The abundance of materials for thermal insulation allows you to choose the best option for each specific case. Along with slab insulation, expanded clay is also often used. This material attracts not only its reasonable cost, but also its environmental friendliness. The versatility of expanded clay allows it to be used for floors, roofs or foundations, but most often it is used for thermal insulation of walls.

Well masonry with expanded clay layer

Expanded clay production technologies

Thermal insulation material is obtained by firing low-melting clay. Under the influence of temperature, swelling occurs and the fractions acquire a porous structure, due to which heat is retained. At the same time, the outer shell is quite strong, which makes it possible to withstand natural influences. Strength characteristics depend on the chosen production method, as well as on the accuracy of the technology. The most common manufacturing methods are:

- plastic;

- wet;

- dry;

- powder-plastic.

Expanded clay production scheme

The most common is the plastic method, the essence of which is to moisten the material. Next, it is dried and granules are formed. The popularity of this method is due to the fact that the result is expanded clay with high quality characteristics.

The wet method is used when the source material has many rocky inclusions, since it allows the raw material to be purified. It is also rational to use this method if the clay is too wet. The dry method is used to work with stone-like raw materials. It is important to use it in cases where the source material has a minimum of harmful impurities.

The powder-plastic method is quite expensive, since it involves preliminary grinding of raw materials, moistening, and then heat treatment. From the resulting plastic mass it is necessary to form granules of the same size, as this affects the final parameters of expanded clay.

To give the material additional characteristics and increase its strength, various impurities are added to the composition. They can be of both organic and inorganic origin. After firing, the granules are cooled and then crushed into fractions of the required size.

Expanded clay production process

Disadvantages of wall insulation with expanded clay

Expanded clay has certain disadvantages, which is why some people refuse to use it, since if installed incorrectly, all the shortcomings are clearly visible and can negatively affect the result of insulation:

- High level of moisture absorption . In the absence of a special protective crust on the granules, moisture is absorbed quite actively. In this case, drying takes quite a long time. The presence of a hygroscopic layer will help solve this problem.

- Increased dust formation . When insulating the facade, it is recommended to use a respirator.

- Reducing usable area . In order for the thermal insulation to be of high quality, it is necessary to lay expanded clay in a thick layer, which can “eat up” part of the room.

- Fragility of granules , due to which mechanical damage is possible during compaction, which leads to deterioration in thermal insulation characteristics.

- The need to use a sealant when insulating to prevent shrinkage and exposure of parts of the wall. This is due to the friability of expanded clay.

Insulating walls with expanded clay has both its advantages and disadvantages.

However, by strictly following the laying technology and purchasing high-quality expanded clay, you can avoid unpleasant moments.

Accessories

Those who grow indoor flowers have probably noticed that some pots have no drainage holes at all. Experts note that this is even very good. Such a pot can be safely called universal, because the number and size of holes can be controlled independently. To make holes for draining water, you need to use the following tools:

- Carefully heat an iron object (for example, a thick nail, awl or knife) over the fire and make all the necessary holes with it.

- Using a conventional drill, drill holes of the required diameter.

Advantages of expanded clay as insulation

The use of expanded clay for insulation allows you to create a comfortable atmosphere in the house and retain heat as much as possible. In addition, the material has the following advantages:

- Durability. The natural origin of the insulation has endowed it with high strength.

- Safety. Expanded clay is an environmentally friendly material and therefore does not harm the health of residents.

- High level of sound insulation.

- Resistance to damage by rodents , as well as resistance to pathogens, fungus, and rot.

- Fire safety . Thanks to the pores inside the granules, expanded clay is not afraid of fire and sudden temperature changes.

- Easy to install . Laying is carried out without the use of additional equipment. If you have basic construction skills and strictly follow the technology, it is possible to carry out the procedure yourself.

Different types of expanded clay

Insulating indoor walls with expanded clay has obvious advantages, but only if high-quality material is used, as well as strict adherence to installation rules.

