Owners of summer cottages and private houses who grow fruits, berries and vegetables often build a greenhouse made of polycarbonate. These structures are necessary to create suitable conditions for crops sensitive to sub-zero temperatures. If you plan to use a greenhouse all year round, then you need to know how to insulate it for the winter.

If you skip this procedure, it will be quite cold in the greenhouse, the ground will freeze very much and there is a high probability that the seed sown in the fall will not sprout in the spring. You can insulate a structure in several ways, the difference between which is in the degree of execution, the cost of labor and financial resources.

Place for a greenhouse

Initially, you need to choose a good location for the greenhouse - this will help retain more heat and, accordingly, reduce heating costs.

The main nuance here is sunlight. A good place is open to light and free penetration of heat. It is advisable to place the structure in a place protected from the wind: for example, attach one side closer to the house or other building - the wind will not chill or cool it. Near trees or a high fence, the greenhouse should be placed not along, but with the end facing them. It is imperative to take into account where the wind most often blows in the area. An excellent option would be to place the structure like a winter garden: between two stationary walls, but at such a distance that they do not block the sun.

The place should be illuminated by the sun from morning to evening. If the greenhouse is used starting in the spring, then its orientation does not matter. It is advisable to place structures in the northern regions with the ridge directed from east to west (latitude orientation); in the middle zone, it is recommended to place the long side from north to south (meridian orientation).

Profitability

Experts estimate the average profitability of a winter greenhouse at 20%.

When growing flowers and herbs, it reaches 30% and higher, the profitability of vegetable greenhouses is no more than 15%.

Payback periods depend on the size of greenhouses and the level of demand.

To get the maximum benefit from your greenhouse business, you must:

- Choose the right crop to grow. Undemanding greens are suitable for novice farmers; flowers or strawberries are suitable for more experienced farmers. Vegetables should only be grown in regions with a temperate climate and low competition.

- Build a high-quality greenhouse that will not require annual repairs. Structures made from decommissioned double-glazed windows are not suitable for business. Consider the issue of lighting and heating.

- Choose a growing technology. Soil technologies are too expensive, and consumers do not like crops grown hydroponically. A compromise option is hanging growing or shelving technologies. The soil layers are placed in tiers, each equipped with lighting and an irrigation system. Strawberries can be grown in special mats placed in vertical or horizontal plastic sleeves.

- Control the composition of the soil. The greenhouse business requires frequent replacement of the soil; with continuous cultivation and dense planting, it is quickly depleted. It is necessary to apply fertilizer every 2 weeks.

- Use varieties cultivated for growing in greenhouses. They are disease resistant, have a short growing season and excellent yield. It is recommended to focus on the 2-3 most popular varieties, excluding constant experiments with new products.

A greenhouse business can become successful and provide the owner with a constant profit

In order not to be disappointed, it is important to analyze your capabilities long before the start, draw up a detailed business plan and think through the issues of product sales

Microclimate support system

An all-season greenhouse model must have a system for maintaining an optimal microclimate for plants, in hot and cold weather.

Greenhouse heating

Various types of heating systems are used to heat rooms:

- Electrical - imply that the building has the ability to connect to the electrical network. They are represented by all kinds of convectors, fireplaces, etc.

- Stove rooms are located at the entrance and imply the presence of a high-quality supply and exhaust system.

- Water - are a water heating tank that transmits heated liquid through a system of pipes located along the entire perimeter of the building.

- Gas - are gas burners and heaters.

- Air - involves laying a hose that supplies a flow of warm air around the entire perimeter of the greenhouse. Such a system can heat an area of any size in a few minutes, but it reduces the humidity too much.

- Infrared - represented by appropriate heaters and lamps. This system does not dry out the air and is economical in energy consumption.

Important! In order to avoid the spread of fungal diseases, immediately after completing all work, it is necessary to carry out a final disinfection treatment of the finished greenhouse with an antiseptic

Soil heating

Heating the soil is best done biologically. To do this, even before starting construction, 30–40 cm of soil is removed throughout the entire territory. Then add 10 kg of fresh mullein, or even better horse manure, and compost for each 1 m². After this, the removed soil is returned to its place. When overheated, biomaterials will release heat and warm the soil to the optimal temperature.

Irrigation system

When equipping an irrigation system, you need to understand that regardless of the source of water supply, it must first be prepared for use:

- defend;

- warm up to ambient temperature;

- if necessary, add mineral fertilizers or soften.

In this regard, you will have to take care not only of connecting to a water source, but also of the presence of storage tanks, as well as a supply system. As a source, you can use a water supply or a well equipped with a pump. The type of irrigation system is selected according to the type of plant.

In total, there are 4 types of irrigation systems:

- drip;

- sprinkling;

- fogging;

- flooding.

In greenhouses intended for private use, watering and irrigation can be done manually.

Lighting and shading

In the autumn-winter period, most crops will have to be illuminated. The optimal length of daylight for plants is 10–14 hours.

