own hands.

Making a warm shutter

What is a warm shutter?

It must be stated that this is a specialized cork with small holes made in it. One of them serves for ventilation and prevents water spoilage. The second is for the intake hose. This option will be optimal for a summer cottage, which is supplied with well water using a pump.

How to make such a shutter lid?

- It is necessary to make two similar rings from moisture-resistant plywood, corresponding in size to the inner diameter of the concrete ring of the well.

- One of the rings is covered with 5-centimeter polystyrene foam. All remnants are carefully cut off: the foam circle should exactly repeat the shape of the plywood one.

- The second plywood circle is glued on top of the foamed polymer.

- Final stage. We drill two 6-centimeter holes (for ventilation and for the hose), make a handle to which we attach a thick rope or chain, so that in the spring you can easily remove this plug.

There is nothing difficult in all these events, but there is also no special beauty here.

It should be noted that the considered methods of thermal insulation with polystyrene foam are suitable only if the water supply is carried out using a pump.

If water is taken from the well with a bucket and a collar, then it is unlikely that the stopper will help. In this case, there is another, third method of insulating a well with your own hands.

Insulation of water wells

This is an excellent option for every occasion. There is an optimal way to thermally insulate a well, which solves several problems at the same time: the appearance of the site outside the city will not be affected at all, and the insulation will be done really well. This primitive and good method is the construction of a special closed well house.

Closed well house

This design solves the following problems:

- Prevents water from clogging with leaves and other small debris. A thoughtful and airtight house with a tight lid will not allow anything unnecessary to get into the source.

- The well will not freeze in winter. In the only case such a house will not save you from freezing if the water level in the well is higher than the ground freezing level. If this is the case, then it will be necessary to implement additional insulation of the upper wall ring with polystyrene foam.

If insulating a well yourself seems too difficult to you, you can make the task easier for yourself. At a minimum, you won't have to do most of the work yourself. Foam half-rings, a warm seal and good sealed houses themselves can be purchased at hardware stores.

All you need to do is install such products, and this, of course, is several times easier. Well, factory-made products, in most cases, will look much more beautiful than homemade ones. This is especially true for a well house. Still, only homemade interior items will give the site an original and distinctive look.

How to prevent well rings from moving in the future

You will have to come to terms with the displacement of the lower rings - digging out a trunk to such a depth is an extremely time-consuming and expensive task. Since most often the shift occurs due to weak soil or quicksand, there is no guarantee that after repair the problem will not recur. As for the upper 2-3 rings, they should be returned to their place without fail - this will allow for high-quality waterproofing and thereby avoid flooding of the mine with perched water.

The use of well rings with rebated locks prevents their horizontal displacement

The simplest thing that can be done to prevent horizontal movement of well rings is to replace them with hollow reinforced concrete modules with interlocking connections. For those who are embarrassed by the additional costs, we can recommend connecting adjacent rings using durable metal brackets or thick steel plates. To do this, holes are drilled at a distance of at least 25 cm from the joint, into which the bracket is driven from the outside. The edges sticking out inside are folded and carefully sealed. If plates are used, they are installed on both sides and secured with bolts with a diameter of at least 12-14 mm.

Concrete rings can be connected together with metal clamps and straight or curved plates made of thick steel strip

On heaving soils, cracks in the joints appear due to the fact that the soil tries to push the upper rings upward, lifting them above other parts of the well shaft. In this case, the trunk is dismantled to a depth below the calculated freezing point and the cylindrical modules are replaced with conical ones.

Factory or hand-cast cone rings will remain in place even on the most heaving soil

Prefabricated cone rings are almost impossible to find, so you will have to cast them yourself. The slope of the latter should be directed inside the structure and range from 10 to 15 degrees. Due to this, the buoyant forces reverse their direction, pressing the upper concrete module against the well shaft.

In what cases is insulation required?

If the well was built according to ancient traditions (read: made of wood), then, of course, it does not need any thermal insulation. There are exceptions - for example, a well cover needs insulation. In this case, it is necessary to make an additional cover from wood and fix it inside the structure itself. This cover will protect the country well from:

- snowfall;

- temperature changes;

- ingress of dry leaves and other debris.