Exterior decoration

Thermal insulation materials

From the point of view of reducing heat loss, insulating the facade of a wooden house with your own hands is one of the most effective technologies. And here the result largely depends on what material we choose to solve the problem.

You can use a variety of materials for work

The range of insulation materials can be studied in the table below:

| Variety of materials | Features of application |

| Mineral wool and its analogues | Plates, mats and roll insulation based on mineral wool are the preferred material for both external and internal insulation of wooden houses. |

Among the advantages of mineral wool are:

- Good thermal insulation potential.

- Vapor permeability, which allows you to normalize the humidity conditions in the house and protect the wood from rotting.

- Low flammability.

- Hydrophobicity, i.e. minimal loss of heat transfer resistance upon contact with water.

In addition, mineral wool is relatively easy to install, and after installation it is not damaged by rodents and insects, which often live in wooden houses.

The reason is as follows:

- Firstly, the material is inconvenient to install, since during installation you need to pay close attention to protecting the skin and respiratory organs.

- Secondly, loose glass wool is easily compacted, losing a significant part of its thermal insulation properties.

- Thirdly, the material “cakes” quite quickly, so that literally after a few years voids will appear in the thermal insulation layer of glass wool.

However, if you do not take into account the price, synthetic insulation is inferior to mineral insulation:

- Firstly, both polystyrene foam and polystyrene are vapor-proof, so when using them as wrist insulation there is a risk of wood rotting.

- Secondly, the materials (especially cheap foam) are highly flammable.

- Thirdly, their service life is relatively short, in addition, they often suffer from rodents.

Types and quality of expanded clay: which one to choose?

Thermal insulation technology, first of all, depends on the selected type of insulation. Expanded clay is presented on the construction market in the form of gravel, sand and crushed stone. Each type has a different fraction size and varies from 2 to 40 mm.

Gravel

Expanded clay gravel

has the largest grains . In turn, it is divided into three types:

- 5-10 mm;

- 10-20 mm;

- 20-40 mm.

The level of thermal insulation depends directly on the size of the fraction, so to use large expanded clay for wall insulation Expanded clay gravel is used not only for thermal insulation of floors, but also for heating mains.

Sand

Expanded clay fine fraction

In this case, the fractions have minimal sizes - up to 5 mm . It is rational to use such expanded clay for insulating interior partitions and floors. In addition, expanded clay sand is often used as a filler in the production of ultra-light concrete. It is important to use this particular type in order to reduce the weight of the finished structure.

Crushed stone

Formed by grinding expanded clay gravel . Together with other types it is used in the production of lightweight concrete. As for the thermal insulation characteristics, they are lower than those of gravel.

Alternative materials

Today, making drainage for flowers with your own hands is quite simple. To do this, it is enough to use available materials that can be found in any home:

- Aquarium stone. Such stones are considered a good alternative, but they are quite expensive. But if such material is available, then it must be used.

- Gravel and crushed stone. Draining the soil with such material is considered a very common solution. The only drawback is that such elements significantly increase the weight of the pot. Gravel and crushed stone are especially appropriate if they are used for small containers that do not need to be moved frequently.

- Broken brick. This is one of the most budget options. Such material is considered natural, due to which it brings only benefits to the plant. But before you send the brick particles into the pot for color, they need to be sharpened so that the sharp edges do not injure the root system of the plant. It is also worth considering that white brick is more suitable for drainage than red brick.

- Styrofoam. This material perfectly replaces the elements familiar to everyone. But you can’t crumble it: the foam needs to be cut into small cubes, which are evenly placed in the pot. The only disadvantage is that the root system often entwines such drainage material, which is why it is then subjected to injury.

When choosing the most suitable drainage for indoor plants, you need to remember that it must be safe for the plant itself. Only in this case will the flower develop quickly, delighting with its beauty and freshness.

https://youtube.com/watch?v=REUAmx3LIEI

How to count expanded clay?