Suitable for additional lighting:

- gas-charging sodium lamps (DNaT, DNaZ) - suitable for large premises; to connect them, you must first equip a trigger mechanism;

- mercury lamps (DRI, DRIZ) - not entirely safe due to the toxicity of the mercury contained inside;

- fluorescent lamps - most plants respond positively to additional illumination with such equipment;

- LEDs - lamps do not heat up when connected, so they can be located in close proximity to the plant organism, but have a high cost;

- night lighting lamps are lamps of the green spectrum, the light of which the plant organism does not perceive as daylight, and therefore is at rest; they are advisable if you need to carry out agricultural work in the greenhouse in the evening.

Vegetables with reduced daylight hours and most flowers require shade. For this purpose, curtains, vertical or horizontal, are organized in greenhouse buildings. The first type involves curtaining the walls with a thick, light-proof fabric, the second - the ceiling.

Heating without loss: a practical and inexpensive way to insulate the base of a greenhouse

The choice of method depends on the location of the structure on the site and the financial capabilities of the summer resident. The price includes the purchase of consumables and the cost of maintaining the internal temperature.

The following heating methods are used:

- Water. The most labor-intensive method requires the installation of a concrete base on the floor of the greenhouse into which the pipes are laid. It is beneficial if it is possible to connect greenhouse pipes to the heating of the house. Installation of water heating requires the involvement of builders.

- Infrared. Emitters are installed on the frame of the greenhouse, creating different temperature zones for plants. Uniform heating is achieved by installing heaters around the perimeter. The installation height is changed as the planted crops grow.

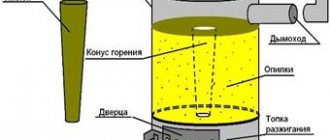

- Solid fuel. A stove burning coal, wood, sawdust briquettes, etc. is installed in the greenhouse. The disadvantage of this method is the uneven distribution of heat and the need to install a chimney.

Installing heating will allow you to grow vegetables on your site even in winter.

The fastest way to insulate greenhouses with improvised means is plastic bottles of water. But you can use it in the off-season; it will not help protect against frost.

In winter, you can use the following as additional heating:

- high beds with insulation of the lower layer;

- laying cables along the beds;

- gas heating (gas heaters, injection infrared heaters);

- soil chimney (the stove is located outside the greenhouse, the chimney is placed in the soil);

- catalyst burners.

There are various ways to heat the interior space, we will look at the main ones.

Water heating. Water heating in most designs is realized through heating boilers. If the heated greenhouse is small, you can limit yourself to heating devices on only one side of the room. There will be enough convection currents. The advantage of water heating is that it is safer than electric or gas. It is also worth considering that the specificity of polycarbonate is that it does not tend to collect moisture on the walls in winter. This way, moisture will naturally return to the ground.

- Infrared radiation. One of the advantages of infrared heaters is convenience. There is no need to monitor the stove or add firewood. The air is heated evenly. Infrared heaters do not take up much space and are easy to install. Cons: high cost of equipment and installation.

- Gas heating. We produce special gas equipment that is designed for use in greenhouses. A significant disadvantage is that it must be connected to the general gas supply system, which means that this requires a special permit. Of course, you can use cylinders, but you can go broke pretty quickly on cylinders. One is not enough even for a month.

- Electric heaters. The most ineffective option. A conventional electric heater is unlikely to cope with even the smallest greenhouse, and using more electrical appliances will cause excessive load on the network. And the electricity bill will be impressive.

In the process of insulating a structure, it is important to take into account not only the technical characteristics of future heating systems, but also factors that you may simply not pay attention to at first. This applies, for example, to the installation location of the future greenhouse

It should be remembered that when preparing a greenhouse for winter, first of all, you should focus on creating a favorable microclimate for future plants.

If thermal insulation is carried out in accordance with all requirements and technical regulations, you can increase the productivity of the greenhouse by 100% or more. How to insulate during the cold season is everyone’s personal choice. It depends on financial capabilities and availability of time. But if everything is done correctly, the greenhouse will produce fresh crops all year round.

To learn how to insulate a greenhouse, see the following video.

Installation of a water floor

Before installing a water heated floor, you need to remove a small layer of soil (approximately 40 cm). Some craftsmen recommend removing a smaller layer so that eventually a layer of soil rises above the floor surface. This will greatly facilitate the process of caring for crops. In addition, the soil will receive additional air heating.

Laying a water-heated floor in a greenhouse

Next, you need to perform several steps in the same sequence in which they are listed below.

Heated floor pipe circuit length calculator

Go to calculations

- Compacting the site. It is advisable to walk around the entire perimeter with a roller or compact it with your feet.

- A layer of sand (approximately 8-10 cm) is laid on the compacted surface. Before falling asleep, the sand must be cleared of various shells and pebbles.

- Watering the sand layer. The use of water is required to compact the material. Also, after watering, air bubbles will not appear on the floor.

- Installation of the mounting grid. This is required for subsequent fixation of the heating elements. Thanks to the installed mesh, all elements can be fixed in the desired position.

- Installation of hoses or cables. This is an important stage, since the efficiency of the heating system will depend on the correct installation of the cable. The cable should cover the maximum amount of area, so it is recommended to lay it in a snake pattern.

Pipes for water heated floors

- Installing a temperature sensor. The type and dimensions of the sensor, as well as its installation location, are selected individually.

- Output of all control and power wires.

- Laying the second layer of sand and its subsequent watering. The thickness of the sand layer should also be from 8 to 10 cm.