Note that almost all modern wells are constructed using reinforced concrete rings. Such wells have numerous advantages, including:

- strength;

- reliability;

- durability;

- ease of installation and further maintenance.

Despite this, they have one significant drawback: they need to be insulated for the winter.

On a note! If the water in the structure is located below the soil freezing level, then the structure itself will not freeze. But if it’s higher, then installation of insulating material is required!

There are three thermal insulation technologies:

- insulation of the structure cover;

- thermal insulation of the upper ring;

- construction of a decorative house.

Let's take a closer look at each of the possible methods.

On a note

Experts advise preserving all wells that are not used in winter for the cold period. To do this, disinfection is carried out, and then water is pumped out of the mine. An insulated lid is lowered onto the top ring. On top it is covered with plastic film and generously filled with any insulation of natural origin - fallen leaves, straw, sawdust. It is believed that the water in the well will arrive only in the spring. Although in fact this can happen much earlier if a well shaft is placed on a powerful water vein.

Wells that have wooden walls instead of concrete rings are not insulated with anything additional, except for the lid.

Expanded polystyrene is rightfully considered the best insulation for rings. It is resistant to moisture and fungus, does not deform and can be easily dismantled if necessary. The only disadvantage of the material is the fear of ultraviolet radiation.

Method two. We thermally insulate the upper ring of the structure

Every specialist will tell you that in order to prevent freezing of a well, you need to reduce the thermal conductivity of its upper ring. This method of thermal insulation is performed in two ways:

- by means of polystyrene foam;

- using polyurethane foam.

Let's look at the first method first.

We use polystyrene foam for the ring “under a fur coat”

Here you should prepare the following consumables for work:

- polyurethane foam;

- paint;

- plaster;

- insulating blocks made of polystyrene foam, which are connected using a tongue-and-groove system.

On a note! According to this technology, the first ring on top will be completely insulated, while the second only partially. Now to work!

Step one. Work should begin with preparatory activities. Dig a pit 20 centimeters wide and approximately 0.5 meters deep around the ring. Then thoroughly clean the surfaces from dirt and install the first “fur coat” ball. At this time, make sure that the density of all connections is maximum! Blow out the joints with foam to seal them. Having finished with the first level, proceed to assembling the second and gluing it to the ring. Blow out the gaps that have formed between the layers with foam.

Step two. Next, begin plastering the surface of the rings. This will protect the foam from the negative effects of the sun's rays, which, as we know, worsen the thermal insulation properties of this material. After the plaster has completely dried, apply paint to it - this will prevent the finish from getting wet.

Step three. All that remains is to fill the pit and thoroughly compact the earth.

Penoplex, we insulate the foundation reliably and correctly

We recommend that you read our article on insulating the foundation yourself. You can find out more here

We use polyurethane foam for the ring “under a fur coat”

If you chose polyurethane foam as insulation, then follow these steps. First, dig a similar pit (as in the previous method of insulating a well for the winter), and then build a wooden frame around the first ring. But this is in general terms; let’s analyze the procedure in more detail. Prepare the following materials for work:

- paint;

- dowels;

- polyurethane foam sprayer;

- collapsible metal formwork;

- plaster;

- a piece of plastic film;

- wooden bars.

Step one. Traditionally, start by digging a pit, but narrower (maximum 10 centimeters). After this, install bars around the first ring in increments of approximately 40 centimeters. Cover the edges of the trench with formwork made of thin sheet steel, which will exactly follow all the contours. Cover the formwork with the prepared film. For what? This is explained by the fact that the adhesion of foam plastic is very significant, and therefore dismantling the formwork is impossible.

Step two. Having finished building the formwork, you will notice that a void has formed between it and the ring - this is what needs to be filled with insulation. Upon completion of pouring, the polyurethane foam will increase in volume, and the trench will therefore be filled as densely as possible.

After this, you need to wait until the material is completely dry. As soon as this happens, dismantle the formwork. Plaster the finished surface and apply a layer of paint to it. Fill the void left after formwork with earth and compact it thoroughly.

On a note! It is also advisable to cover the well with a lid, which was described in one of the previous paragraphs of the article.