Before you begin insulation, it is important to calculate the amount of expanded clay needed. The required thickness of the insulation layer will depend on:

- characteristics of thermal insulation material;

- climatic features of the region;

- wall material.

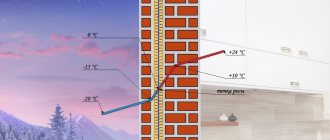

When thermally insulating walls or insulating the foundation, you should take into account:

- thermal conductivity: for expanded clay the indicator is 0.17 W/m * K;

- minimum thickness – 200 mm;

- the ratio of the wall thickness to the thermal conductivity coefficient of the material from which it is made, the so-called thermal resistance.

Next, a calculation is made depending on the surface area that should be insulated. Experts recommend entrusting this process to professionals, but today there are special online calculators that allow you to carry out the calculations yourself.

Technology for insulating a brick wall with expanded clay

The most common use of expanded clay is in three-layer structures. The fractions are poured into the frame, so it is important to understand that the insulation process should take place precisely at the stage of wall construction. There are 3 main methods of thermal insulation.

Lightweight well masonry

Lightweight well masonry

A structure is constructed from two rows of bricks, the space between which is filled with a heat insulator. This happens as the wall is being built. When falling asleep, compaction occurs. In order to prevent subsidence, a special cement mortar is used to bind the fractions. It is important to tie every 1-2 rows of bricks using jumpers. The distance between the rows should be approximately 15-30 cm. However, this parameter can be increased, especially for cold regions.

Well masonry with stiffening diaphragms

Transverse diaphragms in well masonry

With this technology, a frame is also constructed, and the outer wall can be made not only of brick, but also of concrete or ceramic blocks. The heat insulator is filled in after 5 rows of masonry. Compaction and filling with cement laitance takes place. After this, the stiffness diaphragm is laid out. It is laid over the entire thickness of the wall, so in the future, when the expanded clay shrinks, it will be impossible to get inside and add insulation. This is the only drawback of the described technology. As for the advantages, this design allows you to add rigidity to the height, while avoiding the use of anchors for dressing.

Masonry with embedded parts

Anchoring brickwork with steel rods

The process is similar to lightweight masonry, the only difference is the use of anchors . They can be either metal or metal-plastic. With this method, the consumption of bricks is reduced, while the strength characteristics of the structure remain high. The optimal gap for backfilling is 30-50 cm. It is at this distance that it is easier to tamp and fill with cement mortar.

Preparatory work

Before installing the insulation, it is necessary to lay waterproofing. It will protect expanded clay from excess moisture. To do this, you can use regular plastic film. After laying it, the edges are fixed with construction tape.

It is better to use expanded clay when insulating a new building, when its construction is just underway. In this case, three-layer masonry is used. Each layer is associated with certain characteristics. The load-bearing layer is made using expanded clay concrete blocks with a thickness of 20 to 40 cm. For the main layer, granulated expanded clay and cement laitance are used. The last layer is represented by wooden, panel or brick protection.

Before laying the heat insulator, it is doused with cement laitance. At the same time, individual fractions set faster, and as a result, the entire layer as a whole hardens faster. Installation requires many tools. The work is carried out using a trowel, which is used by masons, a mortar shovel, a hammer, and a chisel. When performing work, you cannot do without levels and plumb lines, and a measuring tape. In addition, it is necessary to prepare a container in which the solution is mixed.