- Installing a protective mesh and laying a 25 cm layer of soil. The mesh is an important element of the underfloor heating system, since it will protect the heating elements from mechanical damage.

- Connecting a temperature sensor. With its help it will be possible to regulate the temperature of the water in the system. This is the last and most difficult stage of installing a water floor in a greenhouse.

With a warm floor, plants in the greenhouse will be more comfortable

What you need to know about greenhouse construction

An earthen greenhouse is literally sunk into the ground. Part of it is located below the soil surface. Since in temperate latitudes, even in frosts at a depth of 1 m, the earth maintains a positive temperature, plants in such a greenhouse can be grown in winter with a full harvest. “Dugout” is intended for year-round farming. It is appropriate for regions with slight soil freezing and areas with low groundwater levels.

There are two types of dugouts:

- Underground greenhouse. “Planted” to a depth of 1.5 m. Involves supplying stairs and creating passages between the beds.

- Recessed greenhouse. The beds are placed only 50-80 cm below the ground surface. Not as warm, but easier to build. Provides easy care of plants with the help of an opening roof.

The most common shape of a recessed thermos is a rectangle. The roof is made of film, glass, polycarbonate. The frame of the structure is made of metal profiles or wooden beams

As in a regular greenhouse, it is important for crops to receive solar heat, so the roof must be made and placed correctly

Preliminary information

Requirements for planted crops

- expediency;

- rationality;

- profitability.

So, expediency.

Do you need this or that culture? And where will you put the surplus if it is formed due to incorrectly planned planting volumes? Rationality implies the correct determination of the timing and volume of planting, and the use of optimal agricultural techniques. When choosing a crop, it is necessary to determine in advance how realistic the owner’s capabilities are to create optimal conditions for growing a given sample.

Expediency and rationality are also ensured by the correct choice of the variety of crop being grown. By correctly selecting the design and arrangement of the greenhouse, and rationally planning the change of plants in the greenhouse bed, you can achieve effective year-round operation of this green conveyor.

Recent posts Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives make Secrets of growing seedlings from the Japanese, who are very sensitive to the soil

There is probably no need to explain what profitability is. This criterion is important for those who decide to make income from the greenhouse. Greens and flowers, in terms of profitability, are almost the same. But greenery is the solution to the problem of winter vitamin deficiency, flowers are bright shades in the autumn and winter landscape, joy and a peaceful atmosphere in the house.

Classification of crops

Crops grown in greenhouses can be divided into types:

- greenery;

- vegetables;

- roots;

- fruits;

- berries;

- medicinal plants;

- flowers and other ornamental plants.

When organizing a rational process, plants planted in greenhouses are classified into the following groups:

- Predecessor crops, which serve as early-ripening cold-resistant vegetables and herbs. Examples: early carrots (early), radishes, spinach, dill.

- Main crops. They can be tomatoes and cucumbers, sweet peppers and eggplants.

- Intermediate crops serve to fill the space not occupied by the main plantings. As it grows and develops, the main culture gradually replaces the intermediate one. This technique ensures rational use of greenhouse space.

- Winter crops. Examples: sorrel, chicory, parsnip.

In addition to plant foods, medicinal and ornamental plants can be grown in a greenhouse. Both for yourself and, especially, for sale. Examples: roses and peonies, dahlias, nasturtiums, asters.

Foundation and beds

There is an opinion among gardeners that to create a greenhouse it is not necessary to make a foundation, since it has a small mass and does not need one. This point of view is erroneous, since a prepared base is one of the most effective methods of protecting against soil freezing.

Concrete foundation for a greenhouse

Heat loss will be minimal in the following cases:

- Arrangement of a strip monolithic foundation with insulation. To insulate the structure, polystyrene foam is usually used, covering it with sheets of material.

- Creating a base from timber. It must first be treated with antifungal substances and protected from the negative effects of moisture.

- A concrete foundation is more expensive, but it ensures maximum durability of the entire structure, and when insulated, it protects the soil from freezing. The pouring depth is on average 40-60 cm, the indicator directly depends on climatic conditions. Expanded polystyrene sheets are attached to the bottom of the base and from the outside; for greater reliability, the material is used to cover the tape after removing the formwork.

In addition, it is worth setting up high beds in the greenhouse itself: they are raised to 35-40 cm, and the ground below is covered with a layer of compost.

Simple ways to insulate a greenhouse for the winter

Cultivated plants are grown in polycarbonate greenhouses all year round.

If a summer resident is faced with the task of how to insulate a polycarbonate greenhouse with his own hands, and not how to warm it up before sowing crops, you can resort to simple methods. They are used at the initial stage of its construction or during operation, while the effect remains the same. However, they differ in:

- investment cost;

- efficiency;

- execution speed.

The most important moment is sealing, since the main part of the heat escapes through joints, cracks and holes. In this case, silicone sealant is ideal for cellular polycarbonate. Its cost is quite high, but considering its efficiency and service life, such costs are justified. Taping is effective only if it is for construction purposes (not for painting or office supplies). Interesting article “Greenhouse heating systems and projects.”

The first involves installing a U-shaped polymer profile on the edge. If this is not the case, you can use construction mastic or a viscous sealant to seal the edges. This will partially solve the problem: how to insulate the greenhouse for the winter. This method is sufficient if in winter the temperature outside does not drop below +5. Otherwise, more effective methods must be used.

