The roof is one of the elements of the building envelope. Its main function is to provide a heat-insulating barrier space that protects the interior of the structure from harmful atmospheric influences (rain, snow, wind, hail, etc.). Heat loss in a building with an uninsulated roof is about 15-30%.

Therefore, properly equipped roof insulation will allow you to significantly save on heating costs.

More than half a century of experience insulating roofing structures with expanded clay has shown that this is one of the most versatile, effective and reliable methods.

What is expanded clay?

Expanded clay is a lightweight and highly porous thermal insulation material with a dark brown shell. It is made by firing clay or shale at a temperature of 1050-1300 degrees Celsius for 25-45 minutes. With different processing modes of the clay base, it is possible to obtain expanded clay with a bulk density of 0.35 to 0.6 g/cm3.

Depending on the form, there are three varieties:

- Expanded clay gravel. The cellular elements have a streamlined oval shape. The grain size is 5-40 millimeters . Used when the required thickness of the insulating layer is more than 5 centimeters.

- Expanded clay crushed stone . The dimension of the elements is similar to expanded clay gravel. It has a cube-shaped shape with sharp protruding corners and edges. This type of expanded clay is obtained by crushing large pieces of expanded clay.

- Expanded clay sand. The grain size is in the range of 14-50 millimeters . Small dimensions make it possible to use expanded clay sand with a heat-insulating layer thickness not exceeding 5 centimeters. It is also used as a filler for concrete and other types of mortar.

Advantages and disadvantages of expanded clay

Compared to widely used slab insulation materials such as mineral wool, expanded clay is much more profitable. When insulating a roof with expanded clay, no special skills or abilities are required. The use of bulk thermal insulation does not require adjustment of elements and additional fastenings . Roof insulation with expanded clay has the following advantages:

- Expanded clay is a highly environmentally friendly material . It does not decompose and does not emit toxic gaseous fumes that are hazardous to human health.

- Not edible for rodents.

- Has increased resistance to frost . Can withstand up to 25 cycles of complete freezing and thawing.

- Fireproof and fireproof material.

- Excellent heat and sound insulator .

- When wooden surfaces are insulated with expanded clay, their service life increases to 50 years.

- Lightweight material.

- Resistant to chemical attack.

- Cheap , a cubic meter of slab insulation will cost several times more than expanded clay of the same volume.

- When using high-quality expanded clay insulation, the thermal conductivity of which is 0.07-0.16 W/m, heat loss is reduced by 70-80% .

clay is a bulk material ; it fills almost the entire provided volume. This, unlike slab insulation, allows for the most effective insulation of small cavities.

NOTE!

It is not recommended to lay expanded clay on a plank base without a backing . Small crumbs and dust can enter the living space through the gaps between the boards.

Flat roof

Previously, roof insulation with sawdust was very common, but, unfortunately, due to the high fire hazard, this insulation has now lost its position. However, we must pay tribute to the price range in this case. The cost is significantly lower compared to other materials. You can even use your own dried sawdust after construction work.

It has been replaced by more modern materials. For example, ecowool and expanded clay. Insulation of a sloping roof with expanded clay guarantees an almost imperceptible weight load on the roof, but at the same time demonstrates high fire safety indicators.

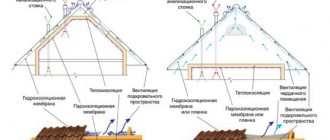

The roof insulation scheme in this case is as follows:

- Laying vapor barrier material to prevent dampness. In this case, roof ventilation is not affected in any way.

- Coating with a thermal insulation layer. Here, additional insulation of the roof with ecowool is acceptable.

- Laying waterproofing to avoid dampness.

- Final insulation of the roof with expanded clay - bulk material. It should also be noted that ventilation is excellent through this material.

It is worth noting that in any case, insulation of the roof from the outside is carried out only after insulation from the inside.

Disadvantages of expanded clay insulation

- The lightness of the material is relative . So, when installing thermal insulation, a layer of expanded clay of 10-40 centimeters is required . Even such light-weight porous elements in such a volume will create a significant load on the underlying supporting structures.

- Expanded clay strongly absorbs moisture , which negatively affects its thermal insulation properties. It is imperative to install layers of hydro- and vapor barrier.

- The fragility of the material can lead to mechanical damage to the integrity of the granules. Water will get into unprotected pores and voids, which will lead to the loss of the positive properties of expanded clay.

How to determine the optimal insulation thickness?

In accordance with regulatory documentation, the required thickness of the thermal insulation layer depends on the climatic zone in which the building is built and the area of the insulated room.

The climate zone is determined by special maps; they can be found in SNiP or TKP for heating engineering.

The required insulation thickness depends on the thermal resistance value of the structure being calculated (R) . This is a standard value, depending on the climatic region, as well as on the type of insulated structure.

The values for the floor, walls and ceiling will vary significantly. If you do not know what layer of expanded clay is needed to insulate the roof, then we suggest you use the formula below.

Roof insulation with expanded clay: layer thickness and calculation formula (P):

P=R*k

Where k is the thermal conductivity coefficient of the material. For expanded clay, its value is 0.16 W/m*k.

Laying methods

For flat structures, it is enough to pour granules onto a vapor barrier and cover it with tiles, roofing felt, or slate.

