Old panel houses especially need insulation. This becomes noticeable with the onset of cold weather, when the heating system cannot cope with its tasks. Today there are many ways to carry out such work, for example, insulating the walls of a panel house from the inside. This technology is relevant if external thermal insulation is impossible due to the fact that the facade of the building is not allowed to be touched.

Features of insulating a cold wall from the inside

The cold penetrates from the outside through the seams in panel houses. If it is not possible to fill them due to certain circumstances, insulation should be carried out from the inside. For this you can use polystyrene foam or mineral wool. These materials are supplemented with foil insulation or insulation paint is used separately. Typically, the work involves installing a frame, inside which additional insulating layers are laid, covered with plasterboard on top.

If you plan to load the walls with something heavy, then you can apply plaster over the insulation, saving money. When there is no desire to install drywall, you can plaster with polystyrene foam, as well as mineral wool. In the latter case, the material must have a high density. If you want to prefer mineral wool for insulating a panel house from the inside, then it is better to choose its basalt variety, which is also called stone. This material is good because it is not afraid of moisture and tolerates heat well. In this case, it is possible to exclude the use of a membrane, which, during external thermal insulation, acts as a vapor and water barrier.

The best materials and methods of thermal insulation: selection criteria and review of market leaders

The easiest and cheapest way to insulate a wall is to hang a carpet or stick thick wallpaper. But it is also the most ineffective. A much more effective method of insulating a wall from the inside in an apartment is to install a heat-insulating material, which is attached (glued) to the wall and subsequently, as a rule, covered with finishing. The thickness of the insulation layer is calculated in such a way that the dew point remains outside in any weather. However, not only the thickness of the material matters, but also the technical qualities of the insulating products.

Materials for insulation must have the following properties:

- The effectiveness of thermal insulation, which is largely determined by the coefficient of thermal conductivity. The lower it is, the better;

- Safety for the health of people and pets;

- Non-flammability (as far as possible);

- Safety for the environment;

- Slightly thick;

- Optimal cost.

On a note! When choosing how to insulate a cold wall from the inside of an apartment, you need to pay attention not only to the characteristics of the material, but also its “compatibility” with the base of the walls.

That is, for example, in the case of thermal insulation of a brick wall, it is better to use one insulation, and in the case of a concrete wall, another.

Types of insulation

When insulating the walls inside an apartment in a panel house, you can use one of many modern solutions. In addition to the above options, it can be polystyrene foam, which is much easier to work with. But it is important to consider that polystyrene foam does not allow steam to pass through, which means that over time dampness will form underneath it, which will cause the formation of fungus and mold.

If you don’t want the walls of the apartment to move inward too much, you can choose warm plaster for interior work, but the effect from it will be much less than from foam materials. You can also choose modern liquid ceramics. Just a 1 mm layer will be enough to equate it to 5 cm of mineral wool. Liquid ceramics consists of bubbles filled with air.

If a store offers you foil insulation, and the seller claims that it can be used as a stand-alone material, you can be sure that this is not the case. The effect of such a layer, of course, will be, but not as significant as they want to imagine it.

Minvata

When insulating the walls of a panel house from the inside, you can use mineral wool. But experts advise using it in extreme cases, because it needs to be protected for at least two reasons. The first is that if particles have free access to a room, they can harm human health. The second is expressed in the fact that mineral wool becomes saturated with moisture, settles and loses its original properties. Even if you cover the insulation layer with film on both sides, water will still penetrate into it, which over time will negate all efforts at thermal insulation. But if you still want to install it, then you will need to install the frame and insert the end parts of the material into profiles.

Expanded polystyrene insulation

If you want to do the thermal insulation yourself, you can use polystyrene foam. It can be installed with glue, additionally reinforced with dowels. A fiberglass mesh is applied on top, which is embedded in the plaster. With such insulation of the walls of a panel house from the inside, you need to additionally consider the ventilation system, since the created layer will have low vapor permeability.

Before installing insulation, you need to remove all old finishes from the walls, including wallpaper. Damage is repaired with putty. Next, the surface can be covered with soil. An acrylic-based composition is perfect. It would be better if it had antifungal properties. Before installing the insulation, waterproofing should be laid on the wall. You can use plastic film for this. Insulation is installed on top; you need to start working from below, installing the slabs in a checkerboard pattern.