In winter you cannot do without a heating system.

If the task is how to insulate the soil in a greenhouse before sowing, then you can resort to the use of organic and inorganic fertilizers. Compost that does not contain plastic residues, as well as horse manure mixed with straw, are ideal for this purpose. You should not use hay for this, as you can infect the ground with cereal weeds. As an alternative, it is better to use sawdust. The mixture is poured in a layer of up to 40 cm. To prevent the development of bacteria and fungi, it is worth using quicklime with a consumption of up to 300 g/m. sq. Plants cannot be planted in such a nuclear mixture, so after warming up the compost is covered with a layer of soil.

Internal insulation work

Insulation and treatment of joints do not always solve the problem of heat preservation - the cold still penetrates through the greenhouse material itself, no matter how high-quality it is. Its windows must remain transparent, so coatings that transmit light well are used for internal insulation.

The standard method is to line the space from the inside of the structure with plastic film: a glass/air/film layer is formed that will prevent heat from escaping. Polyethylene is also used externally in the same way.

Installation of an additional layer

In addition to polyethylene, you can use another layer of polycarbonate; sheets of thinner thickness than those that make up the greenhouse are suitable. In this case, a three-layer coating is formed: two layers of material and a layer of air. The standard thickness of external sheets is 16 mm, internal - 4 mm.

You should know that simple polycarbonate does not hold heat well. For greenhouses, the ideal material would be cellular polycarbonate - it works much better as an insulator. Sheets of this material are easy to cut, drill, and are quite flexible.

A few nuances of installing an additional layer:

- the hole to be drilled must be at a distance of at least 40 mm from the edges of the sheet - this way the material will not crack;

- the hole should be 1-2 mm larger than the thickness of the screw;

- For fastening it is better to use a special thermal washer; you can make it yourself. It consists of a sealing washer (made of rubber material), a plastic washer, a self-tapping screw (sold separately), and a thermal washer cover.

Biological method for heating polycarbonate structures

Self-heating substrates will help here. Otherwise they are called biofuels. Every summer resident knows that when organic matter decomposes, it releases heat. This property should be taken advantage of. The classic in this case is horse manure. It decomposes quite quickly and heats up just as quickly (on average up to 60°C). If it (or any other manure) is placed in the beds at a distance sufficient to ensure that it does not burn the roots of the plants, then it provides not only heating, but also nutrition. For these purposes, it is recommended to use horse, sheep, rabbit, pig or cow manure.

If liquid fractions are used, sawdust, husks, firewood or any other suitable filler must be mixed with them. You need to stock up on organic matter in advance: based on the greenhouse according to the following conditions:

a pit with a depth of half a meter to 60 cm is formed; optimal width -1.5 m; Cooler manure is placed on the bottom, hotter manure is placed on top; It is important to maintain the thickness of the organic layer. It depends on the season: if laying is done in early spring (February-March), then a thickness of 50-60 cm will be required

If later – 30-40 cm; organic matter is compacted and covered with heat-insulating materials: glass, wood, etc.; the manure needs to settle within a few days; Soil is laid on top and plants are planted.

Typical construction

To make a polycarbonate greenhouse correctlyTo make a polycarbonate greenhouse correctly

To install a greenhouse, you should choose a flat, well-lit area away from buildings and trees. It is better to avoid a place with high soil moisture.

Construction is carried out in several stages.

Foundation

The sequence of work is as follows:

- Markings are made along the entire perimeter of the future greenhouse and a trench is dug 0.2 - 0.3 m wide and 0.7-0.8 m deep;

- a layer of sand 0.2 m thick is poured onto the bottom, which is then carefully compacted;

- for waterproofing, roofing material is laid on the sand cushion;

- a reinforcement cage is mounted: rods are laid at the top and bottom of the future foundation and connected to each other by transverse sections of reinforcement;

- formwork is installed, which should be 0.2 - 0.5 m above ground level;

- concrete is poured;

- insulation is carried out with polystyrene foam, a blind area is made.

The height of the formed base is determined by personal preference.

Walls

The sequence of work depends on the type of material used. If you plan to install a finished factory-made product, follow the instructions.

The assembly of the wooden frame begins with a beam of the bottom trim, laid on the base. All timber must be treated with special agents to prevent rotting. The vertical racks are installed in such a way that the edges of the polycarbonate sheets rest on them.

Having installed the vertical posts, check their spatial location and secure them with braces. If the greenhouse is long, several intermediate posts should be provided.

Main walls are laid in one brick. Window openings are formed at a height of 0.5 - 0.75 m from the ground level, maintaining a distance of two to three bricks between them (0.5 m or 0.75 m). The frames installed in them must have transoms to ensure ventilation.

Roof

The gable roof has become most widespread due to the possibility of free flow of atmospheric water. The roof planes have an inclination angle of 20 – 25°. Laying of the lower strapping beams with a section of 120 by 150 mm is carried out along the side walls on the roofing paper. The fastening of the ridge (made from timber of the same size) to the strapping is carried out using paired rafters. For the latter, you can use timber measuring 70 by 100 mm.