Construction of a decorative house

The advantages of the house are that it not only insulates the well, but also protects the source from dirt and decorates the area as an element of landscape design. Types of well houses:

- roof mounted on shaft rings;

- a log house similar to a gazebo;

- large 2-pitch roof covering concrete rings;

- with canopy;

- with a winch.

Materials for its construction:

- Brick, building blocks or concrete. With their help, the structure can be given any shape. It is durable and inexpensive, but requires cladding.

- Metal. This option is chosen by lovers of high-tech style. The metal frame is sheathed with sheet iron.

- Natural stone. It is easier to lay flagstone, because... it's flatter. The house from it looks natural.

- Tree. Due to its high performance and aesthetic appearance, it is most often chosen.

Walls that are too thick will make the structure bulky, and thin, lightweight structures will not withstand wind and other loads.

The house should not stand on the ground, but on a concrete platform. Therefore, work begins with it, taking into account the following:

- the platform must be reinforced;

- concrete layer - at least 15 cm;

- it is necessary to make a slope for water drainage;

- if a project with a canopy and a winch is selected, racks for them are installed before the site is poured.

The stages of building a house depend on the materials chosen, but installation always begins with the construction of the frame. Afterwards, the space between the walls of the house and the well is insulated, for example, with expanded clay. The structure is decorated with carvings, painting parts in different colors, artificially aging wooden surfaces, and installing figures made of wood or plaster.

Polyurethane foam

Polyurethane foam is a material that is even more resistant to the negative effects of environmental factors. It is used even in extreme Arctic climates and on space stations. Polyurethane foam is non-toxic, moisture resistant, and rodents cannot live in it.

Spray polyurethane foam is very lightweight and lasts up to 50 years.

What is polyurethane foam

Polyurethane foam in its original form is the contents of two containers. A special spray gun is required to use it. In a special chamber under high pressure, the components from both containers are mixed and applied in the form of foam to the concrete head of the well. This must be done at room temperature (25-30°C), otherwise the reaction of the components will not be active enough and, as a result, the consumption of polyurethane foam will increase.

To insulate a well with polyurethane foam with your own hands, you do not need to carry out any special preparation of the surface of the concrete rings protruding above the ground. Polyurethane foam fills all the smallest cracks and crevices in concrete and, after hardening, forms a monolithic coating with high heat and moisture insulation characteristics. This coating, like polystyrene, must be protected from exposure to ultraviolet radiation.

Preventing the well from freezing

To prevent the well structure from freezing with the onset of winter, thermal insulation should be taken care of during its construction. If the suburban area will be visited occasionally (for example, only on weekends), then, in principle, there is no need to insulate the well. In such cases, it is only necessary to clean it and treat it with some kind of disinfectant (such as chloramine) before leaving.

After this, pump out the water completely and close the structure with a lid. Lay a polyethylene film over the lid and cover it all with leaves. Now you can go to the city with a clear conscience, because with the onset of warmth, the well will again provide clean water.

But if the well is used regularly, then the measures should be more serious. For example, pipes to the house must be located below the soil freezing line, the structure itself must be protected by the house described above, or by other available means.

What to do if you're already frozen

Having opened the well, it is clear that frost has covered the entire area of the walls of the ring and has tightened the pumping equipment. Perhaps the installation depth of the cover is incorrectly calculated, or the source is not insulated correctly.

If there are signs of freezing, but water is still flowing into the house, nothing needs to be done until the air temperature rises. Then it should be properly insulated.

Frozen equipment can be warmed up with a hair dryer right on the spot, or, after removing it, bring it into a warm place and let it stand for a day.

Method three. Construction of a wooden house

If your site is located in an area where the temperature in winter is not too low, you can build a protective wooden frame over the shaft. To do this, prepare:

- wire;

- nails;

- waterproof film;

- logs;

- plywood sheets;

- expanded polystyrene.

Step one. First of all, cover the inside of the top ring with a pre-prepared film. Next, take the foam and cut out six rectangles from it. Make the dimensions of the latter such that as a result of lining the ring, an even hexagon is formed. This little trick will significantly increase the adhesion density of the foam.