As soon as the adhesive composition has dried completely, which will happen in about 2 days, you can make holes in the insulation, of which there should be 6 pieces for each sheet. Dowels will be inserted there, which will further increase the strength of the structure. The end seams should be filled with pieces of insulation. At the next stage, a reinforced mesh is applied, which is embedded in the liquid finishing layer. Putty should be applied on top, which is covered with wallpaper or other decorative material.

Extruded polystyrene foam

Insulation of the walls of a panel house from the inside is often carried out with an extruded type of polystyrene foam. The work is carried out according to the same algorithm as described above. This material can be selected taking into account the density, which reaches 47 kg/m3. This indicator affects the strength of the material, but in indoor conditions this is not very important. The formed layer will be flammable, so it must be well protected from ignition. For more convenient installation, you should choose products with recesses on the edges. It ensures a tight fit of the plates to each other.

Use of polystyrene foam

When insulating the walls of a panel house from the inside, foam is rarely used, since its effect on health has not been proven. If it is necessary to carry out work in the ceiling area, it is better to mount it from the attic side. When purchasing this material, it is important to exclude the artisanal production method by requesting a certificate confirming the quality.

Application of keramoizol

If you want to insulate your walls yourself, you should consider liquid thermal insulation, which is made on the basis of polymer resins. Among the ingredients there are mineral fillers that look like balls. They provide reflection of thermal energy. When applied, polymerization of the composition and balls occurs, which makes it possible to obtain an imitation of a thermos.

This material allows not only to insulate walls, but also to make them more protected from the penetration of extraneous noise. This relatively new material is sold in containers of different sizes. It is characterized by the qualities of steam and water resistance, as well as durability. Installation consists of forming several layers. To achieve the best effect, you need to apply 6 layers. The direction of movement of the brush should be perpendicular between approaches. The only disadvantage of this solution is the high cost.

Penoizol insulation

Insulation of the walls of a panel house from the inside is sometimes carried out with foam insulation. It is a liquid version of foam that is manufactured directly on the construction site and poured into hollow structures or formwork. In this case we are talking about carbamide foam, which is quite difficult to use in domestic conditions.

The work is inexpensive, the result is practical, and the manipulation time is reduced. Penoizol has a low density, is ready to last for a long time and is characterized by low thermal conductivity. The layer is not dangerous in the event of a fire; the material has environmentally friendly qualities and cannot create suitable conditions for the emergence of biological life.

Using Asstratek

For internal insulation of a panel house, Astratek, which is a liquid thermal insulation, can be used. The structure of the material is microporous. Using it, you can form a seamless coating that significantly reduces heat loss without creating additional loads on walls and ceilings.

With such insulation of a panel house from the inside, you can be sure that the material can be used under different temperature conditions, as well as on different objects. The material adheres well to the surface, eliminates corrosion, and contains organic solvents among the ingredients.

Myth 3 - Cork is an impractical material

You can even include a few misconceptions here:

- Does it absorb odors? No, it's covered with wax.

- It can be easily damaged - children will throw something, a champagne cork will fly off. You can damage a cork panel only on purpose, by taking a nail, for example. Normal use is not scary for her.

- Can't be washed. Can! Wash, wipe, use non-aggressive detergents. The plug is not afraid of water, flooding, or condensation.

- Difficult to glue. Easy, even easier than wallpaper, because the 600x300 mm format is much more convenient than stripes the entire height of the wall.

Warm, comfortable, elegant, environmentally friendly cork panels are an ideal option for the home.

Cork 3D panels

Are you still thinking? Then the last argument. Invest in a wall plug and forget about renovations for years to come. Wall panels will serve not only to insulate the walls from the inside, but also for beauty. Choose a shade and texture that you like, let the walls be the backdrop for other details with which you can update the interior in the future. Cork panels are a repair once and almost forever, no re-gluing every 5 years. Wet cleaning and they are as good as new. Now it’s worth taking a look at the range.