Traditionally, double glass with a thickness of at least 4 mm is used to cover the roof. Glazing is carried out using 40 x 75 mm grooves with the formation of gutters for condensate drainage. However, recently, roofing work is more often carried out using cellular polycarbonate. The latter is characterized by lighter weight and ease of installation work.

A greenhouse built using it can last at least 12–15 years.

Tillage

You can insulate the soil with your own hands using heat-insulating material. It is used to separate the cold from the top layer of the earth, which will be heated by light and air. It is better to start preparing the soil in the spring, when it has already warmed up sufficiently. Typically, twigs, shavings, sawdust, planks, etc. are used as heat-insulating material.

The described biological heating functions as follows.

- First, organic substances begin to decompose under the influence of natural processes. At the same time, thermal energy is released.

- The heat rises, simultaneously heating the soil.

- It is worth noting that instead of natural material, you can use artificial one. For example, you can insulate the soil with penoplex.

Period of use

To determine what type of industrial greenhouse needs to be installed, you should determine the temporary period of operation of the structure. Two types of industrial greenhouses can be distinguished.

A seasonal greenhouse is suitable for use in the warm season. In the spring, pre-prepared seedlings are planted in the greenhouse, and as they ripen, the harvest is harvested.

The frame of the greenhouse complex is made of durable materials that can withstand frost. To preserve the fertile properties of the soil in the greenhouse in winter, it is recommended to cover the ground with snow.

A year-round production greenhouse makes it possible to generate profits throughout the year. Compared to a seasonal type of structure, such a greenhouse complex requires large financial investments.

The basis of a year-round greenhouse should be a strong foundation that eliminates the possibility of the ground freezing. You will also need to install a heating system and place powerful lighting fixtures. The profit from growing fresh vegetables and fruits, flowers and berries will be many times greater than the initial costs.

Greenhouse insulation with polystyrene foam

In recent years, polycarbonate structures have become widespread. To insulate the soil in them, experts recommend some modern materials, including extruded polystyrene foam. In the construction industry it is used for thermal insulation of various structures. Excellent thermophysical properties make it suitable for insulating soil in a greenhouse.

From the point of view of arranging a greenhouse, polystyrene foam structures have the following undeniable advantages.

- Low thermal conductivity. Compared to the more common polystyrene foam, this figure is half as high. Thus, it is possible to maintain a stable temperature regime inside the greenhouse. As a result, the fertile soil layer also warms up.

- Little moisture absorption. Accumulating condensation can cool the ground. Insulating the greenhouse with expanded polystyrene slabs helps minimize this effect. Moisture can only accumulate in the upper layers of the material; thanks to the structure with very small pores, it does not penetrate into the depths.

- Long service life. By insulating the greenhouse structure with polystyrene foam boards, the problem of soil freezing can be solved for many years to come. The material can even be laid on the ground, which is especially important for insulating the fertile soil layer. From it you can construct a kind of air cushion, by analogy with the layer of brick described above. The compositional features of the material allow it to maintain a stable shape and characteristics.

Thus, the problem of soil insulation can be solved in several ways. Our specialists will help you choose the most suitable option for a particular site from all points of view.

How professionals work

Proper sealing of joints for a polycarbonate greenhouse is a guarantee of durability with reasonable use. Professionals successfully use thermal bonding for such work - it is reliable, practical, and aesthetically pleasing.

Two sheets of polycarbonate are heated simultaneously, as indicated in the instructions for the device, and then they are automatically connected by soldering

When working, it is important not to deviate from the recommended temperature regime. With this type of fastening, gaps should be provided to ensure the drainage of water - rain, melted snow

With this type of fastening, gaps should be provided to ensure the drainage of water - rain, melted snow.

For home work, this method is not optimal, as it requires certain skills and special equipment. Of course, this is not a reason for despondency - there are always alternatives.

Connecting individual polycarbonate sheets using a profile, glue or point fastening is simple and accessible to everyone.

Place for a greenhouse

Initially, you need to choose a good location for the greenhouse - this will help retain more heat and, accordingly, reduce heating costs. The main nuance here is sunlight. A good place is open to light and free penetration of heat.

It is advisable to place the structure in a place protected from the wind: for example, attach one side closer to the house or other building - the wind will not chill or cool it. Near trees or a high fence, the greenhouse should be placed not along, but with the end facing them. It is imperative to take into account where the wind most often blows in the area. An excellent option would be to place the structure like a winter garden: between two stationary walls, but at such a distance that they do not block the sun.

The place should be illuminated by the sun from morning to evening. If the greenhouse is used starting in the spring, then its orientation does not matter. It is advisable to place structures in the northern regions with the ridge directed from east to west (latitude orientation); in the middle zone, it is recommended to place the long side from north to south (meridian orientation).

Design Features

A trench greenhouse is a structure with solid walls, buried to the depth of soil freezing. This feature allows you to use the heat accumulated in the soil over several cold months.

The walls of the greenhouse are made of heat-intensive materials and are insulated from the outside to avoid cooling from the upper freezing layers of the soil. Additionally, the soil is protected from freezing using an insulated blind area around the entire perimeter of the greenhouse.

The roof can be of any shape - arched, gable or pitched. It is covered with two layers of polycarbonate with insulation of the air space between them or frames with double glazing. When the greenhouse is oriented from west to east, the northern slope of the roof can be sewn tightly to reduce heat loss.