The result is a simple and beneficial thermal insulation layer.- This method is not suitable for houses with pitched roofs It will be necessary to install additional structures that will prevent the expanded clay from rolling down. The role of such pockets is performed by horizontally nailed slats.

Advice . It is advisable to think about ceramic insulation for the roof of a wooden house. The expanded clay embankment evenly presses on the entire area of the building structure, which ensures its uniform shrinkage.

Alternative types of insulation

Expanded clay is not the only widespread thermal insulation material used in roofing structures. Let's look at the most common options:

- Expanded polystyrene, better known as a type of polystyrene foam. The thermal protection of such material is much better than that of cotton insulation. The layer of polystyrene foam insulation will be much thinner. Polystyrene foam does not absorb water and is quite rigid and durable. The use of specialized additives allows for increased fire resistance. But, if the material does catch fire, toxic gases will be released that are dangerous to human health and life. Unlike expanded clay, mice and rats love to chew foam.

- Basalt wool and mineral wool. The fibrous structure of this type of insulation ensures its high saturation with air. This allows them to be used as a thermal insulation material. When laying fiberglass, you will need additional protection: gloves and a respirator. Disadvantages include susceptibility to rotting, as well as high cost .

- Polyurethane foam. Foam insulation manufactured directly on the construction site. Application is carried out with a special gun. The expansion of the material after application allows you to create a monolithic insulating structure. It is lightweight and fire resistant . The service life is about half a century. The disadvantage is the need to use specialized equipment and an experienced team for high-quality work.

- Ecowool. A material containing 80% cellulose fiber and 20% fire-resistant and antiseptic additives. Has good heat and sound insulation . Ecowool forms a seamless coating that eliminates the formation of cold bridges. Service life - more than 50 years .

Vapor barrier

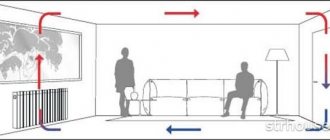

A vapor barrier is needed to prevent warm air from the room from penetrating into the insulation in winter. When this happens, condensation forms.

Polyethylene film, foil, and roofing felt are used as a vapor barrier. The material is laid over the entire surface in overlapping strips. Insulation of a pitched roof is carried out from the attic side, the insulating sheets are fastened horizontally, the work is carried out from top to bottom.

Places adjacent to all elements, overlaps of canvases, places where pipes pass through the vapor barrier are carefully taped to prevent moisture penetration.

Roof insulation with expanded clay: technology and features

Required tools and materials :

- Vapor barrier;

- Waterproofing;

- Rake used for compacting and leveling;

- Shovel;

- Buckets;

- sharp knife;

- expanded clay

Before insulation, some preparatory work should be carried out. They include leveling and cleaning the covered surface, as well as sealing cracks and cracks. You can read more about roof insulation here.

Flat roof roof pie

If laying is done on metal, it should be cleaned of oxidation products and painted with an anti-corrosion compound .

- The first layer on the base is a vapor barrier. You can use both membrane and ordinary polyethylene films. Using a vapor barrier with one foil side will provide an additional effect of heat reflection into the room. Any vapor barrier material is overlapped and also pulled tight. The joints are glued together with specialized tape .

- Expanded clay insulation is carried out in strips. To do this, guide rails are attached to the vapor-insulated base in increments of 2-3 meters. The thickness of the expanded clay layer must correspond to the calculated value . A smaller layer will not provide the necessary thermal insulation, and a thicker one can lead to the destruction of the load-bearing structure being covered.

- After filling the entire area, the expanded clay layer is leveled and compacted .

- A layer of waterproofing is laid on top of the expanded clay or a cement screed is installed, which improves the strength and rigidity of the structure.

- To assess the quality of the thermal insulation work performed, it is necessary to warm the room to a certain temperature, while closing all doors and windows.

- After a couple of hours, check the thermometer readings before and after. If there is a significant drop in temperature, then you need to inspect the insulated surface for gaps and cracks.

Floor lathing allows you to divide expanded clay into separate cells and serves as joists for the subfloor

Leveling the expanded clay layer using a building level

CAREFULLY!

Laying and compacting expanded clay must be done very carefully so as not to damage the fragile porous elements.

Preparatory stage

Preparation for roof insulation work comes down to removing dirt and carefully sealing all holes. The installation of flooring on a pitched roof and waterproofing on a flat roof are carried out by default according to the basic roofing technology.

Volume calculation

To calculate the volume of expanded clay granules required for insulation, you can use the formula:

V = S x h x K , where

- S - S insulated area;

- h —thickness;

- K is the shrinkage coefficient (for a flat roof 1.2, for a pitched roof - 1.1).

Expanded clay bags indicate the volume in liters. In 1 cubic m includes 1000 l. The resulting volume (V) must be multiplied by 1000 and divided by the liters written on the packaging.

Tools and materials

To work on flat and pitched roofs, in the private sector and on a higher floor, you will need different tools and materials.

Common list:

actual expanded clay insulation;- cement;

- edged board 20-25 mm or plywood;

- timber 25x50 mm;

- vapor barrier;

- windproof membrane;

- adhesive tape;

- rule;

- sealing board;

- screws, slats;

- steel corners;

- reinforcing mesh;

- screwdriver;

- roulette.