Author of the article Alena Samkova

Still have questions? Ask in chat or by phone +7 (495) 514-56-67

Installing insulation on brick walls

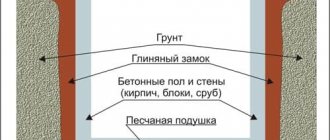

Before starting work, it is important to decide what material will act as insulation. It is important to begin with to weigh all the pros and cons and understand that condensation will form during internal insulation in any case. If you nevertheless decide to install foam plastic or any other material from the side of the room, you must attach a vapor barrier material to the wall that will extend to the ceiling and floor. The seams are taped and should be laid overlapping each other.

Now you can install the sheathing, the step between the elements of which should be less than the width of the thermal insulation used, if it is elastic. The depth of the frame must correspond to the thickness of the insulation. Thermal insulation slabs are laid out in cells, covered with a vapor barrier, and the seams are sealed. The next layer will be a counter-lattice, which is sheathed with chipboard or any other sheet material. This work is necessary to ensure that the materials inside are as well ventilated as possible.

Composite selection

When choosing a material for thermal insulation from the inside of a room, you must first of all proceed from the indicators of vapor permeability and moisture absorption. Next, it is worth considering that seams and joint gaps are places where moisture escapes into the room and air enters the cold surface.

What won't work

Glass and mineral wool, liquid ceramics, balsa wood coverings, drywall, etc. are categorically unacceptable for this purpose.

Polystyrene foam forms many seams that require additional sealing, and also has a high moisture absorption rate. From the point of view of fire safety of a residential building, it is better not to use it, since it burns and releases toxic substances.

Polyurethane foam

It has excellent moisture protection and thermal insulation, as well as good adhesion on brick surfaces. The masonry does not require special processing or leveling. The only significant drawback is the complexity of installation.

Cured polyurethane foam is unstable to mechanical stress and requires additional protection. The moisture formation boundary will be either on the inner surface of the wall or in the thickness of the insulation. But due to the good sealing properties of polyurethane, condensation is not observed.

Expanded polystyrene

Among the available materials, polystyrene foam produced by high-pressure extrusion is also suitable. Although it is installed with the formation of a large number of joints, it has good indicators of moisture resistance and vapor permeability, and when it ignites, it smolders.

It is quite possible to install it yourself, without involving professional builders. But you should strictly adhere to the assembly technology and process stages.

Insulation of walls using the electric floor method

If you decide to abandon the installation of extruded polystyrene foam, replacing this method with wall insulation using the electric floor method, you must weigh all the positive and negative aspects of this technology. Experts say that good heat transfer cannot be achieved. The heating components will be located in the wall, and the heat will have to work its way through the trim or drywall. In this case, the space only a few tens of centimeters from the wall will warm up, while the heated air will immediately begin to rise upward. The result will be the need to install an additional electric heating device, which will entail costs.

If wallpaper and decorative tiles are pasted on the walls as a finishing touch, you may encounter the fact that the materials will move away from the surface under constant heating. With such a heating arrangement, it will not be possible to place furniture or electrical equipment against the wall, as they will quickly fail and, in addition, will block the air flow.

Having installed such a heating system, you will be faced with impressive heat losses, because energy will go not only inside the room, but also outside the house. Foil thermal insulation is placed under the infrared fabric (to prevent such phenomena), but this only aggravates the situation, and heating is even reduced. Such walls, where the electrical cable is laid, can no longer be used for hanging equipment and furniture. The same condensation will form between the warm and cold surfaces of the wall, which cannot but become a serious obstacle to installing such a heating system.

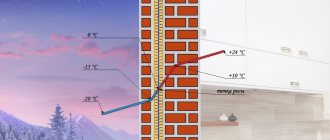

Dew point: physics of the phenomenon

The ratio of humidity and temperature at which steam turns into droplets is called the dew point. Under natural conditions, this is how fog, dew, frost and clouds are formed.

If the water vapor is at the dew point, it is called saturated. The amount of steam at which it becomes saturated depends on the temperature: the colder it is, the less steam is required. To indicate how close steam is to the dew point for a given temperature, relative humidity is used, which is expressed as a percentage. 100% is saturated vapor that is ready to fall out as mist or dew.