The entrance to the greenhouse is located at the end and is equipped with an insulated vestibule. To descend into the greenhouse, a staircase is made in the vestibule. You can also place heating equipment or a storage room for storing tools and planting material - tubers, cuttings and bulbs.

The recessed greenhouse is equipped with a forced supply and exhaust ventilation system. For this purpose, plastic pipes and built-in fans are used. When using glazed frames, some of them can be made to open - in the summer this will help avoid overheating.

Fans for forced air exchange in a greenhouse

In the southern regions, in a trench greenhouse in winter the temperature does not drop below zero even without additional heating. In temperate latitudes, during frosts it needs to be heated. A stove, electric heaters or a water boiler can be used as a heating device.

Stove heating of a trench greenhouse

Effective heating can be achieved by laying a heating cable or water heating pipes in the ground. The heated soil is capable of releasing heat into the greenhouse space for a long time and warming the air.

Scheme of soil heating using an electric cable

Plants in a trench greenhouse can be placed either on beds or on racks. The beds are made of brick or concrete blocks - the walls are an additional heat accumulator. The height of the beds is made within 0.8-1.2 m so that the plants receive enough sunlight. Fill with organic components to obtain the effect of a warm bed and additional heating.

When growing plants on shelves, it is better to concrete the floor, having previously laid waterproofing and insulation boards underneath it. In this case, it is better to place additional heating under the shelving.

Growing container plants and seedlings in a trench greenhouse

Energy saving screens

Horizontal curtain systems for greenhouses at night are another way to retain heat. A heat shield made of aluminum fiber fabric (ALUMINET) prevents the cooling of greenhouse structures. Under the influence of reflective components (aluminum has a high heat-reflecting ability), the infrared heat of the earth accumulated during the day is returned back to the greenhouse. When using screens with aluminum elements, heating costs are reduced - 50% energy savings are achieved. The greenhouse can be left covered with a heat-reflecting screen for 16 hours, since daylight hours in winter are only 8 hours.

There are other screens with a lower percentage of energy savings. For example, diffuse or shading curtains (such as LS 10) save 40% of energy, and film curtains save 30%. Polyethylene screens are installed permanently.

Horizontal shading is installed in separate sections under the roof of the greenhouse. All sections of the screen are driven synchronously by a special curtain mechanism - a cable drive or rack and pinion drive is used for this. There is also vertical shading, but it is still less common.

Automated curtain systems are suitable for industrial-scale greenhouse structures, and for small greenhouses you can design a screen yourself that will work on the principle of a roller blind. The heat-insulating material is attached to a horizontal shaft (aluminum pipe) with a drum mechanism and wound into a roll. Fastening elements are installed on the other end of the canvas. The shaft with the roll is fixed under the ceiling of the wall opposite to the entrance. As needed, the canvas is unwound under the surface of the greenhouse in approximately 1 m increments. All components of such an energy-saving roller blind can be found freely available at any hardware store.

Place for a greenhouse

Initially, you need to choose a good location for the greenhouse - this will help retain more heat and, accordingly, reduce heating costs. The main nuance here is sunlight. A good place is open to light and free penetration of heat.

It is advisable to place the structure in a place protected from the wind: for example, attach one side closer to the house or other building - the wind will not chill or cool it. Near trees or a high fence, the greenhouse should be placed not along, but with the end facing them. It is imperative to take into account where the wind most often blows in the area.

The place should be illuminated by the sun from morning to evening. If the greenhouse is used starting in the spring, then its orientation does not matter. It is advisable to place structures in the northern regions with the ridge directed from east to west (latitude orientation); in the middle zone, it is recommended to place the long side from north to south (meridian orientation).

Foundation

The basis of the structure - the foundation - plays an important role in maintaining heat inside.

Sellers of greenhouses made from polycarbonate greenhouses claim that they are lightweight and do not require a foundation - they can serve as timber or just soil. But if the owner wants his greenhouse to effectively retain heat, then a reliable insulated base is needed.

Base insulation

Insulating the base of a greenhouse consists of two points:

- warm foundation;

- soil thermal insulation.

If the greenhouse is located without a foundation - from below, a small distance is created between its covering and the soil, since it is impossible to perfectly level the site. The soil not only gives off heat during the day, but also takes it away at night - the structure cools down faster. A concrete or timber foundation will help prevent this. So, the most popular materials were:

- concrete - a strip of concrete is poured, which is lined with foam plastic on the bottom and sides;

- beam - the greenhouse is installed on beams with a large cross-section.

Creating and pouring a concrete foundation

A platform of strip concrete base along the perimeter will protect the interior from environmental influences and increase the frost resistance of the structure as a whole. The depth of the foundation is determined by the level of soil freezing - in most cases, 50–60 cm is enough. You can create the foundation yourself using the following steps:

- marking corners, measuring diagonals;

- a cast-off is installed - this is a wooden structure with fishing lines to determine the external and internal boundaries of the base;

- the soil is removed to the required depth (at least to the freezing depth);

- at the bottom there is a cushion of sand, or best of all, several layers - for example, sand or gravel. The layer will protect against deformation and create additional insulation. An excellent solution would be to backfill layers of waterproofing film, which is applied to the bottom and walls of the pit.