Technology of wall insulation with expanded clay

In addition to the three main methods, there are others that are used for walls made of other building materials or in cases where the building has already been erected, but external insulation is required.

| Surface type | Insulation option |

| Aerated concrete | When a building has already been erected, it is necessary to build an additional wall from facade material, and fill the resulting gap with insulation. As with any other option, compaction and impregnation are mandatory. Ventilation gaps should also be left to protect against dampness. |

| Frame walls | Here, expanded clay is not an ideal option, since it can cake and leave parts of the surface without thermal insulation. This can be avoided by careful compaction, but this must be done carefully to avoid damage to the frame. |

| Tree | This heat insulator is rarely used for insulating wooden houses, since the wall cannot withstand such a load. To solve this problem, it is necessary to build an additional foundation. From an economic point of view, this is unprofitable. |

In addition to walls, due to the cost-effectiveness of the material, many prefer to insulate floors and attics with expanded clay.

Inter-crown seal

Before we begin covering walls made of logs or timber with materials with low thermal conductivity, we need to put the walls themselves in order, providing them with maximum protection from thermal energy loss. For this purpose, seams are sealed using various materials.

For caulking a log or timber wall, the following can be used:

- Moss is a natural material characterized by good hygroscopicity and good heat-saving ability. Caulking walls with moss is a traditional technology, but it is still quite labor-intensive, so it is used relatively rarely.

Caulking crowns with moss

- Jute is a natural fiber that is sometimes impregnated with antiseptic components. Most often, jute tapes are laid between the crowns when building a log house, but it is also suitable for secondary compaction.

- Tow is another material used to insulate seams in a wooden house. Like previous types of insulation, tow resists energy loss well; in addition, it holds well inside the gap between structural parts.

The process of caulking the crowns itself is quite simple: we place the selected material in the seam between the logs and hammer it into the cavity using a special wooden or metal spatula, which we hit with a mallet. The higher the density of the clogged material, the more reliably we will protect the room from drafts and heat loss.

Arranging a “warm seam”

Separately, it is worth mentioning such technology as insulating a wooden house with a warm seam. When implementing it, cords made of extruded polymer (polyethylene is most often used) are laid in the gaps between the rims, as well as in large cracks, after which the cavity is filled with acrylic sealant.

When the sealant polymerizes, the seam becomes impenetrable to moisture and air, which has a positive effect on the microclimate in the house.

Note! The use of wood sealants with pigment additives can improve the appearance of the building by emphasizing or, conversely, masking the seams between the crowns.

Calculating the thickness of insulation for the roof

Ceiling insulation with expanded clay

To insulate the roof, it is best to use expanded clay gravel, since sand is too heavy and crushed stone has sharp edges. The thickness of the insulation in this case will depend on a number of factors:

- architectural features;

- roof shape;

- design.

Calculations are carried out separately for each specific case, but the layer should not be less than 25 cm. In this case, the total thermal insulation layer will be larger, since it is additionally necessary to install a layer of vapor and waterproofing.

The minimum thickness can be increased, but it is necessary to take into account what load the structure can withstand.

Advice from the experts

Let's consider some recommendations that experienced builders give when working with expanded clay:

- When working with insulation, it is better to use a respirator, as the material is very dusty.

- Buy expanded clay in bags. This will not increase its cost much, but will simplify installation.

- Work in warm weather. Expanded clay quickly absorbs moisture. It is better to store it under a canopy, in a ventilated place.

- One of the cheapest insulation options: a combination of coarse expanded clay with foam chips.

Use insulation from one manufacturer. It is better to take insulation with a small reserve than to later buy additional insulation from an untested place.

Insulating the floor: calculating the thickness of expanded clay

When thermally insulating a floor, it is important to take into account the material from which it is made, since the thickness of the layer will depend on this:

- 40 cm or more – for wood;

- 30 cm – for concrete.

To insulate floors between floors, the layer will be half as large. Also, when calculating the thickness, it is important to take into account the load on the floor. Having decided on the layer, you can calculate the required amount of expanded clay to insulate 1 m². Then the resulting figure should be multiplied by the floor area and you will get the volume of expanded clay that will be required for thermal insulation.

Using expanded clay for insulation allows for significant savings, but this is only possible if all requirements for its installation are met, as well as when using exclusively high-quality material with high thermal insulation properties.