Step two. Then you need to secure the foam. To do this, wrap it with ordinary wire in at least three rings. It is advisable to use aluminum wire for this, since it does not rust and is quite soft. As a result, it will be easy to manipulate, and there will be no corrosion on the surface of the insulating layer.

Step three. After this, build a log house from small-sized logs. The height of the log house must be level with the well itself, and its shape must be hexagonal. Place a cover consisting of several layers on top of the finished house (as described in the first insulation method). Then you can paint the structure so that it is not only functional, but also aesthetic.

Video - House installation

For a more detailed introduction to the technology, we recommend watching the thematic video material.

https://youtube.com/watch?v=zFxBdPaUM

Why freezing wells is dangerous

It is a mistake to think that well insulation is only necessary when it is used year-round. Many summer residents and seasonal residents of country houses sincerely do not understand why insulate a well that no one uses in winter anyway. Meanwhile, such seasonal wells also need effective thermal insulation!

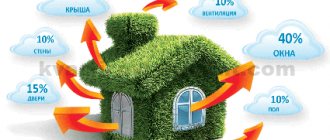

Otherwise, a variety of problems may arise that make the operation of the well difficult or completely impossible:

- the formation of an ice plug in the water supply system;

- displacement of the rings resulting from the expansion of frozen water in the surrounding soils;

- failure of the ice plug and damage to pumping equipment;

- divergence of the joints of reinforced concrete rings when water gets between the seams.

Wells that are not protected from low temperatures require repair work much more often. And in terms of financial costs, repair measures are often more significant than carrying out one-time insulation work.

If a water supply system based on a well is installed in a suburban area, then in addition to the shaft itself, it is necessary to insulate the pipes to protect the supply line of the system from low temperatures.

The need for thermal insulation

This is by no means the main problem. The main thing is that the water does not freeze!

Where the well is planned to be used throughout the year, the structure is usually insulated during the construction stage. But country wells are sometimes made uninsulated. The result is not long in coming - already in the first fairly cold winter, serious problems begin.

It is necessary to protect a well from freezing for a number of reasons:

- The first, and most obvious, is the freezing of water and its transformation into ice. This process occurs quite slowly, because ice usually forms when the outside temperature reaches -15 ... -250C. However, even until this moment it will be inconvenient to use the source, since each time you will have to break through a thin ice crust with a bucket.

A layer of ice blocks access to water and leads to structural failure

- An ice plug that forms on the surface of the water can damage the walls of the well. This is due to the fact that when ice forms, its volume increases, and the edges of the plug begin to put pressure on the surrounding surfaces. If pressure is applied to the joint of reinforced concrete rings, then there is a possibility that they will separate, and if it is applied to a continuous area, then cracks may appear.

A small beginning of a big disaster

- The same problem is typical for wooden log houses. The difference is that in the case of a wooden structure, in almost 100% of cases, a layer of ice wedges between the crowns and pushes them apart. As a result, cracks form in the wall of the log house, through which a large amount of soil then falls into the water.

Concrete track joints have to be repaired more often

- The formation of ice also harms well equipment: pumps can completely fail, hoses can crack and lose their tightness. That is why it is not worth leaving any equipment in an uninsulated well for the winter.

- The same will be true for a caisson with installed external pumping equipment, and for a sewer well. Any structures with pumping or water-measuring equipment must be equipped with thermal insulation, otherwise the service life of the equipment will be greatly reduced.

The caisson, insulated inside with polystyrene foam, can be used in winter

- Another minus is the ice plugs themselves. During the thaw, they partially thaw and fall into the water under their own weight. The result may be damage to the pump or even broken cables.

Either way, freezing can lead to serious problems. Moreover, the higher the water level in the source, the more noticeable the negative impact of low temperatures will be. That is why shallow wells need to be insulated more carefully.

Method one. Cover insulation

This technology is not complicated and consists of installing an additional cover inside the structure itself at ground level. We remind you that water from a well can be obtained in two ways - the old fashioned way, that is, using buckets, and using an electric pump. This article discusses exclusively the modern method.

You should start by preparing everything you need. Prepare for work:

- plywood sheet;

- glue;

- wire;

- a plastic pipe, which is necessary for ventilation;

- insulation, the thickness of which will be at least 5 centimeters (foam is ideal for this);

- polyurethane foam.