The trench is ready - they are making formwork. It is a simple structure made of wooden planks and panels. Its height is determined by the planned thickness of the foundation. It is desirable that they be equal - this will make it more convenient to compact and level the concrete mixture. The next stage is reinforcement. It will achieve high strength and is created with steel and iron rods, they are laid evenly or a reinforced mesh is made. Its elements are connected using knitting wire or welded into a solid structure.

Kneading and leveling

Concrete is mixed. The following composition is suitable: one part cement, two parts sand, four parts crushed stone. As a rule, the volume of water should be half the volume of cement. The concrete should not be too thick or too thin. Lightweight concrete can also be used for a greenhouse. The concrete mixture is poured evenly throughout the formwork.

The concrete is leveled and compacted using a special vibrating device or a simple board with a handle. It is imperative to release the accumulated air - to do this, the mixture is pierced with metal pins.

The foundation can be covered with roofing felt (additional waterproofing), exposing it from the inside, and making a 20-25 cm canopy on the outside. Foam plastic is also laid around the perimeter of the foundation from the inside and covered with a layer of sand 40 cm thick - this will additionally protect from moisture and cold.

Insulating the base with foam plastic

It’s even easier to create a warm base for a foam structure with your own hands. This is a cheap and accessible material; it can perform heat preservation functions. It must be taken into account that such a foundation will not last long - it is much less effective and of high quality than a concrete foundation.

To prevent it from deteriorating, it is advisable to pack it in plastic before laying it. Mice love this material: they do not eat it, but gnaw holes and place their homes there. To protect such a foundation, you can create a perimeter of 1/4 or ½ brick. Foam glass is a good substitute for polystyrene foam - it is not afraid of moisture and rodents, but is more expensive.

Soil preparation

When setting up a greenhouse for the winter season, first of all you should carefully prepare the soil. Maximum thermal insulation will be provided by a strip foundation.

Soil preparation can be divided into stages.

- First, the future foundation is marked. After marking, a cast-off is installed, which is usually made from boards. This casting will help determine the internal and external boundaries of the base.

- The next step involves excavating the soil to the required depth. Sand is poured into the bottom of the dug trench to protect the supporting structure. If possible, it is worth taking care of waterproofing the underside.

- Formwork is installed on the prepared trench. The most important requirement is its strength.

- Having decided on the formwork, you can move on to reinforcement. After installing the reinforcing mesh, the structure will become even stronger.

- The last stage is pouring concrete. It is recommended to lubricate the formwork walls with a water-based composition before doing this, so that after the mixture has hardened, it will be easier to separate the elements from it.

Features of the construction of an in-depth greenhouse

In addition, the gardener needs to consider:

- Direction of the wind. Air masses create a draft, which is why you have to spend a lot of money on heating the underground building.

- Relief. Many farmers build a buried greenhouse with their own hands on the slopes of hills. Thus, they save on walls and heating.

- Lighting. Trees should not grow near the building, which, with their shadow, prevent the penetration of sunlight.

A universal type of earthen greenhouse is a gable greenhouse with brick walls. The foundation pouring depth is 80 cm when using a strip base. The walls are erected in one brick, coating all joints with waterproofing mortar. At the same time, they are reinforced with vertical metal fixtures. The optimal roof slope is 25˚. It is constructed of glass or polycarbonate. You can even grow garden crops in such a thermos greenhouse.

Project of a lean-to in-ground greenhouse

The greenhouse frame is made of three types of material:

- wooden beams;

- profiled pipes;

- polyvinyl chloride profile.

In such a complex process, diagrams and drawings of the building will become assistants to the gardener. The exact dimensions of a recessed lean-to or gable greenhouse will help the farmer build a reliable and practical building that he will use for decades.

How to insulate a greenhouse for the winter, photos and diagrams

Insulating a greenhouse may be necessary in different cases. For example, if a sharp cold snap is expected in the region, but it is not possible to organize a heating point in addition to the existing one. Or the structure was not originally planned as a winter structure, so the covering material is too thin.

In the end, it may simply be a desire to save a little on heating. We will look at different options for insulating greenhouses.

Options for insulating greenhouses entirely

The first method is to cover the inside of the structure with plastic film. Typically, the thickness of the slats/frame profiles is at least 5 cm. Accordingly, an air gap is formed between the covering material and the film. That's the whole point - still air is a poor conductor of heat. The main thing is that the outer covering is hermetically sealed.

How to insulate a polycarbonate greenhouse, it’s very easy to stretch the film with your own hands

The second method is external insulation of the greenhouse with foam plastic or extruded polystyrene. Typically used for single-/double-slope structures on a wooden frame, covered with film. Sheets of material are applied to the walls of the building, the spaces between them are blown with foam. Everything is covered with polyethylene on top, which will finally fix the foam. Additionally, you can make several ties with rope.

Please note: such insulation, even if it is done on one side, deprives the plants of access to a significant part of the sunlight. Therefore, here you will have to think about the lighting system. . How to insulate a greenhouse for the winter: use polystyrene foam

How to insulate a greenhouse for the winter: use polystyrene foam

Partial insulation: perimeter and soil

To get a warm greenhouse for the winter, we build the following pie around the perimeter: waterproofing + thermal insulation + waterproofing + infrared tape + slate. All layers should not reach the junction with the roof (by 5-7 cm), so that moisture trapped between them can freely escape. Installation of heating is variable; if we don’t do it, slate is not needed. Just like when insulating with foam plastic, you will have to organize additional lighting.