In construction, the dew point is not a point on a temperature scale, but rather the area where water vapor can become saturated. This point should always be outside the wall on the street side. To achieve this effect in winter, you need to carefully calculate the vapor permeability and thermal conductivity of surfaces. In any weather, the outer wall of the building must be warmer than the surrounding air so that the steam evaporates from its surface and has time to dissipate before it falls in the form of frost. It should be taken into account that in cold weather the dew point approaches the wall, and in warm weather it moves away.

If the temperature difference between the wall and the air outside is insufficient, the dew point moves closer to the wall or inside it. Moisture condenses on the surface or between layers of material where cold and warm air come into contact. This leads to negative consequences, which include:

- In the destruction of materials;

- Freezing of the wall in frost;

- The appearance of mold and mildew.

When is it not possible to insulate the outside?

Ideally, place a layer of insulation on the outside of the building along its facade. But owners do not always manage to implement this option. There may be several reasons for this:

- the facade of the house is prohibited from changing due to its historical value (the situation is typical for old brick apartment buildings); insulation work must be carried out at a high altitude, and the owners do not have the opportunity to turn to professional builders; the distance between neighboring houses is too small to allow work with external walls.

In all of the above cases, you will have to resort to internal insulation. The main task in such a situation is to avoid the harmful effects of condensation on the insulation.

There are two common ways to solve this:

- When using mineral (basalt) wool, the vapor barrier film is overlapped, and all seams are carefully taped. When using materials with very low permeability, you can dispense with the vapor barrier film, since the insulation does not get wet. As such a material, you can choose polystyrene foam or penofol with a foil layer.

Thermal insulation of a corner room

The corner room has two common walls with the street, as a result of which heat loss in such a room increases significantly. Over time, the constantly freezing corner becomes damp, the wallpaper deteriorates, and fungus appears.

Outdoor

Insulation of external walls in a corner apartment is carried out using the following technologies:

- "sandwich";

- ventilated design.

When insulating an apartment from the outside using the “sandwich” type, it means using three-layer panels with heat-insulating material inside. Also, the insulation can be fixed between the load-bearing and decorative outer walls of the apartment.

Scheme of a ventilated facade.

A ventilated façade is installed if a layer of decorative finishing is mounted on top of its metal frame, serving as a protective screen. A layer of thermal insulation is laid between the cladding and the load-bearing wall of the corner apartment. This is how the ventilation effect will be achieved, preventing the appearance of dampness and condensation on the wall surface.

The real state of affairs

The reality is that not in all cases it is possible to carry out work according to the textbook. In some cases, it is impossible to insulate a house from the outside:

- The building is an architectural monument. The facade must be left untouched. The upper floors of a brick house in the absence of the ability to work at high altitudes. The distance between the houses is too small, which does not allow work to insulate them from the outside.

Let's consider actions in a situation where insulation from the outside of the building is impossible. How to insulate the walls of a brick house from the inside with your own hands?

The main problem that residents of the house will face is condensation in undesirable places with all that it entails. To protect yourself from this trouble, you need to hermetically insulate the walls with insulation from the rest of the room.

There are two ways to do this task yourself:

When choosing insulation, you should give preference to a material with very low permeability to water vapor. Common options include penofol and extruded polystyrene foam. The side with the foam foil and the compacted surface of the polystyrene foam should face the inside of the room.

Only in this way will it be possible to avoid the absorption of steam by the insulation. If mineral or basalt insulation is used, then they can be protected with the help of a vapor barrier. However, sealing should be carried out with special care: no possibility of steam contact with the insulation or wall should be left. The film is attached with an overlap, and the seam is taped.

Vapor permeability

In a residential building, the vapor permeability of walls should increase towards the street. The main reason lies in the different humidity levels inside and outside the house in winter. The reasons for high humidity in the house are:

There are people living in the house who breathe, cook, wash floors and dishes, and do laundry.

All these habitual operations make the air more humid. And when the windows are closed, the exchange of air is difficult and is carried out only by the forces of the ventilation system. From the course of physics, we know that heated air is capable of holding more moisture compared to cool air. For this reason, condensation occurs from “excess” moisture as the air cools.

Foggy windows and dampness in the corners of a building are a practical example of this. But water vapor leaves the house not only through ventilation, but also through the pores of the wall. If the wall outside is more permeable to steam, then it can pass through it without difficulty. Otherwise, having encountered an obstacle, water vapor begins to condense directly in the wall, which leads to its dampness.