After this, proceed directly to the construction process.

Step one. Take a plywood sheet and cut out a couple of even circles with a diameter similar to the diameter of the structure itself. Make two holes in each circle - one for the hose and the other for ventilation.

On a note! Ventilation in this case is mandatory, since without it the water will soon begin to smell unpleasant, and its taste will noticeably deteriorate.

The diameter of the drilled holes is insignificant - no more than 6 centimeters, otherwise frosty air will be able to penetrate through the resulting cracks. It is more convenient to drill holes at one edge. Next, make 4 more holes for the wire around the perimeter of the second circle.

Step two. We continue to insulate the well for the winter. Cut a third circle of the same diameter, but this time from foam. Glue it to the bottom circle using high-quality wood glue, and fix the third circle on top. Once the glue has dried, place the ventilation pipe into the prepared hole. You can use polyurethane foam to seal joints.

Step three. The work is almost finished, all that remains is to make a special ring from the wire. To do this, take it and wrap it around the first ring, thereby fixing its circumference. After this, attach the wire to the ring, fixed in the four holes of the lower ring. Pass the hose into the required hole, and then lower the finished “sandwich” onto the ground line. The lid will be held in place with a wire, the well will be properly ventilated, but the water will not freeze.

Reports of our work

- Insulation of the source shaft. Marfino November 8, 2016

- Insulation of the shaft and cover. Village Goluboe September 28, 2016

- Mine insulation. Bolshoye Snopovo August 23, 2016

- Guarantee of the quality of our services

- Samples of contracts for our services

- Service areas

Order in 1 minute Online consultation

Well cover and wooden house

To ensure the best protection of the well from freezing, in addition to insulating the well shaft, it is also necessary to carry out external insulation work. They consist of constructing and insulating the well cover and/or erecting a wooden house over the well.

The well cover must be installed taking into account the maximum water level. The movement of the cover is ensured by a cable or rope. The best material for making a lid is wood. Also an excellent option would be a three-layer cover made of two layers of thick plywood with insulation between them.

It is advisable to use polystyrene foam or polystyrene foam as insulation.

If you decide to use a well cover made of reinforced concrete, then it also needs to be insulated by attaching a layer of foam plastic or other insulation. Fastening is carried out using glue for external use and dowel-nails for concrete.

Installing a house over a well is a more expensive method, however, it has its advantages:

- reliable shelter of the well shaft from debris and precipitation;

- the ability to use the well in any weather (rain, strong wind);

- aesthetic appearance, a wooden house is perceived as an element of landscape design.

You can make such a wooden house yourself or buy a ready-made version. In any case, it is worth knowing that the house is not simply installed on the surface of the ground. It requires a foundation, which is done as follows: the area around the well is leveled and a blind area is made, on which a layer of fine crushed stone is poured or tiles are laid.

After this, a wooden house is mounted, and the space between it and the reinforced concrete ring is filled with insulation. In this case, expanded clay, an inexpensive bulk material, can be used as insulation.

Advice from professionals

To obtain the most positive result, you must adhere to the following recommendations from experienced professionals:

- From the wide variety of insulation materials, choose those options that are resistant to a humid environment and respond well to temperature changes. The following should be used for thermal insulation of concrete wells: foam sheets, polystyrene foam, polyurethane foam. Roofing felt, hard plastic, film are suitable for these purposes.

- It is possible to ensure good protection of a well from low temperatures not only by insulating the well shaft, but also by erecting a wooden house above it. The cover of the hydraulic structure must also be thermally insulated; 2 sheets of plywood are used, and insulation is laid between them.

- There is no need to plaster the concrete surface; it is enough to use a waterproofing film.

Why is insulation necessary?

By insulating the well, it will be possible to maintain a satisfactory temperature inside it, allowing water to remain in liquid form even in high frosts, without forming ice on the surface.

The appearance of an ice layer not only makes it difficult to collect fluid, but can also lead to cracks in concrete circles, or damage wires or pipes located in the well.

The circles begin to break down and age ahead of schedule. As a result, their service life is significantly reduced. If pipes freeze or cables are damaged, repairs will be necessary, which will not be cheap and will require labor-intensive processes.