How to insulate a polycarbonate greenhouse by installing a multi-layer cake around the perimeter

The soil in a greenhouse can be insulated in two ways:

- Laying sheets of foam plastic or extruded polystyrene under the beds.

- Forming a multi-layer pillow that will heat up on its own. We remove a half-meter layer of soil, lay layers of gravel (5cm), last year's foliage (5cm), compacted manure (15m), and again last year's foliage (5cm) into the trench. On top is a layer of soil with compost (20cm).

Below is the scheme for insulating the ground in a greenhouse described here.

Please note: the thickness of the last layer of leaves cannot be reduced. It protects plant roots from chemical burns that can occur due to them getting into a layer of manure.

How to insulate a polycarbonate greenhouse for the winter: diagram of a multilayer cushion under the soil

Second layer of thermal insulation

Effective insulation of greenhouses is carried out by installing a second film layer. Polyethylene film is the most accessible and cheapest material. Today, modern markets offer stabilized films with high levels of wear resistance, elasticity and frost resistance.

It has excellent transmission capacity for ultraviolet rays and oxygen; has a light-scattering effect, which is important for greenhouse crops; resistant to dust formation. Manufacturers of film products guarantee a service life of the film coating of up to 7 years (Richel - PE film)! Such a service life has not been observed in any known film of previous years.

The quality of new generation materials cannot but please greenhouse owners.

Ethylene vinyl acetate copolymer film is ideal for insulating a greenhouse structure - a particularly durable material with a light transmittance of 92%.

Various methods of sealing glazing: a - using sealing mastic; b - putty-free glazing; c - using a sealant; g - fastening the glass to the T-section sprocket; d - fastening glass with putty to a wooden sprocket; e - connecting glass using a clamp; 1 - glass; 2 - sprats; 3 — clamps; 4 - sealing mastic, putty or sealant; 5 — clasp KL-3; 6 - pins

Characteristics of copolymer film:

- resistance to wind loads and punctures;

- long service life;

- excellent light transmission;

- strength;

- frost resistance;

- elasticity;

- antistatic properties (dust repellent);

- hydrophilic surface (condensation rolling off);

- energy saving up to 40%.

A simple frame made of wire, metal or plastic pipes (whatever is at hand) is installed inside the greenhouse. The frame structure must have 5 cm indentations from the main walls of the greenhouse. The air cushion that appears between the walls of the main and additional frames reduces heat loss by up to 50%. Significant energy savings are guaranteed only if tightness is maintained at the joints and fastenings of the film - special clip locks (Richel) and sealants (polyurethane, silicone) have been developed for this purpose.

Production of industrial greenhouses: a deliberate approach to business

The use of cellular polycarbonate for the construction of industrial structures is easily explained by the excellent qualities of this material. Such greenhouses have good thermal insulation, which makes it possible to maintain the required temperature regime.

To correctly draw up the drawings, the customer must accurately determine the list of plants that he will grow and the volumes of vegetables produced. A whole book has even been written about the design of industrial greenhouse structures. The leader in the production of large greenhouse complexes are the Dutch specialists of the manufacturing company Venlo.

Industrial greenhouses are produced in the following types:

- Arched;

- Rectangular;

- Trapezoidal;

- Pyramid;

- Single-pitch;

- Tunnel.

With the advent of polycarbonate on the construction market, greenhouses began to be made primarily in arched shapes, as this model is most easily suitable for flexible material. But it is not suitable for a wooden frame, so a metal profile is used to build the skeleton.

Strong arguments in favor of PENOPLEX®

Do not forget one very, very important point: you will spend this amount on insulating the base only once during the entire life of the greenhouse, since PENOPLEX is a truly durable material. Biostable (unfavorable for the development of dangerous and harmful microorganisms, fungi and mold), chemically and physically neutral. Eco-friendly (its use in greenhouses is safe) - allows you to grow useful and healthy products, creates favorable natural conditions for them.

And the last, but compelling argument in favor of this method of insulating greenhouses. This is not a dacha initiative of local “Kulibins”, but a proven technology that has long been successfully used by the agricultural leaders of the industry.

Insulation using this technology is also used for industrial greenhouse complexes. As a clear example, I will cite the illustrative experience of the Maysky agricultural complex in the Republic of Tatarstan. The productivity of industrial greenhouses with a total area of more than 50 hectares today is more than 15,000 tons of vegetables (cucumbers, tomatoes, peppers, eggplants and others).

How and with what to insulate your greenhouses is up to you. But do not forget that the stingy pays twice: by choosing low-quality materials from an unknown manufacturer, you risk simply throwing money away, leaving greenhouse plants without protection from the cold.

Joints

The complete process of transforming a greenhouse for the harsh winter season involves sealing the joints. According to many experts, they are the main cause of heat loss. Through small holes between the finishing materials used in the construction of the structure, cold air enters inside. Both film and glass greenhouses need sealing.

The presence of joints leads to drafts, which negatively affect the process of fruit ripening. Even if a hydraulic barrier was used when creating the heifer, it is recommended to carry out an additional procedure for sealing the joints.